Forged Piston to bore clearance?

#1

Good day,

So my 383 LS1 was knocking pretty bad, I tried all the valvetrain parts I could think of, didn't fix the problem.

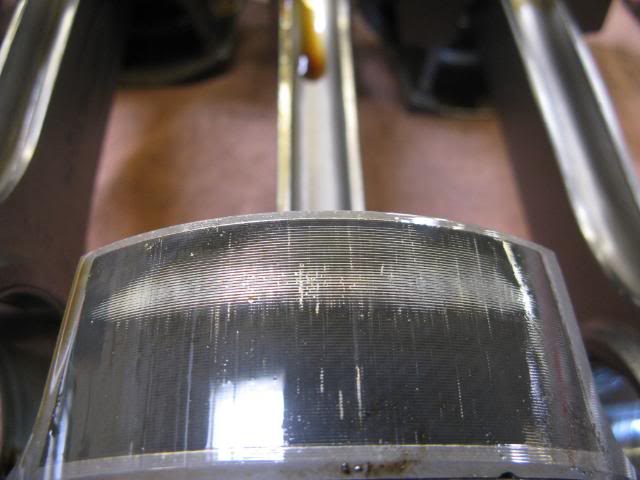

So I decided to tear it down and get to the bottom of this. The shortblock was balanced, and assembled by the machine shop. So I pulled a rod cap off, bearings looked cherry. Pulled the piston out and find this.

Is this kind of scoring normal after 5k miles???

So I started measuring things.

Pistons-3.900"

Bores-3.912"

Clearance-.012"

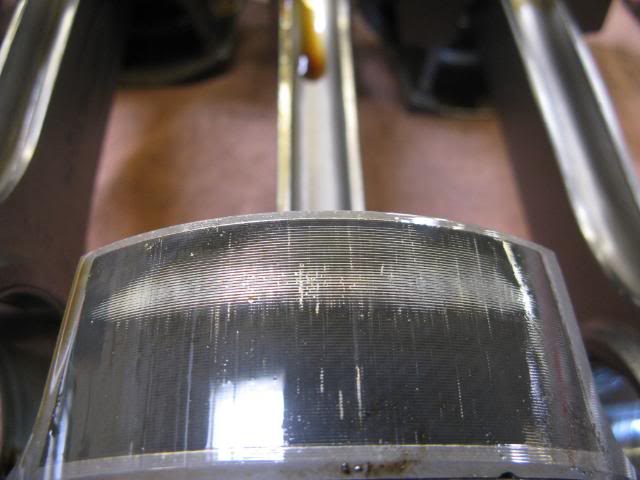

This is a .010" feeler gauge....

This is a huge clearance as I can rock the piston back and forth considerably while it is installed and torqued down.

So I would like to know what the average clearance for forged pistons to bore clearances are. These are Mahle 383 pistons.

And do you guys think the machine shop should be responsible for this? I have a 12 month warranty on the engine.

WOULD THIS CAUSE AN AUDIBLE 'KNOCKING' or 'TAPPING' NOISE???

BTW Every single piston is like this...

So my 383 LS1 was knocking pretty bad, I tried all the valvetrain parts I could think of, didn't fix the problem.

So I decided to tear it down and get to the bottom of this. The shortblock was balanced, and assembled by the machine shop. So I pulled a rod cap off, bearings looked cherry. Pulled the piston out and find this.

Is this kind of scoring normal after 5k miles???

So I started measuring things.

Pistons-3.900"

Bores-3.912"

Clearance-.012"

This is a .010" feeler gauge....

This is a huge clearance as I can rock the piston back and forth considerably while it is installed and torqued down.

So I would like to know what the average clearance for forged pistons to bore clearances are. These are Mahle 383 pistons.

And do you guys think the machine shop should be responsible for this? I have a 12 month warranty on the engine.

WOULD THIS CAUSE AN AUDIBLE 'KNOCKING' or 'TAPPING' NOISE???

BTW Every single piston is like this...

Last edited by 89L98T56; 08-21-2010 at 06:33 PM.

#4

It seems a little large especially since its an iron sleeve ally block, which has a bit more of an expansion rate than an iron block. You're also missing some of the coating, so your measurement will be big.

Piston material also plays a part in clearance, a 2618 alloy expands more than same piston of 4032.

Where on the piston did you measure?

Piston material also plays a part in clearance, a 2618 alloy expands more than same piston of 4032.

Where on the piston did you measure?

#5

I don't know, and I don't know where to find out.

I measured from skirt to skirt, middle, bottom, top, and the top part of the piston. Anyone know what material Mahle uses for their pistons?

It seems a little large especially since its an iron sleeve ally block, which has a bit more of an expansion rate than an iron block. You're also missing some of the coating, so your measurement will be big.

Piston material also plays a part in clearance, a 2618 alloy expands more than same piston of 4032.

Where on the piston did you measure?

Piston material also plays a part in clearance, a 2618 alloy expands more than same piston of 4032.

Where on the piston did you measure?

#6

Wiseco can have as little as 0.004". I would guess that Mahle would be about the same. Check your part number, its got to be a 3.908" piston.

Last edited by indeed; 08-21-2010 at 10:07 PM.

Trending Topics

#9

Old School Heavy

iTrader: (16)

You should get your piston to wall clearance specs from the piston manufacturer. Only they know the materials and design details that determine what their products require. They can vary from design to design.

I do not know you, or your abilities, so do not take this as directed at you. But, also required is a high quality bore gauge with a very experienced operator. This way you can check the cylinder from top to bottom for roundness and bore taper. A cheap bore gauge or an inexperienced operator can both contribute to inaccurate measurement results and have you looking in the wrong direction for solutions.

I do not know you, or your abilities, so do not take this as directed at you. But, also required is a high quality bore gauge with a very experienced operator. This way you can check the cylinder from top to bottom for roundness and bore taper. A cheap bore gauge or an inexperienced operator can both contribute to inaccurate measurement results and have you looking in the wrong direction for solutions.

#10

TECH Enthusiast

You should get your piston to wall clearance specs from the piston manufacturer. Only they know the materials and design details that determine what their products require. They can vary from design to design.

I do not know you, or your abilities, so do not take this as directed at you. But, also required is a high quality bore gauge with a very experienced operator. This way you can check the cylinder from top to bottom for roundness and bore taper. A cheap bore gauge or an inexperienced operator can both contribute to inaccurate measurement results and have you looking in the wrong direction for solutions.

I do not know you, or your abilities, so do not take this as directed at you. But, also required is a high quality bore gauge with a very experienced operator. This way you can check the cylinder from top to bottom for roundness and bore taper. A cheap bore gauge or an inexperienced operator can both contribute to inaccurate measurement results and have you looking in the wrong direction for solutions.

#11

I don't know where some of you are getting your measurements from, since we don't even know the material used for the piston.

Also, what tools do you have to measure the bore?

Lastly, give the engine builder a call. He'll know what mahle wanted for clearances, and you obviously want to do something about this excessive piston rocking/slapping.

Also, what tools do you have to measure the bore?

Lastly, give the engine builder a call. He'll know what mahle wanted for clearances, and you obviously want to do something about this excessive piston rocking/slapping.

#12

.010 is insane! Of course its going to knock like box of rocks. You should have 1/2 of that MAX!

How much you wanna bet someone thought they had it at .005, when actually they were at .010 because they doubled the measument.

That thing must knock like hell.

take the block and pistons back to the machine shop and make um check it in frt of you then school um!

How much you wanna bet someone thought they had it at .005, when actually they were at .010 because they doubled the measument.

That thing must knock like hell.

take the block and pistons back to the machine shop and make um check it in frt of you then school um!

Last edited by HotSilverBird; 08-22-2010 at 12:59 PM.

#13

You should get your piston to wall clearance specs from the piston manufacturer. Only they know the materials and design details that determine what their products require. They can vary from design to design.

I do not know you, or your abilities, so do not take this as directed at you. But, also required is a high quality bore gauge with a very experienced operator. This way you can check the cylinder from top to bottom for roundness and bore taper. A cheap bore gauge or an inexperienced operator can both contribute to inaccurate measurement results and have you looking in the wrong direction for solutions.

I do not know you, or your abilities, so do not take this as directed at you. But, also required is a high quality bore gauge with a very experienced operator. This way you can check the cylinder from top to bottom for roundness and bore taper. A cheap bore gauge or an inexperienced operator can both contribute to inaccurate measurement results and have you looking in the wrong direction for solutions.

I need to call Mahle on Monday and get their opinion and then call the machine shop who built this.

This sucks because I am in the military and had the shortblock built while I was overseas, when I got home I put the motor in my car and drove out to CA where I am now stationed. So I am about a 12hr drive away from the machine shop who built this engine.

.010 is insane! Of course its going to knock like box of rocks. You should have 1/2 of that MAX!

How much you wanna bet someone thought they had it at .005, when actually they were at .010 because they doubled the measument.

That thing must knock like hell.

take the block and pistons back to the machine shop and make um check it in frt of you then school um!

How much you wanna bet someone thought they had it at .005, when actually they were at .010 because they doubled the measument.

That thing must knock like hell.

take the block and pistons back to the machine shop and make um check it in frt of you then school um!

Last edited by 89L98T56; 10-01-2010 at 01:07 AM.

#14

Hell yeah it made good power cause LOOSE is FAST! It also makes for loud knocking sounds ans worn rings and oill consumption. You can't have pistons rocking constantly like that in the bores!

.010 clearance is INSANE!

.010 clearance is INSANE!

#15

This is gonna **** you off........

PISTONS: Cast Eutectic Aluminum, +'03 have coated skirts

Weight = 434 grams

Piston OD: 98.964-98.982mm / 3.8962-3.8969"

Piston to Bore Clearance(P): 0.018-0.054mm/0.0007-0.00212"

Piston to Bore Clear. (SL): 0.018-0.054mm / 0.0007-0.00212"

(Maximum)

Piston Deck Height in Operation: 0.203mm / 0.008"

(Above Deck Surface)

Top Land Thickness: 34mm / 0.177"

thats stock but still you are not even close!

PISTONS: Cast Eutectic Aluminum, +'03 have coated skirts

Weight = 434 grams

Piston OD: 98.964-98.982mm / 3.8962-3.8969"

Piston to Bore Clearance(P): 0.018-0.054mm/0.0007-0.00212"

Piston to Bore Clear. (SL): 0.018-0.054mm / 0.0007-0.00212"

(Maximum)

Piston Deck Height in Operation: 0.203mm / 0.008"

(Above Deck Surface)

Top Land Thickness: 34mm / 0.177"

thats stock but still you are not even close!

#16

Even ay at the max .005 i wouldn't be happy...why start off so loose? Loose does make more hp but it also causes a list of other troubles. At .010 the pistons are basicly rocking and floping back and forth. Did you call the builder before you tore it down?

I'll bet you at .010 you could of rocked the pistons in the bores with the heads off with your hands!. I've seen it already...on engines with 200k on um!

I know exactly what your machine shop did, they figured .005 clearance all the way around the piston! so that equals .010.

I'll bet you at .010 you could of rocked the pistons in the bores with the heads off with your hands!. I've seen it already...on engines with 200k on um!

I know exactly what your machine shop did, they figured .005 clearance all the way around the piston! so that equals .010.

Last edited by HotSilverBird; 08-22-2010 at 05:59 PM.

#17

Even ay at the max .005 i wouldn't be happy...why start off so loose? Loose does make more hp but it also causes a list of other troubles. At .010 the pistons are basicly rocking and floping back and forth. Did you call the builder before you tore it down?

I'll bet you at .010 you could of rocked the pistons in the bores with the heads off with your hands!. I've seen it already...on engines with 200k on um!

I know exactly what your machine shop did, they figured .005 clearance all the way around the piston! so that equals .010.

I'll bet you at .010 you could of rocked the pistons in the bores with the heads off with your hands!. I've seen it already...on engines with 200k on um!

I know exactly what your machine shop did, they figured .005 clearance all the way around the piston! so that equals .010.

http://www.youtube.com/watch?v=Vja9KnZmPK8

I have called them before I knew it was the pistons. I thought it was a spun bearing and asked if they would warranty it and they said if it wasn't caused by lack of oiling. So I am pretty sure they will own up to this mistake. only problem is that they are in Albuquerque NM and I am in San diego....

I'm thinking if I were to do it myself which I would rather do than to trust someone else again. It would be cheaper to buy a standard block and hone each cylinder to the pistons I already have since this rotating assembly is already balanced, and the pistons are about $750. The only problem would be the clearancing for the 4.00" stroke crank. Anyone know how hard it would be to clearance the block myself?

#18

On The Tree

iTrader: (9)

Join Date: Jul 2010

Location: Gadsden AL

Posts: 104

Likes: 0

Received 0 Likes

on

0 Posts

Im no expert(not even close) but it would seem to me that with the scuffing on the piston you have on each one, timed by 8 pistons that your rotating assembly wont be balanced anymore. BUT I could be wrong