4L60E, 6k mile on rebuild, 3/4 slipping

#1

Hey guys,

Just rebuilt this trans with all the go-fast goody parts, was hoping to make this a done deal for the foreseeable future, but unfortunately it's coming out.

Transmission is in a 2002 S10 Blazer w/ L33 5.3L V8 w/ '04 ZO6 cam/springs, swap headers, custom tuning. The trans is original to the blazer (4.3L V6), has 185k on valvebody, but all hard parts have been inspected / replaced.

Here's a rundown of the shopping list that went into this:

-all new bushings / seals

-thrust washers / thrust bearings

-shift/pressure solenoids

-beast sunshell

-banner kit w/ molded pistons

-new vanes in pump w/ hardened pump ring set

-new spring packs (no 3/4 return)

-wide 2-4 band

-new boost valve w/ no o-rings

-new HD borg warner input sprag

-new large hole accumulator pistons

-new small hole accumulator pistons

-new blue scarf cut pump rings

-wide rear sun gear bushing

-k034 4th gear apply servo

-new overrun, forward, lo-reverse steels

-alto red eagle clutch setup, non commercial set

-valvebody pump and filter screens

-metal clead seals

-rebuilt s10 torque converter (stalls 2200-2300rpm)

I may have missed something but that's just about everything on the list that I know of. I went through and thoroughly cleaned every component in the trans before the rebuild. Ran every passageway through w/ air, and cleaned every nook and cranny of the valve body.

Friend of mine told me what to get and came over once all parts were in and the trans was clean. We drilled out all the pertinent holes in the seperator plate to 1/8", I installed hardened seats on all the check ball holes, and my friend did the assembly.

I'm pretty sure he put 9 clutches in the 3/4 pack, mentioned it was tight but would work well and it did for a while.

6000 miles later 2-3 went from a nice hard shift to shifting like a stock trans. Couple more miles on the odometer and now it's slipping to the point that I have to manually shift to 2nd to get up to speed / go up a incline. Before it would chirp the fan belt going from 2nd to 3rd, now I have to go 0 throttle, then manually shift and ease into it hoping it holds.

Truck is parked and I'm hoping to get the trans down tonight. I put a pressure gauge on there, it's hitting 195 psi during shifts, 1 & 2 will plant you in the seat and send the blazer sideways shifting into 2nd, but 3 & 4 are gone. Seems like I have 3rd and 4th for a couple miles until the trans starts to warm up. I do have a large trans cooler on there, don't have the exact specs in front of me but it "should" work for what I'm doing.

I'm assuming I need to be looking in the 3/4 clutch pack areas (seals, check ball, input drum crack) Anywhere else I should be looking?

The transmission has always shifted 1-2 like a dropped anvil no matter what ECM tuning / tps position / speed. I was also getting intermittant tcc unlocking. I'm going to put a transgo SK kit to see if that solves that problem. I have no history on the trans, when I bought the blazer the engine had a blown headgasket and 5 gallons of milkshake in the crankcase.

Thanks for reading, hoping to get this back on the road. Thinking about upgrading the converter but this is a daily driver and don't want to go too insane w/ the stall, any suggestions?

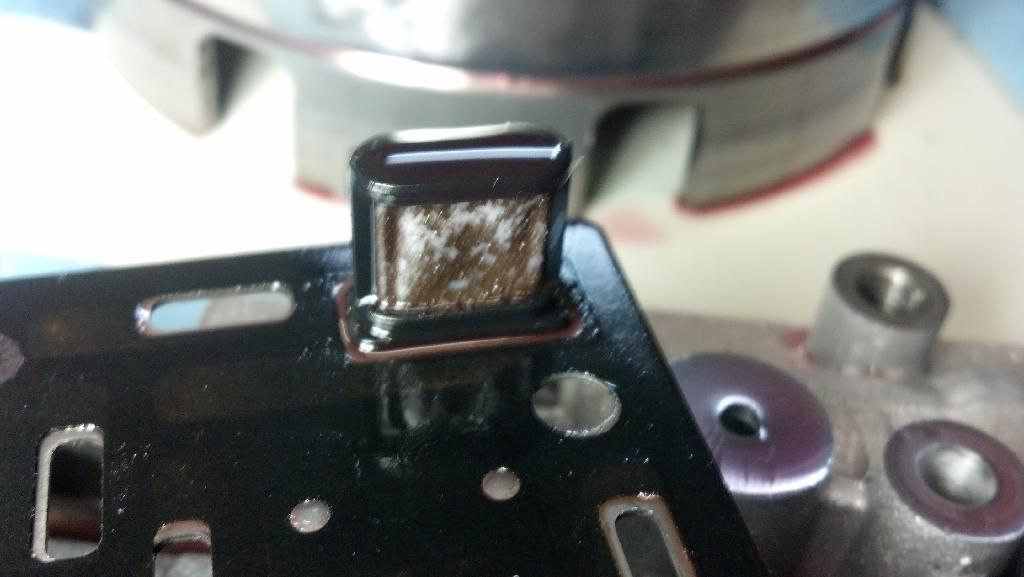

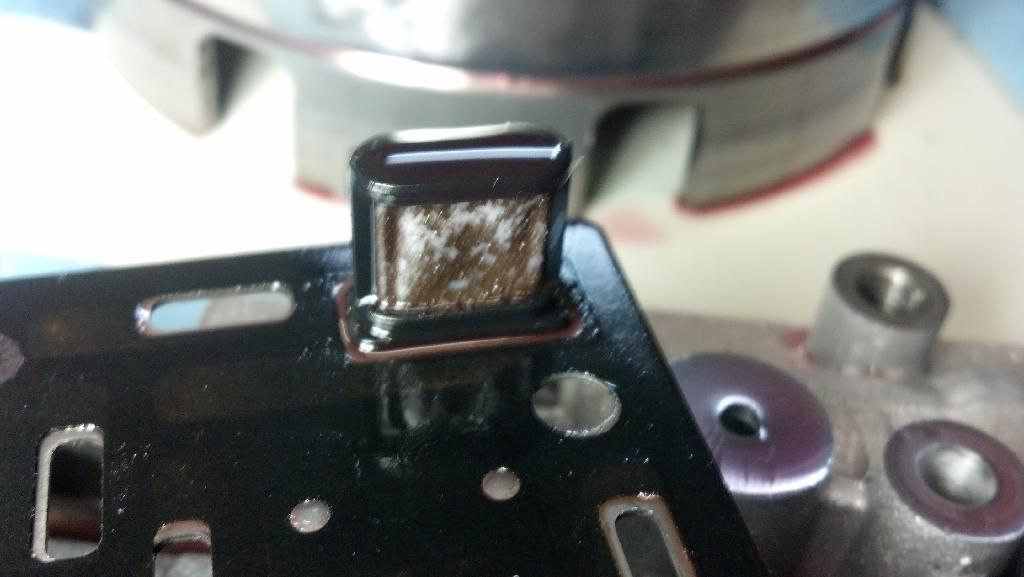

How the fluid looks, think it's clutch material @ the fold in the napkin:

The blazer:

Just rebuilt this trans with all the go-fast goody parts, was hoping to make this a done deal for the foreseeable future, but unfortunately it's coming out.

Transmission is in a 2002 S10 Blazer w/ L33 5.3L V8 w/ '04 ZO6 cam/springs, swap headers, custom tuning. The trans is original to the blazer (4.3L V6), has 185k on valvebody, but all hard parts have been inspected / replaced.

Here's a rundown of the shopping list that went into this:

-all new bushings / seals

-thrust washers / thrust bearings

-shift/pressure solenoids

-beast sunshell

-banner kit w/ molded pistons

-new vanes in pump w/ hardened pump ring set

-new spring packs (no 3/4 return)

-wide 2-4 band

-new boost valve w/ no o-rings

-new HD borg warner input sprag

-new large hole accumulator pistons

-new small hole accumulator pistons

-new blue scarf cut pump rings

-wide rear sun gear bushing

-k034 4th gear apply servo

-new overrun, forward, lo-reverse steels

-alto red eagle clutch setup, non commercial set

-valvebody pump and filter screens

-metal clead seals

-rebuilt s10 torque converter (stalls 2200-2300rpm)

I may have missed something but that's just about everything on the list that I know of. I went through and thoroughly cleaned every component in the trans before the rebuild. Ran every passageway through w/ air, and cleaned every nook and cranny of the valve body.

Friend of mine told me what to get and came over once all parts were in and the trans was clean. We drilled out all the pertinent holes in the seperator plate to 1/8", I installed hardened seats on all the check ball holes, and my friend did the assembly.

I'm pretty sure he put 9 clutches in the 3/4 pack, mentioned it was tight but would work well and it did for a while.

6000 miles later 2-3 went from a nice hard shift to shifting like a stock trans. Couple more miles on the odometer and now it's slipping to the point that I have to manually shift to 2nd to get up to speed / go up a incline. Before it would chirp the fan belt going from 2nd to 3rd, now I have to go 0 throttle, then manually shift and ease into it hoping it holds.

Truck is parked and I'm hoping to get the trans down tonight. I put a pressure gauge on there, it's hitting 195 psi during shifts, 1 & 2 will plant you in the seat and send the blazer sideways shifting into 2nd, but 3 & 4 are gone. Seems like I have 3rd and 4th for a couple miles until the trans starts to warm up. I do have a large trans cooler on there, don't have the exact specs in front of me but it "should" work for what I'm doing.

I'm assuming I need to be looking in the 3/4 clutch pack areas (seals, check ball, input drum crack) Anywhere else I should be looking?

The transmission has always shifted 1-2 like a dropped anvil no matter what ECM tuning / tps position / speed. I was also getting intermittant tcc unlocking. I'm going to put a transgo SK kit to see if that solves that problem. I have no history on the trans, when I bought the blazer the engine had a blown headgasket and 5 gallons of milkshake in the crankcase.

Thanks for reading, hoping to get this back on the road. Thinking about upgrading the converter but this is a daily driver and don't want to go too insane w/ the stall, any suggestions?

How the fluid looks, think it's clutch material @ the fold in the napkin:

The blazer:

#2

Moderator

I'm working on a very extensive post (more like an article) about the 3-4 clutch. Here is a preview of sometimes relevant:

"Besides the marginal design of the 3/4 clutch, a major reason for failure is a leak in its fairly complex hydraulic circuit. Leakage can occur in the servo area including the 3rd accumulator check valve, in the teflon seals of the input shaft, where the input shaft enters the input drum, the check ball or bleed orifice in the input drum, and the seal on the 3-4 piston. Since any leak can quickly ruin a brand new clutch, it is critical that these areas be carefully checked and fixed if needed."

------------

Also IMHO 9 clutches is too many as it will create too small a clearance and may lead to rapid wear. I don't think any of the pro builders or sponsors here use 9 clutches in anything other than race-only transmission that will be rebuilt every month.

While some pros recommend only 7, the majority opinion is probably 8. The opinion is then slip between using .065 frictions and .080 steels or using .080 frictions and .065 steels. I don't think it matter as long as the shifts are fast and not generating heat - that means a boost valve and drilling the separator plate as you have done.

While again no consensus, there is a split opinion on using the 3-4 load release springs. If using stock spring cages and a tight clearance, I recommend them to keep the apply and backing plates apart while having "fun" in 1st and 2nd gear.

I suspect your trans developed a leak or the clearance was simply too tight.

Some builders replace the 3rd accumulator check valve with every rebuild, because it is a common source of 3/4 clutch failure.

"Besides the marginal design of the 3/4 clutch, a major reason for failure is a leak in its fairly complex hydraulic circuit. Leakage can occur in the servo area including the 3rd accumulator check valve, in the teflon seals of the input shaft, where the input shaft enters the input drum, the check ball or bleed orifice in the input drum, and the seal on the 3-4 piston. Since any leak can quickly ruin a brand new clutch, it is critical that these areas be carefully checked and fixed if needed."

------------

Also IMHO 9 clutches is too many as it will create too small a clearance and may lead to rapid wear. I don't think any of the pro builders or sponsors here use 9 clutches in anything other than race-only transmission that will be rebuilt every month.

While some pros recommend only 7, the majority opinion is probably 8. The opinion is then slip between using .065 frictions and .080 steels or using .080 frictions and .065 steels. I don't think it matter as long as the shifts are fast and not generating heat - that means a boost valve and drilling the separator plate as you have done.

While again no consensus, there is a split opinion on using the 3-4 load release springs. If using stock spring cages and a tight clearance, I recommend them to keep the apply and backing plates apart while having "fun" in 1st and 2nd gear.

I suspect your trans developed a leak or the clearance was simply too tight.

Some builders replace the 3rd accumulator check valve with every rebuild, because it is a common source of 3/4 clutch failure.

#3

Thanks for the info, I greatly appreciate it, please provide a link when you're done as this hopefully can help others.

Is there a way to test 3rd gear hydraulics before tearing the trans all the way down? I know I can hit the input shaft with air, but that doesn't test the Teflon seals. He had forgotten his seal resizer, we got everything together with the seals looking good though. I want to do this right and not have to pull this again. Sumbish is tight in there!

Pulled the pan and I'm probably in the market for new clutch/steels.

My buddy helped me out by building this, trying to fix it without leaning on him too much, but if he gets involved I'll keep everything updated.

Is there a way to test 3rd gear hydraulics before tearing the trans all the way down? I know I can hit the input shaft with air, but that doesn't test the Teflon seals. He had forgotten his seal resizer, we got everything together with the seals looking good though. I want to do this right and not have to pull this again. Sumbish is tight in there!

Pulled the pan and I'm probably in the market for new clutch/steels.

My buddy helped me out by building this, trying to fix it without leaning on him too much, but if he gets involved I'll keep everything updated.

#4

Teflon between forward and over run clutches was cut, input housing has 2 lugs snapped off of it where the snap rings go. Everything else appears to be ok.. pistons/seals all are still new, no damage, check ***** all in place. Anything else I should be looking at?

With that seal being cut.. what was it doing to my trans?

How far should I tear into the trans? All the way and clean everything? What should I replace, even though it was pretty much all replaced 6k ago?

With that seal being cut.. what was it doing to my trans?

How far should I tear into the trans? All the way and clean everything? What should I replace, even though it was pretty much all replaced 6k ago?

#5

Moderator

Glad you found the problem.

I doubt any damage was done to the trans; you could replace the overrun frictions just to be safe, but even I would probably skip it. (Overrun are engaged with 3/4 in [D3] anyway.)

Have you selected a 3/4 clutch setup yet? I'm not ready to post my 3/4 article, but if you PM with your email address, I will send it to you with a spreadsheet which lists my setups, pro builder setups and will calculate clearance for you based on your own parts.

Unless a pro tells you otherwise, I don't think you need to rebuild the trans. Put some cheap ATF in it and change the fluid and filter in 100 miles or so; that should get the rest of the friction material out.

I doubt any damage was done to the trans; you could replace the overrun frictions just to be safe, but even I would probably skip it. (Overrun are engaged with 3/4 in [D3] anyway.)

Have you selected a 3/4 clutch setup yet? I'm not ready to post my 3/4 article, but if you PM with your email address, I will send it to you with a spreadsheet which lists my setups, pro builder setups and will calculate clearance for you based on your own parts.

Unless a pro tells you otherwise, I don't think you need to rebuild the trans. Put some cheap ATF in it and change the fluid and filter in 100 miles or so; that should get the rest of the friction material out.

#6

Thanks, I was a worried about not finding the failure component. Contemplating going back w/ the red alto pack?

He did put 9 frictions in, possibly going with 8 and getting thicker steels to dissapate (sp?) heat better? Been doing a lot of reading lately trying to get a grasp on it. Would love to see what you've put together and possibly help however I can, proofreading, etc? Sending PM right after this.

Talked with my buddy today, he's got a input housing assembly, he said to just clean the case out and don't worry about pulling the rear of the trans apart. I am going to clean out the valvebody, flush the cooler lines, and replace the converter. Going to try a little higher stall might bump up to 3000..

He did put 9 frictions in, possibly going with 8 and getting thicker steels to dissapate (sp?) heat better? Been doing a lot of reading lately trying to get a grasp on it. Would love to see what you've put together and possibly help however I can, proofreading, etc? Sending PM right after this.

Talked with my buddy today, he's got a input housing assembly, he said to just clean the case out and don't worry about pulling the rear of the trans apart. I am going to clean out the valvebody, flush the cooler lines, and replace the converter. Going to try a little higher stall might bump up to 3000..

Trending Topics

#8

Got it back together, kolene steels/red alto clutches,cleaned everything out, completely blew vb apart and cleaned everything, installed trans go parts for tcc lock up, rebuilt converter, flushed cooler lines. Get it back together, pressures are great, shifting like a champ, etc.

4 days later I've got a hellacious vibration, knocking change out of the ashtray bad. Starting out no problems cold, 5 miles down the road you can start to feel it. The farther you drive the worse it gets.

I assumed u joint as it's definitely driveline, anything over 35mph and it vibrates, rpm/neutral/gear change had little effect. U joints feel fine, nothing in the suspension changed.. I replaced the rear joint just because it felt a tiny tight. I went through the rear end even though I rebuilt in Nov, everything looked ok.

Pulled the trans and went through it, everything looks ok except for the sunshell/lo/reverse thrust washer is heated up/trashed and one of the filters is full.

Any ideas?

4 days later I've got a hellacious vibration, knocking change out of the ashtray bad. Starting out no problems cold, 5 miles down the road you can start to feel it. The farther you drive the worse it gets.

I assumed u joint as it's definitely driveline, anything over 35mph and it vibrates, rpm/neutral/gear change had little effect. U joints feel fine, nothing in the suspension changed.. I replaced the rear joint just because it felt a tiny tight. I went through the rear end even though I rebuilt in Nov, everything looked ok.

Pulled the trans and went through it, everything looks ok except for the sunshell/lo/reverse thrust washer is heated up/trashed and one of the filters is full.

Any ideas?

#10

Well... up to this point I've had a buddy assembling the trans, he used to run a performance trans shop. I assumed he did but, can't say he did or not.

He gave me a input drum to replace mine, it came out of a trans that burned up its planetaries.. I wasn't sure about pressing the input shaft in/out of a new drum. The end play should have changed but.. the thrust washer behind the pump looks fine.

I'm heading to the parts house, going to warranty out the converter and get gaskets/seals/input shims. Hoping they have a input drum in better shape for sale.

He gave me a input drum to replace mine, it came out of a trans that burned up its planetaries.. I wasn't sure about pressing the input shaft in/out of a new drum. The end play should have changed but.. the thrust washer behind the pump looks fine.

I'm heading to the parts house, going to warranty out the converter and get gaskets/seals/input shims. Hoping they have a input drum in better shape for sale.

#11

Moderator

The thrust washer behind the pump is not part of the input/output shaft end play - it only reduces end play for the reverse drum, nothing else. In fact it is easier to measure end play without even installing the reverse drum; I don't even install the 3/4 clutch into the input drum until after I have set the end play.