Anyone ever make their harness from scratch?

#1

Staging Lane

Thread Starter

Join Date: Nov 2008

Location: Central NJ

Posts: 91

Likes: 0

Received 0 Likes

on

0 Posts

I will be getting a harness with my motor but have been told it was cut in order to remove the motor. Not know how bad until I obtain it, I was curious if anyone has fixed a damaged/cut harness before or even made one from scratch?

I am pretty decent with wiring and figure I should be able to modify a harness in decent shape, but not sure how much effort it would take if I had to actually purchase wire and run a good part of it from scratch myself.

I am pretty decent with wiring and figure I should be able to modify a harness in decent shape, but not sure how much effort it would take if I had to actually purchase wire and run a good part of it from scratch myself.

#2

The trouble I would see is buying all the different color wire needed to do the job correctly. Most places have minimum orders, so you would end up buying a **** load more wire than you would use. For a shop that expects to do multiple harnesses no problem. In this sense modifying a factory harness, or even splicing together two harnesses, is the cheapest option.

Beyond that it doesn't seem too hard to me either.

Beyond that it doesn't seem too hard to me either.

#4

Staging Lane

Thread Starter

Join Date: Nov 2008

Location: Central NJ

Posts: 91

Likes: 0

Received 0 Likes

on

0 Posts

The trouble I would see is buying all the different color wire needed to do the job correctly. Most places have minimum orders, so you would end up buying a **** load more wire than you would use. For a shop that expects to do multiple harnesses no problem. In this sense modifying a factory harness, or even splicing together two harnesses, is the cheapest option.

Beyond that it doesn't seem too hard to me either.

Beyond that it doesn't seem too hard to me either.

Out of a newer van. Like I said, the harness may not have been butchered that bad, but knowing my luck it will be a complete mess.

#5

TECH Junkie

iTrader: (9)

Its very doable but its also just as easy to start with a factory harness and go. Pull out all the wires and route as nec then clean up after. Looks cherry if done right. Some great links in this thread to help you out'

https://ls1tech.com/forums/conversio...pe-source.html

https://ls1tech.com/forums/conversio...pe-source.html

#6

From what I hear, the van harnesses are much longer than say a truck harness, I dont know from personal experience but hopefully all your important stuff is intact and you can use it.

Trending Topics

#8

TECH Addict

iTrader: (22)

If they cut it removing it from a van, then they are extremely lazy. The PCM is bolted to the battery tray. Undo that and lay it on the intake and the majority of the wiring is free. The C100 comes off with a 5/16" bolt for newer vans. Rest of the connections are minor and you wont be reusing them anyways so they can be cut or unplugged. Cutting the main harness saves them 5 mins tops and causes you about two days worth of trouble

As long as a cut harness has the majority of the connectors on the intake, coils, crank, cam and trans connectors, the harness is still usable. Any other missing connectors are super common on FWD cars in JYs such as the IAT, MAF, O2s and conversions connectors for dumping DBW like TPS, IAC

If the main harness is cut, then you have no choice but to completely rework it and repair the +140 wires to the PCM and your new chassis

You dont have to use the correct color for the lengthened wires. The signal sent through each could care less about jacket dye color. Just be sure the wire size is the same or larger. LSx engines use 18, 20, 22ga wires depending on the function and load. A single 500' roll of 18ga TXL wire will be more than enough to do the job and can be had for around $30 from numerous suppliers

I posted a detailed how-to on TGO along with a follow-up to clear the most common questions I see people ask

http://www.thirdgen.org/techboard/lt...rt-finish.html

http://www.thirdgen.org/techboard/lt...revisited.html

As long as a cut harness has the majority of the connectors on the intake, coils, crank, cam and trans connectors, the harness is still usable. Any other missing connectors are super common on FWD cars in JYs such as the IAT, MAF, O2s and conversions connectors for dumping DBW like TPS, IAC

If the main harness is cut, then you have no choice but to completely rework it and repair the +140 wires to the PCM and your new chassis

You dont have to use the correct color for the lengthened wires. The signal sent through each could care less about jacket dye color. Just be sure the wire size is the same or larger. LSx engines use 18, 20, 22ga wires depending on the function and load. A single 500' roll of 18ga TXL wire will be more than enough to do the job and can be had for around $30 from numerous suppliers

I posted a detailed how-to on TGO along with a follow-up to clear the most common questions I see people ask

http://www.thirdgen.org/techboard/lt...rt-finish.html

http://www.thirdgen.org/techboard/lt...revisited.html

#12

Where can one get the proper replacement pins for these GM terminals? And a crimper to go with them. There are a few plugs on my harness that will need to be replaced.

Also, Im thinking about getting the remnants of a cut harness and using it to extend any circuits that need it. That way I can get the proper colors. It seems like most of the harnesses in the local u pull it yards are butchered pretty bad, but the extra wire in the proper color would sure be nice.

Also, Im thinking about getting the remnants of a cut harness and using it to extend any circuits that need it. That way I can get the proper colors. It seems like most of the harnesses in the local u pull it yards are butchered pretty bad, but the extra wire in the proper color would sure be nice.

#13

TECH Addict

iTrader: (22)

EFIConnection is the cheapest store that sells PCM terminals along with the tool

Alternative would be any FWD car. 98+ cars used the same PCM connectors and the terminals interchange. Grab the majority of one FWD harness and you should have ample terminals and wire along with some spare sensor connectors

Alternative would be any FWD car. 98+ cars used the same PCM connectors and the terminals interchange. Grab the majority of one FWD harness and you should have ample terminals and wire along with some spare sensor connectors

#14

To do it right, unless you make the harness from scratch, you're going to end up cutting/splicing every wire. I did on my swap, couldn't bring myself to fold the excess lengths to take up the difference. Depending on where you put PCM, some wires will be shortened and others will be lengthened. It doesn't matter what color is in the middle of the ones you lengthen, unless your not going to loom them and your making a show piece. Get yourself a bunch of adhesive lined heat shrink and a good soldering iron, either that or get the solder filled-adhesive shrink splices.

Mine came out of a van as well, all wires came out the driver side of engine which I didn't like. I ended up routing all the connections out the back.

Mine came out of a van as well, all wires came out the driver side of engine which I didn't like. I ended up routing all the connections out the back.

#16

#17

Staging Lane

Thread Starter

Join Date: Nov 2008

Location: Central NJ

Posts: 91

Likes: 0

Received 0 Likes

on

0 Posts

Thanks guys. Since this was from an 08 motor/ecm, I was not sure if there were only certain year harnesses I could use instead if I went to a junk yard. If it is that bad, I will probably look for a clean replacement. Good idea about getting another harness just to have the right colors for extending them.

#18

TECH Addict

iTrader: (22)

If you make one, might as well make a few and sell em for a few hundred.

Sure would be a lot of fun trouble shooting a wiring problem if all 140 of those PCM wires are the same color.

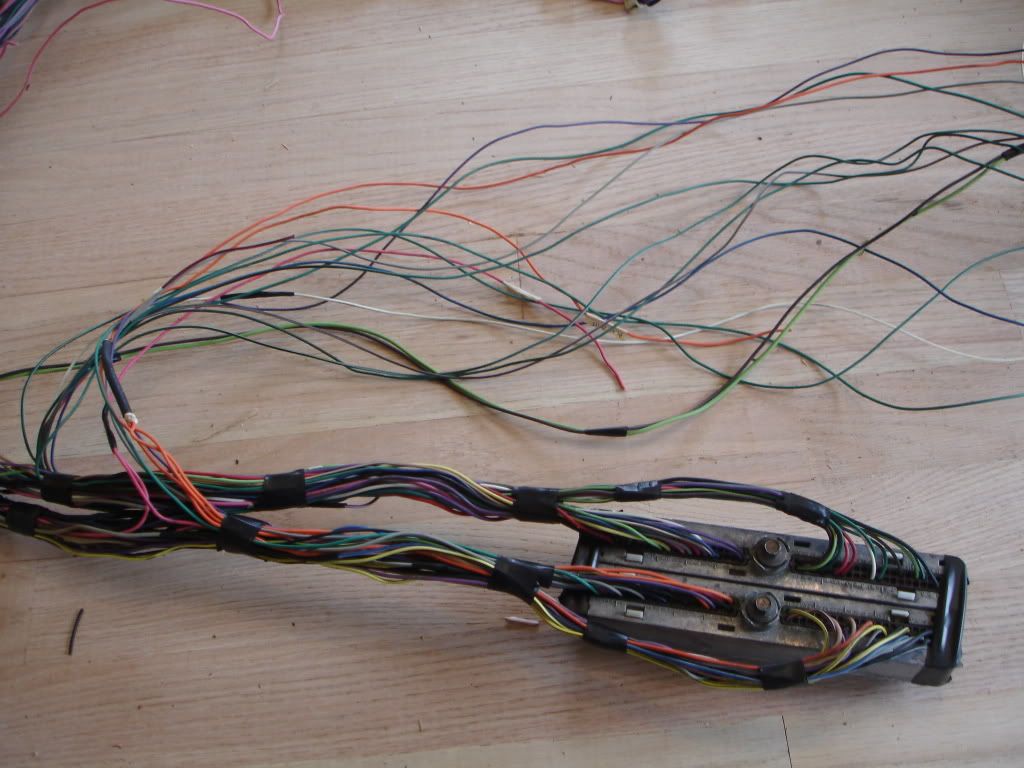

Most of the harnesses I build go through the firewall so only 30-50 wires need a few inches added. The rest get shortened. Truck harnesses are massively long though and even PCM extensions like the pic above can be done with minimal lengths added. IIRC that harness above was set with the PCM 7 feet from the middle of the intake. It is not typical for most swaps

Most look like this

#19

When lengthening harness wires, what are you guys using to splice those small gauge wires together? Most crimp/solder splices are kind of large especially after you add heat shrink tubing over them; or do you simply solder the wires together with a parallel joint, twisted joint, or? Ideas/suggestions/links?

Thanks,

Andy1

Thanks,

Andy1

#20

TECH Addict

iTrader: (22)

For 1:1 splices I strip one wire about 1" and the other about 1/2". Twist them together evenly so the longer stripped wire is twisted for approx 1/2" and still has 1/2" exposed. Fold the twisted section over the bare and coil it around then solder and shrink tube. This gives a secure lock and lots of contact without being very big. Its still larger than the wire, but not excessive

For two into one Tees, I take one longer wire and strip about 3/4" and remove the jacket with a razor blade and use the tip to spread a small loop. The shorter wire I strip approx 1/2" and feed it through the loop and twist together. These are generally VERY tight compared to the standard splice, but tees are uncommon especially on LSx harnesses. LTx harnesses use multiple shared signals for 5v, ground, low refs etc

For two into one Tees, I take one longer wire and strip about 3/4" and remove the jacket with a razor blade and use the tip to spread a small loop. The shorter wire I strip approx 1/2" and feed it through the loop and twist together. These are generally VERY tight compared to the standard splice, but tees are uncommon especially on LSx harnesses. LTx harnesses use multiple shared signals for 5v, ground, low refs etc