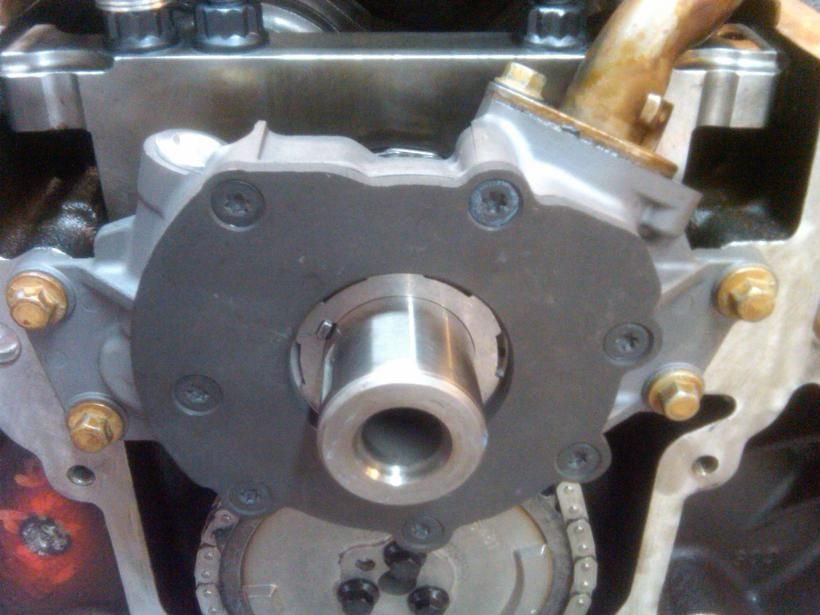

Oil Pump Pickup Tube

#1

On The Tree

Thread Starter

After seeing some photos of some untouched engines, the pickup tube seems to be flush with the pump when installed. On my 5.3L, it is mostly flush, but towards the side without the bolt, it comes up from the pump a tad. Should this be an issue? It seals well with the new O-Ring, but I am not taking any changes with this engine.

Last edited by Treyvs; 08-31-2013 at 08:44 PM.

#3

Fix that for sure! I'd replace the oring and buy a truss kit so you can use both bolt holes to hold the pickup in place. GM engineers need to pull their heads outta their azzes..........

#5

TECH Fanatic

#7

Yeah...you need to fix that pick-up tube installation as stated. Make it flush with the oil pump, also a girdle which isn't needed doesn't hurt either.

http://www.classicindustries.com/196...s/1026000.html

http://www.classicindustries.com/196...s/1026000.html

Trending Topics

#8

On The Tree

Thread Starter

Upon inspection, the O-Ring was seated perfectly. I suppose that the pickup tube itself is cocked a little which led to it appearing as if it was not correctly installed. The O-Ring came out perfect and went back in perfect. Can't count on quality this day in age...

#12

On The Tree

Thread Starter

I took the tube off today and I believe that the tube itself is flawed, so I think the girdle will do the trick to keep the O-Ring sealed and not let air in.

Even though I think everything will be fine, I don't want to put my $4800 engine on the line for a silly/lazy mistake.

I will post a photo when completed.

Even though I think everything will be fine, I don't want to put my $4800 engine on the line for a silly/lazy mistake.

I will post a photo when completed.

#15

On The Tree

Thread Starter

Well, I received the girdle yesterday and decided not to wait until the weekend to install it. The girdle comes with two bolts, as to replace the GM bolt. Upon trying to install the girdle, one of the bolts decided to break in half while threading.

With some needle nose pliers and some choice words, I was able to coax it out of the threads of the oil pump. I then went back and tried to use the GM bolt along with one of the bolts from the kit, and then the GM bolt's threads decided to fail and fall off.

Today, I am going to get the strongest bolts on the planet for this thing, just as long as the threads in the oil pump are still in good shape...

I recommend the girdle, just discard the supplied bolts.

One more post to follow with photos of the girdle installed.

With some needle nose pliers and some choice words, I was able to coax it out of the threads of the oil pump. I then went back and tried to use the GM bolt along with one of the bolts from the kit, and then the GM bolt's threads decided to fail and fall off.

Today, I am going to get the strongest bolts on the planet for this thing, just as long as the threads in the oil pump are still in good shape...

I recommend the girdle, just discard the supplied bolts.

One more post to follow with photos of the girdle installed.

#16

TECH Fanatic

It sounds like you have much bigger problems than weak bolts. Part of knowing how to assemble a threaded fastener is to stop and back off if something starts binding.

Did you test fit the bolts in the oil pump first?

Did you test fit the bolts in the oil pump first?

#17

On The Tree

Thread Starter

That is the odd thing. The bolt threaded perfectly and upon torquing to spec, it gave up. Not one time did it bind. The other side, however did bind and it even appears as though the threads in the pump are screwed up. I will inspect it closer tonight.

#19

On The Tree

Thread Starter

Ended up not using the girdle, as I am happy with where the O-Ring sits. I re tapped pickup tube threads, and I don't foresee any issues coming from it in its current state. Also purchased new bolts for the oil pump itself. It turned out rather well I think. As I stated before, the tube itself must be flawed and gives the impression that a firm seal is not being made, but everything ends up good as before.

#20

On The Tree

Thread Starter

Sorry to revisit this thread, but I still lose sleep over this issue. Does anyone else think that the tube itself is flawed and that everything SHOULD be okay? I know the O-ring seats correctly and it not pinched, as I have physically inspected in multiple times.