AWD operation - Front Diff (Open vs. LSD)

#1

Okay, I canít believe Iím even making this thread, but Iím looking converting my car over to AWD. Just to give an idea of power range the car has run high 9ís at 145 on slicks. So Iím trying to build a setup that will work in the 900 whp range with sticky tires for street/strip use. This isnít the build thread (yet) so Iím not going to into details. Instead Iím interested in hearing thoughts on the type of front diff to use as this will determine a lot.

What Iím really struggling with is that most front differentials are open diffs and not LSDís. Iíve googled a lot of AWD launch videoís and the majority of them are poor Ė usually with spinning front tires. Iím concerned this has a lot to do with utilizing an open front diff.

First, the two transfer cases that seem to have the greatest potential are:

-Syclone/GM van viscous coupling T-case

-TBSS Torsen center diff

The syclone T-case gives a constant torque split which seems like it would work poorly with an open front diff. If/when a front tire decides to spin, the open diff will send most of the front axle torque to that wheel, and the wheel with traction will get little/no torque. In a hard launch situation, Iím envisioning this working more like a 3-wheel drive.

With the TBSS center diff, my understanding that when a front wheel begins to spin, the Torsen will start biasing torque more to the rear. This seems like it will work Ďokayí in theory, but you will still be limited by the front wheel with the least tractive capability.

Ideally, having the Torsen center and a true LSD in the front (like a truetrac or equivalent) would be the way to go. However, it is just about impossible to find a Ďcar sizedí front diff with an LSD.

Suggestions/comments? Would the open diff and Torsen center diff work well enough? It would just suck to go through this monumental effort and have something that canít pull 1.5 60í times on the street because of a poor front diff choice.

What Iím really struggling with is that most front differentials are open diffs and not LSDís. Iíve googled a lot of AWD launch videoís and the majority of them are poor Ė usually with spinning front tires. Iím concerned this has a lot to do with utilizing an open front diff.

First, the two transfer cases that seem to have the greatest potential are:

-Syclone/GM van viscous coupling T-case

-TBSS Torsen center diff

The syclone T-case gives a constant torque split which seems like it would work poorly with an open front diff. If/when a front tire decides to spin, the open diff will send most of the front axle torque to that wheel, and the wheel with traction will get little/no torque. In a hard launch situation, Iím envisioning this working more like a 3-wheel drive.

With the TBSS center diff, my understanding that when a front wheel begins to spin, the Torsen will start biasing torque more to the rear. This seems like it will work Ďokayí in theory, but you will still be limited by the front wheel with the least tractive capability.

Ideally, having the Torsen center and a true LSD in the front (like a truetrac or equivalent) would be the way to go. However, it is just about impossible to find a Ďcar sizedí front diff with an LSD.

Suggestions/comments? Would the open diff and Torsen center diff work well enough? It would just suck to go through this monumental effort and have something that canít pull 1.5 60í times on the street because of a poor front diff choice.

#2

TECH Apprentice

iTrader: (6)

I think I would go with the TBSS transfer case and try to use a locker in the front differential. Keep it open for street use and just lock it in if you need to launch hard. Since I don't know what you are putting it in I have no idea what will work but have you thought of the TBSS front diff that mounts to the pan and has the shaft run through the pan?

#3

I think I would go with the TBSS transfer case and try to use a locker in the front differential. Keep it open for street use and just lock it in if you need to launch hard. Since I don't know what you are putting it in I have no idea what will work but have you thought of the TBSS front diff that mounts to the pan and has the shaft run through the pan?

I purposely didn't mention the car this was going in - to avoid the inevitable "it won't fit", "it's going to be so expensive", "give up now" type of comments. It's going to require a new front subframe anyways, so I can kinda make things fit (to a point).

I have given a lot of thought to the TBSS front diff. I know I could probably make that work. However, it is small and so i'm not sure how it would like repeated 1.5 60ft times in a 3700 lb car. There are also no LSD options for this diff.

I've actually been pondering the 8.25" IFS diff out of the 1500 series trucks (no LSD options) or the 9.25" IFS diff (which has LSD options). They have 3.73 or 3.46 ratio's available which is also a necessity. My concern is that the 9.25" is too big, and that the 8.25" might be too weak. Though, it's hard to judge that as I only really hear about them breaking in off-roading/rock crawling type situations.

#4

TECH Apprentice

iTrader: (6)

What if you used a rpm switch for the locker? In essence if you hit a certain rpm it would engage on its own.

I think any of the front diffs on the street will be more than capable of handling the power. You have to remember you are splitting the power between the front and rear so even at 900hp you would at most be throwing 450hp to the front. Also you are in a much lighter vehicle than what those front diffs were designed for. And on top of that you are getting weight transfer to the rear. I think your transmission is going to suffer more than anything.

I had a AWD Denali truck running 9lbs of boost on a supercharger and I never had any problems with the drivetrain except the trans.

I think any of the front diffs on the street will be more than capable of handling the power. You have to remember you are splitting the power between the front and rear so even at 900hp you would at most be throwing 450hp to the front. Also you are in a much lighter vehicle than what those front diffs were designed for. And on top of that you are getting weight transfer to the rear. I think your transmission is going to suffer more than anything.

I had a AWD Denali truck running 9lbs of boost on a supercharger and I never had any problems with the drivetrain except the trans.

#5

I think the 2500 series truck front diff (9.25" I think) is your best bet. It might be physically big but you said you were going to have to redesign the front subframe anyway.....I think that is the front diff parish8 put in his twin turbo 408 1500 truck that was nearly running 9s.

#6

What if you used a rpm switch for the locker? In essence if you hit a certain rpm it would engage on its own.

I think any of the front diffs on the street will be more than capable of handling the power. You have to remember you are splitting the power between the front and rear so even at 900hp you would at most be throwing 450hp to the front. Also you are in a much lighter vehicle than what those front diffs were designed for. And on top of that you are getting weight transfer to the rear. I think your transmission is going to suffer more than anything.

I had a AWD Denali truck running 9lbs of boost on a supercharger and I never had any problems with the drivetrain except the trans.

I think any of the front diffs on the street will be more than capable of handling the power. You have to remember you are splitting the power between the front and rear so even at 900hp you would at most be throwing 450hp to the front. Also you are in a much lighter vehicle than what those front diffs were designed for. And on top of that you are getting weight transfer to the rear. I think your transmission is going to suffer more than anything.

I had a AWD Denali truck running 9lbs of boost on a supercharger and I never had any problems with the drivetrain except the trans.

I have to ask this question: I assume your truck had an open front diff? How did it perform in a hard launch? In the rain, how did the truck respond during too much throttle from a dig?

I think the 2500 series truck front diff (9.25" I think) is your best bet. It might be physically big but you said you were going to have to redesign the front subframe anyway.....I think that is the front diff parish8 put in his twin turbo 408 1500 truck that was nearly running 9s.

I went ahead and picked up a GM 8.25" for test fitment since it was super cheap. Here's a comparsion between the 8.25 and 9.25.

What I would love to run (from pictures at least) is the following out of a tundra. It's small, and has a Truetrac available for it. However, the lowest ratio available for the toyoto 7.5" IFS diffs is 4.11.

Last edited by FSAE_Junkie; 11-26-2012 at 08:58 PM.

#7

TECH Apprentice

iTrader: (6)

Now my truck at that time was probably only making 450 to 500hp and it weighed just under 6000lbs so with lighter weight and double the hp I'm sure your results will be different. I believe the reason I had a transmission failure was because my truck hooked so the trans took all the abuse.

Trending Topics

#9

TECH Apprentice

iTrader: (1)

Join Date: Aug 2008

Location: Va Beach

Posts: 304

Likes: 0

Received 0 Likes

on

0 Posts

No ralation to your thread, but I saw your screen name and that you were involved with FSAE. I started a thread on another website for all FSAE such as myself to check in. I'll start one here too!

#10

My truck would bark pretty hard on a good launch but would otherwise hook fairly well. In the rain if you mashed on it hard especially while turning you could feel the truck loose traction for a fraction of a second but the transfer case with the viscous coupling would then transfer the power to the wheels that weren't slipping. I guess I could best describe it as doing a little dance through the curve but at no time would it be out of control. The earlier trucks didn't have traction control either so it wouldn't pull the power, just transfer it to the other wheels. Oh and yes I had an open diff in the front.

Now my truck at that time was probably only making 450 to 500hp and it weighed just under 6000lbs so with lighter weight and double the hp I'm sure your results will be different. I believe the reason I had a transmission failure was because my truck hooked so the trans took all the abuse.

Now my truck at that time was probably only making 450 to 500hp and it weighed just under 6000lbs so with lighter weight and double the hp I'm sure your results will be different. I believe the reason I had a transmission failure was because my truck hooked so the trans took all the abuse.

My fear was that that if one front tire spun, all the front 38% torque would get sent to the spinning wheel - essentially throwing away all your front axle traction/torque.

Ha, you should do that. 4 years of FSAE was the best experience I could have asked for. It's largely what gives me the confidence to attempt something like I'm suggesting. I remember engineering differential housings for our car which is something I've contemplated here, but we didn't have to deal with a ring and pinion! They're a little bit more finicky than a chain drive.

#11

TECH Apprentice

iTrader: (6)

Well, that's what I was hoping to hear. The reason I was asking about rain performance as it would be comparable to a higher hp car on dry pavement. You mention a viscous coupling, my understanding of which is that it sends a constant torque split to each axle. I thought a true center differential was needed in order for it to start biasing torque more towards one axle or another?

My fear was that that if one front tire spun, all the front 38% torque would get sent to the spinning wheel - essentially throwing away all your front axle traction/torque.

My fear was that that if one front tire spun, all the front 38% torque would get sent to the spinning wheel - essentially throwing away all your front axle traction/torque.

You could really feel it in my 01 truck. Launching it in a turn in the rain would make the rear slip and you would feel rear of the truck start to slide out but at the same instant the front would grab and the rear would settle down, then the front would slip and the rear would grab. It really felt like a little dance but at no time did the truck completely break traction or get out of control nor would you lose your line through the curve. All of this was at WOT without lifting.

In my previous truck which was 2WD and less power I would have completely spun around with a total loss of control in that same situation.

I really think that with a LSD in the rear and an open diff in the front you will be fine unless you start lifting the front wheel in hard turns on a road course. I'm not really sure what it would do in that situation. And as previously stated a locker in the front would be great for straight line launches but leave it unlocked for road courses.

#12

Staging Lane

iTrader: (1)

Join Date: Dec 2006

Location: Oakville, Ct

Posts: 55

Likes: 0

Received 0 Likes

on

0 Posts

Pardon me for asking, but if you have 500 hp going into the transfer case and it splits the power evenly to the front and rear output shaft. how are you only getting 250 to each diff? By that theory arent you only getting 125 to each wheel? If I use your math then my car with one driveshaft but two halfshafts makes twice the HP that I thought it did.

Back to the original post... if you want a real locker for the front diff, look into an OX-locker. They are cable operated so you dont have to do wiring or wait for the oil can to heat up and engauge the other axle shaft (GM style diff). Lockers are not good for front end applications unless used on loose surfaces.

A limited slip and a Torsen work similar. The LSD is clutch type and allows good steering. The Torsen is gear driven and functions well in fronts also.

Hope it helps... best of luck with the project.

Back to the original post... if you want a real locker for the front diff, look into an OX-locker. They are cable operated so you dont have to do wiring or wait for the oil can to heat up and engauge the other axle shaft (GM style diff). Lockers are not good for front end applications unless used on loose surfaces.

A limited slip and a Torsen work similar. The LSD is clutch type and allows good steering. The Torsen is gear driven and functions well in fronts also.

Hope it helps... best of luck with the project.

#13

I need a gauge for that

iTrader: (37)

My little stock 8.25" with 250k on it hasnt complained any, and I probably have 100 passes on it this summer. Truck weighs about 5000lb with me in it, and makes close to the 1krwhp mark. This was on some really shitty shocks (hence the bouncing). I think I can get 1.39s out of it.

Keep in mind with a 4wd you do not want weight transfer, so set your suspension accordingly and lifting the front becomes less of an issue.

Keep in mind with a 4wd you do not want weight transfer, so set your suspension accordingly and lifting the front becomes less of an issue.

Last edited by Atomic; 11-28-2012 at 12:09 AM.

#14

Launching!

iTrader: (5)

Join Date: Mar 2004

Location: Chippewa Falls, WI

Posts: 292

Likes: 0

Received 0 Likes

on

0 Posts

I wouldn't worry too much about the front diff breaking, there are a decent amount of fast syty's with stock front diffs and axles (stock CV's as well) that have lived. A smooth launch and a open diff does help longivity, but even with lockers installed( lockright's) the only issues found were constant ratcheting associated with that style locker.

There are ls swapped trucks, built v6's with 1000+ hp keeping the stock 7.25 diff going. With a fullsize diff I also dont see any issues as well.

There are ls swapped trucks, built v6's with 1000+ hp keeping the stock 7.25 diff going. With a fullsize diff I also dont see any issues as well.

#15

TECH Apprentice

iTrader: (6)

Pardon me for asking, but if you have 500 hp going into the transfer case and it splits the power evenly to the front and rear output shaft. how are you only getting 250 to each diff? By that theory arent you only getting 125 to each wheel? If I use your math then my car with one driveshaft but two halfshafts makes twice the HP that I thought it did.

#16

On The Tree

Well, that's what I was hoping to hear. The reason I was asking about rain performance as it would be comparable to a higher hp car on dry pavement. You mention a viscous coupling, my understanding of which is that it sends a constant torque split to each axle. I thought a true center differential was needed in order for it to start biasing torque more towards one axle or another?

My fear was that that if one front tire spun, all the front 38% torque would get sent to the spinning wheel - essentially throwing away all your front axle traction/torque.

My fear was that that if one front tire spun, all the front 38% torque would get sent to the spinning wheel - essentially throwing away all your front axle traction/torque.

I am currently building a car with an AWD conversion, and the suspension and wheel hubs you intend to use are also worth investigating while you research this. Since these choices matched with your front diff help determine your cost involved.

For example: Cadillac AWD CTS front hubs + a IRS ford 9" front diff with 5th gen camaro output flanges = custom drive shafts coupling my front hubs to my front diff.... or $$$!

Keep this in mind. I predict custom driveshafts alone will add about $4,000.00 to my over-all build cost.

#17

My little stock 8.25" with 250k on it hasnt complained any, and I probably have 100 passes on it this summer. Truck weighs about 5000lb with me in it, and makes close to the 1krwhp mark. This was on some really shitty shocks (hence the bouncing). I think I can get 1.39s out of it.

Keep in mind with a 4wd you do not want weight transfer, so set your suspension accordingly and lifting the front becomes less of an issue.

Keep in mind with a 4wd you do not want weight transfer, so set your suspension accordingly and lifting the front becomes less of an issue.

It's tough researching truck parts. Inevitably, someone knows somebody in their tube chassiss rock crawler with a 16:1 transfer case and 1000 lb-ft of torque who broke a stock front diff and thus it becomes categorized as a 'glass differential' to everyone else. So then you have a bunch of people in 250 hp trucks talking about how weak said differential is. I digress....

I would also like to note here, the BW 4472 out of the sy/ty's work this way with their viscous coupler set-up. They have a planetary gear set inside them that helps with the torque transfer to the wheels that still have traction.

I am currently building a car with an AWD conversion, and the suspension and wheel hubs you intend to use are also worth investigating while you research this. Since these choices matched with your front diff help determine your cost involved.

For example: Cadillac AWD CTS front hubs + a IRS ford 9" front diff with 5th gen camaro output flanges = custom drive shafts coupling my front hubs to my front diff.... or $$$!

Keep this in mind. I predict custom driveshafts alone will add about $4,000.00 to my over-all build cost.

I am currently building a car with an AWD conversion, and the suspension and wheel hubs you intend to use are also worth investigating while you research this. Since these choices matched with your front diff help determine your cost involved.

For example: Cadillac AWD CTS front hubs + a IRS ford 9" front diff with 5th gen camaro output flanges = custom drive shafts coupling my front hubs to my front diff.... or $$$!

Keep this in mind. I predict custom driveshafts alone will add about $4,000.00 to my over-all build cost.

My plan right now (which may change as I order parts and see them in person), is to use C5 vette rear hubs in the front vette uprights, which I've read is easily done as they have the same bolt pattern. Then to use the stock front LCA from the vette, and a CNC'd upper control arm (it has to be custom so I don't have to chop into the frame).

On the outboard side I'd obviously use part of the C5 CV joints, and on the inboard side, I'd use whatver CV bolts to the diff. This will then just require custom halfshafts going from one set of splines to the other. I've had custom halfshafts made before for $300 each so I'm not too worried about that. Coincidently, I'm actually pulling the trigger on a 4-axis CNC tomorrow, and this project would be a great way to break it in.

You mention using a Ford 9" IRS diff up front. Can you do this just because of how you are situating the engine?

#19

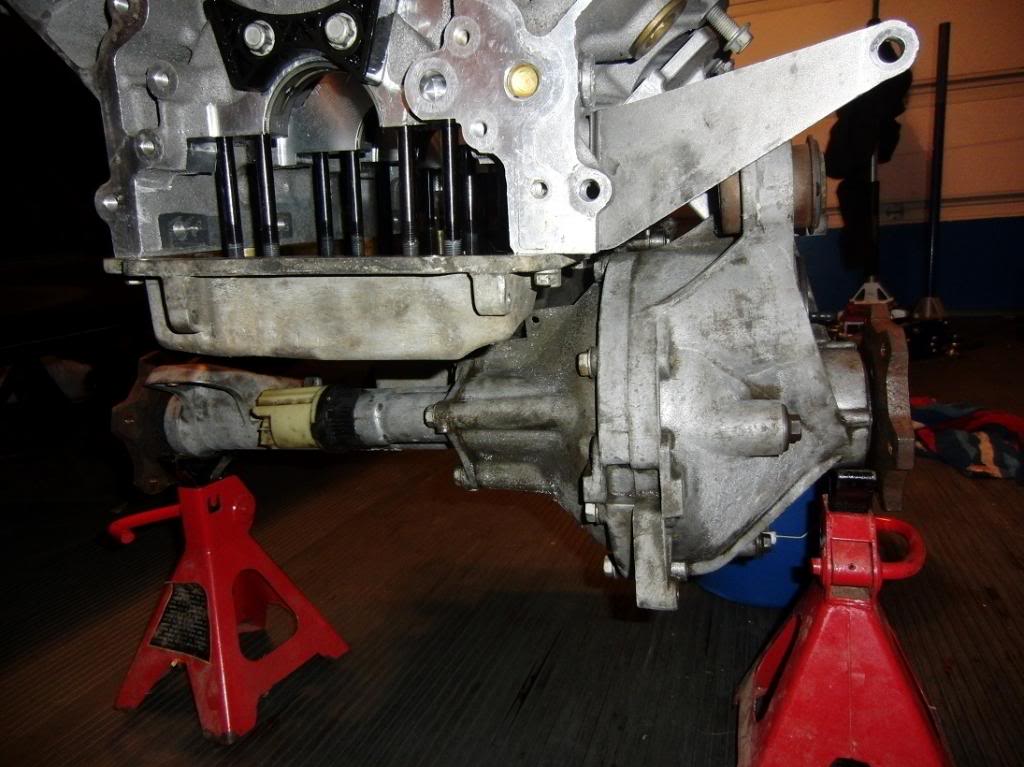

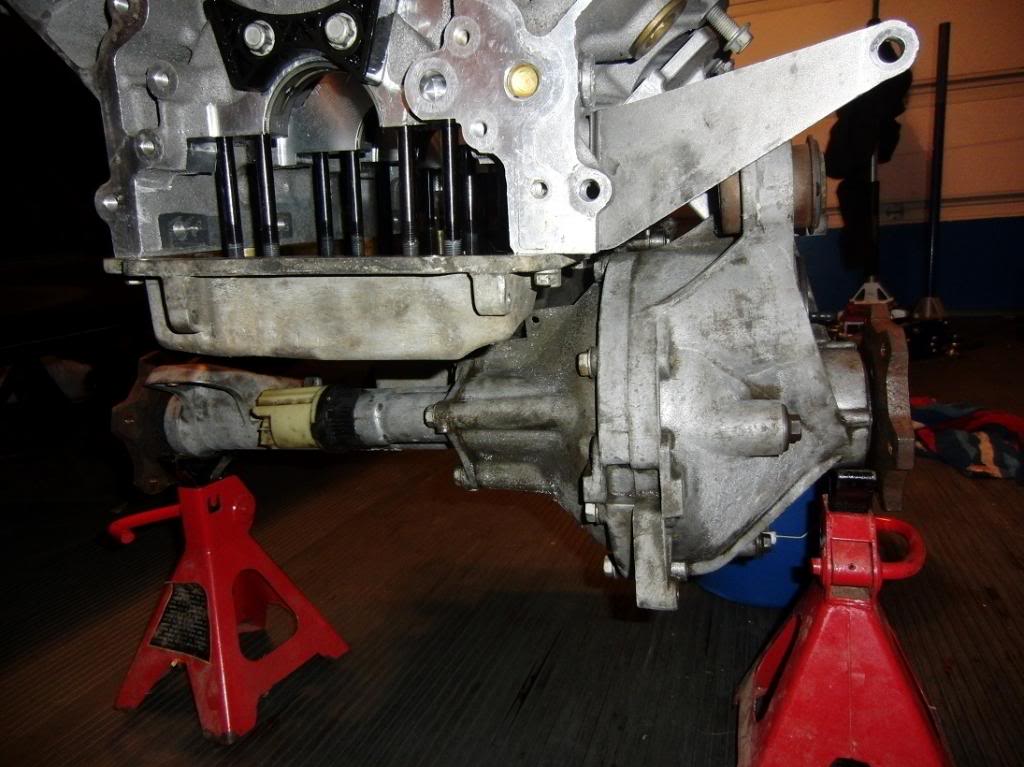

Well, I did a very very preliminary mockup of the 8.25 diff relative to the truck pan I had laying around. I spent a good 7 hours cleaning up the oil pan and diff so I didn't have as much time at the end of the day for lining this up as I would have liked.

You can see in the last picture that if I were to just notch the side of the oil pan a bit, I could move the diff upward a good 2-3 inches. You may also notice that the diff starts to get in the way of the driver side engine mount. I'm either going to have to fabricate a different mount or just relocate the mount all together.

This diff is also a bit heavier than I was hoping. It comes in at about 80.5 lbs. So, my options are to either try and cram the 9.25" up front with a limited slip (and 20 more lbs). OR, what I'm leaning towards is just picking up a 7.25" diff. It will be easier to package, and weigh about 15-20 lbs less. Or hell, if notch the pan this week and this fits well enough, I might just run the 8.25".

Any thoughts?

You can see in the last picture that if I were to just notch the side of the oil pan a bit, I could move the diff upward a good 2-3 inches. You may also notice that the diff starts to get in the way of the driver side engine mount. I'm either going to have to fabricate a different mount or just relocate the mount all together.

This diff is also a bit heavier than I was hoping. It comes in at about 80.5 lbs. So, my options are to either try and cram the 9.25" up front with a limited slip (and 20 more lbs). OR, what I'm leaning towards is just picking up a 7.25" diff. It will be easier to package, and weigh about 15-20 lbs less. Or hell, if notch the pan this week and this fits well enough, I might just run the 8.25".

Any thoughts?

The following users liked this post:

Conley Anderson (01-30-2021)