Maggied LS6 throttlebody issues

#21

TECH Fanatic

What tensioner are you running?

You going to this? http://www.ctsvowners.com/forum/51-m...rs-coffee.html

You going to this? http://www.ctsvowners.com/forum/51-m...rs-coffee.html

#22

TECH Enthusiast

Thread Starter

What tensioner are you running?

You going to this? http://www.ctsvowners.com/forum/51-m...rs-coffee.html

You going to this? http://www.ctsvowners.com/forum/51-m...rs-coffee.html

I'll try and make it to C&C. It'll be fun to hang with you guys.

#23

So in my rush to clean up the vac lines I mistakenly Tee'd the two PCV lines into the vac port on the driver side of the Snout....Whoops. This resulted in a fantastic oily smoke show from the tail pipes. lol.

I fixed it by buying a 3/8" Heater hose fitting with 1/4" NPT thread , cutting down the length of the PCV hose and drilled a hole into the Maggie intake tube. All is well now!

Haven't taken it to tuner yet so idle is still a bit bouncy. Hopefully after the holiday weekend he'll be able to get me in.

I fixed it by buying a 3/8" Heater hose fitting with 1/4" NPT thread , cutting down the length of the PCV hose and drilled a hole into the Maggie intake tube. All is well now!

Haven't taken it to tuner yet so idle is still a bit bouncy. Hopefully after the holiday weekend he'll be able to get me in.

#24

...

My Bypass valve was also hooked up to a small sensor looking thing on the firewall that has a wire going to the magnavolt. It also had a vac line going from the 78mm snout back to the sensor, and another vac line going to the bypass valve. My tuner and I found that whatever that thing is was actually preventing the bypass to open at idle causing the supercharger to make some excellent rock crushing noise. pushing the bypass valve manually made the noise go away. So when I started re-routing things for the 90mm conversion I eliminated that "sensor thing" and just put a direct vac line from the bypass to the snout. Idles good and sounds normal now. Since I did this though I definitely need to get it re-tuned as it surges off throttle then eventually stabilizes. minor stuff, but overall great success.

Next step is to delete the maggie fuel return loop hose and plug the stock fuel line into the opposite side of fuel manifold (needs to be drilled out) and plug other end with an oring'd fitting.

My Bypass valve was also hooked up to a small sensor looking thing on the firewall that has a wire going to the magnavolt. It also had a vac line going from the 78mm snout back to the sensor, and another vac line going to the bypass valve. My tuner and I found that whatever that thing is was actually preventing the bypass to open at idle causing the supercharger to make some excellent rock crushing noise. pushing the bypass valve manually made the noise go away. So when I started re-routing things for the 90mm conversion I eliminated that "sensor thing" and just put a direct vac line from the bypass to the snout. Idles good and sounds normal now. Since I did this though I definitely need to get it re-tuned as it surges off throttle then eventually stabilizes. minor stuff, but overall great success.

Next step is to delete the maggie fuel return loop hose and plug the stock fuel line into the opposite side of fuel manifold (needs to be drilled out) and plug other end with an oring'd fitting.

Do you have pictures of the "sensor thing" you removed? Might be able to identify it for you.

If the behavior of the car/idle changed when you changed those vacuum lines you either had un-metered air (air leak) to the engine before and fixed it or you didn't before and now you caused it.

Regarding the Magnuson fuel cross over - does your car have two cross over lines, one at the back and one at the front. If so make sure you keep both. Do not use just one. The original Magnuson kits had only one cross over and they had a fuel rail pulsation problem that causes erratic fuel trims at certain injector pulse widths/firing intervals. The second cross over line was done to fix that (and it did).

#25

TECH Fanatic

iTrader: (6)

So you disabled the Magnavolt or do you still have boost going to the Magnavolt? Don't disable the Magnavolt.

Do you have pictures of the "sensor thing" you removed? Might be able to identify it for you.

If the behavior of the car/idle changed when you changed those vacuum lines you either had un-metered air (air leak) to the engine before and fixed it or you didn't before and now you caused it.

Regarding the Magnuson fuel cross over - does your car have two cross over lines, one at the back and one at the front. If so make sure you keep both. Do not use just one. The original Magnuson kits had only one cross over and they had a fuel rail pulsation problem that causes erratic fuel trims at certain injector pulse widths/firing intervals. The second cross over line was done to fix that (and it did).

Do you have pictures of the "sensor thing" you removed? Might be able to identify it for you.

If the behavior of the car/idle changed when you changed those vacuum lines you either had un-metered air (air leak) to the engine before and fixed it or you didn't before and now you caused it.

Regarding the Magnuson fuel cross over - does your car have two cross over lines, one at the back and one at the front. If so make sure you keep both. Do not use just one. The original Magnuson kits had only one cross over and they had a fuel rail pulsation problem that causes erratic fuel trims at certain injector pulse widths/firing intervals. The second cross over line was done to fix that (and it did).

I didnt like that at all and ran a aero Y-block with equal length lines to the rear of both rails with retaining the front crossover. .. -8 lines from the block to rails for now and my fuel pressure has stabilized over the old set up. Havent messed with the car much lately but gonna run -8.. From tank and -6 from a reg.

I honestly believe the magnavolt doesnt ramp the voltage correctly and causes a slight cavitation at the rails from the sudden 18 volts ive seen it throw at the pump the instant im over 4lbs lol... Which is even at part throttle on my dumb extreme over driven set up.

Once i changed the stock maggie fuel feed to what i have the initial shock i was seeing was slightly diminished but still caused cavitation. I know my set up is prolly extreme and know and plan on the full return but guys that are less prone to riding the ragged edge might benefit from a simple line upgrade/y-block. What is your experience is what im getting at?

#26

How would the ramping of the Magnavolt cause cavitation at the rails? How are you determining you are having cavitation (maybe we should define cavitation first so we are all on the same page as to what it is)?

Cavitation:

Source, American Heritage dictionary:

The single input into the side of the rail and then the cross over and the front and back is a perfectly good solution. A Y-block isn't any better. The fairly large diameter rails at pressure provide fairly good reservoir/damping of the momentary fuel demand changes.

No value at all in equal length lines after a Y.

Been able to run much more power than the any of the Eaton blowers can produce with a dead-headed fuel system and the OEM size fuel lines so I don't see the need to replumb your fuel system. Likely a waste of money for a less reliable system.

If you are really worried about it get a high quality pressure transducer (or a few of them) and a data acquisition system and log fuel pressure multiple locations at the rail (left and right/front and back etc) under WOT and transitions. Log AFR and fuel trims (ST and LT) at the same time and see if a correlation exists. Probably cost you less than replumbing the fuel system and then you have the equipment and the knowledge to do it on the next vehicle too.

Cavitation:

Source, American Heritage dictionary:

The sudden formation and collapse of low-pressure bubbles in liquids by means of mechanical forces, such as those resulting from rotation of a marine propeller.

Source, Wiki:Cavitation is the formation of vapour cavities in a liquid – i.e. small liquid-cavitation-free zones ("bubbles" or "voids") – that are the consequence of cavitational forces acting upon the cavitational liquid. It usually occurs when a liquid is subjected to rapid changes of pressure that cause the formation of cavities where the pressure is relatively low. When subjected to higher pressure, the voids implode and can generate an intense shockwave.

If anything a sudden spike in voltage would cause a sudden increase in pump speed that would result in a sudden rush of fuel that would result in a spike in fuel pressure since the regulator would not have time to fully compensate for the increased pressure. You are less likely to cavitate at high pressure. If cavitation is occuring anywhere it would be on the inlet side of the pump if a high differential pressure (aka vacuum) existed and caused the fuel to vaporize/form fuel vapor bubbles at the inlet to the pump or inside the pump mechanism itself.The single input into the side of the rail and then the cross over and the front and back is a perfectly good solution. A Y-block isn't any better. The fairly large diameter rails at pressure provide fairly good reservoir/damping of the momentary fuel demand changes.

No value at all in equal length lines after a Y.

Been able to run much more power than the any of the Eaton blowers can produce with a dead-headed fuel system and the OEM size fuel lines so I don't see the need to replumb your fuel system. Likely a waste of money for a less reliable system.

If you are really worried about it get a high quality pressure transducer (or a few of them) and a data acquisition system and log fuel pressure multiple locations at the rail (left and right/front and back etc) under WOT and transitions. Log AFR and fuel trims (ST and LT) at the same time and see if a correlation exists. Probably cost you less than replumbing the fuel system and then you have the equipment and the knowledge to do it on the next vehicle too.

Question for you on the topic of the two cross overs and feed on just the center of the passenger rail.

I didnt like that at all and ran a aero Y-block with equal length lines to the rear of both rails with retaining the front crossover. .. -8 lines from the block to rails for now and my fuel pressure has stabilized over the old set up. Havent messed with the car much lately but gonna run -8.. From tank and -6 from a reg.

I honestly believe the magnavolt doesnt ramp the voltage correctly and causes a slight cavitation at the rails from the sudden 18 volts ive seen it throw at the pump the instant im over 4lbs lol... Which is even at part throttle on my dumb extreme over driven set up.

Once i changed the stock maggie fuel feed to what i have the initial shock i was seeing was slightly diminished but still caused cavitation. I know my set up is prolly extreme and know and plan on the full return but guys that are less prone to riding the ragged edge might benefit from a simple line upgrade/y-block. What is your experience is what im getting at?

I didnt like that at all and ran a aero Y-block with equal length lines to the rear of both rails with retaining the front crossover. .. -8 lines from the block to rails for now and my fuel pressure has stabilized over the old set up. Havent messed with the car much lately but gonna run -8.. From tank and -6 from a reg.

I honestly believe the magnavolt doesnt ramp the voltage correctly and causes a slight cavitation at the rails from the sudden 18 volts ive seen it throw at the pump the instant im over 4lbs lol... Which is even at part throttle on my dumb extreme over driven set up.

Once i changed the stock maggie fuel feed to what i have the initial shock i was seeing was slightly diminished but still caused cavitation. I know my set up is prolly extreme and know and plan on the full return but guys that are less prone to riding the ragged edge might benefit from a simple line upgrade/y-block. What is your experience is what im getting at?

#27

TECH Enthusiast

Thread Starter

So you disabled the Magnavolt or do you still have boost going to the Magnavolt? Don't disable the Magnavolt.

Do you have pictures of the "sensor thing" you removed? Might be able to identify it for you.

If the behavior of the car/idle changed when you changed those vacuum lines you either had un-metered air (air leak) to the engine before and fixed it or you didn't before and now you caused it.

Regarding the Magnuson fuel cross over - does your car have two cross over lines, one at the back and one at the front. If so make sure you keep both. Do not use just one. The original Magnuson kits had only one cross over and they had a fuel rail pulsation problem that causes erratic fuel trims at certain injector pulse widths/firing intervals. The second cross over line was done to fix that (and it did).

Do you have pictures of the "sensor thing" you removed? Might be able to identify it for you.

If the behavior of the car/idle changed when you changed those vacuum lines you either had un-metered air (air leak) to the engine before and fixed it or you didn't before and now you caused it.

Regarding the Magnuson fuel cross over - does your car have two cross over lines, one at the back and one at the front. If so make sure you keep both. Do not use just one. The original Magnuson kits had only one cross over and they had a fuel rail pulsation problem that causes erratic fuel trims at certain injector pulse widths/firing intervals. The second cross over line was done to fix that (and it did).

Let me explain how the system was set up, and how it is now.

The s/c bypass valve had a vac line going out of it into some kind of solenoid. The solenoid has another line that plugged into the maggie vac port. in addition to those two vac lines there was a T in one of them that goes off to some round thing bolted to the firewall next to the brake booster (between fender and brake booster). I have no idea what that thing is. Another vac line comes out of the round thing and goes into the top of the solenoid

What was happening was at idle the bypass valve was not opening causing the supercharger to cavitate. It was an awful rock crusher sound at idle. So i bought some vac line and went direct from the maggie vac port to the bypass valve, and now it opens at idle, which has thrown off my idle, because now there is more air and that's what needs the re-tune mostly.

So currently all that solenoid vac lines and round thing vac lines are intact, but not plugged into any vac source. I simppy have the bypass valve plugged into the maggie vac port which is what most pics I've seen of maggie's look like.

My fuel rails have a crossover at the front, and a hardline crossover at the rear of the rails. I wasn't planning on deleting either of them. I'm planning on deleting the fuel line loop and plumb it directly into the fuel rail manifold, instead of going around in a circle.

If anybody has any idea of what this stuff is let me know. (the joy of buying a used modded car)

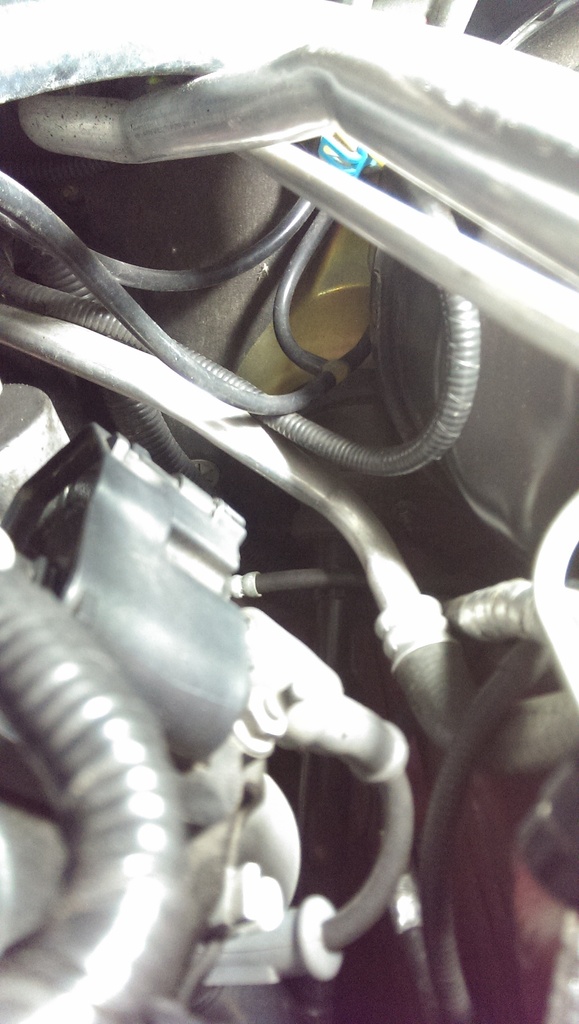

Here is what I think is a bypass valve disable solenoid. There is another, not visible in this pic, vac line that comes out of the top of this and goes to the round thing in pic#3.

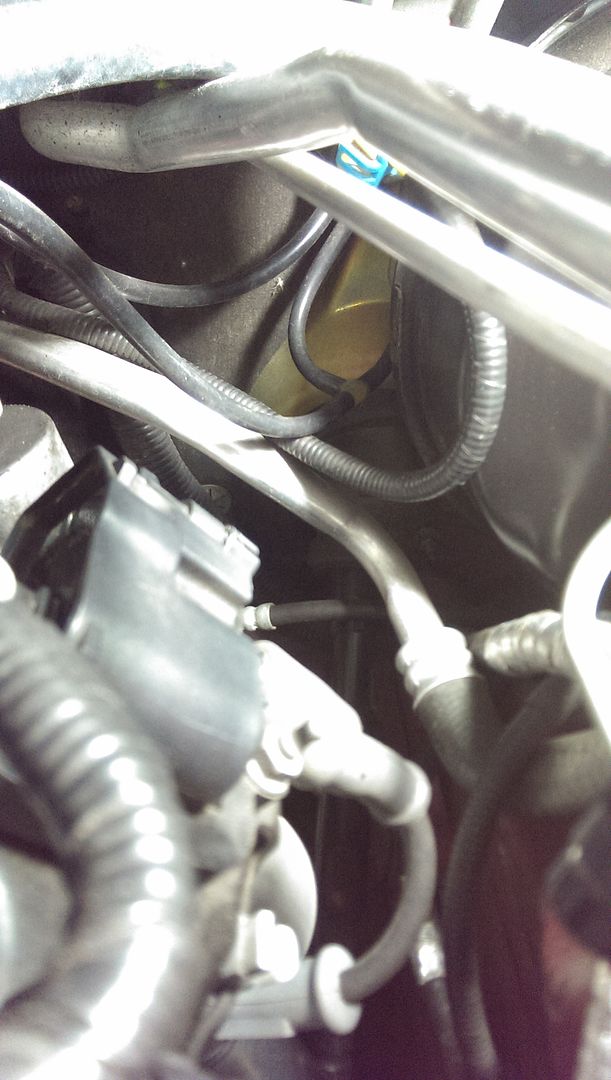

Here is the image of the "Tee"

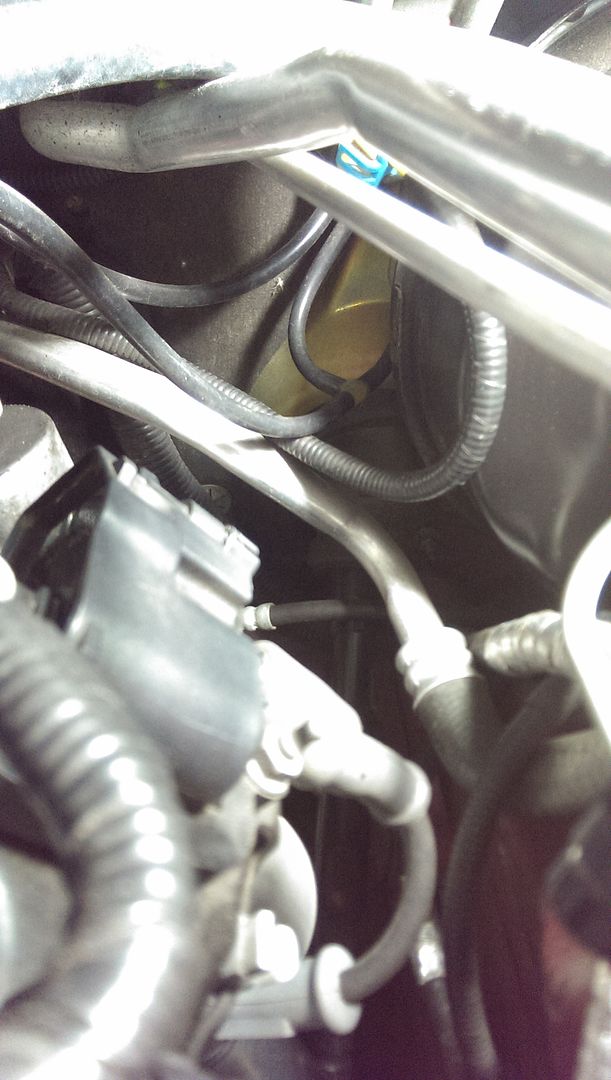

Here is what the T goes into (no idea what this is). The other vac line coming out of this thing goes into the top of the solenoid thing in the first pic.

#28

That appears to be a Lingenfelter RPM based boost bypass. You should have an RPM switch somewhere in the vehicle that is connected to the electronic solenoid wiring. The solenoid is similar to the bypass used on the production LSA and LS9 engines. The canister with the vacuum lines is a vacuum reservoir.

You may also have a valet key somewhere in the vehicle (probably in the center console or glove compartment) tied to the solenoid that disables boost (forces the bypass open), significantly reducing boost/power.

The RPM based boost bypass device is used to keep the supercharger bypass open (not closed) to disable boost below a certain RPM even when you go to wide open throttle. The switch point is usually set at around 1800-2200 RPM. Vacuum from behind the throttle blade normally is what controls the bypass actuator and opens the bypass. When you go to wide open throttle the amount of vacuum in the inlet before the supercharger (before the throttle) is reduced significantly. Without vacuum acting on the bypass actuator, the bypass valve closes and now the air has to go through the supercharger, generating airflow and boost. When the bypass valve is open, the supercharger doesn't generate nearly as much airflow (and on Eaton/Roots type blower makes little to no boost).

The reason the bypass control is used is that on many stock compression engines when running positive displacement superchargers (Eaton/Whipple etc) you can make too much airflow/boost/cylinder pressure at low rpm and have to reduce the timing so much that either performance is less than it was without the boost and/or combustion becomes unstable. This is especially a problem on manual transmission vehicles where you can be at full load at 1600 rpm (and automatic will usually downshift or at least unlock the torque converter).

The supercharger isn't cavitating when the bypass valve is open or closed. The term cavitation doesn't really apply to the airflow at the inlet of a supercharger. The supercharger is just not generating the airflow/boost when the bypass is open. The bypass is doing what it was designed to do (reduce airflow/boost and therefore reducing supercharger load and heat when driver demand doesn't require the additional power).

You may also have a valet key somewhere in the vehicle (probably in the center console or glove compartment) tied to the solenoid that disables boost (forces the bypass open), significantly reducing boost/power.

The RPM based boost bypass device is used to keep the supercharger bypass open (not closed) to disable boost below a certain RPM even when you go to wide open throttle. The switch point is usually set at around 1800-2200 RPM. Vacuum from behind the throttle blade normally is what controls the bypass actuator and opens the bypass. When you go to wide open throttle the amount of vacuum in the inlet before the supercharger (before the throttle) is reduced significantly. Without vacuum acting on the bypass actuator, the bypass valve closes and now the air has to go through the supercharger, generating airflow and boost. When the bypass valve is open, the supercharger doesn't generate nearly as much airflow (and on Eaton/Roots type blower makes little to no boost).

The reason the bypass control is used is that on many stock compression engines when running positive displacement superchargers (Eaton/Whipple etc) you can make too much airflow/boost/cylinder pressure at low rpm and have to reduce the timing so much that either performance is less than it was without the boost and/or combustion becomes unstable. This is especially a problem on manual transmission vehicles where you can be at full load at 1600 rpm (and automatic will usually downshift or at least unlock the torque converter).

The supercharger isn't cavitating when the bypass valve is open or closed. The term cavitation doesn't really apply to the airflow at the inlet of a supercharger. The supercharger is just not generating the airflow/boost when the bypass is open. The bypass is doing what it was designed to do (reduce airflow/boost and therefore reducing supercharger load and heat when driver demand doesn't require the additional power).

I didn't disable the magnavolt.

Let me explain how the system was set up, and how it is now.

The s/c bypass valve had a vac line going out of it into some kind of solenoid. The solenoid has another line that plugged into the maggie vac port. in addition to those two vac lines there was a T in one of them that goes off to some round thing bolted to the firewall next to the brake booster (between fender and brake booster). I have no idea what that thing is. Another vac line comes out of the round thing and goes into the top of the solenoid

What was happening was at idle the bypass valve was not opening causing the supercharger to cavitate. It was an awful rock crusher sound at idle. So i bought some vac line and went direct from the maggie vac port to the bypass valve, and now it opens at idle, which has thrown off my idle, because now there is more air and that's what needs the re-tune mostly.

So currently all that solenoid vac lines and round thing vac lines are intact, but not plugged into any vac source. I simppy have the bypass valve plugged into the maggie vac port which is what most pics I've seen of maggie's look like.

My fuel rails have a crossover at the front, and a hardline crossover at the rear of the rails. I wasn't planning on deleting either of them. I'm planning on deleting the fuel line loop and plumb it directly into the fuel rail manifold, instead of going around in a circle.

If anybody has any idea of what this stuff is let me know. (the joy of buying a used modded car)

Here is what I think is a bypass valve disable solenoid. There is another, not visible in this pic, vac line that comes out of the top of this and goes to the round thing in pic#3.

Here is the image of the "Tee"

Here is what the T goes into (no idea what this is). The other vac line coming out of this thing goes into the top of the solenoid thing in the first pic.

Let me explain how the system was set up, and how it is now.

The s/c bypass valve had a vac line going out of it into some kind of solenoid. The solenoid has another line that plugged into the maggie vac port. in addition to those two vac lines there was a T in one of them that goes off to some round thing bolted to the firewall next to the brake booster (between fender and brake booster). I have no idea what that thing is. Another vac line comes out of the round thing and goes into the top of the solenoid

What was happening was at idle the bypass valve was not opening causing the supercharger to cavitate. It was an awful rock crusher sound at idle. So i bought some vac line and went direct from the maggie vac port to the bypass valve, and now it opens at idle, which has thrown off my idle, because now there is more air and that's what needs the re-tune mostly.

So currently all that solenoid vac lines and round thing vac lines are intact, but not plugged into any vac source. I simppy have the bypass valve plugged into the maggie vac port which is what most pics I've seen of maggie's look like.

My fuel rails have a crossover at the front, and a hardline crossover at the rear of the rails. I wasn't planning on deleting either of them. I'm planning on deleting the fuel line loop and plumb it directly into the fuel rail manifold, instead of going around in a circle.

If anybody has any idea of what this stuff is let me know. (the joy of buying a used modded car)

Here is what I think is a bypass valve disable solenoid. There is another, not visible in this pic, vac line that comes out of the top of this and goes to the round thing in pic#3.

Here is the image of the "Tee"

Here is what the T goes into (no idea what this is). The other vac line coming out of this thing goes into the top of the solenoid thing in the first pic.

#29

TECH Enthusiast

Thread Starter

That appears to be a Lingenfelter RPM based boost bypass. You should have an RPM switch somewhere in the vehicle that is connected to the electronic solenoid wiring. The solenoid is similar to the bypass used on the production LSA and LS9 engines. The canister with the vacuum lines is a vacuum reservoir.

You may also have a valet key somewhere in the vehicle (probably in the center console or glove compartment) tied to the solenoid that disables boost (forces the bypass open), significantly reducing boost/power.

The RPM based boost bypass device is used to keep the supercharger bypass open (not closed) to disable boost below a certain RPM even when you go to wide open throttle. The switch point is usually set at around 1800-2200 RPM. Vacuum from behind the throttle blade normally is what controls the bypass actuator and opens the bypass. When you go to wide open throttle the amount of vacuum in the inlet before the supercharger (before the throttle) is reduced significantly. Without vacuum acting on the bypass actuator, the bypass valve closes and now the air has to go through the supercharger, generating airflow and boost. When the bypass valve is open, the supercharger doesn't generate nearly as much airflow (and on Eaton/Roots type blower makes little to no boost).

The reason the bypass control is used is that on many stock compression engines when running positive displacement superchargers (Eaton/Whipple etc) you can make too much airflow/boost/cylinder pressure at low rpm and have to reduce the timing so much that either performance is less than it was without the boost and/or combustion becomes unstable. This is especially a problem on manual transmission vehicles where you can be at full load at 1600 rpm (and automatic will usually downshift or at least unlock the torque converter).

The supercharger isn't cavitating when the bypass valve is open or closed. The term cavitation doesn't really apply to the airflow at the inlet of a supercharger. The supercharger is just not generating the airflow/boost when the bypass is open. The bypass is doing what it was designed to do (reduce airflow/boost and therefore reducing supercharger load and heat when driver demand doesn't require the additional power).

You may also have a valet key somewhere in the vehicle (probably in the center console or glove compartment) tied to the solenoid that disables boost (forces the bypass open), significantly reducing boost/power.

The RPM based boost bypass device is used to keep the supercharger bypass open (not closed) to disable boost below a certain RPM even when you go to wide open throttle. The switch point is usually set at around 1800-2200 RPM. Vacuum from behind the throttle blade normally is what controls the bypass actuator and opens the bypass. When you go to wide open throttle the amount of vacuum in the inlet before the supercharger (before the throttle) is reduced significantly. Without vacuum acting on the bypass actuator, the bypass valve closes and now the air has to go through the supercharger, generating airflow and boost. When the bypass valve is open, the supercharger doesn't generate nearly as much airflow (and on Eaton/Roots type blower makes little to no boost).

The reason the bypass control is used is that on many stock compression engines when running positive displacement superchargers (Eaton/Whipple etc) you can make too much airflow/boost/cylinder pressure at low rpm and have to reduce the timing so much that either performance is less than it was without the boost and/or combustion becomes unstable. This is especially a problem on manual transmission vehicles where you can be at full load at 1600 rpm (and automatic will usually downshift or at least unlock the torque converter).

The supercharger isn't cavitating when the bypass valve is open or closed. The term cavitation doesn't really apply to the airflow at the inlet of a supercharger. The supercharger is just not generating the airflow/boost when the bypass is open. The bypass is doing what it was designed to do (reduce airflow/boost and therefore reducing supercharger load and heat when driver demand doesn't require the additional power).

Cavitating is probably the wrong word, more like chattering with the lobes vibrating due to the fact that at idle my bypass is closed with the vac lines hooked up to that system and making boost.

The guy I bought the car from told me that this was a sub control ****, but that the previous owner had removed the sub. Could this be the RPM adjustment??

hmm...I wonder where the boost limiter switch could be? I'm going to have to trace some wires when I get some free time.

#30

No, that isn't the RPM adjustment. The RPM switch will likely be in the engine compartment somewhere or in the back of the glove compartment. It will either be an MSD RPM activated switch with an external RPM "pill" on the side that indicates the RPM switch point or it will be a Lingenfelter RPM switch (RPM-001 or RPM-002) with dials on the face you adjust with a screw driver.

The valet mode switch would be inside the vehicle and would be a small key switch usually mounted inside the glove compartment or center console.

BTW - I didn't know what the device in your picture below was either so I just Google'd it and it is a stereo amplifier adjustment device, probably used to control the volume when an external device like a iPod or similar was connected to the vehicle.

Here is a link to some product info (more can easily be found online):

http://www.pac-audio.com/productDeta...&CategoryID=28

The valet mode switch would be inside the vehicle and would be a small key switch usually mounted inside the glove compartment or center console.

BTW - I didn't know what the device in your picture below was either so I just Google'd it and it is a stereo amplifier adjustment device, probably used to control the volume when an external device like a iPod or similar was connected to the vehicle.

Here is a link to some product info (more can easily be found online):

http://www.pac-audio.com/productDeta...&CategoryID=28

Interesting.....

Cavitating is probably the wrong word, more like chattering with the lobes vibrating due to the fact that at idle my bypass is closed with the vac lines hooked up to that system and making boost.

The guy I bought the car from told me that this was a sub control ****, but that the previous owner had removed the sub. Could this be the RPM adjustment??

hmm...I wonder where the boost limiter switch could be? I'm going to have to trace some wires when I get some free time.

Cavitating is probably the wrong word, more like chattering with the lobes vibrating due to the fact that at idle my bypass is closed with the vac lines hooked up to that system and making boost.

The guy I bought the car from told me that this was a sub control ****, but that the previous owner had removed the sub. Could this be the RPM adjustment??

hmm...I wonder where the boost limiter switch could be? I'm going to have to trace some wires when I get some free time.

#31

The RPM switch could likely be traced by finding the tachometer signal wire in your ECM/PCM harness. The RPM switch is likely connected to that to get an RPM signal. The RPM switch is also connected to that solenoid you showed in an earlier picture so you could follow those wires to.

#33

TECH Enthusiast

Thread Starter

Thanks guys.

Looks like I have some wiring investigation to do tomorrow.

I looked up the Pac-1 too and it definitely looks like it was for the trunk sub that was previously in the car before I got it as I found all wires coming from it running to the trunk area.

The search continues....

Looks like I have some wiring investigation to do tomorrow.

I looked up the Pac-1 too and it definitely looks like it was for the trunk sub that was previously in the car before I got it as I found all wires coming from it running to the trunk area.

The search continues....

#34

TECH Enthusiast

Thread Starter

*small update*

LS6 TB with stock V rear

476/451 @ wheels

LS2 90mm TB with 8.8 3.73 rear

484/459 @ wheels

So +8 whp and + 8ft-lbs @ the wheels with the TB. I've heard that the 8.8 sucks a few extra ponies compared to the stock getrag, so overall it's exactly where I thought it would be. I left the Lingenfelter switch stuff disconnected since it is not operating correctly. I'll most likely be taking it out of the car permanently.

Phil did a great job on the tune. The car runs great now and he was able to improve the bucking I was experiencing on decel since owning this car throughout all the mods and improve between shift fueling to make the tip-in and out's smoother.

Thanks for all the help guys.

LS6 TB with stock V rear

476/451 @ wheels

LS2 90mm TB with 8.8 3.73 rear

484/459 @ wheels

So +8 whp and + 8ft-lbs @ the wheels with the TB. I've heard that the 8.8 sucks a few extra ponies compared to the stock getrag, so overall it's exactly where I thought it would be. I left the Lingenfelter switch stuff disconnected since it is not operating correctly. I'll most likely be taking it out of the car permanently.

Phil did a great job on the tune. The car runs great now and he was able to improve the bucking I was experiencing on decel since owning this car throughout all the mods and improve between shift fueling to make the tip-in and out's smoother.

Thanks for all the help guys.