LS7 Clutch Install Help/Troubleshooting Needed

#1

Staging Lane

Thread Starter

Join Date: Jan 2008

Location: Harisburg Pa

Posts: 52

Likes: 0

Received 0 Likes

on

0 Posts

My installer just finished putting in a LS7 flywheel slave and clutch into my 04V. I ordered the kit from Luke at Lindsay. He bled all the air out of the system. He can not get the clutch to disengage. He thinks it feels like a distance issue. My understanding was that no spacer was needed since i used LS7 slave. Not sure what to do now. :-(

#3

My installer just finished putting in a LS7 flywheel slave and clutch into my 04V. I ordered the kit from Luke at Lindsay. He bled all the air out of the system. He can not get the clutch to disengage. He thinks it feels like a distance issue. My understanding was that no spacer was needed since i used LS7 slave. Not sure what to do now. :-(

#4

On The Tree

Join Date: Apr 2007

Location: Bloomington, MN

Posts: 165

Likes: 0

Received 0 Likes

on

0 Posts

Well if you are doing the diagnosis for your mechanic on the net, i would hope you split the cost of the job.

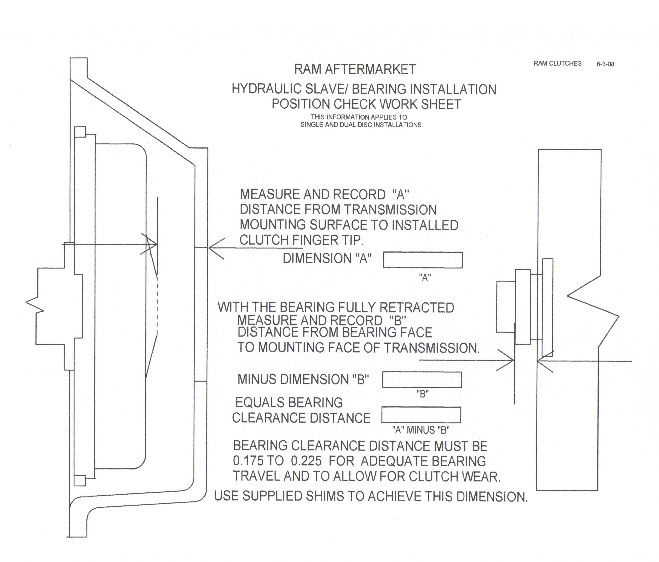

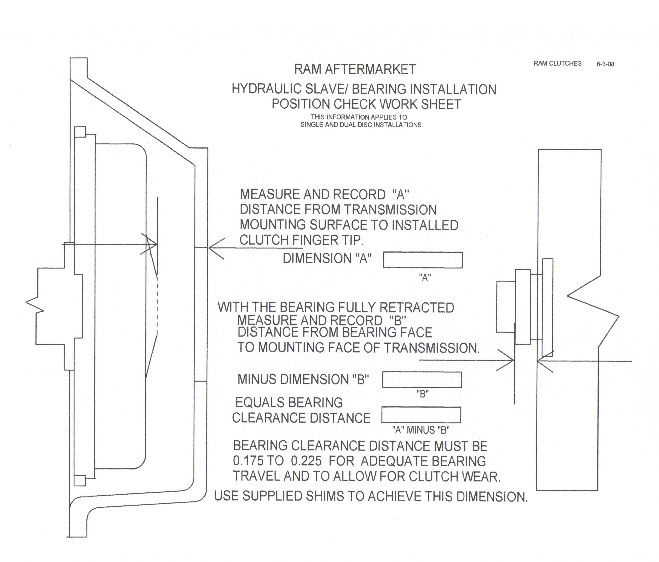

Ask him to pull the trans and measure your A and B dimensions (google it if you dont know what that means). If those dims are correct, then you have a bad/incorrect slave, bad master, or insufficiently bled clutch. If you didnt get a remote bleeder, put one in now and try again. With the LS7 slave, you shouldnt need a shim - it should be spot on.

Ask him to pull the trans and measure your A and B dimensions (google it if you dont know what that means). If those dims are correct, then you have a bad/incorrect slave, bad master, or insufficiently bled clutch. If you didnt get a remote bleeder, put one in now and try again. With the LS7 slave, you shouldnt need a shim - it should be spot on.

#6

Staging Lane

Thread Starter

Join Date: Jan 2008

Location: Harisburg Pa

Posts: 52

Likes: 0

Received 0 Likes

on

0 Posts

How many times did he bleed it? did he notice/mention any issues when installing the flywheel or slave/clutch? Did you reuse your old hardware (big no no)? If you did not purchase new flywheel and clutch plate bolts I can tell you that your issue is a flywheel bolt that is roughly 1/4" too long and will not properly torque the flywheel. Also the original GM bolts are 1 time Torque to yield bolts and should be replaced each time.

#7

Launching!

iTrader: (2)

Join Date: May 2012

Location: PA

Posts: 265

Likes: 0

Received 0 Likes

on

0 Posts

How many times did he bleed it? did he notice/mention any issues when installing the flywheel or slave/clutch? Did you reuse your old hardware (big no no)? If you did not purchase new flywheel and clutch plate bolts I can tell you that your issue is a flywheel bolt that is roughly 1/4" too long and will not properly torque the flywheel. Also the original GM bolts are 1 time Torque to yield bolts and should be replaced each time.

Trending Topics

#8

OEM bolts that were in use with the Dual mass OEM flywheel are longer than what you should be running with an aftermarket flywheel because the dual mass flywheel is extremely wide. Torque to yield bolts should only be used once, they are designed to deform and hold in that manner.

#9

Launching!

iTrader: (2)

Join Date: May 2012

Location: PA

Posts: 265

Likes: 0

Received 0 Likes

on

0 Posts

OEM bolts that were in use with the Dual mass OEM flywheel are longer than what you should be running with an aftermarket flywheel because the dual mass flywheel is extremely wide. Torque to yield bolts should only be used once, they are designed to deform and hold in that manner.

#10

http://www.jegs.com/i/ARP/070/330-2802/10002/-1

Here is what you need

#11

TECH Addict

iTrader: (14)

Join Date: Feb 2007

Location: Owasso, OK

Posts: 2,342

Likes: 0

Received 0 Likes

on

0 Posts

I used ARP bolts but many people use the stock bolts wether it be an F-body or a V. I cant even count how many people have reused the stock bolts. There is still debate whether or not the flywheel bolts are even torque to yeild or not. I wouldn't worry about the bolts being too long. If they where, either you would hear a rather unplesent sound as the rip the rear cover apart, or the unpleasent sound of the flywheel and pressure plate rattling around. The surface that the bolts touch is more or less the same thickness. The bolts go thought the face of the dual mass flywheel and bolt just the same as any other flywheel. You just have an extra 25 lbs of **** hanging of the front side of it. The main thing is to have the bolts torqued properly and in the correct pattern.

Like was said, the correct way to install any clutch is to measure. However, the LS7 swap is as simple as it gets. The V and the Vette share the same crank to transmission dimension so basically it's just like installing in a Vette (should be a bolt in with no measuring required)

I don't recall a single V needing to be shimmed when using LS7 parts. It is possible that you have a bad part but unlikely. It is a well documented fact that bleeding the air out of the V slave is a complete pain in the **** and is almost impossible (almost) but it is doable. My first vote is for air still in the system. I don't care that he said he bled it, I would almost bet money this is the culprit.

Like was said, the correct way to install any clutch is to measure. However, the LS7 swap is as simple as it gets. The V and the Vette share the same crank to transmission dimension so basically it's just like installing in a Vette (should be a bolt in with no measuring required)

I don't recall a single V needing to be shimmed when using LS7 parts. It is possible that you have a bad part but unlikely. It is a well documented fact that bleeding the air out of the V slave is a complete pain in the **** and is almost impossible (almost) but it is doable. My first vote is for air still in the system. I don't care that he said he bled it, I would almost bet money this is the culprit.

#13

I know for a fact the ctsv bolts will bottom out before torquing the ls9 katech flywheel. I had that problem. I am noy sure on the ls7 as I did not risk it and went with proper length ls1 bolts. Whether or not it is the main culprit I would still highly recommend spending the $30-50 dollars to replace hardware after you just spent $700 on a clutch.

see attached for "A" and "B" dimension measurements

see attached for "A" and "B" dimension measurements

Last edited by Onefast V; 12-11-2012 at 08:37 AM.

#16

TECH Enthusiast

Join Date: Jun 2011

Location: New Haven, CT

Posts: 654

Likes: 0

Received 0 Likes

on

0 Posts

These are what I used:

Flywheel Bolts: http://www.ebay.com/itm/LS1-LS2-LS6-...d58674&vxp=mtr

Pressure Plate: http://www.ebay.com/itm/ARP-LS1-LS6-...31b7b0&vxp=mtr

Flywheel Bolts: http://www.ebay.com/itm/LS1-LS2-LS6-...d58674&vxp=mtr

Pressure Plate: http://www.ebay.com/itm/ARP-LS1-LS6-...31b7b0&vxp=mtr

#17

Staging Lane

Thread Starter

Join Date: Jan 2008

Location: Harisburg Pa

Posts: 52

Likes: 0

Received 0 Likes

on

0 Posts

Guys thanks for all the replies. Clutch line coming out of the slave was kinked. All is good now. Loving the new flywheel and Revshift trans mount. Also did a shifter. Car is transformed!