4L60E no end play

#1

Teching In

Thread Starter

iTrader: (1)

Join Date: Apr 2009

Location: MD

Posts: 7

Likes: 0

Received 0 Likes

on

0 Posts

I have been struggling with my 4L60e rebuild and the end play is fighting me. I have built a couple 4L60e's and 700R4's with no problem, this one takes the cake...

With the pump out and the input drums installed I have about a good 1/4 inch of end play, as soon as I put the pump in it goes to zero.

I have changed the selective washers multiple times, the only thing I can get to work is three sonnax endplay shims (.015) which will put me about .027. This makes me uneasy because the smallest washer GM makes is .074 and this combination is almost half that. Has anyone ever experienced this?

The other thing that makes me uneasy about using just the three shims (.045 height) is when I push down on the reverse input drum i cannot move it because its applying pressure to the apply plate in the drum. I'm pretty sure it doesn't matter when everything is installed but it still doesn't feel right.

I upgraded to the beast shell, a new reverse input drum, and a new used input drum (because the old one had grooves worn into the teeth). I also replaced the pump stator shaft with a sonnax version. I double checked everything and all the new parts look and measure indentical to the old parts. I double checked the stator shaft and it is seated against the pump.

What is it that can effect end play other than the selective washers? Is it ok to used just the sonnax shims? If so, am i better off at .027 or .012?

Any help would be greatly appreciated.

Thanks

John

With the pump out and the input drums installed I have about a good 1/4 inch of end play, as soon as I put the pump in it goes to zero.

I have changed the selective washers multiple times, the only thing I can get to work is three sonnax endplay shims (.015) which will put me about .027. This makes me uneasy because the smallest washer GM makes is .074 and this combination is almost half that. Has anyone ever experienced this?

The other thing that makes me uneasy about using just the three shims (.045 height) is when I push down on the reverse input drum i cannot move it because its applying pressure to the apply plate in the drum. I'm pretty sure it doesn't matter when everything is installed but it still doesn't feel right.

I upgraded to the beast shell, a new reverse input drum, and a new used input drum (because the old one had grooves worn into the teeth). I also replaced the pump stator shaft with a sonnax version. I double checked everything and all the new parts look and measure indentical to the old parts. I double checked the stator shaft and it is seated against the pump.

What is it that can effect end play other than the selective washers? Is it ok to used just the sonnax shims? If so, am i better off at .027 or .012?

Any help would be greatly appreciated.

Thanks

John

#2

Moderator

I'm not a trans builder, but I've never heard of anyone needing to go that thin on the washer. This is usually a strong indication that something is wrong.

What year is the trans?

Did you by chance replace the front reaction carrier or planet?

What bearing is between the reaction carrier and the sun shell,

e.g. are you using the flat brass one that came with the beast

or new-style torrington? (Don't use both!)

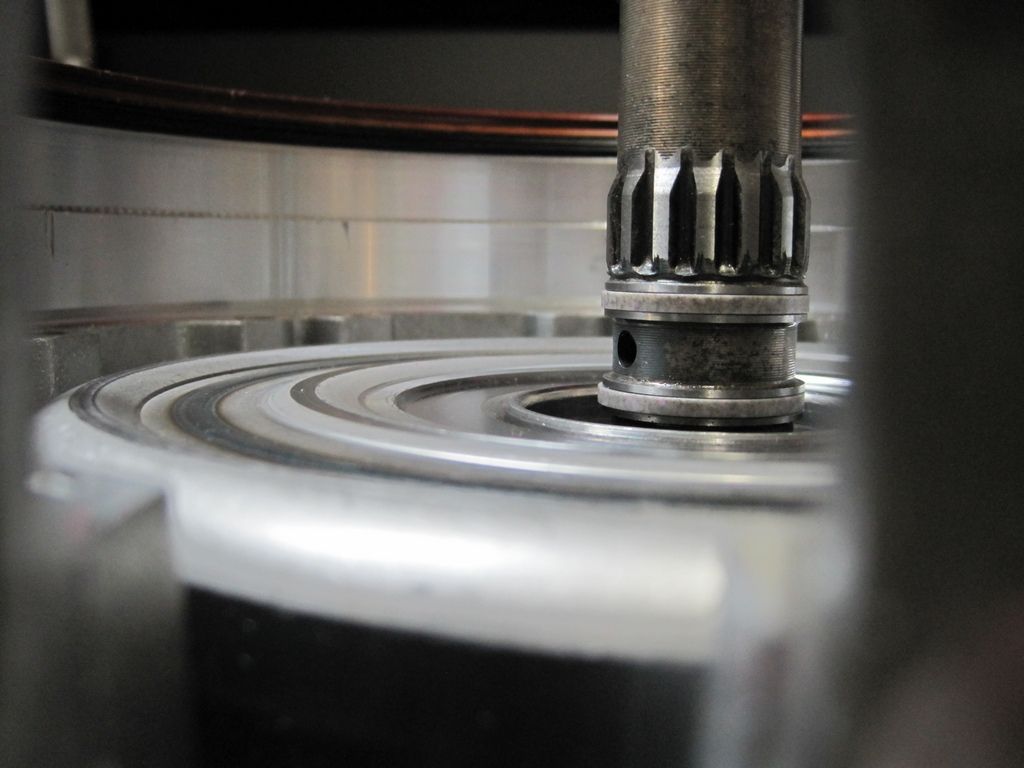

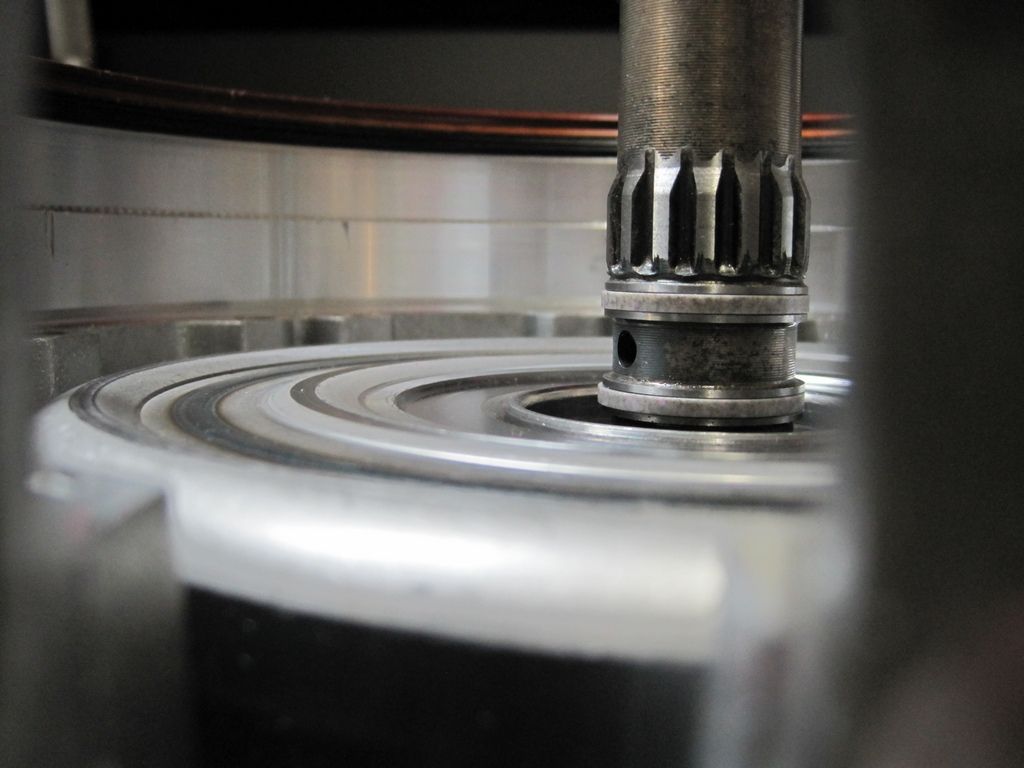

This picture might help you see where the reverse drum sits in relation to the case before you install the pump:

What year is the trans?

Did you by chance replace the front reaction carrier or planet?

What bearing is between the reaction carrier and the sun shell,

e.g. are you using the flat brass one that came with the beast

or new-style torrington? (Don't use both!)

This picture might help you see where the reverse drum sits in relation to the case before you install the pump:

#3

Teching In

Thread Starter

iTrader: (1)

Join Date: Apr 2009

Location: MD

Posts: 7

Likes: 0

Received 0 Likes

on

0 Posts

Its a 2003 unit, I did not replace the reaction carrier and I discarded the brass thrust washer because the unit uses a torrington bearing on the reaction carrier, that took a couple hours to figure out why the out put shaft spring clip wouldn't snap in the groove.

The drum is sitting where it should be, there is roughly a 1/4 inch between the drum and the pump mounting surface.can any of the clutch pack heights effect the end play, maybe the overrun or forward clutch pack effecting the height of the forward sprag? Trying to think outside the box...

Im double checking everything right now to try and find my missing .040...

Thanks for the help, any ideas please pass them on. Ill post if I find anything.

The drum is sitting where it should be, there is roughly a 1/4 inch between the drum and the pump mounting surface.can any of the clutch pack heights effect the end play, maybe the overrun or forward clutch pack effecting the height of the forward sprag? Trying to think outside the box...

Im double checking everything right now to try and find my missing .040...

Thanks for the help, any ideas please pass them on. Ill post if I find anything.

#4

Moderator

I'm no expert, but cannot image any issue in the input drum affecting the end play.

Hopefully one of the pro builder will have an idea. I have to leave for the day right now, but will email a few pros tonight to check this thread if you need.

Hopefully one of the pro builder will have an idea. I have to leave for the day right now, but will email a few pros tonight to check this thread if you need.

#5

The first thing I would do if I was you is take the whole thing back apart and see if anything looks out of place.

The next thing I would do is glue all the washers and torrington bearings on their intended spot with transgel or vaseline so that they do not get misaligned when assembling.

Then make sure that the beast is all the way seated up against the snap ring on the rear sungear. Those splines fit very tight and sometimes they dont want to go all the way on.

I would then reassemble the whole works minus the reverse input drum until you get your end play issue figured out as the reverse input drum has nothing to do with end play and at this point is just one more thing to get in the way in an already frustrating situation.

The next thing I would do is glue all the washers and torrington bearings on their intended spot with transgel or vaseline so that they do not get misaligned when assembling.

Then make sure that the beast is all the way seated up against the snap ring on the rear sungear. Those splines fit very tight and sometimes they dont want to go all the way on.

I would then reassemble the whole works minus the reverse input drum until you get your end play issue figured out as the reverse input drum has nothing to do with end play and at this point is just one more thing to get in the way in an already frustrating situation.

#6

Teching In

Thread Starter

iTrader: (1)

Join Date: Apr 2009

Location: MD

Posts: 7

Likes: 0

Received 0 Likes

on

0 Posts

Just Just got done double checking everything, nothing was out of place and all bearings were where they were supposed be, output shaft fits perfect with .080+ of end play (checked to make sure the lower half had play) put the upper half together and everything was good until the pump was tightened down.

I will try it without the reverse drum and see what happens. This is driving me crazy cuz I never had this problem and im so close to being done.

I will try it without the reverse drum and see what happens. This is driving me crazy cuz I never had this problem and im so close to being done.

#7

The reverse input drum SHOULDN'T affect endplay but it can.

Pull your Beast Sun Shell back out and make sure it completely interfaces with the rev input drum. I've had some Beast shells that needed to be slightly ground/deburred to fit completely into the reverse input drum and it will mess with your fitment.

Does the rev input drum sit completely on the pump stator?

Is the forward sprag completely seated in the input drum? If you mixed the over-run and forward steels you can have a fitment problem there.

Pull your Beast Sun Shell back out and make sure it completely interfaces with the rev input drum. I've had some Beast shells that needed to be slightly ground/deburred to fit completely into the reverse input drum and it will mess with your fitment.

Does the rev input drum sit completely on the pump stator?

Is the forward sprag completely seated in the input drum? If you mixed the over-run and forward steels you can have a fitment problem there.

Trending Topics

#8

Teching In

Thread Starter

iTrader: (1)

Join Date: Apr 2009

Location: MD

Posts: 7

Likes: 0

Received 0 Likes

on

0 Posts

OK I found where the difference went, I installed a sonnax pump stator shaft as I mentioned earlier, I measured the snout length on the shaft going into the transmission and it was the same exact length as the old one. What i failed to measure was the mounting flange thickness, it is .020 thicker than the old one which in turn is moving the end of the shaft .020 away from the pump, which is why I need a smaller selective washer.

My next question, what do I do with this? with the longer shaft it puts it .020 closer to the pump, is there enough room between the plastic washer and pump for the extra .020 or will it melt the washer amoung other things? I can put two pump gaskets which are .015 thick but I don't know if that will stay the same after its torqued down.

My next question, what do I do with this? with the longer shaft it puts it .020 closer to the pump, is there enough room between the plastic washer and pump for the extra .020 or will it melt the washer amoung other things? I can put two pump gaskets which are .015 thick but I don't know if that will stay the same after its torqued down.

#9

Moderator

I have used the Sonnax stator shaft and don't recall it make any difference to the end play. Not to be disagreeable or doubt you, but that just doesn't make sense - the mounting flange might be thicker, but I cannot imagine Sonnax not accounting for that. (Or correct me that the Sonnax stator shaft really is .020 longer than stock.)

Are you absolutely sure the stator shaft is pressed all the way into the pump? The mounting flange has to be absolutely flush with the pump. Sometimes during the pressing operation the mounting flange shears a little bit off the alignment pin and then does not press in flush.

Sorry, I don't understand your 2nd paragraph, but I am glad that pros CarsonAuto and Jake are helping you now.

Are you absolutely sure the stator shaft is pressed all the way into the pump? The mounting flange has to be absolutely flush with the pump. Sometimes during the pressing operation the mounting flange shears a little bit off the alignment pin and then does not press in flush.

Sorry, I don't understand your 2nd paragraph, but I am glad that pros CarsonAuto and Jake are helping you now.

#10

I would not use two pump gaskets for any reason. The flange that the stator support mounts with should be able to be substantially thicker than the stock one and not negatively affect anything. The factory clearance between the plastic washer that goes on it and the reverse input drum is close to .100 and doesnt need to be. There are actually a few things that you can do to reduce that if you so desire. (topic for another day) So with that flange being thicker does it also extend the whole thing out an additional .020 from the rear pump face or just that flange? What is the part number for the stator support that you used? I will grab one and compare it with a stock one and see if I can see a difference in length..