8.8 rear end vibration

#122

TECH Addict

iTrader: (19)

Join Date: Aug 2007

Location: Where the Navy tells me to go

Posts: 2,397

Received 106 Likes

on

88 Posts

First, some background:

- Current setup: UUC engine and tranny mounts; new OEM flex disk; voodoochikin refurbed driveshaft w/30A carrier bearing surround; CS 8.8" driveshaft/pinion adapter; aluminum 8.8" housing w/Truetrac diff, 3.73 gears; CS axles with stock outers

- The 8.8" was rebuilt by a local machine shop / race prep shop using all FRPP parts

A couple months ago I finally got around to having the 8.8" conversion installed. The day prior to the install I swapped out my driveshaft for one that had been refurbed by voodoochikin, so it's got a new carrier bearing and 30A red poly bearing surround. At the same time I installed a new OEM flex disk. I didn't check any driveline angles, I just bolted it in and went with it, since I knew the diff install was going to be done and (presumably) all of the angles would be measured and set properly. Before the driveshaft swap the car was vibration-free; driving the car after the driveshaft swap I found I had picked up a very noticeable vibration from ~40mph up to ~50mph. I didn't get over maybe 65 or 70mph on the way to the shop, but I figured the vibration would come back at higher speeds (~80mph) if I had gotten up that high.

Got the 8.8" installed by a shop. I told them about the new vibration, and we talked about measuring and correcting the driveline angles. Based on the results (and what I have seen with my own 2 eyes as of today), they didn't do **** in that regard. Unfortunately, I had the install done shortly before I was going to be moving out of the area, and I just didn't have time to get anything resolved before I left. Add in the fact that the 8.8 sounds like a ******* gravel truck and I was really thrilled with the whole situation.

I've got about 3500 miles on the setup now. It sucks, and combined with the shitty clutch setup that I also need to correct, it really makes driving the car annoying. This week I got the laser driveline alignment tool from Creative Steel, and today I finally had a chance to get the car up on a lift to try to put things right. (Well, at least 1/3 right - the clutch and noisy diff would still be waiting for resolution.) I spent a few hours working at it, and just could not figure out how to get the damn driveshaft out!

I realize that sounds pretty stupid, but keep in mind I removed and installed the driveshaft (with the stock diff) just 6 or 8 weeks ago, on jack stands in my driveway. I know how it's supposed to work. The problem I was having today is that the driveshaft seems to be compressed to nearly it's shortest length as it is installed. There's maybe 1/8 - 1/4" of play. That means that there was no way I could slide the forward end of the shaft back enough to get it off the nub coming out of the tranny, and there was no way I could slide the aft end of the shaft forward to get the rear CV to clear the CS driveshaft/pinion adapter. I was prying and pulling on stuff in a variety of ways, but I was afraid I was going to break something, or that I wouldn't be able to get the thing reinstalled if I did manage to get either end to clear, so I gave up and put everything back together as it was.

So, for anyone that is using a stock driveshaft with the CS driveshaft/pinion adapter and 8.8" diff, how the hell does that all go in and come out? I'm sure there's something obvious I'm missing.

I'm sure there's something obvious I'm missing.

- Current setup: UUC engine and tranny mounts; new OEM flex disk; voodoochikin refurbed driveshaft w/30A carrier bearing surround; CS 8.8" driveshaft/pinion adapter; aluminum 8.8" housing w/Truetrac diff, 3.73 gears; CS axles with stock outers

- The 8.8" was rebuilt by a local machine shop / race prep shop using all FRPP parts

A couple months ago I finally got around to having the 8.8" conversion installed. The day prior to the install I swapped out my driveshaft for one that had been refurbed by voodoochikin, so it's got a new carrier bearing and 30A red poly bearing surround. At the same time I installed a new OEM flex disk. I didn't check any driveline angles, I just bolted it in and went with it, since I knew the diff install was going to be done and (presumably) all of the angles would be measured and set properly. Before the driveshaft swap the car was vibration-free; driving the car after the driveshaft swap I found I had picked up a very noticeable vibration from ~40mph up to ~50mph. I didn't get over maybe 65 or 70mph on the way to the shop, but I figured the vibration would come back at higher speeds (~80mph) if I had gotten up that high.

Got the 8.8" installed by a shop. I told them about the new vibration, and we talked about measuring and correcting the driveline angles. Based on the results (and what I have seen with my own 2 eyes as of today), they didn't do **** in that regard. Unfortunately, I had the install done shortly before I was going to be moving out of the area, and I just didn't have time to get anything resolved before I left. Add in the fact that the 8.8 sounds like a ******* gravel truck and I was really thrilled with the whole situation.

I've got about 3500 miles on the setup now. It sucks, and combined with the shitty clutch setup that I also need to correct, it really makes driving the car annoying. This week I got the laser driveline alignment tool from Creative Steel, and today I finally had a chance to get the car up on a lift to try to put things right. (Well, at least 1/3 right - the clutch and noisy diff would still be waiting for resolution.) I spent a few hours working at it, and just could not figure out how to get the damn driveshaft out!

I realize that sounds pretty stupid, but keep in mind I removed and installed the driveshaft (with the stock diff) just 6 or 8 weeks ago, on jack stands in my driveway. I know how it's supposed to work. The problem I was having today is that the driveshaft seems to be compressed to nearly it's shortest length as it is installed. There's maybe 1/8 - 1/4" of play. That means that there was no way I could slide the forward end of the shaft back enough to get it off the nub coming out of the tranny, and there was no way I could slide the aft end of the shaft forward to get the rear CV to clear the CS driveshaft/pinion adapter. I was prying and pulling on stuff in a variety of ways, but I was afraid I was going to break something, or that I wouldn't be able to get the thing reinstalled if I did manage to get either end to clear, so I gave up and put everything back together as it was.

So, for anyone that is using a stock driveshaft with the CS driveshaft/pinion adapter and 8.8" diff, how the hell does that all go in and come out?

#123

jw what posi unit is in the car if I missed it sorry. had a 8.8 in my fbody with a auburn pro posi unit and had a bad vibration over about 50 mph. I did a 1,2,3 gear pull and busted spider gears. at the time I didn't know what happened. drove it around but when I went over 50mph no vibration but when I turned left or right it would make a popping noise. so opened rear diff and realized the posi unit what no good. might not be no help but that's what was causing all my vibration issues.

#124

TECH Enthusiast

First, some background:

- Current setup: UUC engine and tranny mounts; new OEM flex disk; voodoochikin refurbed driveshaft w/30A carrier bearing surround; CS 8.8" driveshaft/pinion adapter; aluminum 8.8" housing w/Truetrac diff, 3.73 gears; CS axles with stock outers

- The 8.8" was rebuilt by a local machine shop / race prep shop using all FRPP parts

A couple months ago I finally got around to having the 8.8" conversion installed. The day prior to the install I swapped out my driveshaft for one that had been refurbed by voodoochikin, so it's got a new carrier bearing and 30A red poly bearing surround. At the same time I installed a new OEM flex disk. I didn't check any driveline angles, I just bolted it in and went with it, since I knew the diff install was going to be done and (presumably) all of the angles would be measured and set properly. Before the driveshaft swap the car was vibration-free; driving the car after the driveshaft swap I found I had picked up a very noticeable vibration from ~40mph up to ~50mph. I didn't get over maybe 65 or 70mph on the way to the shop, but I figured the vibration would come back at higher speeds (~80mph) if I had gotten up that high.

Got the 8.8" installed by a shop. I told them about the new vibration, and we talked about measuring and correcting the driveline angles. Based on the results (and what I have seen with my own 2 eyes as of today), they didn't do **** in that regard. Unfortunately, I had the install done shortly before I was going to be moving out of the area, and I just didn't have time to get anything resolved before I left. Add in the fact that the 8.8 sounds like a ******* gravel truck and I was really thrilled with the whole situation.

I've got about 3500 miles on the setup now. It sucks, and combined with the shitty clutch setup that I also need to correct, it really makes driving the car annoying. This week I got the laser driveline alignment tool from Creative Steel, and today I finally had a chance to get the car up on a lift to try to put things right. (Well, at least 1/3 right - the clutch and noisy diff would still be waiting for resolution.) I spent a few hours working at it, and just could not figure out how to get the damn driveshaft out!

I realize that sounds pretty stupid, but keep in mind I removed and installed the driveshaft (with the stock diff) just 6 or 8 weeks ago, on jack stands in my driveway. I know how it's supposed to work. The problem I was having today is that the driveshaft seems to be compressed to nearly it's shortest length as it is installed. There's maybe 1/8 - 1/4" of play. That means that there was no way I could slide the forward end of the shaft back enough to get it off the nub coming out of the tranny, and there was no way I could slide the aft end of the shaft forward to get the rear CV to clear the CS driveshaft/pinion adapter. I was prying and pulling on stuff in a variety of ways, but I was afraid I was going to break something, or that I wouldn't be able to get the thing reinstalled if I did manage to get either end to clear, so I gave up and put everything back together as it was.

So, for anyone that is using a stock driveshaft with the CS driveshaft/pinion adapter and 8.8" diff, how the hell does that all go in and come out? I'm sure there's something obvious I'm missing.

I'm sure there's something obvious I'm missing.

- Current setup: UUC engine and tranny mounts; new OEM flex disk; voodoochikin refurbed driveshaft w/30A carrier bearing surround; CS 8.8" driveshaft/pinion adapter; aluminum 8.8" housing w/Truetrac diff, 3.73 gears; CS axles with stock outers

- The 8.8" was rebuilt by a local machine shop / race prep shop using all FRPP parts

A couple months ago I finally got around to having the 8.8" conversion installed. The day prior to the install I swapped out my driveshaft for one that had been refurbed by voodoochikin, so it's got a new carrier bearing and 30A red poly bearing surround. At the same time I installed a new OEM flex disk. I didn't check any driveline angles, I just bolted it in and went with it, since I knew the diff install was going to be done and (presumably) all of the angles would be measured and set properly. Before the driveshaft swap the car was vibration-free; driving the car after the driveshaft swap I found I had picked up a very noticeable vibration from ~40mph up to ~50mph. I didn't get over maybe 65 or 70mph on the way to the shop, but I figured the vibration would come back at higher speeds (~80mph) if I had gotten up that high.

Got the 8.8" installed by a shop. I told them about the new vibration, and we talked about measuring and correcting the driveline angles. Based on the results (and what I have seen with my own 2 eyes as of today), they didn't do **** in that regard. Unfortunately, I had the install done shortly before I was going to be moving out of the area, and I just didn't have time to get anything resolved before I left. Add in the fact that the 8.8 sounds like a ******* gravel truck and I was really thrilled with the whole situation.

I've got about 3500 miles on the setup now. It sucks, and combined with the shitty clutch setup that I also need to correct, it really makes driving the car annoying. This week I got the laser driveline alignment tool from Creative Steel, and today I finally had a chance to get the car up on a lift to try to put things right. (Well, at least 1/3 right - the clutch and noisy diff would still be waiting for resolution.) I spent a few hours working at it, and just could not figure out how to get the damn driveshaft out!

I realize that sounds pretty stupid, but keep in mind I removed and installed the driveshaft (with the stock diff) just 6 or 8 weeks ago, on jack stands in my driveway. I know how it's supposed to work. The problem I was having today is that the driveshaft seems to be compressed to nearly it's shortest length as it is installed. There's maybe 1/8 - 1/4" of play. That means that there was no way I could slide the forward end of the shaft back enough to get it off the nub coming out of the tranny, and there was no way I could slide the aft end of the shaft forward to get the rear CV to clear the CS driveshaft/pinion adapter. I was prying and pulling on stuff in a variety of ways, but I was afraid I was going to break something, or that I wouldn't be able to get the thing reinstalled if I did manage to get either end to clear, so I gave up and put everything back together as it was.

So, for anyone that is using a stock driveshaft with the CS driveshaft/pinion adapter and 8.8" diff, how the hell does that all go in and come out?

If you can't get enough clearance dropping the cradle a bit then you'll have to loosen up the front diff mounts to get the extra clerance you need.

It's not a fun job.

#125

TECH Addict

iTrader: (2)

While I don't have the adapter, I had to put the carbon shaft in as the cradle was going into the car and compress it that way. As mentioned in another thread, you can drop the diff at the front mount or do as I did and loosen the cradle bolts almost all the way and let the cradle drop far enough for the driveshaft to fall out.

Hate that you're having problems as I know you've been wanting to get this done for a while.

You mentioned getting it "set properly" but unfortunately, there are no specs, there is no book and you just basically have to dick with it until it gets happy. Its easier to just start trying different shim combos than it is to try and measure all this because at the end of the day, you don't have any reference angles to benchmark them against anyway. Shimming the cradle was the easiest to do and ultimately, that's what made mine happy.

Hate that you're having problems as I know you've been wanting to get this done for a while.

You mentioned getting it "set properly" but unfortunately, there are no specs, there is no book and you just basically have to dick with it until it gets happy. Its easier to just start trying different shim combos than it is to try and measure all this because at the end of the day, you don't have any reference angles to benchmark them against anyway. Shimming the cradle was the easiest to do and ultimately, that's what made mine happy.

#126

TECH Addict

iTrader: (19)

Join Date: Aug 2007

Location: Where the Navy tells me to go

Posts: 2,397

Received 106 Likes

on

88 Posts

You need to loosen up the front cradle bolts and have it drop down a bit. My setup was similar with the tightness. I actually ordered a new adapter from them that is supposed to be shorter to improve the situation.

If you can't get enough clearance dropping the cradle a bit then you'll have to loosen up the front diff mounts to get the extra clearance you need.

It's not a fun job.

If you can't get enough clearance dropping the cradle a bit then you'll have to loosen up the front diff mounts to get the extra clearance you need.

It's not a fun job.

While I don't have the adapter, I had to put the carbon shaft in as the cradle was going into the car and compress it that way. As mentioned in another thread, you can drop the diff at the front mount or do as I did and loosen the cradle bolts almost all the way and let the cradle drop far enough for the driveshaft to fall out.

Well, there is a spec in the FSM for the CV joint, which I posted about a couple/few months ago. And the geometry of 2-piece driveshafts is not unique to this platform - there's a proper way to set the angles depending on whether you're working with CV joints or U joints. With that said, I don't know what the forward joint (just behind the carrier bearing) is - is there a CV hiding in there or a U joint?

Last edited by AAIIIC; 12-22-2015 at 09:54 AM.

#127

TECH Addict

iTrader: (2)

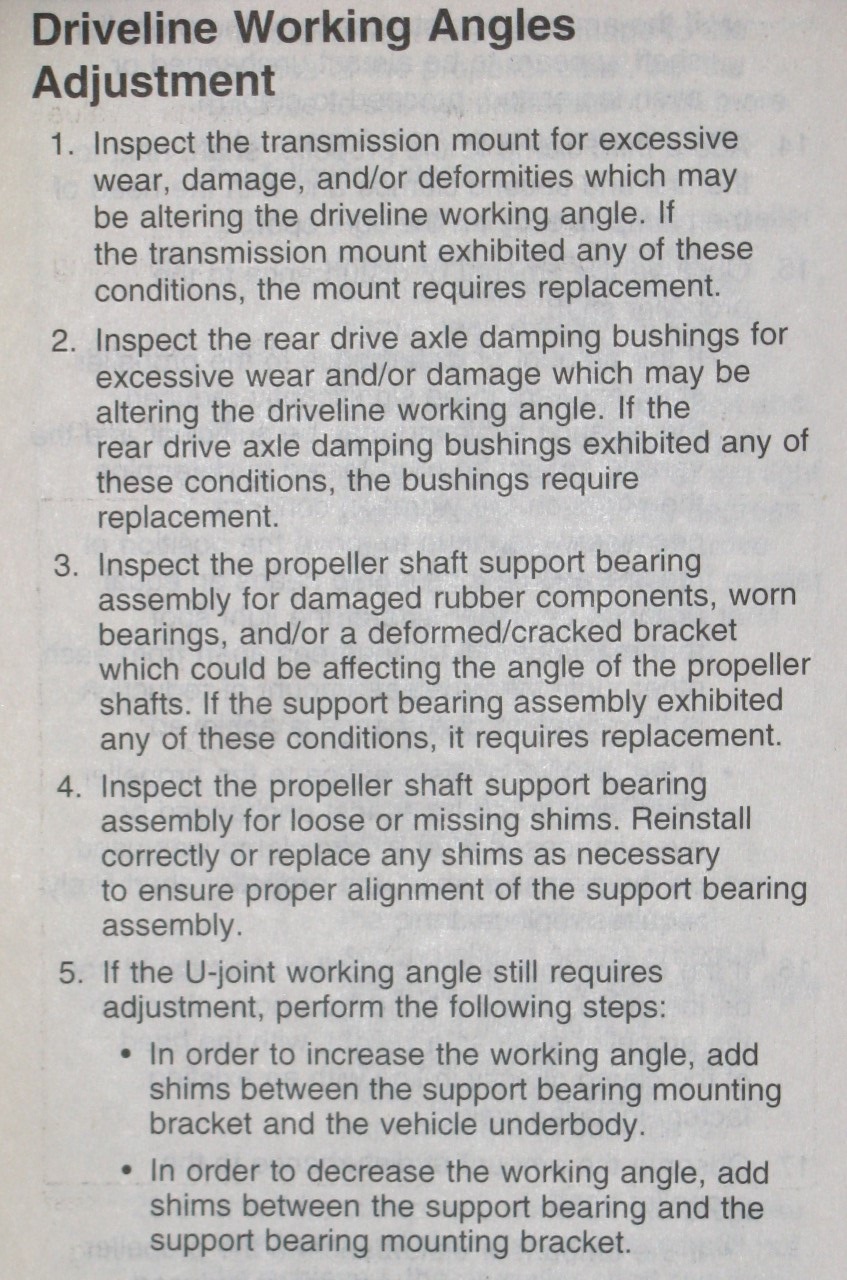

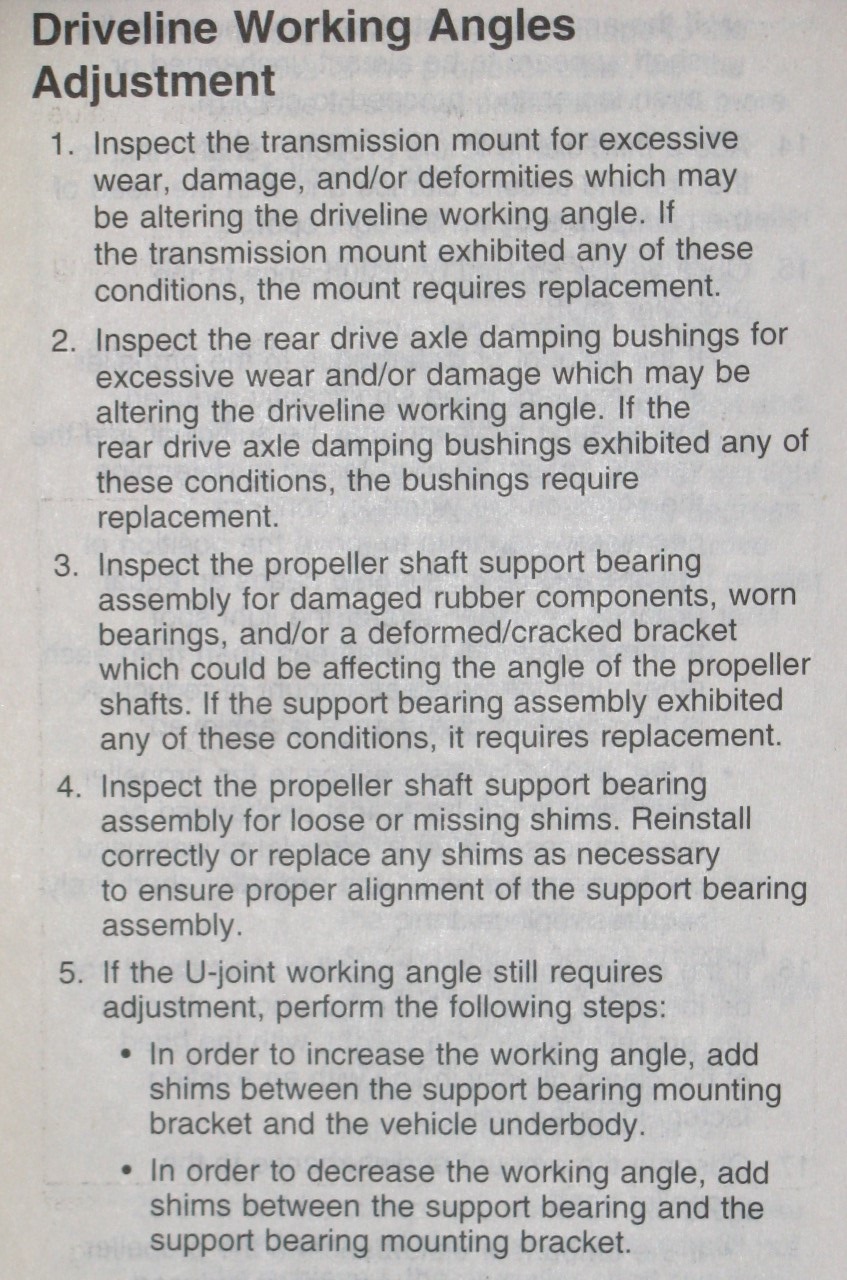

The other day while looking at parts online I noticed that GM sells shims in various sizes for carrier bearing (part #6 in various sizes here). So, I pulled out my FSM to see what it says about those shims. Not much, really, but there's a little information that might come in handy for those fighting vibrations.

The driveshaft replacement procedure doesn't mention the shims at all. But in the front portion of the driveshaft section of the FSM there's troubleshooting guidance for assorted noises. Under "Shudder on Acceleration at Low Speed (CTSV)" [which I realize isn't really what most people are experiencing, but I don't see anything anywhere in the procedure about high speed vibrations] it says "Determine if the driveline angle is incorrect and correct as necessary. Refer to Diagnostic Starting Point - Vibration Diagnosis and Correction on page 0-41 in Vibration Diagnosis and Correction."

The Vibration Diagnosis and Correction section is very extensive - over 60 pages, including diagnostic procedures, vibration theory, etc. Pretty impressive. In the Vibration Analysis - Driveline section, all the way down at step 23 it tells you to measure the propeller shaft angle, "Refer to Driveline Working Angles Measurement on page 0-84."

Although it doesn't specifically say so, that section appears to be written for the V-6 driveshaft, as it tells you to measure the angle of the front and rear portions of the driveshaft, then subtract them to determine the working angle of the U-joint. The V-6 driveshaft has the U-joint in the middle, whereas the V shaft has the U-joint at the rear. (At least, I think that's the case. Right?) The principle would be the same, though, you just would take the measurement at the rear end instead of in the middle of the driveshaft. Anyway, after you determine the working angle it says:

But then it doesn't tell you how to adjust the working angle. If you flip another 10 pages, though, you find a section called Driveline Working Angles Adjustment.

If you flip another 10 pages, though, you find a section called Driveline Working Angles Adjustment.

So, it seems to me that if you're using a stock driveshaft with the pinion flange adapter, then you could add/remove shims at the carrier bearing and/or adjust the bushings at the pinion in order to adjust the working angle of the driveshaft U-joint. If you're using a different driveshaft, then of course the adjustments would be different.

The driveshaft replacement procedure doesn't mention the shims at all. But in the front portion of the driveshaft section of the FSM there's troubleshooting guidance for assorted noises. Under "Shudder on Acceleration at Low Speed (CTSV)" [which I realize isn't really what most people are experiencing, but I don't see anything anywhere in the procedure about high speed vibrations] it says "Determine if the driveline angle is incorrect and correct as necessary. Refer to Diagnostic Starting Point - Vibration Diagnosis and Correction on page 0-41 in Vibration Diagnosis and Correction."

The Vibration Diagnosis and Correction section is very extensive - over 60 pages, including diagnostic procedures, vibration theory, etc. Pretty impressive. In the Vibration Analysis - Driveline section, all the way down at step 23 it tells you to measure the propeller shaft angle, "Refer to Driveline Working Angles Measurement on page 0-84."

Although it doesn't specifically say so, that section appears to be written for the V-6 driveshaft, as it tells you to measure the angle of the front and rear portions of the driveshaft, then subtract them to determine the working angle of the U-joint. The V-6 driveshaft has the U-joint in the middle, whereas the V shaft has the U-joint at the rear. (At least, I think that's the case. Right?) The principle would be the same, though, you just would take the measurement at the rear end instead of in the middle of the driveshaft. Anyway, after you determine the working angle it says:

But then it doesn't tell you how to adjust the working angle.

So, it seems to me that if you're using a stock driveshaft with the pinion flange adapter, then you could add/remove shims at the carrier bearing and/or adjust the bushings at the pinion in order to adjust the working angle of the driveshaft U-joint. If you're using a different driveshaft, then of course the adjustments would be different.

The shaft has 3 joints, 2 cvs and one rubber flex disc. Of the 3, the flex disc is going to be the most rigid so that's where I started when I was working with the factory 2 piece.

This procedure on Revshifts website is on the right track although it should be noted that I didn't use calipers (not much room) so I used the eyeball method. Using the carrier bearing mount, I was able to align the flex disc so that it would be in a position to do a minimal amount of work...in other words, the front portion of the driveshaft needs to be aligned with the transmission tailshaft.

Edit: forgot the link to the Revshift site....http://www.revshift.com/Articles.asp?ID=253

By definition, the CVs on the other end of the shaft should, to an extent, be able to function properly even if they aren't working at the same angles. After I finally got the flex disc working straight and had Voodoo rebuild the shaft, I didn't have any further issues with the 2 piece when using it with the factory diff.

Now, the part of this conversation I haven't been able to get closure on is how "plunged" should the CVs be to work properly. Obviously, the CS adapter is loading them up more than they were from the factory so how do we know they aren't being overly compressed? Again, we have no spec for this.

Last edited by ls1247; 12-21-2015 at 03:40 PM.

#129

TECH Addict

iTrader: (2)

#130

TECH Addict

iTrader: (19)

Join Date: Aug 2007

Location: Where the Navy tells me to go

Posts: 2,397

Received 106 Likes

on

88 Posts

I was getting mixed up on CVs vs U-joints in my head.

I was getting mixed up on CVs vs U-joints in my head.The shaft has 3 joints, 2 cvs and one rubber flex disc. Of the 3, the flex disc is going to be the most rigid so that's where I started when I was working with the factory 2 piece.

This procedure on Revshifts website is on the right track although it should be noted that I didn't use calipers (not much room) so I used the eyeball method. Using the carrier bearing mount, I was able to align the flex disc so that it would be in a position to do a minimal amount of work...in other words, the front portion of the driveshaft needs to be aligned with the transmission tailshaft.

Edit: forgot the link to the Revshift site....http://www.revshift.com/Articles.asp?ID=253

This procedure on Revshifts website is on the right track although it should be noted that I didn't use calipers (not much room) so I used the eyeball method. Using the carrier bearing mount, I was able to align the flex disc so that it would be in a position to do a minimal amount of work...in other words, the front portion of the driveshaft needs to be aligned with the transmission tailshaft.

Edit: forgot the link to the Revshift site....http://www.revshift.com/Articles.asp?ID=253

Now, the part of this conversation I haven't been able to get closure on is how "plunged" should the CVs be to work properly. Obviously, the CS adapter is loading them up more than they were from the factory so how do we know they aren't being overly compressed? Again, we have no spec for this.

#131

TECH Addict

iTrader: (2)

The other way to go about aligning the engine/tranny and carrier bearing is to bolt the front of the driveshaft directly to the tranny output (no flex disk) and see where that puts the carrier bearing - up or down, left or right. That's what Matt (voodoochikin) suggested I do.

I bought a factory replacement CF 1 piece directly from DSS and I had to EXTEND the CVs to get it bolted into the car. It vibbed a little from day one, got progressively worse and they gave me a full refund at 10k miles. At that point, the CVs were sloppy loose.

I get the DSS 1 piece with the CS kit and you have to compress the hell out of the CVs to get it into the car. So far so good...

The factory driveshaft IIRC, the dirveshaft always seemed to go right in with little to no compression or extension of the CVs. The CVs seemed to be fairly relaxed which is where you might think they should be.

So, I'm guessing CS and DSS have different opinions about CV compression/extension or somebody doesn't have their measurement right. Either way, I'm crossing my fingers for the longevity of all this but take comfort in the excellent customer service both these companies have a reputation for.

Edit: You could always have the adapter turned down a little..

Last edited by ls1247; 12-22-2015 at 10:45 AM.

#132

TECH Addict

iTrader: (4)

Installed my DV8S 8.8 brackets, Cobra diff, DSS axles and GForce 2 piece driveshaft.

RevShift 75d Cradle bushings, RevShift Tranny Insert, RevShift MMs.....

No vibrations up to 85 mph.

I still need to wrap up a few small purchases and get an alignment to do some higher speed testing, but very happy with the results.

RevShift 75d Cradle bushings, RevShift Tranny Insert, RevShift MMs.....

No vibrations up to 85 mph.

I still need to wrap up a few small purchases and get an alignment to do some higher speed testing, but very happy with the results.

Still good to go. Retorqued the Axles and did some nice burnouts.

#133

TECH Addict

iTrader: (19)

Join Date: Aug 2007

Location: Where the Navy tells me to go

Posts: 2,397

Received 106 Likes

on

88 Posts

Here's what puzzles me...

I bought a factory replacement CF 1 piece directly from DSS and I had to EXTEND the CVs to get it bolted into the car. It vibbed a little from day one, got progressively worse and they gave me a full refund at 10k miles. At that point, the CVs were sloppy loose.

I get the DSS 1 piece with the CS kit and you have to compress the hell out of the CVs to get it into the car. So far so good...

The factory driveshaft IIRC, the dirveshaft always seemed to go right in with little to no compression or extension of the CVs. The CVs seemed to be fairly relaxed which is where you might think they should be.

So, I'm guessing CS and DSS have different opinions about CV compression/extension or somebody doesn't have their measurement right. Either way, I'm crossing my fingers for the longevity of all this but take comfort in the excellent customer service both these companies have a reputation for.

I bought a factory replacement CF 1 piece directly from DSS and I had to EXTEND the CVs to get it bolted into the car. It vibbed a little from day one, got progressively worse and they gave me a full refund at 10k miles. At that point, the CVs were sloppy loose.

I get the DSS 1 piece with the CS kit and you have to compress the hell out of the CVs to get it into the car. So far so good...

The factory driveshaft IIRC, the dirveshaft always seemed to go right in with little to no compression or extension of the CVs. The CVs seemed to be fairly relaxed which is where you might think they should be.

So, I'm guessing CS and DSS have different opinions about CV compression/extension or somebody doesn't have their measurement right. Either way, I'm crossing my fingers for the longevity of all this but take comfort in the excellent customer service both these companies have a reputation for.

#137

TECH Addict

iTrader: (4)

That sounds like the stock pinion angle.

Thoughts on CVs; do you mean inner stub, as the CV is bolted to that and the CV does not install into the differential? If so, none really; engagement is full.

They stick out a little, but it has nothing to do with the performance of the vehicle from what I have EXPERIENCED; also doesn't seem to hurt us and others from going 179+ mph in standing mile events and as fast as 9 second quarter mile times.

DSS and others could re-manufacture the inner so there is more material but why; it is almost superficial.

Thoughts on CVs; do you mean inner stub, as the CV is bolted to that and the CV does not install into the differential? If so, none really; engagement is full.

They stick out a little, but it has nothing to do with the performance of the vehicle from what I have EXPERIENCED; also doesn't seem to hurt us and others from going 179+ mph in standing mile events and as fast as 9 second quarter mile times.

DSS and others could re-manufacture the inner so there is more material but why; it is almost superficial.

#139

I don't know how many folks CS has sold the adapter to, or if anyone has any significant mileage on the setup to see what the long-term effects may be.

#140

TECH Enthusiast