69 Nova Build - pumpgas twin turbo 408 LS

#121

And that's why I spent my hard earned money on the aftermarket front subframe - even though the Gen III Nova's have quite a bit of room in the engine bay, it is still difficult to package a twin turbo setup. Especially a budget deal done at home. I hope that I can put together a truck manifold setup that 1. performs well; 2. Looks nice & symetric; 3. fits my budget (maybe that should have been #1). I suppose I could let it sit a year or two while I save up enough to pay a shop to build it, but what fun would that be.

#122

Staging Lane

iTrader: (2)

Join Date: Dec 2010

Location: montgomery, al

Posts: 83

Likes: 0

Received 0 Likes

on

0 Posts

good to see nice quality workmanship coming out of Alabama.

How are you going to integrate the turbine inlet piping from the manifolds? I suggest welding on v-bands like:

I've got a better pic somewhere.

BTW, yall have one of the best drag racing drivers up there in hville

How are you going to integrate the turbine inlet piping from the manifolds? I suggest welding on v-bands like:

I've got a better pic somewhere.

BTW, yall have one of the best drag racing drivers up there in hville

#123

I don't know about my craftsmanship, but I've been able to buy a few nice parts  Looks like you have been spending some quality time with a welder and grinder. Nice sweeping bends - should be minimal flow restrictions in your hot piping. I do plan to add 2-1/2" v-bands to my truck manifolds. Probably will order a couple of them this week. Bring that Volvo up to Huntsville Dragway when you get it done. I would love to check it out.

Looks like you have been spending some quality time with a welder and grinder. Nice sweeping bends - should be minimal flow restrictions in your hot piping. I do plan to add 2-1/2" v-bands to my truck manifolds. Probably will order a couple of them this week. Bring that Volvo up to Huntsville Dragway when you get it done. I would love to check it out.

#124

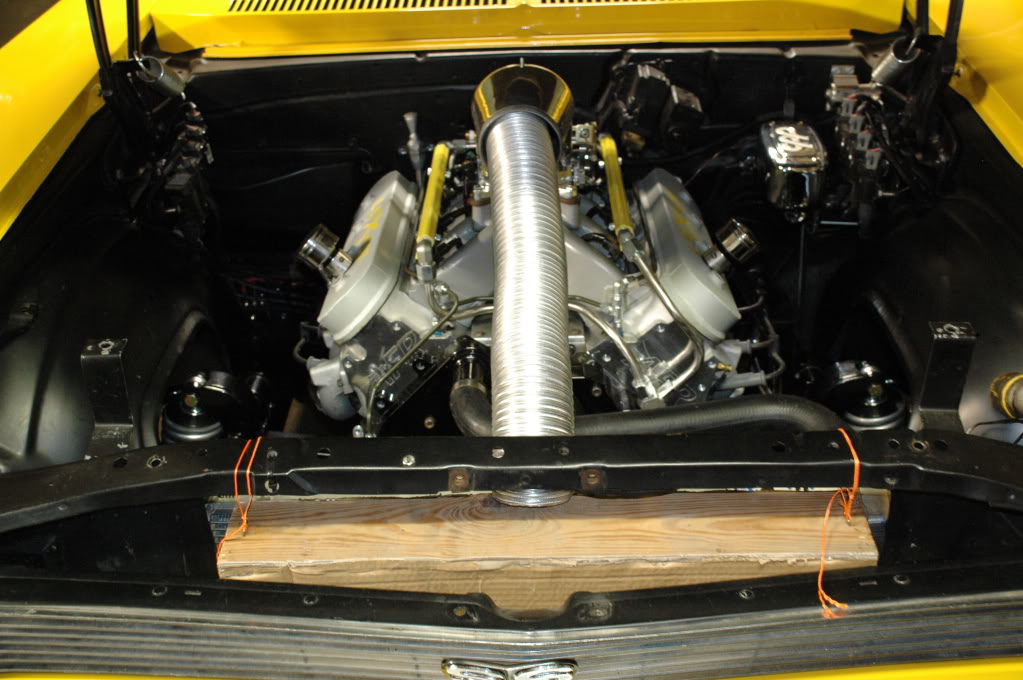

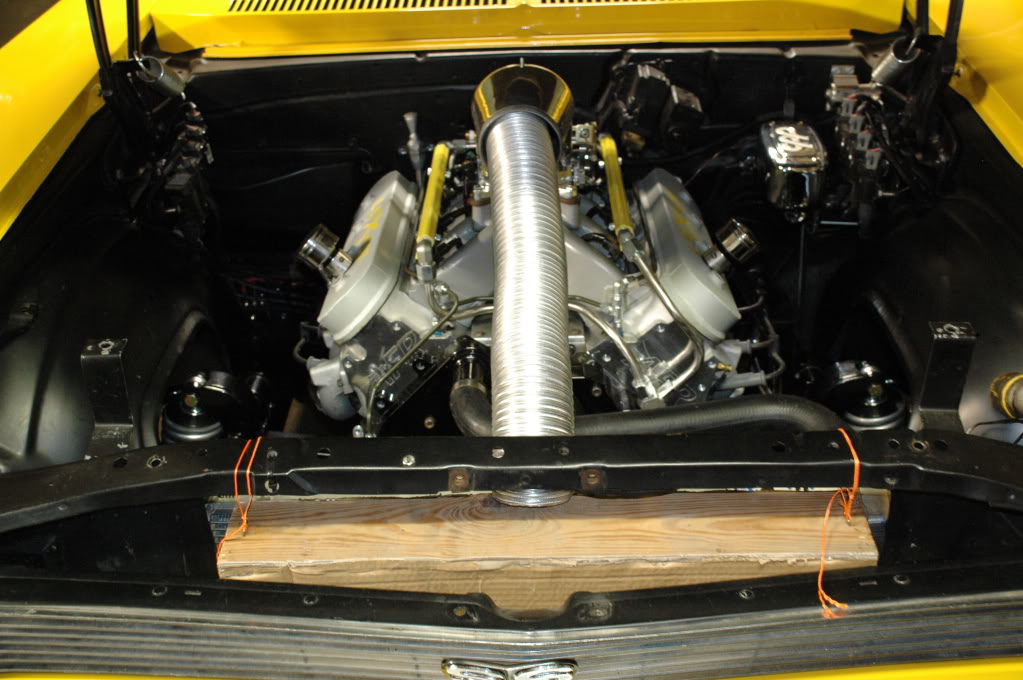

Last night I started mock-up of a Treadstone TRTTC9 air-to-air intercooler in front of my radiator. What do you all think about having a center outlet to the throttle body hat vs two side outlets curved around the radiator and merging in front of the hat? If I go with the center outlet it will require dropping the radiator and modifying the top of the radiator support, but both of those changes are easy enough. This gives a pretty clean look with minimal flow direction changes.

#128

Launching!

iTrader: (5)

Join Date: Mar 2004

Location: Chippewa Falls, WI

Posts: 292

Likes: 0

Received 0 Likes

on

0 Posts

nice! the quality seems pretty good on the treadstone stuff. I have the single top to bottom end tank one and i am pleased with it so far, even though i have not used it yet( still building stages)

#129

Well, Treadstone failed to get me the parts while I was off work for a week, but I finally got them last night. It looks like with a little clearance work on the radiator support I will be able to install the TRTTC9 intercooler 2" forward (toward the grill) of the radiator support. With 2½" silicon 90° bends on the intercooler inlets and a 3" silicon 90° on the outlet it should even clear my old Griffin radiator.

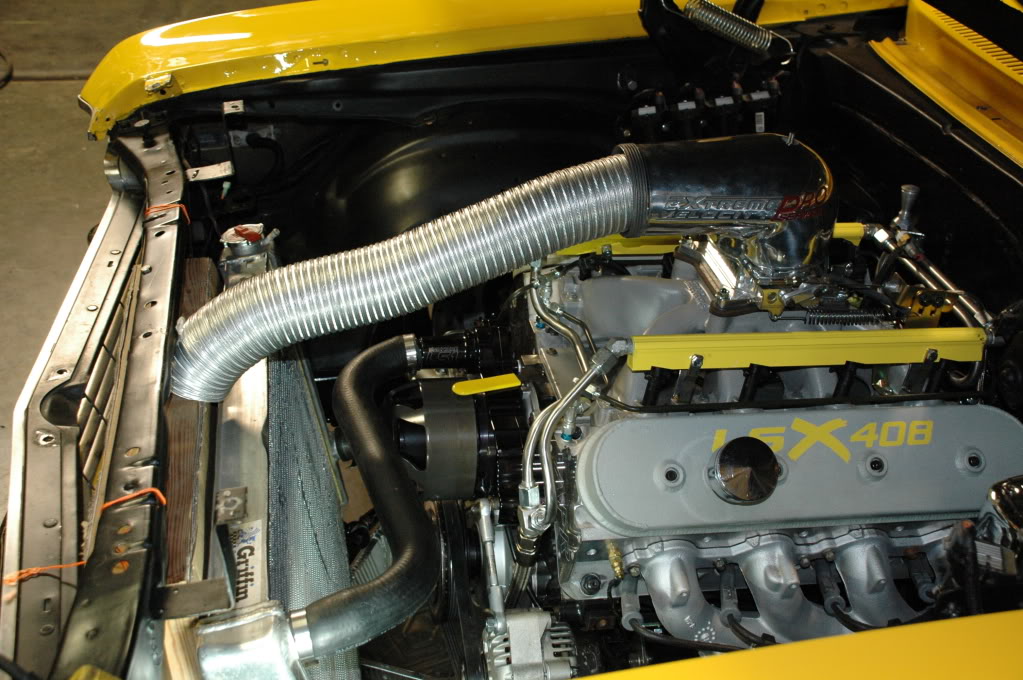

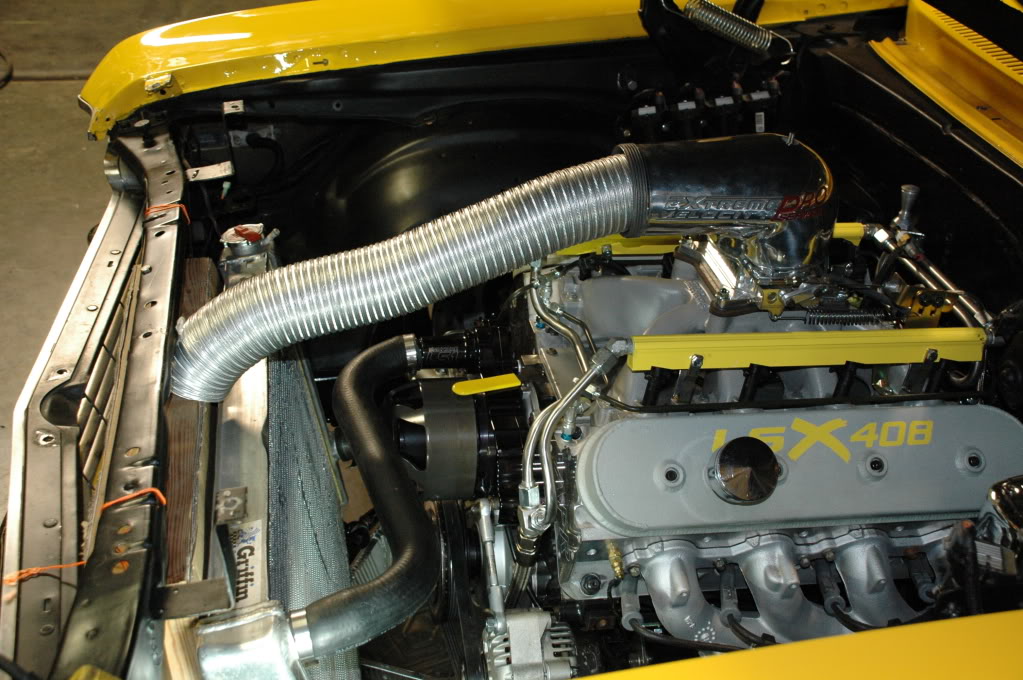

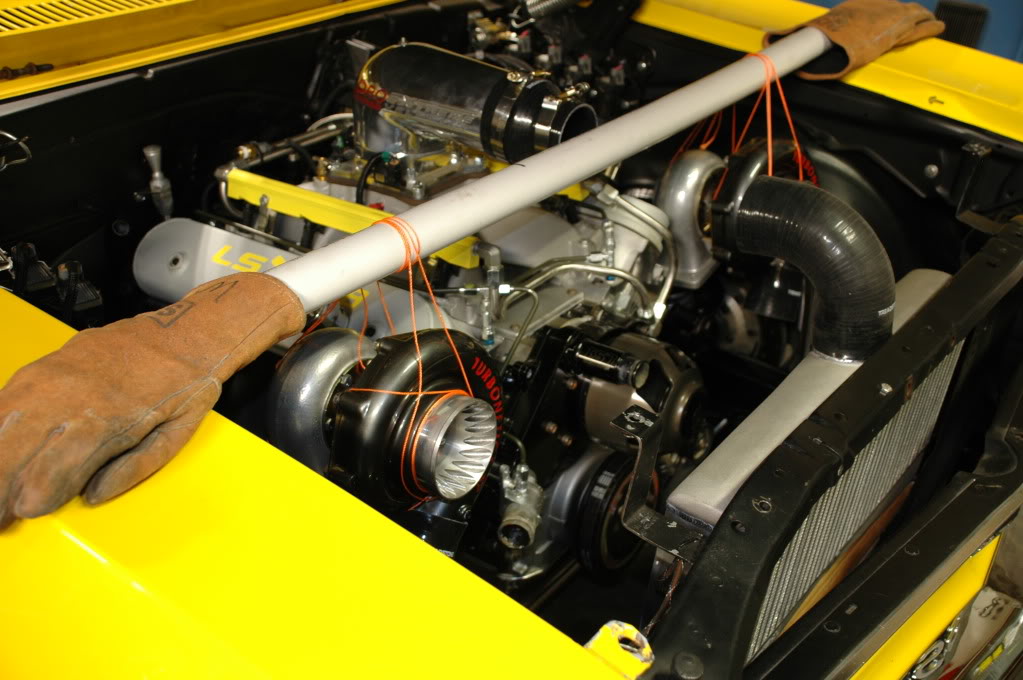

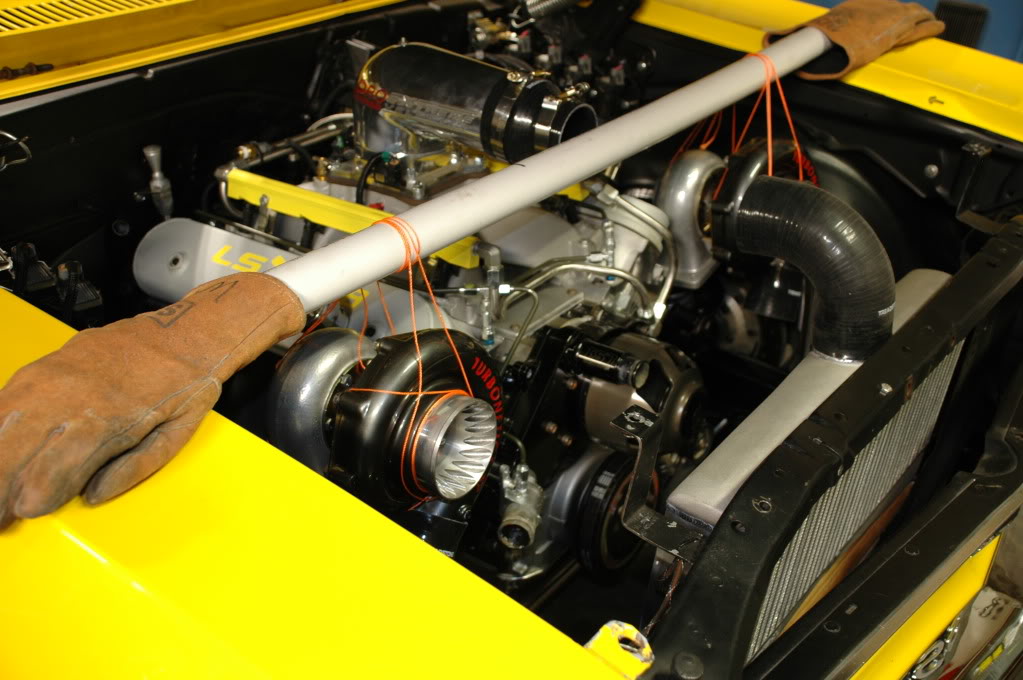

Over Christmas holiday I finalized the location of the turbos and started the hot-side plumbing. After spending several hours on each truck manifold to smooth off the castings and cut off the flanges, I abandoned them. They were placing the turbos too far forward. I found in my case the C6 manifolds turned forward and down made a very easy 180° turn right into the T4 flange using a mandrel bent 180°. The driver's side will be tricky to work around my steering shaft - I'll have to add another u-joint. And the down pipe on the driver's side will be pretty tight. Other than that, everything lays out very nice and simple. Here is a conceptual picture of placement. The passenger side turbo inlet is the only pipe connected at this point. I need to make turbo supports and get rid of the PVC support... Feels really good to finally make some forward progress.

A slight miter cut helps roll the 180° mandrel bend up to the T4 flange:

Over Christmas holiday I finalized the location of the turbos and started the hot-side plumbing. After spending several hours on each truck manifold to smooth off the castings and cut off the flanges, I abandoned them. They were placing the turbos too far forward. I found in my case the C6 manifolds turned forward and down made a very easy 180° turn right into the T4 flange using a mandrel bent 180°. The driver's side will be tricky to work around my steering shaft - I'll have to add another u-joint. And the down pipe on the driver's side will be pretty tight. Other than that, everything lays out very nice and simple. Here is a conceptual picture of placement. The passenger side turbo inlet is the only pipe connected at this point. I need to make turbo supports and get rid of the PVC support... Feels really good to finally make some forward progress.

A slight miter cut helps roll the 180° mandrel bend up to the T4 flange:

#134

I agree with you LSCustoms - these forums are great for motivation and collecting ideas/knowledge. It can be tough to keep motivated on a long term project. I've tried to keep it as a hobby, work on it when I can, and not feel guilty when I don't. But after 2 years it's time to step up the pace a little.

I made a little AutoCAD drawing for my cold air piping into the TB hat. I need to dog-leg up 2" in the 12" span between the IC and the hat. It looks like a pair of 18° mandrel bends separated by 4-13/16" of 3" pipe with 2¼" of straight pipe on each end will accomplish it. If I get the opportunity here at work I might plot out a full size drawing and mock it up in paper before mis-cutting the aluminum pipe.

I made a little AutoCAD drawing for my cold air piping into the TB hat. I need to dog-leg up 2" in the 12" span between the IC and the hat. It looks like a pair of 18° mandrel bends separated by 4-13/16" of 3" pipe with 2¼" of straight pipe on each end will accomplish it. If I get the opportunity here at work I might plot out a full size drawing and mock it up in paper before mis-cutting the aluminum pipe.

#135

TECH Regular

iTrader: (7)

Mr. C looking good bud. Seems as if you are getting closer each day. I got my heads back from Patriot last Friday. Just waiting on ( 1 ) final piece before the H/C/I sway ( CAM ). Give me a call, I've got a lead on a swap meet Jan 20~21 in Nashville. I'am going to try to pick me up a 6.0 block and build it instead of the 5.7.

Eric

Eric

#139

You guys are a lot more kind than my local forum bunch. I've been catching a lot of crap about "helping hands" with the welding gloves and PVC pipe supporting the turbos. I'll probably be doing a C5 clutch swap this weekend for a friend, but I just might have to put him off so I can work on the Nova.

I'll give you a call on the swap meet Eric. That would be a good road trip together.

I'll give you a call on the swap meet Eric. That would be a good road trip together.

#140

Pretty content with my progress this weekend. Basically I just got the intercooler installed, but it took quite a bit of fabrication to get there. I had to cut the bottom off the radiator support, notch the corners of the radiator support for the IC inlets, and trim the inner fenders. Then I had to fab a filler panel to close the radiator support around the IC and a couple little close-out plates for where I cut the radiator support. I also received some more mandrel bends from Columbia River this week. Two 18° 3" aluminum bends will connect the IC to the TB hat and two 90° 2½" bends will connect each turbo to the IC. And the cool thing is - the hood still closes. Lastly I rigged up a couple supports for the turbos to get rid of the "helping hands". Now it's time to finish up the hot piping to the passenger turbo, and then move on the the more difficult driver's side. I did take a step or two back though - my old Griffin radiator is 1½" too wide and my 6" clearance between the IC and water pump will need new electric cooling fan(s). McCarthy warned me that the silicon elbows will blow off once I start turning up the boost, but I'll keep them for now. Later I can weld up some better aluminum elbows. On to some pictures:

The compressed air lines from turbos to IC look like they will be simple with maybe just one weld to extend the horizontal leg.

The compressed air lines from turbos to IC look like they will be simple with maybe just one weld to extend the horizontal leg.

Last edited by Chevy406; 01-16-2012 at 03:50 PM.