Check my logic...and math (clutch slave problems)

#1

On The Tree

Thread Starter

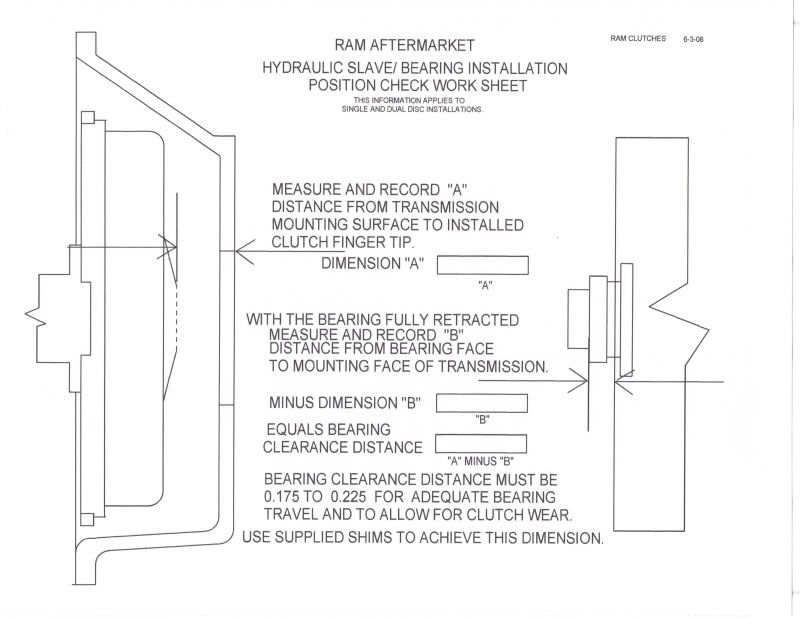

After doing lots of research on this forum on switching to an LS7 clutch/flywheel on my 05 CTSV, here is my situation. I bought a gently used LS7 clutch and flywheel from a member on here. I also purchased a katech CTS slave cylinder spacer with the impression I would have to use this in order to use my stock CTSV slave cylinder. I have the engine and trans out of the car, clutch/flywheel and bellhousing bolted to the engine and slave and spacer bolted to the trans. Using a slide caliper and dropping down a straight edge from the bellhousing surface and trans mating surfaces (checked each measurement 3 times), here are my "A" and "B" measurements:

"B" w/spacer = 3.089"

"A" w/pressure plate bolts torqued to 48 ft/lbs = 2.500"

A - B = -.589" which is way off

I know that the fact I have a used clutch is effecting my A measurement, but I didn't expect it to be this much. Now, whats interesting is if I take the spacer out, the measurements become much more reasonable. The thickness of the katech spacer is 15.46mm or .608". Taking this dimension out of the equation gives these measurements:

B = 2.481"

A= 2.5"

yields a throwout bearing clearance of .019".

I'm under the impression that this number should be around .125"-.175" taking into account I have a clutch that is already broken in and worn some.

I need some advice on next steps, I feel like I should ditch the katech spacer all together and get a shim from Tick and call it good. But why does the spacer push the stock slave out so far? Could it be I don't have stock CTSV slave cylinder? The GM part # on it is 12587376. Any advice will help me out in putting this back together. And before anybody says it, funds are low at the end of this build due to buying a new short block and a slew of other parts that go along with swapping an engine. That is the reason for buying a used clutch and pressure plate, along with I got some other parts as a package deal. I may have plans for a new centerforce clutch in the future if this clutch does not work out though.

"B" w/spacer = 3.089"

"A" w/pressure plate bolts torqued to 48 ft/lbs = 2.500"

A - B = -.589" which is way off

I know that the fact I have a used clutch is effecting my A measurement, but I didn't expect it to be this much. Now, whats interesting is if I take the spacer out, the measurements become much more reasonable. The thickness of the katech spacer is 15.46mm or .608". Taking this dimension out of the equation gives these measurements:

B = 2.481"

A= 2.5"

yields a throwout bearing clearance of .019".

I'm under the impression that this number should be around .125"-.175" taking into account I have a clutch that is already broken in and worn some.

I need some advice on next steps, I feel like I should ditch the katech spacer all together and get a shim from Tick and call it good. But why does the spacer push the stock slave out so far? Could it be I don't have stock CTSV slave cylinder? The GM part # on it is 12587376. Any advice will help me out in putting this back together. And before anybody says it, funds are low at the end of this build due to buying a new short block and a slew of other parts that go along with swapping an engine. That is the reason for buying a used clutch and pressure plate, along with I got some other parts as a package deal. I may have plans for a new centerforce clutch in the future if this clutch does not work out though.

#2

TECH Addict

iTrader: (14)

Join Date: Feb 2007

Location: Owasso, OK

Posts: 2,342

Likes: 0

Received 0 Likes

on

0 Posts

They really should clarify what that katech spacer is for. It's not for use with an LS7 clutch. From my gatherings, that was used to install an LS6 clutch out of a C5 Z06 into the V. When the V came out they didn't have an LS7 so that's what they used. You will need a spacer almost an inch deep to run a stock slave with the LS7. The easy was is to just get the LS7 slave and shim as required.

Also, I'm not sure what going on with your math but the measurement you have are weird. Looks like your first measurement is actually depressing the clutch almost a half inch. And your second on is almost spot on. However, if it is a stock slave that's not right. You may have an LS7 slave already.

You can pos the pics up and we can tell you what you have.

Your measurement should be as follows:

"A" is bell housing (trans mating surface) to clutch fingers.

"B" is a straight edge off the compressed slave to the front of the transmission (bell housing mating surface)

Also, I'm not sure what going on with your math but the measurement you have are weird. Looks like your first measurement is actually depressing the clutch almost a half inch. And your second on is almost spot on. However, if it is a stock slave that's not right. You may have an LS7 slave already.

You can pos the pics up and we can tell you what you have.

Your measurement should be as follows:

"A" is bell housing (trans mating surface) to clutch fingers.

"B" is a straight edge off the compressed slave to the front of the transmission (bell housing mating surface)

Last edited by raven154; 05-05-2014 at 08:52 AM.

#3

On The Tree

Thread Starter

They really should clarify what that katech spacer is for. It's not for use with an LS7 clutch. From my gatherings, that was used to install an LS6 clutch out of a C5 Z06 into the V. When the V came out they didn't have an LS7 so that's what they used. You will need a spacer almost an inch deep to run a stock slave with the LS7. The easy was is to just get the LS7 slave and shim as required.

Also, I'm not sure what going on with your math but the measurement you have are weird. Looks like your first measurement is actually depressing the clutch almost a half inch. And your second on is almost spot on. However, if it is a stock slave that's not right. You may have an LS7 slave already.

You can pos the pics up and we can tell you what you have.

Your measurement should be as follows:

"A" is bell housing (trans mating surface) to clutch fingers.

"B" is a straight edge off the compressed slave to the front of the transmission (bell housing mating surface)

Also, I'm not sure what going on with your math but the measurement you have are weird. Looks like your first measurement is actually depressing the clutch almost a half inch. And your second on is almost spot on. However, if it is a stock slave that's not right. You may have an LS7 slave already.

You can pos the pics up and we can tell you what you have.

Your measurement should be as follows:

"A" is bell housing (trans mating surface) to clutch fingers.

"B" is a straight edge off the compressed slave to the front of the transmission (bell housing mating surface)

#5

TECH Addict

iTrader: (14)

Join Date: Feb 2007

Location: Owasso, OK

Posts: 2,342

Likes: 0

Received 0 Likes

on

0 Posts

Yes the slave must be compressed. It has a spring under the TOB to keep it in contact with the clutch fingers when all assembled. You must push the slave down until it stops and then measure. This is easier with 4 hands.

Trending Topics

#9

On The Tree

Thread Starter

I am definately going to remeasure with the slave compressed. Should I measure from the front of the throwout bearing or take it off and measure from the base where it sits? I may be able to machine my katech spacer down to make it work. Thanks for your help guys, much appreciated.

#10

TECH Addict

iTrader: (14)

Join Date: Feb 2007

Location: Owasso, OK

Posts: 2,342

Likes: 0

Received 0 Likes

on

0 Posts

Measure with the TOB installed. The issue with the Katech spacer is it's not thick enough to use with the stock slave. It would need about another .400" to make it work. You should just return that spacer and get the LS7 slave or measure with the stock slave and have a spacer made. That's what I did on my first setup and it worked perfect.

#11

On The Tree

Thread Starter

Update on this, I remeasured with my slave in the compressed state and the measurements I get with the Katech spacer are right on the money. The distance that the slave cylinder travels when compressed is approximately .750" (5 measurements taken and averaged using 2 sets of hands). Subtracting this from my previous B measurement gives 2.339":

A - B = 2.500" - 2.339" = .161"

This is right about what I was looking to get on a used broken in clutch disk. So just to clarify, I think the Katech spacer I have is right on the money to work with the LS7 clutch combo.

A - B = 2.500" - 2.339" = .161"

This is right about what I was looking to get on a used broken in clutch disk. So just to clarify, I think the Katech spacer I have is right on the money to work with the LS7 clutch combo.

#14

On The Tree

Thread Starter

#15

TECH Addict

iTrader: (14)

Join Date: Feb 2007

Location: Owasso, OK

Posts: 2,342

Likes: 0

Received 0 Likes

on

0 Posts

You can notch the bell housing (common fix) or do what I and many others did and just run a remote bleeder. Its a stainless braided line and you can snake it out the hole without having to notch anything. The pressure line can be bent slightly to make it out the other hole. Just dont kink it. The bleeder is about 50 bucks and then you have to wait for shipping. If you have a cut off wheel you can notch the bellhousing in a few minutes and have it back in the car that day.

Its been a while since I've had a stock slave in there. I forgot all about that issue.

Its been a while since I've had a stock slave in there. I forgot all about that issue.

#19

On The Tree

Thread Starter

N/A for sure. I'm tired of dumping money into this thing. I'll enjoy it over the summer and maybe try to sell it in the fall. I need a truck, and I want a big block chevelle...sooo..