Cam lobe failure analyses.

#1

Anyone else see OE cams fail across the nose of the lobe?

Short version ’01 Suburban 1500 4wd, 5.3 LM7, bone stock, NEVER opened up! We are second owners, purchased the Burb at 27,000 miles. It had slight lifter tick since the day we bought it, that never got worse so we didn’t worry about. (Used replacement engine exhibits similar lifter tick). At 150,000 miles a loud "squeak squeak squeak" noise shows up, follows engine RPM. Sounds exactly like a belt squeal. With mechanics stethoscope didn’t take long to narrow down to the middle of the passenger valve cover. Valve cover removed, narrowed down to #4 intake. Remove rocker squeak gone, reinstall rocker squeak comes back. Rocker checks out fine, even swapped with another rocker to narrow down rocker or lifter. #4 intake “lifter” is the culprit. Ok, sounds like the roller of the lifter is sliding across the lobe, i.e. not rolling any more. Found another complete LM7 to swap in, either ’02 or ’04, (pretty sure its an ’04) swapped engines just prior to Thanksgiving, replacement engine runs great, wife is happy she has her rig back. My plan with the old 5.3 I removed is to swap out the lifters and an LS1 cam into and install it with the new cam and lifters in my '97 BMW M3

https://ls1tech.com/forums/conversio...onversion.html

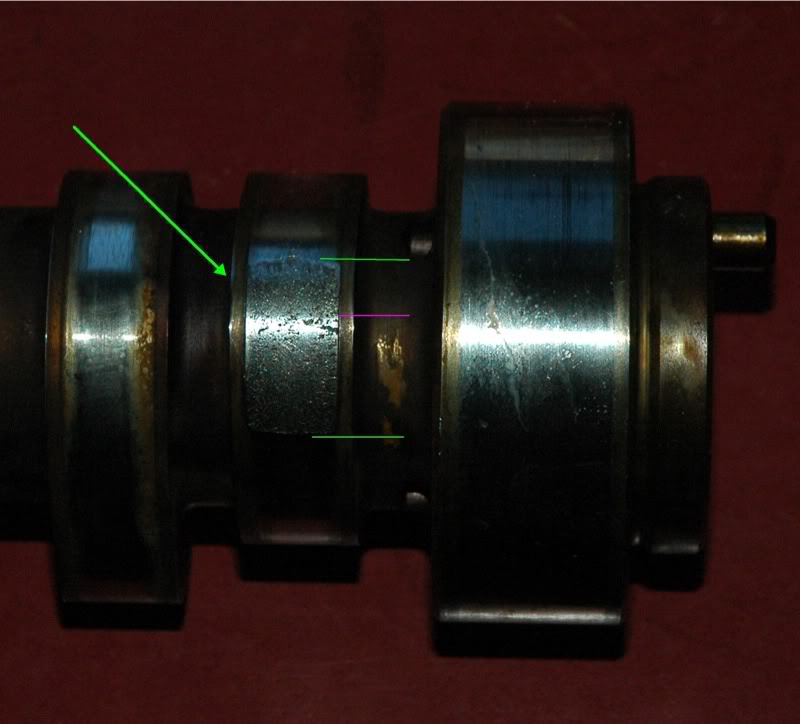

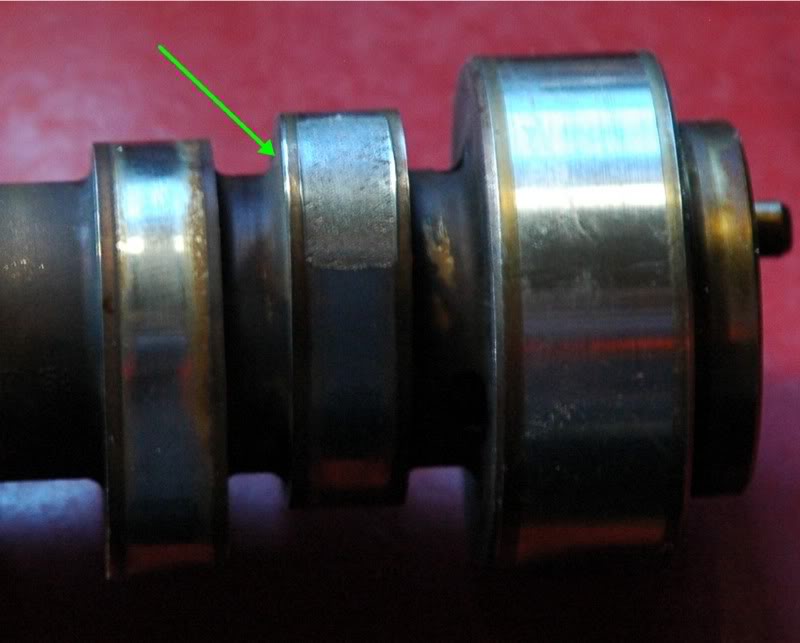

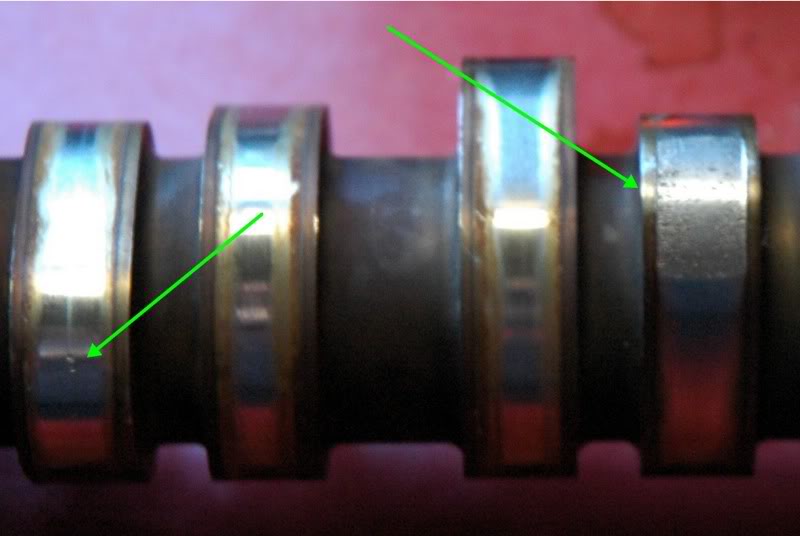

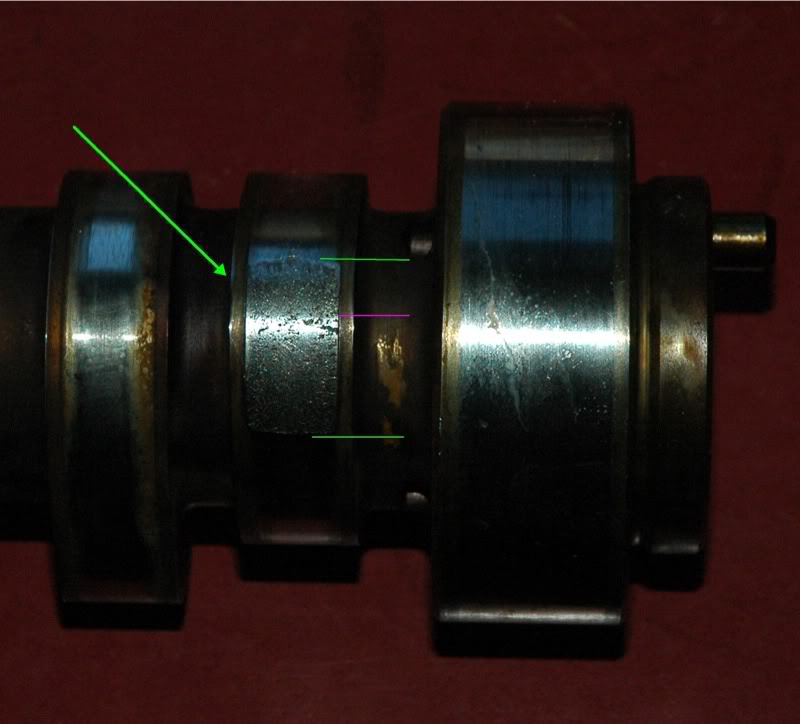

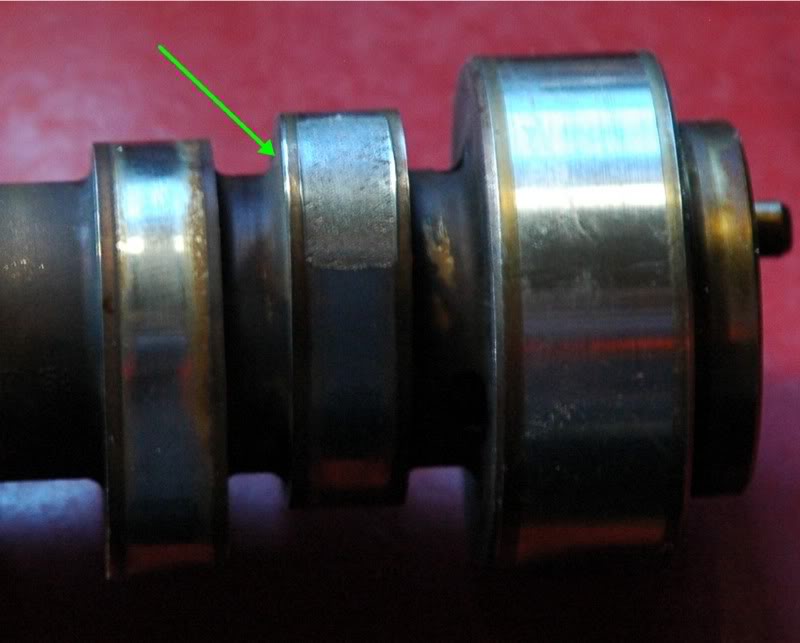

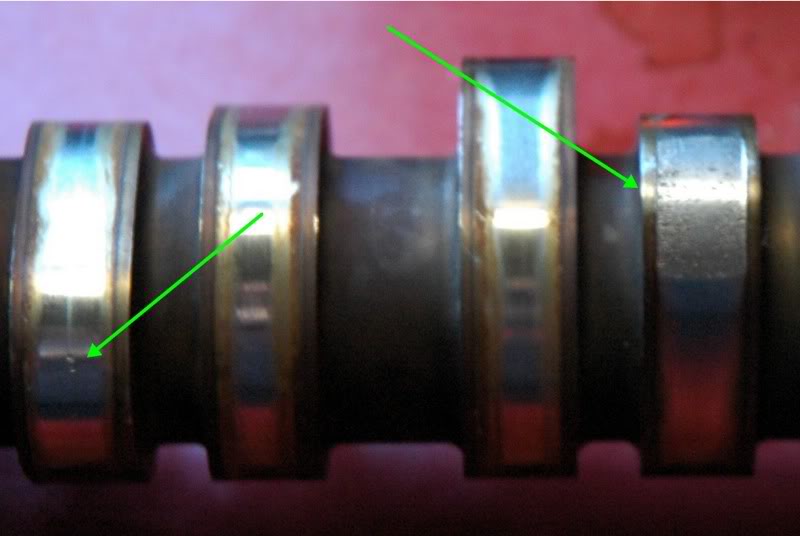

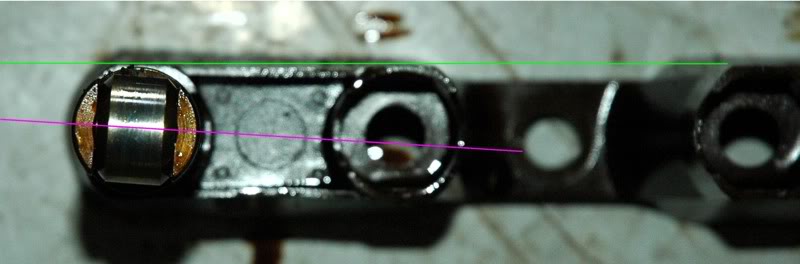

Removed the cam today, 3 of the lobes have severe pitting/fatigue, but only over the nose. 3 other lobes starting to pit, again, only across the nose. Lifters ALL still roll just fine, no wobbles, no slop, no grit, the ones off the pitted lobes do have pits on the rollers, #4 intake obviously the worst. I’m a bit confused here?!?! I would expect to see this sort of lobe failure from coil bind. This is a bone stock never opened up LM7, as such, should not be experiencing coil bind. The opening and closing ramps look fine, i.e. no signs of valve float/bounce or excess loads while opening and closing. The failed portion of the lobe is only across the nose with a slight bias to the closing side, (see below). A few other lobes are showing signs of the same issue, couple pits, across the nose only, on their way to the same failure.

Rollers in the lifters all roll fine. The squeaky lifter, #4 intake, shows signs of the roller sliding across the cam lobe and “severe” pitting on the roller itself, but the roller itself still rolls perfectly fine, no slop, no wobble, no grinding, etc. Feels just like the brand new set of LS6 “crate motor take-out” lifters I just bought?!?!

I’m at a loss as to why the lobes would fail in this manner in a bone stock vehicle, and at this point its life? I could see this at the beginning, or further in its life, struggling to believe that 150,000 is the end of its life?!?! And with lifters, that when out of the engine, seem to have perfectly fine rollers?

Lack of lubrication to the lifter galleys maybe? I would think if that were the case, the cam would fatigue/pit at the point of greatest dynamic loading, such as the start of the opening ramp or on the closing ramp where the lifter is slowing down as well as the over then nose?

Green lines are start and stop of the failure, magenta line is the apex of the lobe.

#4 intake lifter;

Short version ’01 Suburban 1500 4wd, 5.3 LM7, bone stock, NEVER opened up! We are second owners, purchased the Burb at 27,000 miles. It had slight lifter tick since the day we bought it, that never got worse so we didn’t worry about. (Used replacement engine exhibits similar lifter tick). At 150,000 miles a loud "squeak squeak squeak" noise shows up, follows engine RPM. Sounds exactly like a belt squeal. With mechanics stethoscope didn’t take long to narrow down to the middle of the passenger valve cover. Valve cover removed, narrowed down to #4 intake. Remove rocker squeak gone, reinstall rocker squeak comes back. Rocker checks out fine, even swapped with another rocker to narrow down rocker or lifter. #4 intake “lifter” is the culprit. Ok, sounds like the roller of the lifter is sliding across the lobe, i.e. not rolling any more. Found another complete LM7 to swap in, either ’02 or ’04, (pretty sure its an ’04) swapped engines just prior to Thanksgiving, replacement engine runs great, wife is happy she has her rig back. My plan with the old 5.3 I removed is to swap out the lifters and an LS1 cam into and install it with the new cam and lifters in my '97 BMW M3

https://ls1tech.com/forums/conversio...onversion.html

Removed the cam today, 3 of the lobes have severe pitting/fatigue, but only over the nose. 3 other lobes starting to pit, again, only across the nose. Lifters ALL still roll just fine, no wobbles, no slop, no grit, the ones off the pitted lobes do have pits on the rollers, #4 intake obviously the worst. I’m a bit confused here?!?! I would expect to see this sort of lobe failure from coil bind. This is a bone stock never opened up LM7, as such, should not be experiencing coil bind. The opening and closing ramps look fine, i.e. no signs of valve float/bounce or excess loads while opening and closing. The failed portion of the lobe is only across the nose with a slight bias to the closing side, (see below). A few other lobes are showing signs of the same issue, couple pits, across the nose only, on their way to the same failure.

Rollers in the lifters all roll fine. The squeaky lifter, #4 intake, shows signs of the roller sliding across the cam lobe and “severe” pitting on the roller itself, but the roller itself still rolls perfectly fine, no slop, no wobble, no grinding, etc. Feels just like the brand new set of LS6 “crate motor take-out” lifters I just bought?!?!

I’m at a loss as to why the lobes would fail in this manner in a bone stock vehicle, and at this point its life? I could see this at the beginning, or further in its life, struggling to believe that 150,000 is the end of its life?!?! And with lifters, that when out of the engine, seem to have perfectly fine rollers?

Lack of lubrication to the lifter galleys maybe? I would think if that were the case, the cam would fatigue/pit at the point of greatest dynamic loading, such as the start of the opening ramp or on the closing ramp where the lifter is slowing down as well as the over then nose?

Green lines are start and stop of the failure, magenta line is the apex of the lobe.

#4 intake lifter;

Last edited by BRAAPZ; 12-23-2010 at 10:26 AM. Reason: Typo's

#2

Couple more observations. All 6 failing/failed lobes/lifters are intakes. The exhaust all are fine, as are the other 2 intakes.

When I removed the lifters, NONE of the lifters came out with the trays, i.e. trays had no grip on the lifters whatsoever. The lifters did come out the block with ease, no sticking or hanging.

That begs the question, being as the lifter trays are what locate the lifters and keep them clocked true to the cam lobes, (keep them from the rotating), is there a chance that the lifter trays have worn/lost their grip to the point the lifters are able to rotate just enough, even slightly, to the point the misalignment of the roller plane vs the cam lobe is such that the lifter is now sliding sideways, ever so slightly across the lobe, causing this failure?

When I removed the lifters, NONE of the lifters came out with the trays, i.e. trays had no grip on the lifters whatsoever. The lifters did come out the block with ease, no sticking or hanging.

That begs the question, being as the lifter trays are what locate the lifters and keep them clocked true to the cam lobes, (keep them from the rotating), is there a chance that the lifter trays have worn/lost their grip to the point the lifters are able to rotate just enough, even slightly, to the point the misalignment of the roller plane vs the cam lobe is such that the lifter is now sliding sideways, ever so slightly across the lobe, causing this failure?

#3

On The Tree

iTrader: (18)

Join Date: Jan 2006

Location: Wetumpka, AL

Posts: 175

Likes: 0

Received 0 Likes

on

0 Posts

Couple more observations. All 6 failing/failed lobes/lifters are intakes. The exhaust all are fine, as are the other 2 intakes.

When I removed the lifters, NONE of the lifters came out with the trays, i.e. trays had no grip on the lifters whatsoever. The lifters did come out the block with ease, no sticking or hanging.

That begs the question, being as the lifter trays are what locate the lifters and keep them clocked true to the cam lobes, (keep them from the rotating), is there a chance that the lifter trays have worn/lost their grip to the point the lifters are able to rotate just enough, even slightly, to the point the misalignment of the roller plane vs the cam lobe is such that the lifter is now sliding sideways, ever so slightly across the lobe, causing this failure?

When I removed the lifters, NONE of the lifters came out with the trays, i.e. trays had no grip on the lifters whatsoever. The lifters did come out the block with ease, no sticking or hanging.

That begs the question, being as the lifter trays are what locate the lifters and keep them clocked true to the cam lobes, (keep them from the rotating), is there a chance that the lifter trays have worn/lost their grip to the point the lifters are able to rotate just enough, even slightly, to the point the misalignment of the roller plane vs the cam lobe is such that the lifter is now sliding sideways, ever so slightly across the lobe, causing this failure?

Also are you running a blower or turbo? If so you could be pressurizing the crankcase and lots of blowby creating extra pressure on the intake valves

Last edited by zx9rgreen; 03-02-2009 at 10:12 PM.

#4

TECH Senior Member

iTrader: (8)

Poor heat treatment of cam...........

Bad lifters beat up cam .......Possibly by spinning in lifter tray

For sure put in the sturdier LS2 lifter trays back in this motor

All guesses weak and who knows................. Maybe shaft mounted rockers are what is needed

Bad lifters beat up cam .......Possibly by spinning in lifter tray

For sure put in the sturdier LS2 lifter trays back in this motor

All guesses weak and who knows................. Maybe shaft mounted rockers are what is needed

Last edited by SOMbitch; 03-02-2009 at 10:29 PM.

#6

TECH Senior Member

iTrader: (4)

What are the numbers on the bottom of the lifter trays? Some of the ones that are marked "10" had issues with the angle being slightly off. Stock springs being weak would take time to develop a problem. Aftermarket strong springs with the "10" lifter trays developed problems much quicker. the model year of your Suburban is right in the time frame when these trays were installed.

The following users liked this post:

slowpoke96z28 (08-29-2021)

#7

On The Tree

iTrader: (18)

Join Date: Jan 2006

Location: Wetumpka, AL

Posts: 175

Likes: 0

Received 0 Likes

on

0 Posts

What are the numbers on the bottom of the lifter trays? Some of the ones that are marked "10" had issues with the angle being slightly off. Stock springs being weak would take time to develop a problem. Aftermarket strong springs with the "10" lifter trays developed problems much quicker. the model year of your Suburban is right in the time frame when these trays were installed.

There is a guy on the S-10forum that pulled his engine apart and one of his lifters looks the same as the OP. I think he only had about 7k miles on it and used the new lifters and trays.

http://www.s10forum.com/forum/f213/w...oodies-388315/

Trending Topics

#8

I think you are on the path of finding the root cause of that. I think it starts with all of them being intake. The rockers, lifters, lifter trays and pushrods are the same across the board. The camshaft is not the pressed together versions that the asians run, So the camshaft is the same material also. What do the valve stems and Valve seats look like?

Also are you running a blower or turbo? If so you could be pressurizing the crankcase and lots of blowby creating extra pressure on the intake valves

Also are you running a blower or turbo? If so you could be pressurizing the crankcase and lots of blowby creating extra pressure on the intake valves

#9

Gents,

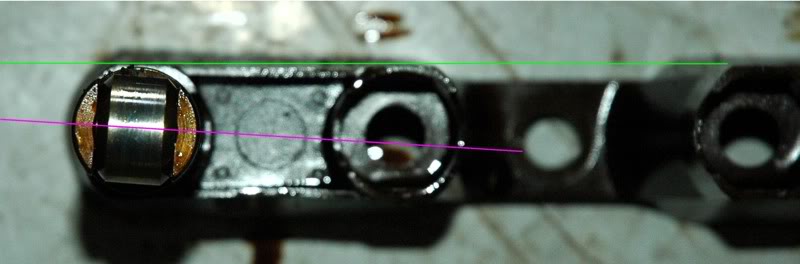

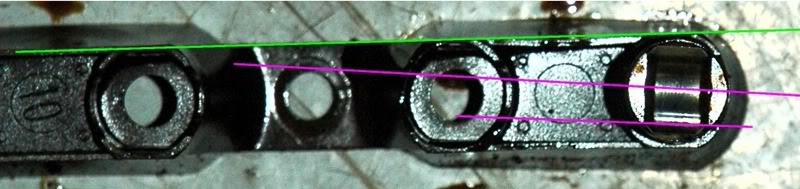

With your suggestions I took a closer look at the lifter trays. When I removed them, I did not witness them for position or orientation, my bad. What I did find was interesting. One tray is a #9, two are #10’s, and one is #11. Lifters fall into their slots in the trays, some do allow just a very slight amount of rotation, maybe between 1-2 degrees? Not as much as I thought might be present.

Just as Vettenutts pointed out, the #10 trays do not have the flats aligned square to the cam! Very noticeably off!

Something else I will be taking a closer look at are the valve springs. This being evident on the intakes only got me thinking. It could just be coincidence it is the intakes only, but the intake valves are heavier and if the springs are weakening, at elevated RPM’s the lifter could be lightly lofting over the nose and in combination with the lifter not rolling true across the lobe, possibly “chattering” as they roll/slide over the nose?

At any rate, I need to track down the GM specs for valve spring pressures on the seat and over the nose. I will disassemble the heads today and measure the spring pressures at those 2 points and report back. Anyone by chance have a factory service manual with those figures for an '01 LM7 5.3? Cam is the 0967 grind.

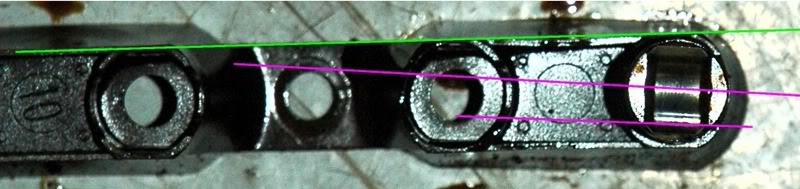

For now, here are the trays;

With your suggestions I took a closer look at the lifter trays. When I removed them, I did not witness them for position or orientation, my bad. What I did find was interesting. One tray is a #9, two are #10’s, and one is #11. Lifters fall into their slots in the trays, some do allow just a very slight amount of rotation, maybe between 1-2 degrees? Not as much as I thought might be present.

Just as Vettenutts pointed out, the #10 trays do not have the flats aligned square to the cam! Very noticeably off!

Something else I will be taking a closer look at are the valve springs. This being evident on the intakes only got me thinking. It could just be coincidence it is the intakes only, but the intake valves are heavier and if the springs are weakening, at elevated RPM’s the lifter could be lightly lofting over the nose and in combination with the lifter not rolling true across the lobe, possibly “chattering” as they roll/slide over the nose?

At any rate, I need to track down the GM specs for valve spring pressures on the seat and over the nose. I will disassemble the heads today and measure the spring pressures at those 2 points and report back. Anyone by chance have a factory service manual with those figures for an '01 LM7 5.3? Cam is the 0967 grind.

For now, here are the trays;

The following users liked this post:

slowpoke96z28 (08-29-2021)

#10

TECH Fanatic

My take on the nose wear is a heat treatment and/or blank problem. As I recall, the cams are a medium/high carbon alloy steel like 5150 and the lobes are induction hardened. Depending on the pre-grind shape and orientation of the lobes and the depth of the induction hardening, the work area may have a "thin case" which eventually fatigued and either developed micro cracks or collapsed. I don't think it was impact, but rather 300 million valve actuations that caused the problem.

A rough guess for 150,000 miles would be 300 million actuations of each valve. [150,000 miles @ 30 mph average speed and 2000 average rpm).

Some aftermarket steel cams have experienced the same type of problem in a much shorter time. It is often traced to the lobes on the blank being at a different LSA from the finished lobe so one side of a lobe gets more of the hard case ground off than the other. It won't be on the base circle, just near the nose and usually on one side.

You might try to file the worn away area and the non-worn area to compare hardness. If you hold the file flat against the lobe you probably won't be able to cut metal on the non-worn part of the lobe, but the file should be able to "dig in" to the worn area.

Is there material built up ("outie") on the one bad intake lifter roller? If so, that is material from the lobe. If the roller surface is "dug out" ("innie"), then the roller probably got beat up by the material bits coming off the lobe.

http://en.wikipedia.org/wiki/Induction_hardening

My $.02

Jon

A rough guess for 150,000 miles would be 300 million actuations of each valve. [150,000 miles @ 30 mph average speed and 2000 average rpm).

Some aftermarket steel cams have experienced the same type of problem in a much shorter time. It is often traced to the lobes on the blank being at a different LSA from the finished lobe so one side of a lobe gets more of the hard case ground off than the other. It won't be on the base circle, just near the nose and usually on one side.

You might try to file the worn away area and the non-worn area to compare hardness. If you hold the file flat against the lobe you probably won't be able to cut metal on the non-worn part of the lobe, but the file should be able to "dig in" to the worn area.

Is there material built up ("outie") on the one bad intake lifter roller? If so, that is material from the lobe. If the roller surface is "dug out" ("innie"), then the roller probably got beat up by the material bits coming off the lobe.

http://en.wikipedia.org/wiki/Induction_hardening

My $.02

Jon

#12

My take on the nose wear is a heat treatment and/or blank problem. As I recall, the cams are a medium/high carbon alloy steel like 5150 and the lobes are induction hardened. Depending on the pre-grind shape and orientation of the lobes and the depth of the induction hardening, the work area may have a "thin case" which eventually fatigued and either developed micro cracks or collapsed. I don't think it was impact, but rather 300 million valve actuations that caused the problem.

A rough guess for 150,000 miles would be 300 million actuations of each valve. [150,000 miles @ 30 mph average speed and 2000 average rpm).

Some aftermarket steel cams have experienced the same type of problem in a much shorter time. It is often traced to the lobes on the blank being at a different LSA from the finished lobe so one side of a lobe gets more of the hard case ground off than the other. It won't be on the base circle, just near the nose and usually on one side.

You might try to file the worn away area and the non-worn area to compare hardness. If you hold the file flat against the lobe you probably won't be able to cut metal on the non-worn part of the lobe, but the file should be able to "dig in" to the worn area.

Is there material built up ("outie") on the one bad intake lifter roller? If so, that is material from the lobe. If the roller surface is "dug out" ("innie"), then the roller probably got beat up by the material bits coming off the lobe.

http://en.wikipedia.org/wiki/Induction_hardening

My $.02

Jon

A rough guess for 150,000 miles would be 300 million actuations of each valve. [150,000 miles @ 30 mph average speed and 2000 average rpm).

Some aftermarket steel cams have experienced the same type of problem in a much shorter time. It is often traced to the lobes on the blank being at a different LSA from the finished lobe so one side of a lobe gets more of the hard case ground off than the other. It won't be on the base circle, just near the nose and usually on one side.

You might try to file the worn away area and the non-worn area to compare hardness. If you hold the file flat against the lobe you probably won't be able to cut metal on the non-worn part of the lobe, but the file should be able to "dig in" to the worn area.

Is there material built up ("outie") on the one bad intake lifter roller? If so, that is material from the lobe. If the roller surface is "dug out" ("innie"), then the roller probably got beat up by the material bits coming off the lobe.

http://en.wikipedia.org/wiki/Induction_hardening

My $.02

Jon

Jon,

Good info thank you. There is no build up on the lifter roller, only material fractured out of the roller.

Per your advice, I also took a file to the cam. Across unaffected lobe areas, across trashed lobe areas and across bearing journals. Bearing journals are definitely softer, more “dig” with the file than the lobes. I was amazed at how much the file did mar up the good lobes! Base circle, ramps, nose, I can get it to dig and mar the surface, though it is noticeably “harder” than the bearing journals. The trashed portions also would dig in, though it was difficult to accurately deduce if it was any softer than a good lobe. The worst parts of the trashed lobes are still harder than the bearing journals, if that means anything.

#14

Looking closer at the #4 intake lifter, the shine on the edge of the flats indicates that the cam was doing its best to straighten out the lifter.

Also, the lifter slots with the worst twist in the #10 trays are VERY lose around the lifter within the lifter travel of the tray and have significantly more rotation than the others.

Disassembled the heads. Haven’t been able to find service limts in regards to LM7 valve springs seat and over the nose spring pressures.

Installed spring heights measured consistent 1.790”-1.795”

All springs compressed to 1.795” for seat pressure; 70-75 lbs.

Intake compressed to 1.335”; 200-210 lbs(1.338” is calculated compressed height for .457” lift)

Exhaust compressed to 1.330”; 195-205 lbs (1.329” is calculated compressed height for .466” lift)

So possible culprits thus far;

1) Bad cam core, (soft/improper hardening, etc).

2) Lifters not tracking true on the cam lobe.

3) Possible soft springs, lofting/chattering lifters across nose of lobe (still need spring pressure service limits specs).

4) Combination of any of the above.

5) ???

Also, the lifter slots with the worst twist in the #10 trays are VERY lose around the lifter within the lifter travel of the tray and have significantly more rotation than the others.

Disassembled the heads. Haven’t been able to find service limts in regards to LM7 valve springs seat and over the nose spring pressures.

Installed spring heights measured consistent 1.790”-1.795”

All springs compressed to 1.795” for seat pressure; 70-75 lbs.

Intake compressed to 1.335”; 200-210 lbs(1.338” is calculated compressed height for .457” lift)

Exhaust compressed to 1.330”; 195-205 lbs (1.329” is calculated compressed height for .466” lift)

So possible culprits thus far;

1) Bad cam core, (soft/improper hardening, etc).

2) Lifters not tracking true on the cam lobe.

3) Possible soft springs, lofting/chattering lifters across nose of lobe (still need spring pressure service limits specs).

4) Combination of any of the above.

5) ???

Last edited by BRAAPZ; 03-09-2009 at 09:30 PM.

#15

Anyone else see OE cams fail across the nose of the lobe?

Short version ’01 Suburban 1500 4wd, 5.3 LM7, bone stock, NEVER opened up! We are second owners, purchased the Burb at 27,000 miles. It had slight lifter tick since the day we bought it, that never got worse so we didn’t worry about. (Used replacement engine exhibits similar lifter tick). At 150,000 miles a loud "squeak squeak squeak" noise shows up, follows engine RPM. Sounds exactly like a belt squeal. With mechanics stethoscope didn’t take long to narrow down to the middle of the passenger valve cover. Valve cover removed, narrowed down to #4 intake. Remove rocker squeak gone, reinstall rocker squeak comes back. Rocker checks out fine, even swapped with another rocker to narrow down rocker or lifter. #4 intake “lifter” is the culprit. Ok, sounds like the roller of the lifter is sliding across the lobe, i.e. not rolling any more. Found another complete LM7 to swap in, either ’02 or ’04, (pretty sure its an ’04) swapped engines just prior to Thanksgiving, replacement engine runs great, wife is happy she has her rig back. My plan with the old 5.3 I removed is to swap out the lifters and an LS1 cam into and install it with the new cam and lifters in my 300-ZX.

Short version ’01 Suburban 1500 4wd, 5.3 LM7, bone stock, NEVER opened up! We are second owners, purchased the Burb at 27,000 miles. It had slight lifter tick since the day we bought it, that never got worse so we didn’t worry about. (Used replacement engine exhibits similar lifter tick). At 150,000 miles a loud "squeak squeak squeak" noise shows up, follows engine RPM. Sounds exactly like a belt squeal. With mechanics stethoscope didn’t take long to narrow down to the middle of the passenger valve cover. Valve cover removed, narrowed down to #4 intake. Remove rocker squeak gone, reinstall rocker squeak comes back. Rocker checks out fine, even swapped with another rocker to narrow down rocker or lifter. #4 intake “lifter” is the culprit. Ok, sounds like the roller of the lifter is sliding across the lobe, i.e. not rolling any more. Found another complete LM7 to swap in, either ’02 or ’04, (pretty sure its an ’04) swapped engines just prior to Thanksgiving, replacement engine runs great, wife is happy she has her rig back. My plan with the old 5.3 I removed is to swap out the lifters and an LS1 cam into and install it with the new cam and lifters in my 300-ZX.

That means you removed the rocker arm, the pushrod, left the lifter in place, and started the engine?

I would think that is what caused the damage to your cam and lifters.

#16

Teching In

iTrader: (3)

Join Date: Jun 2007

Location: Tampa, FL

Posts: 26

Likes: 0

Received 0 Likes

on

0 Posts

My LS1 cam had the same EXACT mark on one of the rear lobes. My lifters were perfect and engine didn't make any odd noises. However, not many lifter cam out with the trays.

I think its just a manufacturing defect on the cam

I think its just a manufacturing defect on the cam

#17

holy **** i think all of you just saved me from overhauling my engine again. i just bought a salvage motor with "84000" and i wanted to pull the heads machine them and get a real good look at everything as the heads came off and got sent out i took the stock push rods out and tossed them they looked fine but showed sighns of owner neglect you could tell oil changes didnt come regularly. anyhow i pulled out the lifter trays and had to retrive 3 lifters with a needle nose, the came looks fine no issues the lifters look fine as well except for the fact that most of the lifter pushrod seat had no movement in the lifter i bought new set of crane cams lifters and am planing to put them in soon but i had no idea about the trays. time for some ls2 trays any on have a set???

#18

my 2000 z28 had a ticking noise in it at 67km, the surface on one lobe of the stock cam was worn off. One lifter was pitted a bit . Replaced with another GM cam and and lifter. Changed the oil a few times to get the cam filings out of engine.. Works fine now. wondered if it was from driving hard occasionally .. or a bad cam .