PUO Motor Mounts

#22

Also there are already at least 3 aftermarket motor mounts available with multiple levels of hardness. These mounts have all had revisions and suffered a large trial and error period, heat issues etc, before these mounts are what they are today. Plus they pull from research from all the applications they are made for, especially when it comes to polyurethane types/recipes. Whats the need to make a new "style"?

#23

TECH Addict

iTrader: (2)

Just an FYI I DD a set of revshift "blue" (soft) motor mounts and I could not be happier, very smooth and almost zero shake or vibration, plus they will last forever unlike rubber mounts. I felt the old worn out stock mounts shake around alot more, when I replaced them I almost didn't know the engine was on!

Also there are already at least 3 aftermarket motor mounts available with multiple levels of hardness. These mounts have all had revisions and suffered a large trial and error period, heat issues etc, before these mounts are what they are today. Plus they pull from research from all the applications they are made for, especially when it comes to polyurethane types/recipes. Whats the need to make a new "style"?

Also there are already at least 3 aftermarket motor mounts available with multiple levels of hardness. These mounts have all had revisions and suffered a large trial and error period, heat issues etc, before these mounts are what they are today. Plus they pull from research from all the applications they are made for, especially when it comes to polyurethane types/recipes. Whats the need to make a new "style"?

An added benefit to this style of mount was being able to take the through bolt out of it during my clutch install, dropping the motor almost and inch making for easier access to the transmission and bell-housing bolts. As an ex line mechanic, I appreciate this!! Brain if you clearance your mounts a bit, you could get more than an inch which would really help at clutch install time.

Last edited by ls1247; 08-07-2014 at 10:43 AM.

#24

Just an FYI I DD a set of revshift "blue" (soft) motor mounts and I could not be happier, very smooth and almost zero shake or vibration, plus they will last forever unlike rubber mounts. I felt the old worn out stock mounts shake around alot more, when I replaced them I almost didn't know the engine was on!

Also there are already at least 3 aftermarket motor mounts available with multiple levels of hardness. These mounts have all had revisions and suffered a large trial and error period, heat issues etc, before these mounts are what they are today. Plus they pull from research from all the applications they are made for, especially when it comes to polyurethane types/recipes. Whats the need to make a new "style"?

Also there are already at least 3 aftermarket motor mounts available with multiple levels of hardness. These mounts have all had revisions and suffered a large trial and error period, heat issues etc, before these mounts are what they are today. Plus they pull from research from all the applications they are made for, especially when it comes to polyurethane types/recipes. Whats the need to make a new "style"?

#25

I seriously am considering scrapping this whole motor mount idea and just living with swapping out the crap mounts from Revshift that continually fail in my car and the mounts that are transmitting vibration. The amount of time and effort involved in designing the parts, getting them made, powdercoated, assembled, boxed and shipped is really not worth the damn hassle. I don't do this to support my family and the amount of profit per set is damn near nothing.

#30

TECH Regular

iTrader: (16)

Had my first set of revshift blues for 20k + miles, the bolt loosened up in the poly. Very similar to Brian's video. I used the silicone jackets too. Revshift had me a replacement set in about 4 days after calling.

Tried the creative steel black mounts, hated the vibrations from them. Felt like metal on metal, almost like the exhaust was banging against something. Had more than a few people convince my flywheel had gone bad. Returned for a refund.

Made my own mounts from solid steel. Surprisingly the had less vibrations than the creative steel mounts but still more than I wanted to live with. Had a nice massage effect at idle.

Put the revshift replacements in and I have zero, and I mean zero vibrations. Revshift has told me that they revised the design to keep the bolt from spinning as the previous sets did.

But because Brian is an awesome guy, I'd be willing to try them out and change my mounts for a fifth time. Would also be an opportunity to check the new revshift design to see if the spinning is eliminated. I got it down to around a 2.5 hour job now. .

.

Tried the creative steel black mounts, hated the vibrations from them. Felt like metal on metal, almost like the exhaust was banging against something. Had more than a few people convince my flywheel had gone bad. Returned for a refund.

Made my own mounts from solid steel. Surprisingly the had less vibrations than the creative steel mounts but still more than I wanted to live with. Had a nice massage effect at idle.

Put the revshift replacements in and I have zero, and I mean zero vibrations. Revshift has told me that they revised the design to keep the bolt from spinning as the previous sets did.

But because Brian is an awesome guy, I'd be willing to try them out and change my mounts for a fifth time. Would also be an opportunity to check the new revshift design to see if the spinning is eliminated. I got it down to around a 2.5 hour job now.

.

.

#31

TECH Addict

iTrader: (2)

as a compromise, maybe you could get the UMIs (dealer status maybe), remove the urethane (or buy them raw?) and make a split bushing insert of softer material for those and resell them. I am heading in that direction myself at some point.

can't say as I blame you on the design heist theory...

good luck either way.

can't say as I blame you on the design heist theory...

good luck either way.

#33

TECH Regular

iTrader: (2)

They will all have a chance to see the mounts before I ship them. I will show everybody when they are completed.

I seriously am considering scrapping this whole motor mount idea and just living with swapping out the crap mounts from Revshift that continually fail in my car and the mounts that are transmitting vibration. The amount of time and effort involved in designing the parts, getting them made, powdercoated, assembled, boxed and shipped is really not worth the damn hassle. I don't do this to support my family and the amount of profit per set is damn near nothing.

I seriously am considering scrapping this whole motor mount idea and just living with swapping out the crap mounts from Revshift that continually fail in my car and the mounts that are transmitting vibration. The amount of time and effort involved in designing the parts, getting them made, powdercoated, assembled, boxed and shipped is really not worth the damn hassle. I don't do this to support my family and the amount of profit per set is damn near nothing.

I spent hours in a hotel room in my spare time 3D modeling concept renderings while I traveled. I scrapped good designs in favor of simplicity and lower cost. I worked a mockup studying every movement and modeling everything to perfection. I had to reduce tolerances for critical areas and change this/that etc until I finally had something that worked...on paper. Then it's the risk of machining and crossing your fingers no mistakes were made and that overwhelming joy when it all comes together and you give it a test and it works.

Then you have to work a price that clears cost of production, insurance, possible replacement parts and bring it to the community that satisfies that need/want.

Having gone down that path, it raises a greater understanding of what is involved and the sacrifices that are made with our free time - it is done for the passion of the car community. Sometimes there are praises and other times, it is met with a double edge sword and filled with rants, flames, diatribes, over-critical nonsense, drama, he called your mother a ***** - shut your mouth b*tch!

But I digress...looking forward to seeing this design become an offering to the community.

#36

Brian, don't let the negative Nancy's get you down. The shifter you make is awesome! I love mine. Looking forward very much to trying the motor mounts.

Last edited by Rock44; 08-08-2014 at 08:10 AM.

#37

TECH Enthusiast

Comparing one to the other if the polyeurethane fails on both mounts:The CS mount will still be holding your motor to the cradle, vs. the RS mount will be fully disconnected and you'll have a very floppy engine.

#38

TECH Addict

iTrader: (19)

Join Date: Aug 2007

Location: Where the Navy tells me to go

Posts: 2,397

Received 106 Likes

on

88 Posts

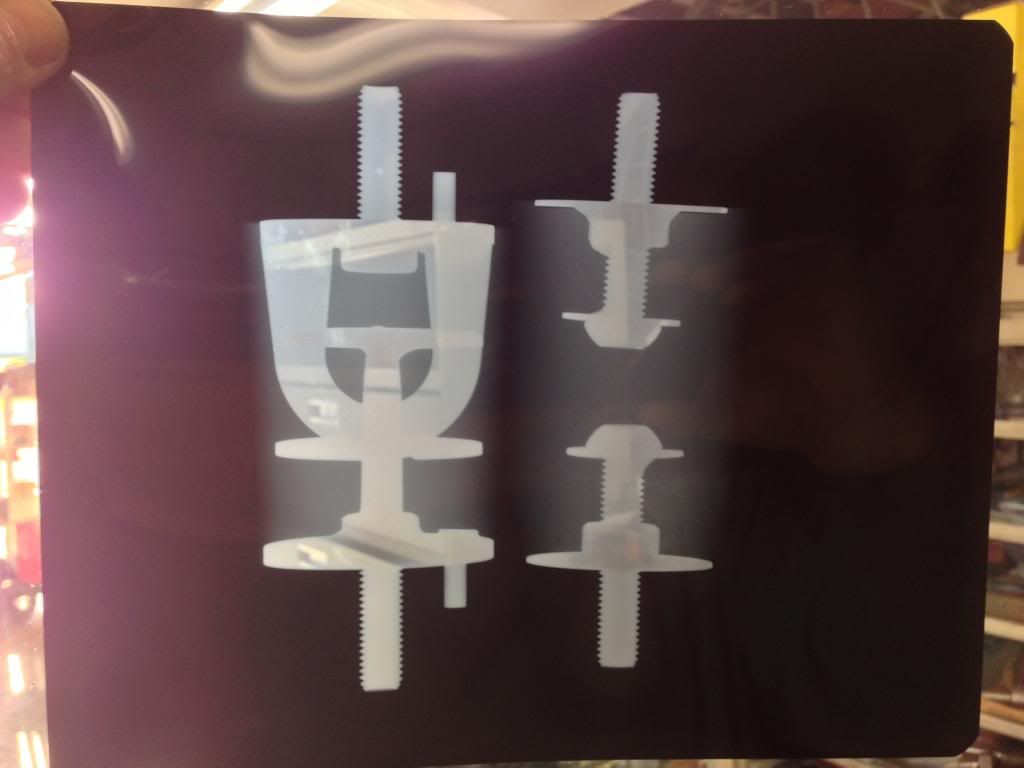

Take a Solo cup, and turn it into steel with your transmogrifier. Put a 14mm hole in the bottom. Take a 13mm bolt with a big fender washer and drop it down through the hole. Pass another 13mm bolt with a big fender washer up through a steel Solo cup lid, and weld that upper bolt to the lid. Weld the lid onto the cup. Cut away some of the side of the cup so the bottom and the lid are joined by 4 strips. So the lid with the welded bolt is the top of the cage. The bottom of the cage is the bottom of the Solo cup. The lower bolt can float up and down inside the Solo cup (so you can set the proper length of the surrounding urethane mount), but it can't pull out because the fender washer keeps the head of the bolt inside the bottom of the cup.

(I say 13mm, but I honestly don't recall what the dimensions of the bolts are. The sizing isn't important, but hopefully that gives you a better image in your head than the X-ray.)

Last edited by AAIIIC; 08-08-2014 at 08:16 AM.

#39

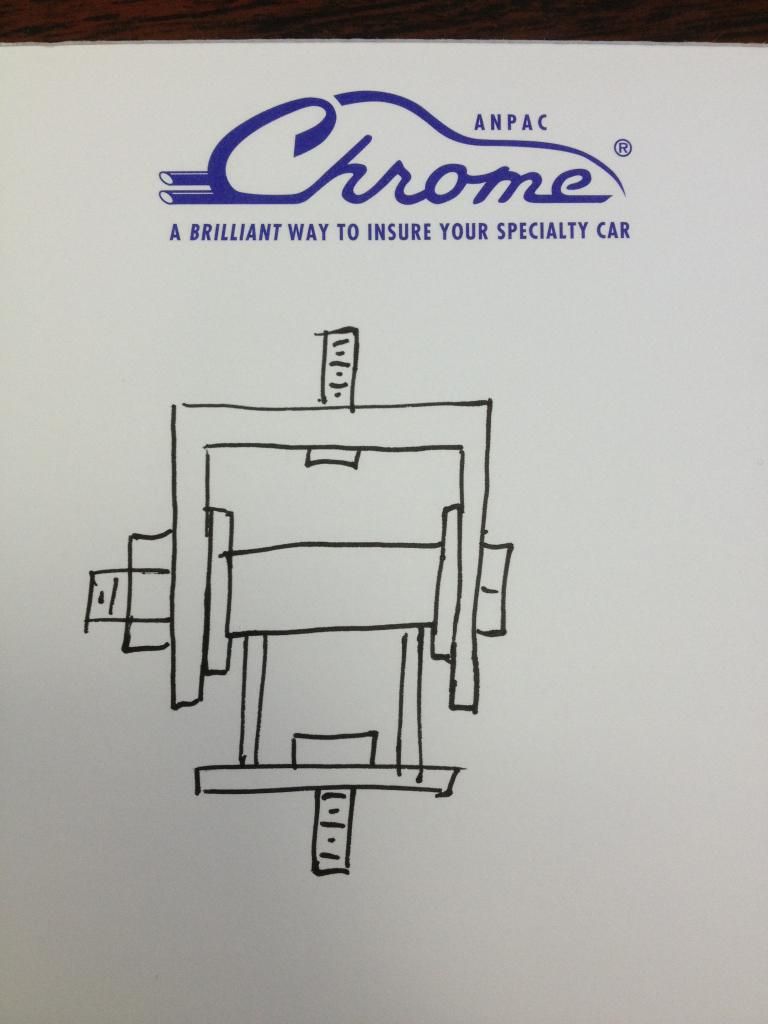

I was trying to draw something using Powerpoint, but my 3D drawing skills are, uhhh... not so good.

Take a Solo cup, and turn it into steel with your transmogrifier. Put a 14mm hole in the bottom. Take a 13mm bolt with a big fender washer and drop it down through the hole. Pass another 13mm bolt with a big fender washer up through a steel Solo cup lid, and weld that upper bolt to the lid. Weld the lid onto the cup. Cut away some of the side of the cup so the bottom and the lid are joined by 4 strips. So the lid with the welded bolt is the top of the cage. The bottom of the cage is the bottom of the Solo cup. The lower bolt can float up and down inside the Solo cup (so you can set the proper length of the surrounding urethane mount), but it can't pull out because the fender washer keeps the head of the bolt inside the bottom of the cup.

(I say 13mm, but I honestly don't recall what the dimensions of the bolts are. The sizing isn't important, but hopefully that gives you a better image in your head than the X-ray.)

Take a Solo cup, and turn it into steel with your transmogrifier. Put a 14mm hole in the bottom. Take a 13mm bolt with a big fender washer and drop it down through the hole. Pass another 13mm bolt with a big fender washer up through a steel Solo cup lid, and weld that upper bolt to the lid. Weld the lid onto the cup. Cut away some of the side of the cup so the bottom and the lid are joined by 4 strips. So the lid with the welded bolt is the top of the cage. The bottom of the cage is the bottom of the Solo cup. The lower bolt can float up and down inside the Solo cup (so you can set the proper length of the surrounding urethane mount), but it can't pull out because the fender washer keeps the head of the bolt inside the bottom of the cup.

(I say 13mm, but I honestly don't recall what the dimensions of the bolts are. The sizing isn't important, but hopefully that gives you a better image in your head than the X-ray.)

Can I rent a transmogrifier from AutoZone?