Trans issue

#1

Launching!

Thread Starter

iTrader: (5)

Join Date: Feb 2013

Posts: 252

Likes: 0

Received 0 Likes

on

0 Posts

Alright so lets start with some background engine is 02(what i was told) 5.3 lm7 trans is a 4l60e believed to be a 00 2wd truck trans and converter is from an fbody heres my problem motor can be turned by socket/ratchet smoothly can also turn trans with the converter installed once i bolt them up i cant turn the assembly I know it shouldnt be easy to turn but i aint no b**** ive pulled it out three times now last time noticed that the flywheel was bent, bought a new one, checked vanes on the pump if i move one so does the other, also held converter up the the flywheel snout on the converter fits in the crank just fine carefully rotated the converter against the new flywheel it doesnt rub what else could be the issue is a stock converter from a fbody to thick? bellhousing need changed? Im at a loss and need help

#2

TECH Addict

Are you saying that with the trans bolted to the back of the engine and the torque converter unbolted you can turn the engine and torque converter, but when the torque converter is bolted to the flywheel you can’t turn the engine? How did you bolt the torque converter up if the engine won’t turn once the torque converter is bolted up?

Last edited by bbond105; 04-09-2015 at 03:32 PM.

#5

TECH Enthusiast

iTrader: (1)

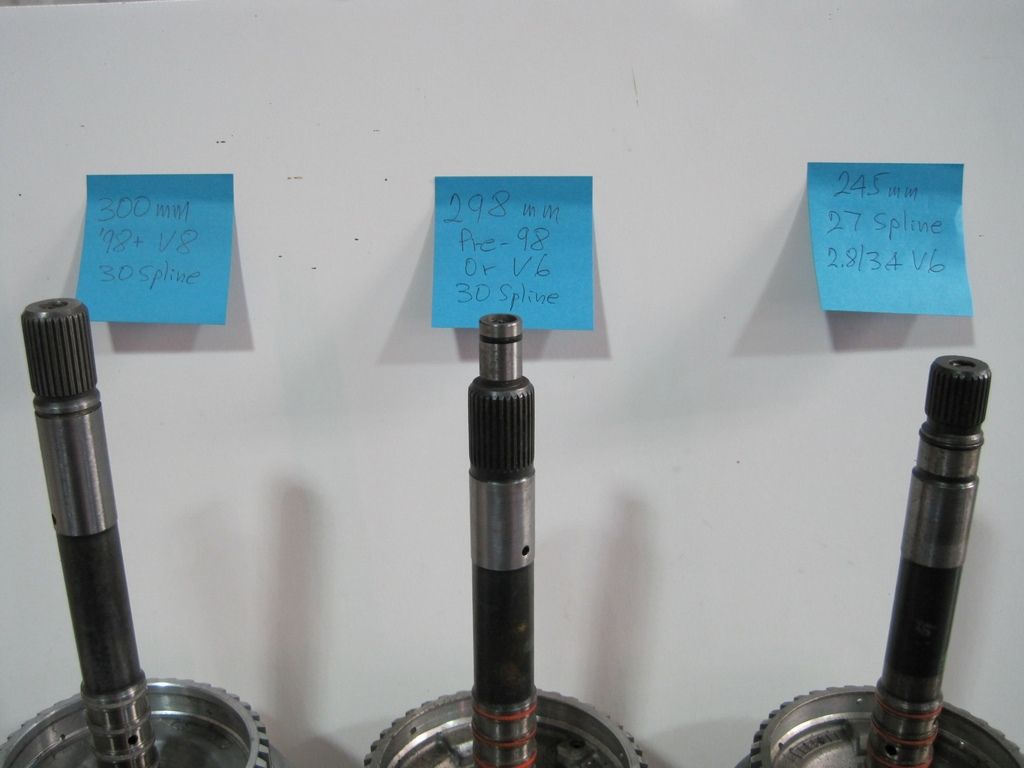

A good question might be is it even possible to change a 298mm 4l60e into a 300mm 4l60e without spending a lot of money. I imagine there's a slew of potential compatibility issues, including a new input drum for the bigger shaft, and a new pump? Would the output shaft need to be changed, other hard parts? How would it affect the driveshaft, would the old case work, etc?

We need some builders to give their opinions.

We need some builders to give their opinions.

#6

Moderator

Converting a 298mm trans (which makes it almost certainly a '97 or earlier) into a 300mm would require an extensive rebuild and a bunch of different parts. Not a good idea.

If the trans is a '96 or a '97 you need a spacer and longer crank bolts, and a 298 converter, as detailed in this thread:

https://ls1tech.com/forums/automatic...s-spacers.html

If the 4L60E is a '94 or '95, forget it, as the electrics are incompatible.

I suggest selling the trans and purchasing a 300mm from a '98 - '07 LS powered car or 2WD truck.

If the trans is a '96 or a '97 you need a spacer and longer crank bolts, and a 298 converter, as detailed in this thread:

https://ls1tech.com/forums/automatic...s-spacers.html

If the 4L60E is a '94 or '95, forget it, as the electrics are incompatible.

I suggest selling the trans and purchasing a 300mm from a '98 - '07 LS powered car or 2WD truck.

#7

Launching!

Thread Starter

iTrader: (5)

Join Date: Feb 2013

Posts: 252

Likes: 0

Received 0 Likes

on

0 Posts

It's a 00 v6 truck trans that I just had rebuilt selling really isn't an option so new shaft/drum/pump only plus side my builder only charged me $200 labor for the rebuild so this shouldn't cost much besides the parts