LS6 Dies at 150k miles - Texas Speed 383ci LS6 Build

#22

TECH Regular

Thread Starter

iTrader: (10)

Join Date: Nov 2010

Posts: 406

Likes: 0

Received 0 Likes

on

0 Posts

Fuzzy, for the time being I'm just going to go with the F1 Lightweight flywheel until the Spec clutch bites the dust. It doesn't have enough miles or any issues to just toss it. Plus, I'm already dumping quite a bit of money on the car in a very short amount of time so another $500 bucks isn't quite where I want to be.

Now for the bad news....

After pulling the shortblock out of the car and further inspecting it, I found a small hairline crack. I was right when I said the cylinder wall didn't have any issues, but seemed to of overlooked this little crack. Let me know what you think of it. I don't believe there is any way to remedy the situation and re-use this block. Therefore I'm on the hunt for a new block. I've found a LS6 block from a 03 zo6 with 80,000 miles that I can have at my door in 6 business days for $575.00, but figured I would check on the forum to see if anyone else has any suggestions, opinions, possible bare blocks they would be willing to sell. Help a brother out.

Onto the pictures of the crack

First picture without a flash shows the crack right on the outside of the sleeve.

The second picture with a flash makes it to where you can kind of see where the crack runs down into the block.

Now for the bad news....

After pulling the shortblock out of the car and further inspecting it, I found a small hairline crack. I was right when I said the cylinder wall didn't have any issues, but seemed to of overlooked this little crack. Let me know what you think of it. I don't believe there is any way to remedy the situation and re-use this block. Therefore I'm on the hunt for a new block. I've found a LS6 block from a 03 zo6 with 80,000 miles that I can have at my door in 6 business days for $575.00, but figured I would check on the forum to see if anyone else has any suggestions, opinions, possible bare blocks they would be willing to sell. Help a brother out.

Onto the pictures of the crack

First picture without a flash shows the crack right on the outside of the sleeve.

The second picture with a flash makes it to where you can kind of see where the crack runs down into the block.

#26

TECH Fanatic

You could toss in some Darton Wet sleeves. They would mill that section out anyways. But the sleeves alone are more money that that replacement block you said you could get for 575 bux. Hell I'd do that depending on your future plans with the car.

How far down does the crack go? Does it go all the way through the block? Or does it stop at the bottom of the water jacket?

If it was me... I'd buy that 03 Z06 LS6 and swap that into your car. But i would keep the current block and then do wet sleeves when you can. That way you can do an FI on the current LS6 as time and money allows.

If you aren't going to keep the current block I'll take it off your hands.

How far down does the crack go? Does it go all the way through the block? Or does it stop at the bottom of the water jacket?

If it was me... I'd buy that 03 Z06 LS6 and swap that into your car. But i would keep the current block and then do wet sleeves when you can. That way you can do an FI on the current LS6 as time and money allows.

If you aren't going to keep the current block I'll take it off your hands.

#28

TECH Senior Member

iTrader: (18)

You could toss in some Darton Wet sleeves. They would mill that section out anyways. But the sleeves alone are more money that that replacement block you said you could get for 575 bux. Hell I'd do that depending on your future plans with the car.

How far down does the crack go? Does it go all the way through the block? Or does it stop at the bottom of the water jacket?

If it was me... I'd buy that 03 Z06 LS6 and swap that into your car. But i would keep the current block and then do wet sleeves when you can. That way you can do an FI on the current LS6 as time and money allows.

If you aren't going to keep the current block I'll take it off your hands.

How far down does the crack go? Does it go all the way through the block? Or does it stop at the bottom of the water jacket?

If it was me... I'd buy that 03 Z06 LS6 and swap that into your car. But i would keep the current block and then do wet sleeves when you can. That way you can do an FI on the current LS6 as time and money allows.

If you aren't going to keep the current block I'll take it off your hands.

#29

TECH Fanatic

#30

TECH Regular

Thread Starter

iTrader: (10)

Join Date: Nov 2010

Posts: 406

Likes: 0

Received 0 Likes

on

0 Posts

A quick update on where this build is at;

The shortblock and rotating assembly were dropped off at the machine shop on Friday to be cleaned, honed using a torque plate, decked, and assembled. I should have this back in my hands either Wednesday or Thursday. $750 for the whole shebang with a 4-5 day turn around wasn't a bad deal.

I also tore down the rest of the old LS6 shortblock and got the CPS sensor and oil pressure sensor out of it, took the crank pulley, front timing cover, oil pump, cam, etc out of it.

I got the heads back from the cylinder head shop, and I must say I was impressed for the price. $160 and he was able to fix all of the damage that were taken out of cylinder 1, cleaned both heads, deck the heads back flat, 3 angle valve job, fixed the seat for the intake and exhaust valve on cylinder 1 after they were chewed up, installed the new seals, valves and springs and even showed me how to use a couple of his machines.

I receieved the following parts over the week as well;

Tick remote bleeder

New Waterpump

New Crank Pulley

DW301 Fuel Pump

Racetronix Hot Wire Kit

Siemens 60# Deka Injectors

Seals/Gaskets

F1 20.4 Steel flywheel

More parts that I just cant think of...

If everything goes smoothly and as planned, I am going to try and have the car back up and running this coming weekend. I have my tuner who will be driving over from Pensacola FL to help get it running properly. I was also able to confirm that the cam that is in the car is the TSP Torquer V3, as it is engraved into the front of the cam.

My questions for y'all;

What oil should be used for the break in process (I know to not use synthetic, but looking for brand recommendations) and how long should I go before I change it? 50 miles, change, 500 miles, change?

What steps should I take to break in the motor? From what I have seen and read, people suggest idling for 15 minutes, then going 1/2 throttle a couple pulls, 3/4 throttle a couple pulls, finally going WOT a couple pulls. Letting the car cool down for 15 minutes or so between the pulls? Please give me suggestions as to how you have broken in your motors.

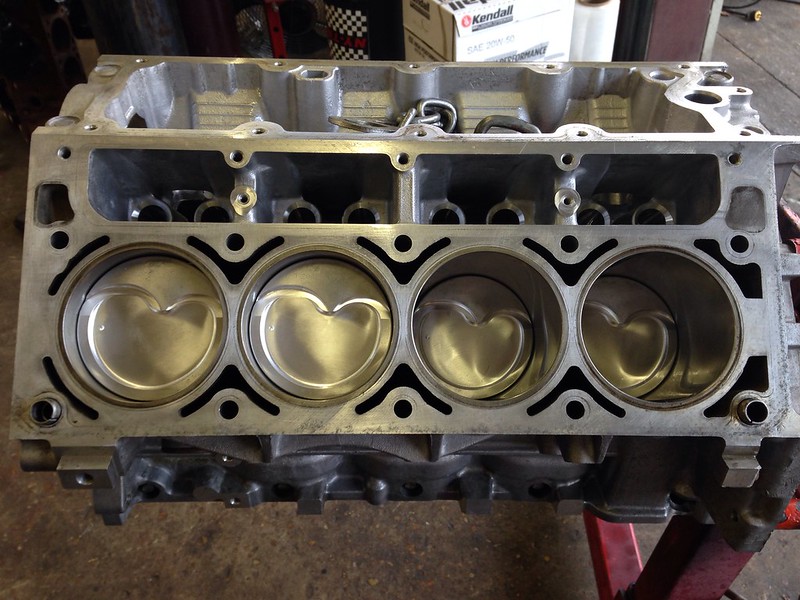

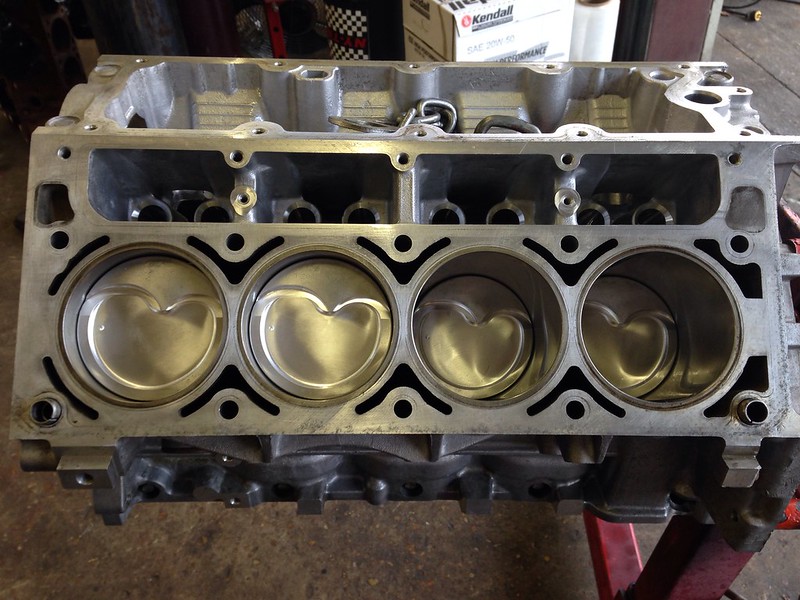

and a couple pictures to sum things up...

The shortblock and rotating assembly were dropped off at the machine shop on Friday to be cleaned, honed using a torque plate, decked, and assembled. I should have this back in my hands either Wednesday or Thursday. $750 for the whole shebang with a 4-5 day turn around wasn't a bad deal.

I also tore down the rest of the old LS6 shortblock and got the CPS sensor and oil pressure sensor out of it, took the crank pulley, front timing cover, oil pump, cam, etc out of it.

I got the heads back from the cylinder head shop, and I must say I was impressed for the price. $160 and he was able to fix all of the damage that were taken out of cylinder 1, cleaned both heads, deck the heads back flat, 3 angle valve job, fixed the seat for the intake and exhaust valve on cylinder 1 after they were chewed up, installed the new seals, valves and springs and even showed me how to use a couple of his machines.

I receieved the following parts over the week as well;

Tick remote bleeder

New Waterpump

New Crank Pulley

DW301 Fuel Pump

Racetronix Hot Wire Kit

Siemens 60# Deka Injectors

Seals/Gaskets

F1 20.4 Steel flywheel

More parts that I just cant think of...

If everything goes smoothly and as planned, I am going to try and have the car back up and running this coming weekend. I have my tuner who will be driving over from Pensacola FL to help get it running properly. I was also able to confirm that the cam that is in the car is the TSP Torquer V3, as it is engraved into the front of the cam.

My questions for y'all;

What oil should be used for the break in process (I know to not use synthetic, but looking for brand recommendations) and how long should I go before I change it? 50 miles, change, 500 miles, change?

What steps should I take to break in the motor? From what I have seen and read, people suggest idling for 15 minutes, then going 1/2 throttle a couple pulls, 3/4 throttle a couple pulls, finally going WOT a couple pulls. Letting the car cool down for 15 minutes or so between the pulls? Please give me suggestions as to how you have broken in your motors.

and a couple pictures to sum things up...

#31

TECH Regular

Thread Starter

iTrader: (10)

Join Date: Nov 2010

Posts: 406

Likes: 0

Received 0 Likes

on

0 Posts

Update on the build;

The machine shop finished up the shortblock assembly yesterday afternoon, two days ahead of schedule. Tonight I spent the night getting the short block together, following by what I though would be the long block. After getting the cam, lifters, trays, oil pump, timing chain, pilot bearing, and covers on the shortblock as well as the valley cover and sensors.

Then I went to bolt the heads onto the shortblock...

Problem; I didn't realize that the ARP headbolts differed from LS1/LS6 blocks that were made before or after 2003. So I'm now waiting another day for new ARP headbolts that are the proper sizes, I believe just a 5mm difference in length for 8 out of the 10 head bolts.

Other than that, I plan to have it back into the car and started up/ready for break in by Saturday afternoon.

I will break the motor in on the current fuel pump and injectors, then once my tuner drivers over on Monday/Tuesday I will be throwing in the Detchzwork 301, Siemens 60# injectors, and the Racetronix hotwire kit.

Here's a few pictures;

The machine shop finished up the shortblock assembly yesterday afternoon, two days ahead of schedule. Tonight I spent the night getting the short block together, following by what I though would be the long block. After getting the cam, lifters, trays, oil pump, timing chain, pilot bearing, and covers on the shortblock as well as the valley cover and sensors.

Then I went to bolt the heads onto the shortblock...

Problem; I didn't realize that the ARP headbolts differed from LS1/LS6 blocks that were made before or after 2003. So I'm now waiting another day for new ARP headbolts that are the proper sizes, I believe just a 5mm difference in length for 8 out of the 10 head bolts.

Other than that, I plan to have it back into the car and started up/ready for break in by Saturday afternoon.

I will break the motor in on the current fuel pump and injectors, then once my tuner drivers over on Monday/Tuesday I will be throwing in the Detchzwork 301, Siemens 60# injectors, and the Racetronix hotwire kit.

Here's a few pictures;

#33

TECH Fanatic

That's an excellent price on the cylinder head work.

As far as oil... I think everyone has their own personal preference. I like the Brad Penn break in oil.

http://www.penngrade1.com/products/H...ak-In-Oil.aspx

As far as oil... I think everyone has their own personal preference. I like the Brad Penn break in oil.

http://www.penngrade1.com/products/H...ak-In-Oil.aspx

#36

TECH Regular

Thread Starter

iTrader: (10)

Join Date: Nov 2010

Posts: 406

Likes: 0

Received 0 Likes

on

0 Posts

Well the motor and trans are both in the car, ready to go. Just have to finish bolting up the A/C compressor, run all of the harnesses where necessary, bolt the headers and exhaust back up, bolt the shifter back in, install the radiator, fill it fluids and fire it up.

I will post a video of startup, etc. once I get to that point.

Here's a few pictures for the night.

I will post a video of startup, etc. once I get to that point.

Here's a few pictures for the night.

#37

TECH Fanatic

I think I missed it, but did you go ahead and reuse the original block or did you pick up that other LS6 for $575?

Good luck with finishing it up. I always hate wiring ****, even if it's plug n play like reinstalling this is, I always seem to miss one.

Also as far as break in, I did 500 miles on an LT1 me and pops built like 15 years ago, after the first change I recall us doing one more 500 mile interval before going to standard 3000 mile changes. Not sure if that's still the preferred interval or not.

Good luck with finishing it up. I always hate wiring ****, even if it's plug n play like reinstalling this is, I always seem to miss one.

Also as far as break in, I did 500 miles on an LT1 me and pops built like 15 years ago, after the first change I recall us doing one more 500 mile interval before going to standard 3000 mile changes. Not sure if that's still the preferred interval or not.

#38

I only use Joe Gibbs Break in oil, then switch to Joe Gibbs LS1 oil. TSP boys would probably supply you a case for your break in.

As for the compression comments, I would like to suggest going by static compression for boost does not mean much when discussing - Boost vs compression and how much can you go type talk. It is about dynamic compression and cyl pressure, not static.

Thought I don't have all the information, not sure how you get 10:1 static with that you stated:

Using 65cc heads, .051 MLS GM gaskets stock are 3.94 bore, those 6.125 rods, 383.\

Piston to deck clearance using pn K394X3903 gives you 0.00 flush to the LS block deck.

Your static would be 9.695:1. not 10:1. And you have a big quench distance.

Again, the CAM and dynamic compression is what matters for boost.it ALL depends on the CAM and max cyl pressure at what RPM. Centrifugals vs Twin Screw apply very different cyl pressure curves.

just some thought...

Enjoy the build regardless which route you go.

As for the compression comments, I would like to suggest going by static compression for boost does not mean much when discussing - Boost vs compression and how much can you go type talk. It is about dynamic compression and cyl pressure, not static.

Thought I don't have all the information, not sure how you get 10:1 static with that you stated:

Using 65cc heads, .051 MLS GM gaskets stock are 3.94 bore, those 6.125 rods, 383.\

Piston to deck clearance using pn K394X3903 gives you 0.00 flush to the LS block deck.

Your static would be 9.695:1. not 10:1. And you have a big quench distance.

Again, the CAM and dynamic compression is what matters for boost.it ALL depends on the CAM and max cyl pressure at what RPM. Centrifugals vs Twin Screw apply very different cyl pressure curves.

just some thought...

Enjoy the build regardless which route you go.

#39

Vmapper, can you explain what you meant by "a big quench distance" and explain how that might impact the inherent power production capability of the engine vs. difficulty in tuning?

#40

TECH Fanatic

This is from a builder on another forum...

“The last function is quench, like it sounds it dampens the end burn. The end burn is where detonation occurs, the last mixture furthest from the plug is subjected to high pressures and temperatures that cause it to self ignite ahead of the burn, it's explosion is the ping you hear when the pressure wave slams into the metal parts. The quench is an area of little volume and a lot of surface area, so it sinks the heat of the late burn delaying the point where the unburnt mixture explodes. This lets you push the engine harder, at cruise you can operate at higher temps which increase thermal efficiency and at WOT it holds off detonation which raises the RPM operating limit, assuming the cam will sustain more RPM and bottom end is strong enough.