Steel braided lines...tranny cooler lines.....Easiest way...?

#1

I have a B&M stacked cooler up in front of my condensor. I want to do steel braided lines from the tranny and then returning to the tranny.

What needs to be done....?

Is there a complete bolt-on kit out there...?

What AN fittings need to be welded onto my B&M cooler ports...?

Thanks....

.

What needs to be done....?

Is there a complete bolt-on kit out there...?

What AN fittings need to be welded onto my B&M cooler ports...?

Thanks....

.

#3

10 Second Club

iTrader: (16)

I used this thread here when I did mine.

https://ls1tech.com/forums/automatic...e-install.html

That should help you out a good bit. Except I ordered my stuff thru jegs tho. Here is also another thread if you want to run -8an stuff...

https://ls1tech.com/forums/automatic...oler-line.html

https://ls1tech.com/forums/automatic...e-install.html

That should help you out a good bit. Except I ordered my stuff thru jegs tho. Here is also another thread if you want to run -8an stuff...

https://ls1tech.com/forums/automatic...oler-line.html

Trending Topics

#9

11 Second Club

iTrader: (49)

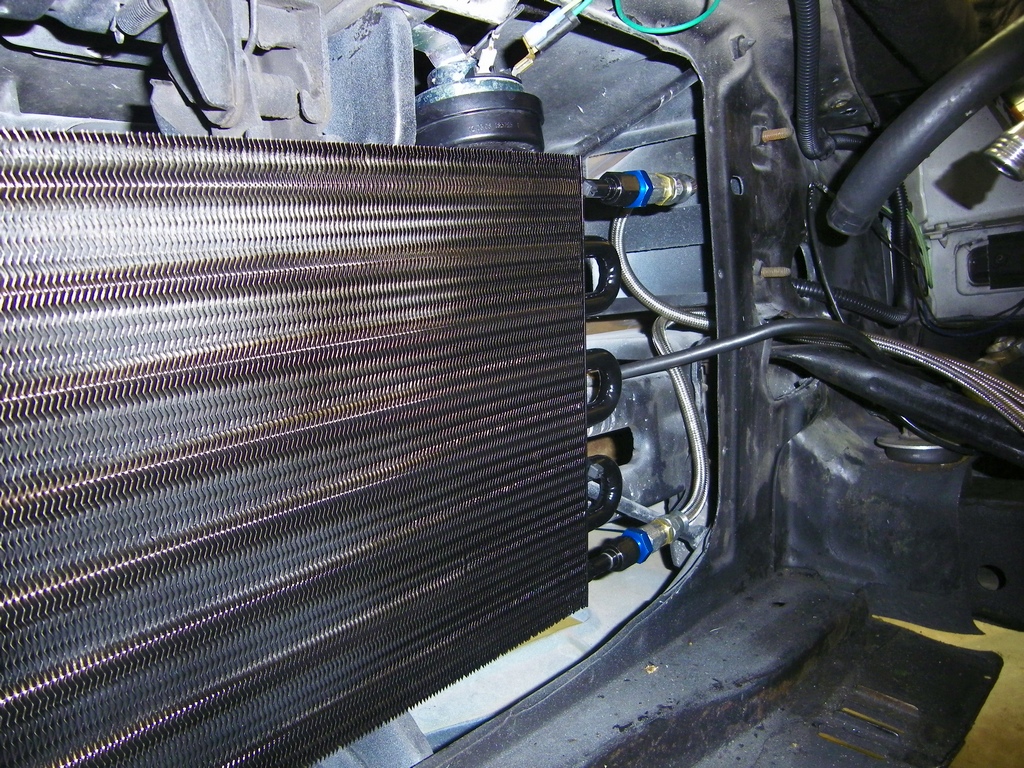

Jegs hose and jegs fittings assemble very easy, and are cost effective. I did my entire fuel system, oil cooler, and an elaborate dual trans cooler setup with all of the black style hose.

#10

Moderator

I have my fuel, transmission and power steering (with Hydraboost) plumbed with AN Teflon stainless steel hoses. Besides handling higher pressure and being resistant to everything, I like the smaller outside diameter of Teflon AN hoses.

I can cut and put a fitting on an regular AN hose in under 3 minutes and 4 minutes for a Telfon hose. The trick is to cut it in 5 seconds with little fraying using this method using just cheap locally available tools:

http://www.anplumbing.com/page/11

I can cut and put a fitting on an regular AN hose in under 3 minutes and 4 minutes for a Telfon hose. The trick is to cut it in 5 seconds with little fraying using this method using just cheap locally available tools:

http://www.anplumbing.com/page/11

#11

On The Tree

You can get AN fittings for pushlock hose.

SS braided hose sucks, it works like a hacksaw on anything it touches.

after some time the wires break and every time you touch it or rub against it you will bleed.

SS braided hose sucks, it works like a hacksaw on anything it touches.

after some time the wires break and every time you touch it or rub against it you will bleed.

#13

BTW....how the heck does the hose and fitting secure themselves to each other...?

http://www.summitracing.com/int/part...690b/overview/

How reliable is that gonna be using this Nylon braided hose.

http://www.summitracing.com/int/parts/sum-240615bp

......It looks like just a small, short piece of hose goes into the fitting and holds onto the fitting.

EDIT: Just watched a few youtube videos.......now I know how...LOL

.

http://www.summitracing.com/int/part...690b/overview/

How reliable is that gonna be using this Nylon braided hose.

http://www.summitracing.com/int/parts/sum-240615bp

......It looks like just a small, short piece of hose goes into the fitting and holds onto the fitting.

EDIT: Just watched a few youtube videos.......now I know how...LOL

.

Last edited by LS6427; 06-27-2015 at 01:19 PM.

#15

On The Tree

#16

TECH Senior Member

iTrader: (23)

Join Date: Jul 2004

Location: Houston, TX

Posts: 9,853

Likes: 0

Received 0 Likes

on

0 Posts

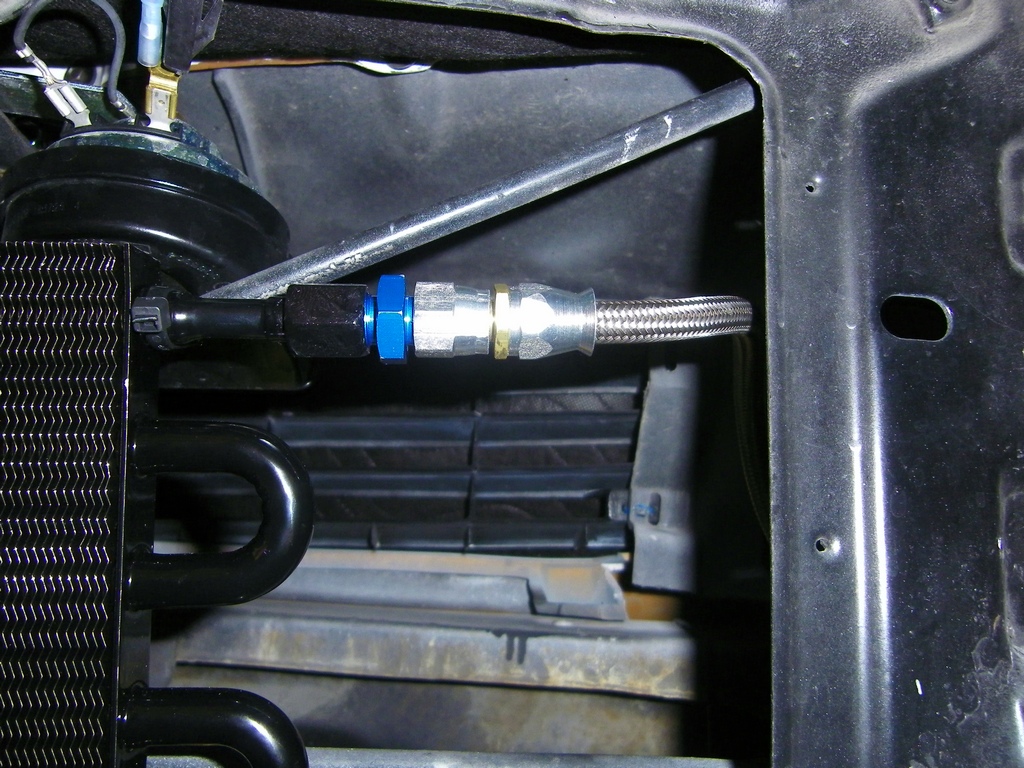

If you have the correct tools, AN fittings are simple and painless to install. When you try assembling with the wrong tools, that's when you get the frustration and bloody fingers.

Using pushlok hose on transmission lines is irresponsible in my opinion, as you risk them blowing off. And never use a clamp on pushlok.

For transmission fluid, the regular rubber AN hoses will work. Fuel you really need to get PTFE hose.

Using pushlok hose on transmission lines is irresponsible in my opinion, as you risk them blowing off. And never use a clamp on pushlok.

For transmission fluid, the regular rubber AN hoses will work. Fuel you really need to get PTFE hose.

#18

Moderator

If I have an AN hose that is even 1/2" too long, I can trivially shorten it in less than 5 minutes.

I have no experience with any pushlok hoses, but I have helped various members who's non-stock-steel and non-AN hoses sprung leaks, sometimes resulting in complete trans failure.

I've posted this pics before, but here is how mine is done with Teflon PTFE AN-6 hoses:

#20

Just put a wrap of tape around where you want to cut. Use a manual hose cutter and cut in the middle of the tape, slide on the hose sleeve, take off the tape, put in the little ferrule, go to the grinder or get a file and put a small taper on the fitting that goes into the line, spit on it or a drip of oil, insert and tighten. Measure the gap. Done