Brunton M-Spec 1,600 pounds and LS POWER!!

#43

TECH Fanatic

Thread Starter

iTrader: (15)

Join Date: Jun 2006

Location: Janesville WI

Posts: 1,155

Likes: 0

Received 0 Likes

on

0 Posts

Thanks for all the positive feedback guys! I really want to finish this build and get to scaring myself!

We have made a small amount of progress since the last update. We installed the front suspension (again) and plumbed the brake lines:

It feels good to be permanently installing panels as apposed to the mock up stage.

I hope to make some more strides int he next couple days.

We have made a small amount of progress since the last update. We installed the front suspension (again) and plumbed the brake lines:

It feels good to be permanently installing panels as apposed to the mock up stage.

I hope to make some more strides int he next couple days.

#47

TECH Fanatic

Thread Starter

iTrader: (15)

Join Date: Jun 2006

Location: Janesville WI

Posts: 1,155

Likes: 0

Received 0 Likes

on

0 Posts

We've made some more headway, I will try to catch up.

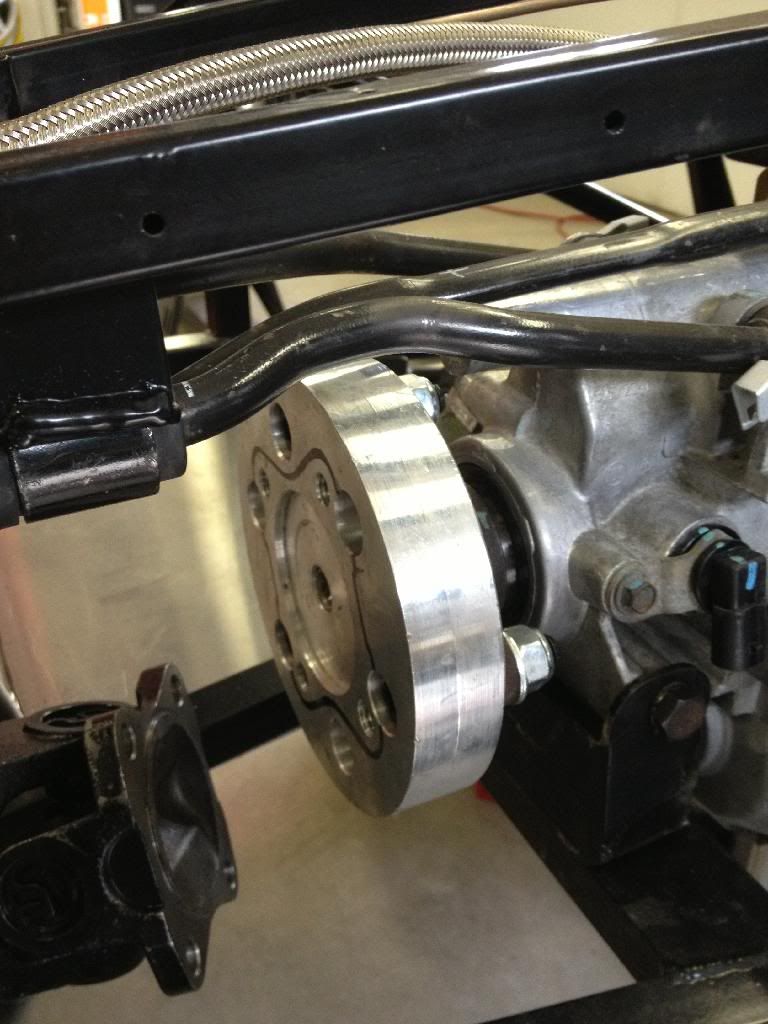

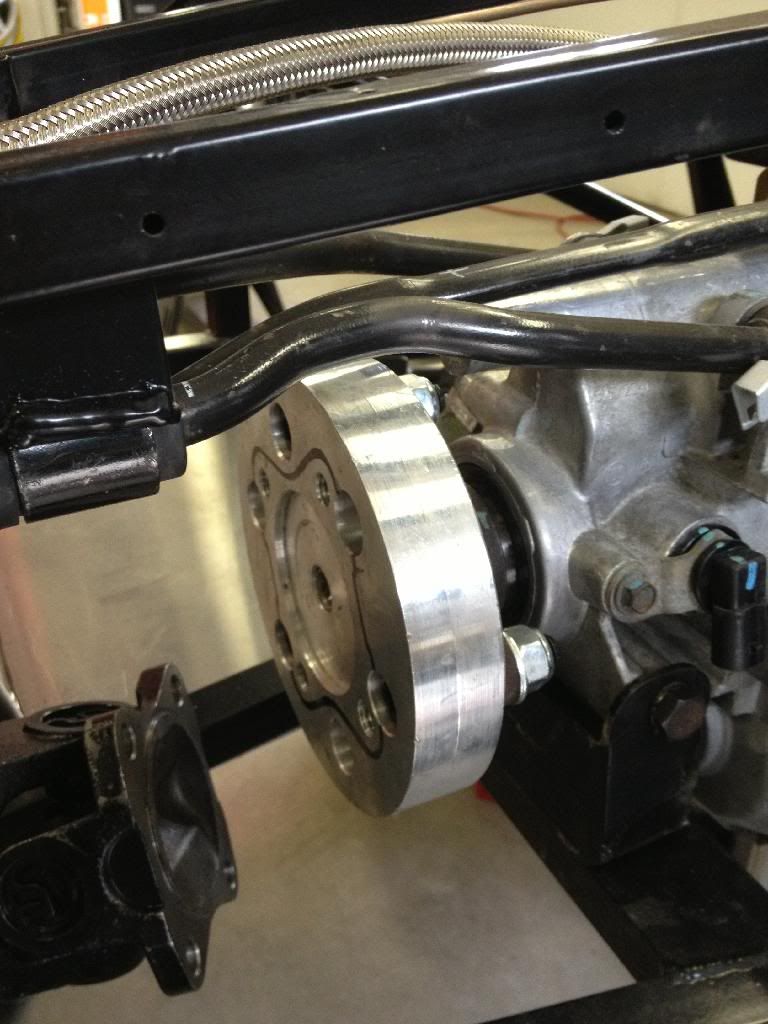

We connected the aftermarket braided clutch lines to a factory style hydraulic throw out bearing (like an 02 Z28). Because I am using a CTS-V T-56, that came this a thicker, dual-mass flywheel, I had to space the through out bearing away from the trans. I used a piece from Katech (they are getting a lot of my $ on this build... ha). Hopefully everything works out, but I wont know for sure until I add fluid to the clutch hydraulics. I am avoiding adding any fluids now, in case things need to come apart again.

I also learned that the CTS-V T56 bell housing is longer than the F-body bell housing. We had to make room for the new hydraulic lines by nothing the CTS-V bell. This was pretty straight forward with the aluminum.

In other trans news, Brunton suggested removing the three bolt flange from the CTS-V T56 so a traditional slip yoke could be used. They also suggested I cut off the alignment dowel. I, wrongly assumed (possibly because I was told...) the output shaft would have the same spline count as an F-body unit, and the F-body rear seal would work if using a slip yoke. Wrong on both counts... The guys at Brunton are working on a custom drive shaft and seal.

I have also since learned the new Camaros also use this three bolt flange. Unfortunately, custom driveshafts are still kind of pricey for the flanges or require adaptors to use more traditional units. So, by converting to slip yoke, hopefully I am saving some money. More on this topic later.

We dropped the engine and trans back in. I finally opened the box for the custom rear CV axles from the Driveshaft shop.

I opted to have some new bearings pressed into the donor Miata rear spindles. I guess that was a good choice as the shop had difficulty getting them together. My rear suspension can now go on.

I noticed the other day that the hubs really fight being turned despite the fact there is no driveshaft connected. I'm guessing that may be the new bearings... Is that normal? I can turn them, but it requires some effort! The diff itself is new, but I couldn't really turn it until the axles were installed. I may have to pull some stuff apart and investigate...

With the engine in, we bolted up a header, and made up the steering linkage. This was big for me. I can now sit in the car, shift the trans, work the pedals (except accelerator, which isn't in yet) and turn the wheels!!

I picked up a pair of front tires and had them mounted up. It is great to see a wheel and tire on the car!

I intend to run a separate wheel/tire combo on the road course (15s and race tires). So, I have been contemplating running 17" drag radials on the back for the street...

I remember reading a few years back how guys were auto-crossing f-bodies on 315 drag radials front and rear (due to lack of availability of good 315s I think). I know the idea of the softer side wall would work against handling but I have a few thoughts on that.

1- This is a very light car so a softer sidewall wont be as big of a deal as a heavier muscle car.

2- I'll be finding 9 and 10/10ths cornering on track, but will likely keep it more civil on the street. And acceleration runs may be the more fun, and safe thing for street driving (and scaring passengers).

3- I will then have my drag combo to drive down to the 1/4 track for kicks.

I would like any feedback on that idea. Especially from guys running DRs on the street, and even more so if in a similarly light car.

I have not yet committed to the idea, but my thought is 275/40/17 drag radials since I already have 17x9" wheels.

We connected the aftermarket braided clutch lines to a factory style hydraulic throw out bearing (like an 02 Z28). Because I am using a CTS-V T-56, that came this a thicker, dual-mass flywheel, I had to space the through out bearing away from the trans. I used a piece from Katech (they are getting a lot of my $ on this build... ha). Hopefully everything works out, but I wont know for sure until I add fluid to the clutch hydraulics. I am avoiding adding any fluids now, in case things need to come apart again.

I also learned that the CTS-V T56 bell housing is longer than the F-body bell housing. We had to make room for the new hydraulic lines by nothing the CTS-V bell. This was pretty straight forward with the aluminum.

In other trans news, Brunton suggested removing the three bolt flange from the CTS-V T56 so a traditional slip yoke could be used. They also suggested I cut off the alignment dowel. I, wrongly assumed (possibly because I was told...) the output shaft would have the same spline count as an F-body unit, and the F-body rear seal would work if using a slip yoke. Wrong on both counts... The guys at Brunton are working on a custom drive shaft and seal.

I have also since learned the new Camaros also use this three bolt flange. Unfortunately, custom driveshafts are still kind of pricey for the flanges or require adaptors to use more traditional units. So, by converting to slip yoke, hopefully I am saving some money. More on this topic later.

We dropped the engine and trans back in. I finally opened the box for the custom rear CV axles from the Driveshaft shop.

I opted to have some new bearings pressed into the donor Miata rear spindles. I guess that was a good choice as the shop had difficulty getting them together. My rear suspension can now go on.

I noticed the other day that the hubs really fight being turned despite the fact there is no driveshaft connected. I'm guessing that may be the new bearings... Is that normal? I can turn them, but it requires some effort! The diff itself is new, but I couldn't really turn it until the axles were installed. I may have to pull some stuff apart and investigate...

With the engine in, we bolted up a header, and made up the steering linkage. This was big for me. I can now sit in the car, shift the trans, work the pedals (except accelerator, which isn't in yet) and turn the wheels!!

I picked up a pair of front tires and had them mounted up. It is great to see a wheel and tire on the car!

I intend to run a separate wheel/tire combo on the road course (15s and race tires). So, I have been contemplating running 17" drag radials on the back for the street...

I remember reading a few years back how guys were auto-crossing f-bodies on 315 drag radials front and rear (due to lack of availability of good 315s I think). I know the idea of the softer side wall would work against handling but I have a few thoughts on that.

1- This is a very light car so a softer sidewall wont be as big of a deal as a heavier muscle car.

2- I'll be finding 9 and 10/10ths cornering on track, but will likely keep it more civil on the street. And acceleration runs may be the more fun, and safe thing for street driving (and scaring passengers).

3- I will then have my drag combo to drive down to the 1/4 track for kicks.

I would like any feedback on that idea. Especially from guys running DRs on the street, and even more so if in a similarly light car.

I have not yet committed to the idea, but my thought is 275/40/17 drag radials since I already have 17x9" wheels.

#49

On The Tree

iTrader: (2)

Join Date: Jun 2011

Location: Nashville, TN

Posts: 170

Likes: 0

Received 0 Likes

on

0 Posts

I have seen multiple people running DRs around autocross tracks with good success. I can't imagine they are as good as a purpose built tire...but your car will be fast no matter what you do to it!

#53

Staging Lane

Join Date: Dec 2005

Location: Portland, Oregon

Posts: 86

Likes: 0

Received 0 Likes

on

0 Posts

Super cool build! I run an f20c powered locost that has an amazing amount of similarities to the new brunton design.

I've only been left wanting for power (~1200lbs/240hp) a few times - I can't imagine how insane one of these with an LS will be.

I'm happy to share tire experience with you - you'll be running VERY different tires than any 'standard' car runs. lightweight cars just behave so much differently than heavier street car derived racers

I've only been left wanting for power (~1200lbs/240hp) a few times - I can't imagine how insane one of these with an LS will be.

I'm happy to share tire experience with you - you'll be running VERY different tires than any 'standard' car runs. lightweight cars just behave so much differently than heavier street car derived racers

#54

Teching In

Join Date: May 2012

Location: Littleton, CO

Posts: 10

Likes: 0

Received 0 Likes

on

0 Posts

Super cool build! I run an f20c powered locost that has an amazing amount of similarities to the new brunton design.

I've only been left wanting for power (~1200lbs/240hp) a few times - I can't imagine how insane one of these with an LS will be.

I'm happy to share tire experience with you - you'll be running VERY different tires than any 'standard' car runs. lightweight cars just behave so much differently than heavier street car derived racers

I've only been left wanting for power (~1200lbs/240hp) a few times - I can't imagine how insane one of these with an LS will be.

I'm happy to share tire experience with you - you'll be running VERY different tires than any 'standard' car runs. lightweight cars just behave so much differently than heavier street car derived racers

#55

TECH Fanatic

Thread Starter

iTrader: (15)

Join Date: Jun 2006

Location: Janesville WI

Posts: 1,155

Likes: 0

Received 0 Likes

on

0 Posts

Insane is an understatement. These cars are hyper-quick. A couple of the guys with LS-equipped Stalkers are running 0-60 times in the 2.2 second range. Due to wheel spin and probably technique, the best I have been able to get so far is 0-60 in 3.2 seconds. That's starting out in second gear; no shift to third required. Having said that, I can do that with relatively no effort. For now, I'm running Hankook R-S3s (255/40R17), but plan to put on something taller and a little wider.

The guys at Brunton keep reminding me this is a corner turning car, not a drag racer. Too much traction equals broken parts, I know. We'll see what kind of launch the independent suspension can muster.

You have a solid axle car, correct? Are the guys running the 2.2s using slicks? Part of me wishes I had a solid axle for durability's sake. However, turning corners is my main objective.

#58

Teching In

Join Date: May 2012

Location: Littleton, CO

Posts: 10

Likes: 0

Received 0 Likes

on

0 Posts

Same guy -MightyMike from USA7s. Photo is of my old Birkin. I put it there when I established my membership and build was underway. I am more of a lurker than poster on this website.

#59

TECH Fanatic

Thread Starter

iTrader: (15)

Join Date: Jun 2006

Location: Janesville WI

Posts: 1,155

Likes: 0

Received 0 Likes

on

0 Posts

We've made some progress on the build. The slip yoke idea didn't work out for the CTS-V T-56, so that meant a new output shaft needed to be put in. Upgraded a couple things while they had it open, and found the unit to be in great condition. That is the silver lining. The trans was the only used part in the drive line so its nice to know all is well with it.

I found a T-56 specialist a couple hours north of me. I decided to hand deliver the trans to avoid any risk of damage in shipping. Since I was making the trip I also brought along a F-body T-56 I scored on Craigslist. I got such a deal on it I assumed it was messed up. However, more good news there. It was good inside, and so I upgraded it with steel 3-4 shift forks, pads and billet keys. Now I have a fresh T-56 for the next project (maybe my DD 2012 Colorado w the 5.3).

We worked on the rear suspension to get a the alignment close, and the settings right to get the shock travel where I wanted it. I purchased a few sets of suspension push rods to play around with length. I found out a big mail order circle track suspension place is like 20 minutes from me (Lefthander Chassis), so that made getting the parts easy.

We bled the brakes, and clutch hydraulics. It is starting to feel like a real car! I ponied up for some pretty parts. I really did not like the factory brackets for the coils. I guess it was to speed up production but on the early LS1s (97-98) the coils mounted directly to the valve covers, which were perimeter bolt. When they went center bolt they went to brackets. Anyway, I picked up some black Holley valve covers that have the bosses to mount the coils direct. I really like how they look.

Next I need to set up the DBW throttle pedal and the air intake. My plan is for the intake to go right back through the scuttle and be in the interior between the shelf and dash. I figure this will be direct, and shield it from debris, water and heat. I don't see a lot of guys doing this so I am up for any advice on why this isn't common.

I found a T-56 specialist a couple hours north of me. I decided to hand deliver the trans to avoid any risk of damage in shipping. Since I was making the trip I also brought along a F-body T-56 I scored on Craigslist. I got such a deal on it I assumed it was messed up. However, more good news there. It was good inside, and so I upgraded it with steel 3-4 shift forks, pads and billet keys. Now I have a fresh T-56 for the next project (maybe my DD 2012 Colorado w the 5.3).

We worked on the rear suspension to get a the alignment close, and the settings right to get the shock travel where I wanted it. I purchased a few sets of suspension push rods to play around with length. I found out a big mail order circle track suspension place is like 20 minutes from me (Lefthander Chassis), so that made getting the parts easy.

We bled the brakes, and clutch hydraulics. It is starting to feel like a real car! I ponied up for some pretty parts. I really did not like the factory brackets for the coils. I guess it was to speed up production but on the early LS1s (97-98) the coils mounted directly to the valve covers, which were perimeter bolt. When they went center bolt they went to brackets. Anyway, I picked up some black Holley valve covers that have the bosses to mount the coils direct. I really like how they look.

Next I need to set up the DBW throttle pedal and the air intake. My plan is for the intake to go right back through the scuttle and be in the interior between the shelf and dash. I figure this will be direct, and shield it from debris, water and heat. I don't see a lot of guys doing this so I am up for any advice on why this isn't common.

#60

TECH Fanatic

Thread Starter

iTrader: (15)

Join Date: Jun 2006

Location: Janesville WI

Posts: 1,155

Likes: 0

Received 0 Likes

on

0 Posts

I mentioned before about some trial and error on the driveshaft. My original stance was to use adaptors on both ends to keep the factory 3 bolt flanges on the CTS differential, and the CTS-V T-56. I figured we could use a driveshaft with a splined section in the middle to take up any movement and ease installation. I had just that kind of driveshaft on my last Jeep Rubicon project.

Well, after some lessons learned, we went with my original idea.

Here is the adaptor made for the T-56 flange:

Here is the shaft:

I asked for some input on running the intake. I liked the direct and literally straight forward (or backward in this case) route. I figured flow would be good, packaging would be clean, and dry air would be assured if the filter was on the cabin side of the cowl shelf.

However, a friend pointed out that it may cause me issue with some racing sanctioning bodies as it more or less defeats the idea of a firewall. Firstly I don't want to risk missing an event due to tech. Secondly the idea of a potential back-fire through the intake emitting fire directly into the cabin seems less than ideal.

In other news, I received my Diamond Racing wheels. Steel 15x10s with a spun rim. I went this route based on budget. I want to get the car to the track soon. The wheels are of great quality! Obviously steel is a bit heavy, but custom aluminum can come later. The wheels are 21 pounds a piece, the Hoosier 23x9.5x15 Road Race Radials are around 19 pounds. So figure about 40 pounds per corner. Bear in mind this was measured using a bathroom scale, so it could be off a bit.

The sun is coming through the window behind the car, but here is pic of the wheels on the car:

Another catch to using steel wheels is the lack of stand off from the wheel flange surface. Diamond racing told me this would be an issue, so it was no surprise. The problem is my brake set up is stock 10" Miata rotors with beefy Wilwood 4 pot calipers. So the caliper protrudes outward of the hub face, and since the rotor is so small, it is to near the center to allow the steel wheels gradual angle away to clear. No worries though. Nothing a spacer (15mm) and longer wheel studs cannot solve.

Well, after some lessons learned, we went with my original idea.

Here is the adaptor made for the T-56 flange:

Here is the shaft:

I asked for some input on running the intake. I liked the direct and literally straight forward (or backward in this case) route. I figured flow would be good, packaging would be clean, and dry air would be assured if the filter was on the cabin side of the cowl shelf.

However, a friend pointed out that it may cause me issue with some racing sanctioning bodies as it more or less defeats the idea of a firewall. Firstly I don't want to risk missing an event due to tech. Secondly the idea of a potential back-fire through the intake emitting fire directly into the cabin seems less than ideal.

In other news, I received my Diamond Racing wheels. Steel 15x10s with a spun rim. I went this route based on budget. I want to get the car to the track soon. The wheels are of great quality! Obviously steel is a bit heavy, but custom aluminum can come later. The wheels are 21 pounds a piece, the Hoosier 23x9.5x15 Road Race Radials are around 19 pounds. So figure about 40 pounds per corner. Bear in mind this was measured using a bathroom scale, so it could be off a bit.

The sun is coming through the window behind the car, but here is pic of the wheels on the car:

Another catch to using steel wheels is the lack of stand off from the wheel flange surface. Diamond racing told me this would be an issue, so it was no surprise. The problem is my brake set up is stock 10" Miata rotors with beefy Wilwood 4 pot calipers. So the caliper protrudes outward of the hub face, and since the rotor is so small, it is to near the center to allow the steel wheels gradual angle away to clear. No worries though. Nothing a spacer (15mm) and longer wheel studs cannot solve.