Torque Converter Installations

#81

Torque converter to flexplate clearance in the range of .080" - .125" is ok. Ideal is apx. .100". This will give maximum rotor to torque converter hub contact. You have to have some clearance for torque converter growth from mainly heat.

#82

Staging Lane

iTrader: (3)

Had My SS3600 for a year now, currently have Dexron VI in it right now which Yank says DEX VI is ok but wanted to see if DEX III would tighting up the Converter a lil, Really no problems just want to see If you guys prefer DEX III or DEX VI for Yank Converters.

---------------------------------------------------------------------

---------------------------------------------------------------------

#84

TECH Apprentice

iTrader: (24)

Bringing back a good thread with a question of my own...

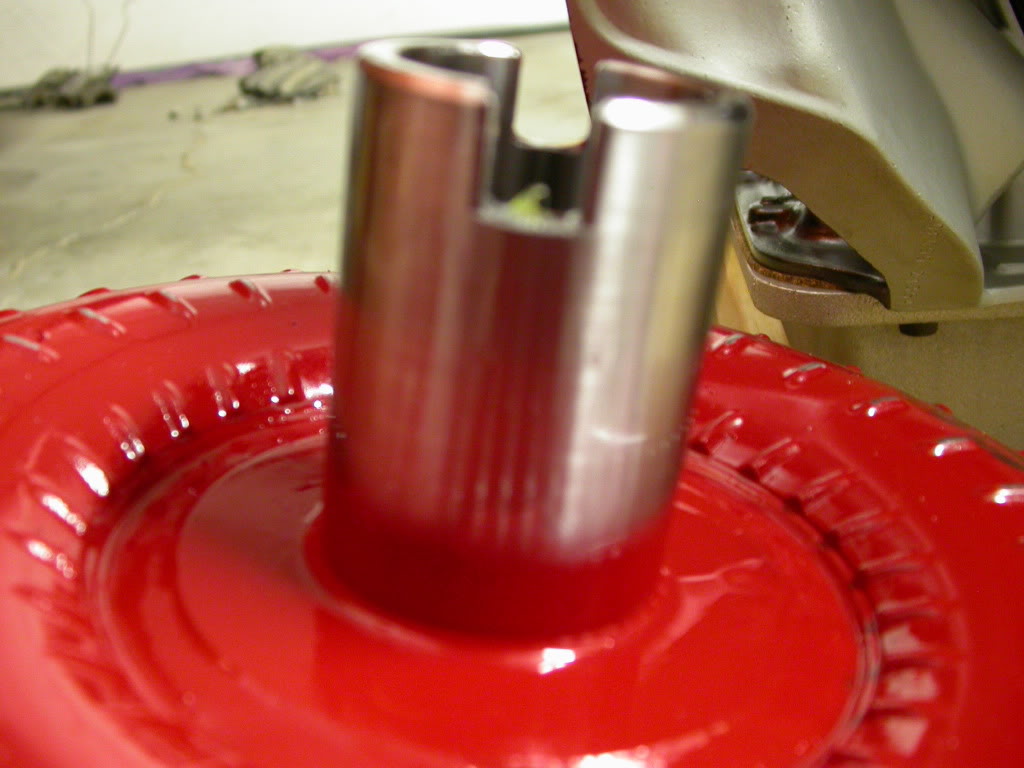

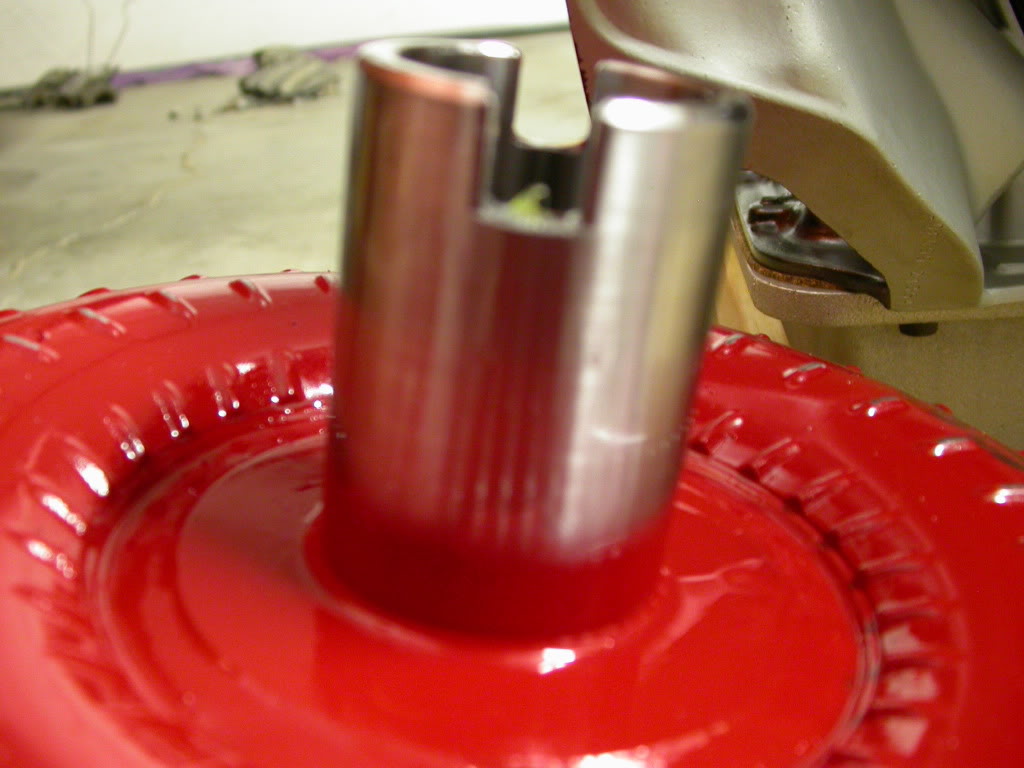

I bought a Yank converter to go with my new TH350 from Rossler. I'm putting the converter into the transmission right now as I'm getting ready to install the transmission. Everything I've read on this forum and on Yank's pamphlet that comes with the converter says you need to have 1.125" from the bell housing to the converter pads, but every time I get the converter seated all the way I am only getting 1" from the bell housing to the converter pads. I've pushed and spun and I cannot get it to seat any further to get the extra .125". I even checked with a trick of mine to see if the converter was seated all the way. As seen in the picture below, I took some all purpose grease and placed it on the converter where the notches are on the end of the shaft. I seated the converter all the way, and then pulled it out. There was clearly grease left behind on the male part of the pump inside the transmission, telling me these two parts mated together, but I still only measured one inch!! If these two parts mate together doesn't this mean the torque converter has been pressed in all the way?

Any advice? Do I have the wrong idea here? I'm just worried I wont get proper pump to converter contact.

I bought a Yank converter to go with my new TH350 from Rossler. I'm putting the converter into the transmission right now as I'm getting ready to install the transmission. Everything I've read on this forum and on Yank's pamphlet that comes with the converter says you need to have 1.125" from the bell housing to the converter pads, but every time I get the converter seated all the way I am only getting 1" from the bell housing to the converter pads. I've pushed and spun and I cannot get it to seat any further to get the extra .125". I even checked with a trick of mine to see if the converter was seated all the way. As seen in the picture below, I took some all purpose grease and placed it on the converter where the notches are on the end of the shaft. I seated the converter all the way, and then pulled it out. There was clearly grease left behind on the male part of the pump inside the transmission, telling me these two parts mated together, but I still only measured one inch!! If these two parts mate together doesn't this mean the torque converter has been pressed in all the way?

Any advice? Do I have the wrong idea here? I'm just worried I wont get proper pump to converter contact.

#88

On The Tree

iTrader: (14)

Join Date: Jun 2009

Location: Oak Lawn IL

Posts: 156

Likes: 0

Received 0 Likes

on

0 Posts

waht are you guys using to measure 1.125 in. are you just basically saying it needs to be 1 and 1/8 gap. i am installing a SS3600 Yank into a stock 1998 TA with the stock trans and flex plate. Stupid ? but want to make sure everything is 100% correct before going ot far!

#89

Restricted User

iTrader: (12)

Join Date: Feb 2010

Location: kansas

Posts: 1,794

Likes: 0

Received 0 Likes

on

0 Posts

waht are you guys using to measure 1.125 in. are you just basically saying it needs to be 1 and 1/8 gap. i am installing a SS3600 Yank into a stock 1998 TA with the stock trans and flex plate. Stupid ? but want to make sure everything is 100% correct before going ot far!

#90

Moderator

iTrader: (1)

Join Date: Sep 2005

Location: Bloomingdale Illinois

Posts: 8,633

Likes: 0

Received 0 Likes

on

0 Posts

Bringing back a good thread with a question of my own...

I bought a Yank converter to go with my new TH350 from Rossler. I'm putting the converter into the transmission right now as I'm getting ready to install the transmission. Everything I've read on this forum and on Yank's pamphlet that comes with the converter says you need to have 1.125" from the bell housing to the converter pads, but every time I get the converter seated all the way I am only getting 1" from the bell housing to the converter pads. I've pushed and spun and I cannot get it to seat any further to get the extra .125". I even checked with a trick of mine to see if the converter was seated all the way. As seen in the picture below, I took some all purpose grease and placed it on the converter where the notches are on the end of the shaft. I seated the converter all the way, and then pulled it out. There was clearly grease left behind on the male part of the pump inside the transmission, telling me these two parts mated together, but I still only measured one inch!! If these two parts mate together doesn't this mean the torque converter has been pressed in all the way?

Any advice? Do I have the wrong idea here? I'm just worried I wont get proper pump to converter contact.

I bought a Yank converter to go with my new TH350 from Rossler. I'm putting the converter into the transmission right now as I'm getting ready to install the transmission. Everything I've read on this forum and on Yank's pamphlet that comes with the converter says you need to have 1.125" from the bell housing to the converter pads, but every time I get the converter seated all the way I am only getting 1" from the bell housing to the converter pads. I've pushed and spun and I cannot get it to seat any further to get the extra .125". I even checked with a trick of mine to see if the converter was seated all the way. As seen in the picture below, I took some all purpose grease and placed it on the converter where the notches are on the end of the shaft. I seated the converter all the way, and then pulled it out. There was clearly grease left behind on the male part of the pump inside the transmission, telling me these two parts mated together, but I still only measured one inch!! If these two parts mate together doesn't this mean the torque converter has been pressed in all the way?

Any advice? Do I have the wrong idea here? I'm just worried I wont get proper pump to converter contact.

The measurements stated in this thread aren't something to worry about. here's the best way to go about checking the clearence yourself.

measure from the edge of the flexplate to the mating surface of the motor. then measure from the edge of the bellhousing to the converter. the distance on the trans should be slightly more than the one you measured on the motor side. I'll see if I can get a good pic to repesent this soon.

measure from the edge of the flexplate to the mating surface of the motor. then measure from the edge of the bellhousing to the converter. the distance on the trans should be slightly more than the one you measured on the motor side. I'll see if I can get a good pic to repesent this soon.

#94

TECH Addict

iTrader: (39)

What i did, was used the plastic ramps up front, with a 2x12 under the front tires, and jackstands under the rear axle. When it came time to get the trans out from under the car, i just jacked it up far enough to slide her on out.

BTW, i just bought an Arcan XL-35R floor jack and it is by far the best jack ive ever used!! Low profile, but lifts high!

#95

10 Second Club

iTrader: (41)

Put the taller jackstands in the front.

What i did, was used the plastic ramps up front, with a 2x12 under the front tires, and jackstands under the rear axle. When it came time to get the trans out from under the car, i just jacked it up far enough to slide her on out.

BTW, i just bought an Arcan XL-35R floor jack and it is by far the best jack ive ever used!! Low profile, but lifts high!

What i did, was used the plastic ramps up front, with a 2x12 under the front tires, and jackstands under the rear axle. When it came time to get the trans out from under the car, i just jacked it up far enough to slide her on out.

BTW, i just bought an Arcan XL-35R floor jack and it is by far the best jack ive ever used!! Low profile, but lifts high!

Thanks for the info. Thats a good way how you did yours. Maybe ill just do it like that. I just hope ill have enough room to get in there to undo the trans with the car only on those ramps.