Dynamic/Static compression

#1

Hi All,

I am in the planning stages of a high compression build. I have been talking with Phil at AI about doing a set of heads and an intake manifold for my jet boat.

In talking to Phil he recommended for me to look for a set of dome pistons vs the flat tops like i was originally looking for.

My 243 heads are currently cut .030" making the combustion chambers somewhere in the 61cc range.

The pistons i am leaning towards are a set of Diamonds. (11526R1)

They are a 10CC dome. With a 62cc head they list a 12.9 static compression ratio.

(http://www.cnc-motorsports.com/diamo...-905-bore.html)

I have never really played with compression ratios much. My last engine i built was 11.5 static and worked well.

Being it is in a jet boat, i dont mind the fuel requirement. But would like to be able to run it on AV fuel for cruising, then have a tank of 110-C12 for bottle passes and hard runs.

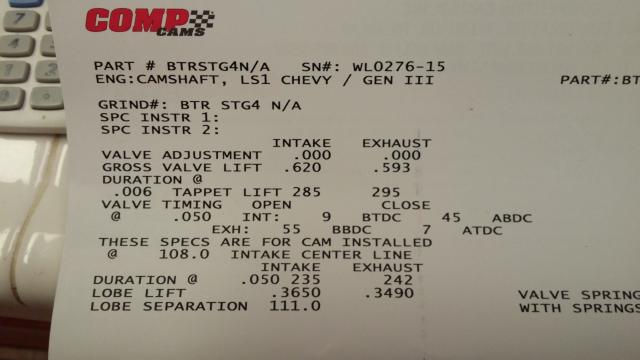

So, i started to do some math, and using the Wallace Dynamic compression calculator, with the below specs im coming up with an insane amount of dynamic compression using my existing cam. Am i doing this correctly? If i understand correctly this kind of compression would land more in the C16 area of fuel requirements. (i have emailed BTR for the cam specs again, i lost my card. But im doing this from memory) Existing cam is a BTR Stage 4 NA LS1 Cam (235/242 .621/.595 111lsa)

8 cylinders

3.905 Bore

3.622 Stroke

6.125 Rod

12.8:1 Static compression

46* Intake Valve closes ABDC (from memory could be wrong)

500' Target altitude (where i will run it)

I am coming up with the following

Static compression ratio of 12.8:1.

Effective stroke is 3.21 inches.

Your dynamic compression ratio is 11.36:1 .

Your dynamic cranking pressure is 250.28 PSI.

Your effective boost compression ratio, reflecting static c.r., cam timing, altitude, and boost of PSI is 11.36 :1.

V/P (Volume to Pressure Index) is 231

Now, i do have a friend i was talking to, and he said he was always told to add 15* to the ABDC timing. Adding the 15* i come up with

Static compression ratio of 12.8:1.

Effective stroke is 2.90 inches.

Your dynamic compression ratio is 10.35:1 .

Your dynamic cranking pressure is 222.49 PSI.

Your effective boost compression ratio, reflecting static c.r., cam timing, altitude, and boost of PSI is 10.35 :1.

V/P (Volume to Pressure Index) is 185

My question to you guys, Am i calculating this correctly? If so it looks like i will need to drop the static compression down a bit. OR go with a bigger cam that bleeds off more compression? What kind of fuel requirements am i looking at?

Thank you

I am in the planning stages of a high compression build. I have been talking with Phil at AI about doing a set of heads and an intake manifold for my jet boat.

In talking to Phil he recommended for me to look for a set of dome pistons vs the flat tops like i was originally looking for.

My 243 heads are currently cut .030" making the combustion chambers somewhere in the 61cc range.

The pistons i am leaning towards are a set of Diamonds. (11526R1)

They are a 10CC dome. With a 62cc head they list a 12.9 static compression ratio.

(http://www.cnc-motorsports.com/diamo...-905-bore.html)

I have never really played with compression ratios much. My last engine i built was 11.5 static and worked well.

Being it is in a jet boat, i dont mind the fuel requirement. But would like to be able to run it on AV fuel for cruising, then have a tank of 110-C12 for bottle passes and hard runs.

So, i started to do some math, and using the Wallace Dynamic compression calculator, with the below specs im coming up with an insane amount of dynamic compression using my existing cam. Am i doing this correctly? If i understand correctly this kind of compression would land more in the C16 area of fuel requirements. (i have emailed BTR for the cam specs again, i lost my card. But im doing this from memory) Existing cam is a BTR Stage 4 NA LS1 Cam (235/242 .621/.595 111lsa)

8 cylinders

3.905 Bore

3.622 Stroke

6.125 Rod

12.8:1 Static compression

46* Intake Valve closes ABDC (from memory could be wrong)

500' Target altitude (where i will run it)

I am coming up with the following

Static compression ratio of 12.8:1.

Effective stroke is 3.21 inches.

Your dynamic compression ratio is 11.36:1 .

Your dynamic cranking pressure is 250.28 PSI.

Your effective boost compression ratio, reflecting static c.r., cam timing, altitude, and boost of PSI is 11.36 :1.

V/P (Volume to Pressure Index) is 231

Now, i do have a friend i was talking to, and he said he was always told to add 15* to the ABDC timing. Adding the 15* i come up with

Static compression ratio of 12.8:1.

Effective stroke is 2.90 inches.

Your dynamic compression ratio is 10.35:1 .

Your dynamic cranking pressure is 222.49 PSI.

Your effective boost compression ratio, reflecting static c.r., cam timing, altitude, and boost of PSI is 10.35 :1.

V/P (Volume to Pressure Index) is 185

My question to you guys, Am i calculating this correctly? If so it looks like i will need to drop the static compression down a bit. OR go with a bigger cam that bleeds off more compression? What kind of fuel requirements am i looking at?

Thank you

Last edited by steves86ta; 09-21-2016 at 10:51 AM.

Trending Topics

#8

I have built many engines. I have always used sort of a "middle of the road" recipe if you will. Basically off the shelf stuff, box stock grinds that sounded like they would work well.

I want this engine to work very well. I am researching as much as possible before buying anything because truly i want to do this once.

My end goals for this engine are somewhere in the 550-600hp range at around 6-6500 rpm. Then anywhere from 150-250 hp on top.

I have bought a couple of the books in the sticky in this forum so i can try to do as much research/learning as possible. As far as assembling the engine that is the least of my worries. I am just trying to identify the recipe one time if that makes sense.

My 5.3 that i have now is already pissing some of the Big block guys off. I want to start pissing off a LOT of them.

Thank you, and any advice you want to send my way would be great

#9

After using a new calculator thanks to KCS's tip. And cross checking it by putting in the @.050" numbers, here are my new compression results. This one sounds a lot more AV fuel friendly. What do you think?

Static compression ratio of 12.8:1.

Effective stroke is 2.64 inches.

Your dynamic compression ratio is 9.50:1 .

Your dynamic cranking pressure is 199.49 PSI.

Your effective boost compression ratio, reflecting static c.r., cam timing, altitude, and boost of PSI is 9.50 :1.

V/P (Volume to Pressure Index) is 151

Static compression ratio of 12.8:1.

Effective stroke is 2.64 inches.

Your dynamic compression ratio is 9.50:1 .

Your dynamic cranking pressure is 199.49 PSI.

Your effective boost compression ratio, reflecting static c.r., cam timing, altitude, and boost of PSI is 9.50 :1.

V/P (Volume to Pressure Index) is 151

#10

TECH Enthusiast

iTrader: (4)

It should work great on 110 leaded octane with a 9.5-1 dynamic. Glad you were able to figure out the numbers with the calculator. I forgot that there are many good calculators online that can be used to figure it out. Not sure what octane AV gas is so I would be no help on if it will run good on AV gas or not.

#11

FormerVendor

iTrader: (1)

Join Date: Nov 2008

Location: Santa Ana, CA. USA

Posts: 2,157

Likes: 0

Received 16 Likes

on

16 Posts

OK, you would need to ADD the effect of "runner length" AND COUNT the Supercharging effect it has on cylinder pressure.

The effect of piston pin offset (reversed), an easy option at RaceTec Pistons, has a great effect on Dynamic Compression.

MY LS-1/7 ITB intake with eight 65mm butterflies will produce 118KPA in the runner with a BARO of 101KPA at song.

This is like a boost of 1.5 .lbs and as we know this effects Dynamic C.R.

Thus a great effect Dynamic Compression.

The OBJECT of this thread is Knock Rating.

I will add :

1. Accuracy of the Spark Instant effect, a TW of 24xe=2 degrees resolution (LS-1) OR a TW "my" 60-2 (GM58x)=1/4 degree resolution (LS-2) will allow for a .5 C.R. increase in Knock Rating

2. Ignition Coil energy effect, the increase in Arc Duration/Coil Energy will allow for a lower spark advance value, thus an increase in Knock Rating.

3. The effect of Arc Duration can be controlled BY changes in Spark Plug Gap/Spark Plug Wire resistance, when correct allows for an increase in Knock Rating.

Lance

The effect of piston pin offset (reversed), an easy option at RaceTec Pistons, has a great effect on Dynamic Compression.

MY LS-1/7 ITB intake with eight 65mm butterflies will produce 118KPA in the runner with a BARO of 101KPA at song.

This is like a boost of 1.5 .lbs and as we know this effects Dynamic C.R.

Thus a great effect Dynamic Compression.

The OBJECT of this thread is Knock Rating.

I will add :

1. Accuracy of the Spark Instant effect, a TW of 24xe=2 degrees resolution (LS-1) OR a TW "my" 60-2 (GM58x)=1/4 degree resolution (LS-2) will allow for a .5 C.R. increase in Knock Rating

2. Ignition Coil energy effect, the increase in Arc Duration/Coil Energy will allow for a lower spark advance value, thus an increase in Knock Rating.

3. The effect of Arc Duration can be controlled BY changes in Spark Plug Gap/Spark Plug Wire resistance, when correct allows for an increase in Knock Rating.

Lance