th350+700rwhp+semi budget=what can i do?

#1

On The Tree

Thread Starter

iTrader: (1)

Join Date: Oct 2010

Posts: 185

Likes: 0

Received 0 Likes

on

0 Posts

the roller that i have came with a stock th350/crossmember and DS already in it etc etc. im on a semi tight budget and plan on sticking with this trans for the time being until a i can do a th400 down the road sometime. a buddy of mine had his th350 done at a local shop and they did some little tricks and all upgraded cluthes for 500 bucks out the door and it was behind a 3500lb car going 9.6 at 141 off the foot brake no trans brake with stock valve body. im hoping to do a little faster with my car. this will be a stock valve body and foot brake launches on a 2 step as well. what kit should i get to rebuild this with the best clutches? do i need a shift kit? should i get some upgraded internals or will that put me way out of budget? i plan on having a freind of mine who has done some transmissions on the side help me out as well but i dont think he knows any small tricks to do. i know some will say just go th400 but the 350 is what its gonna be for now just need to know some stuff to make it live a little like my freinds did going that fast. thanks guys

#2

About the best you can do is get a transgo shift kit with the seperator plate, a set of frictions, reuse the steels, a gasket and rubber parts kit, a hardened intermediate roller clutch race. Other hard parts, bushings, bearings, washers depends on their condition or replacing them for piece of mind.

You don't really need a shift kit, but they're cheap and it takes too much time to explain how to get by without one.

You don't really need a shift kit, but they're cheap and it takes too much time to explain how to get by without one.

#6

You can save the money on the valve body kit.

Dual feed the TH350.

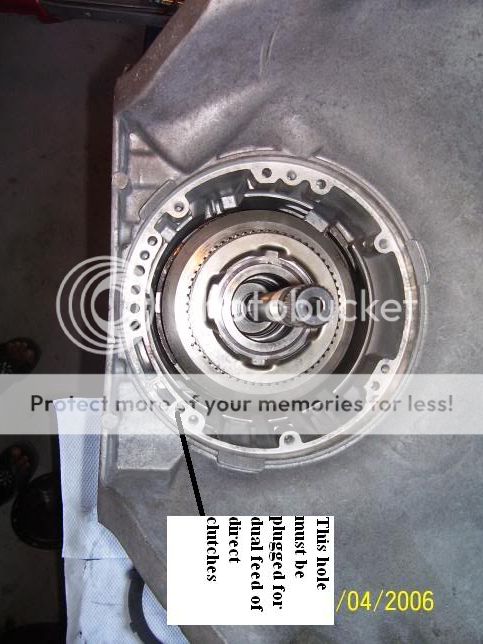

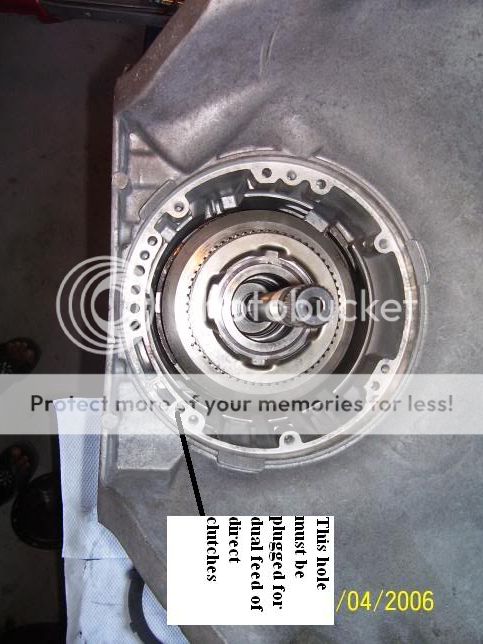

Leave the center seal out of the direct drum, and plug the hole behind the pump at the 4 o'clock position with a 3/8" set screw.

Drill the 2nd and 3rd feed holes. .125" and .140" respectively.

Remove the spring from behind the 2-3 accumulator piston in the valve body, reinstall piston.

That's it.

Stock frictions will outlive the hard parts in a TH350 if properly built.

Dual feed the TH350.

Leave the center seal out of the direct drum, and plug the hole behind the pump at the 4 o'clock position with a 3/8" set screw.

Drill the 2nd and 3rd feed holes. .125" and .140" respectively.

Remove the spring from behind the 2-3 accumulator piston in the valve body, reinstall piston.

That's it.

Stock frictions will outlive the hard parts in a TH350 if properly built.

#7

I agree somewhat with Jake, BUT leave in the middle seal, just leave off the middle direct/reverse apply sealing ring on the stator support. This way the 3rd clutches will release faster on a 3-2 downshift, and you will not have any centrifuge problems in the top of 1st & 2nd gear at high rpm. Always use the teflon apply rings on the stator support and cast iron rings on the accumulators and band apply piston. I like to use the TransGo TH350-1-2 kit here as it "restricts" the accumulation somewhat, but does not eliminate it, and comes with a (orange) higher rate pressure regulator spring. You can drill the feed holes to whatever you want here on this separator plate. When using the 2nd apply band here, run the direct clutches at .060" - .080" so as not to burn up the band when it releases on the 2-3 WOT shift. ALWAYS leave in the waved steel on the 2nd apply. This will take up the shock on the 1-2 shift, and keep the sprag alive. I have seen the stock style sprag races hold up in nine second vehicles when built right. Use the later bearing type pump that uses the "white" plastic ring just above the bearing. This has a much better support for the direct drum at "both ends". This extra support is to help the sprag race stay centered. This helped keep the sprag race from shattering as often as it did on the earlier units. In the forward drum use the waved steel with the "3" tangs on it. This will prevent the drum wear that the earlier waved steel with "no tangs" did. "Always" use the plastic insert on the output shaft. Always run the front pump and governor filters that come in the rebuild kits. Use the bronze case bushing and the Teflon extension housing bushing, with a triple lip Vamac rear seal. Add a pan magnet or two to the bottom of the pan. Find the sunshell that has been hollowed out, it is worth a few hundredths drop in ET in the 60 foot times. Forward clutch clearance .020" - .040". 2nd clutch clearance .030" - .040". If you have too much clutch clearance on the 2nd apply, you will have a 1-2 shift delay at WOT, so this is critical. There is more, but this should get you in the right direction. Dana