Clean wire loom wyes and tees

#1

What's the best way to make a wye or tee in a wire loom? I have F6 split braided loom, shrink tube, and non adhesive tape. I have a few instances of both connections (wye and tee), sometimes all the same size loom and sometimes with smaller runs off bigger ones. What techniques have you used?

#2

Tee fittings from Waytek

http://www.waytekwire.com/products/1...Fittings/&pg=2

Don't recall ever seeing any wye (Y) fittings. Ive always seen the wire loom split off then tape around it all.

http://www.waytekwire.com/products/1...Fittings/&pg=2

Don't recall ever seeing any wye (Y) fittings. Ive always seen the wire loom split off then tape around it all.

#3

TECH Senior Member

iTrader: (12)

On my Nova. .I used split braided loom and zip ties... I not the cleanest.. I usually branch off the smaller harness by tucking another inch of the split loom back inside the main harness zip tie it.. that way the loom appears to be what is coming out of the main harness loom..

But I think you are looking for a more cleaner look.. and ways to hide the harness. If I see anything.. I'll let you know..

But I think you are looking for a more cleaner look.. and ways to hide the harness. If I see anything.. I'll let you know..

#4

TECH Resident

iTrader: (1)

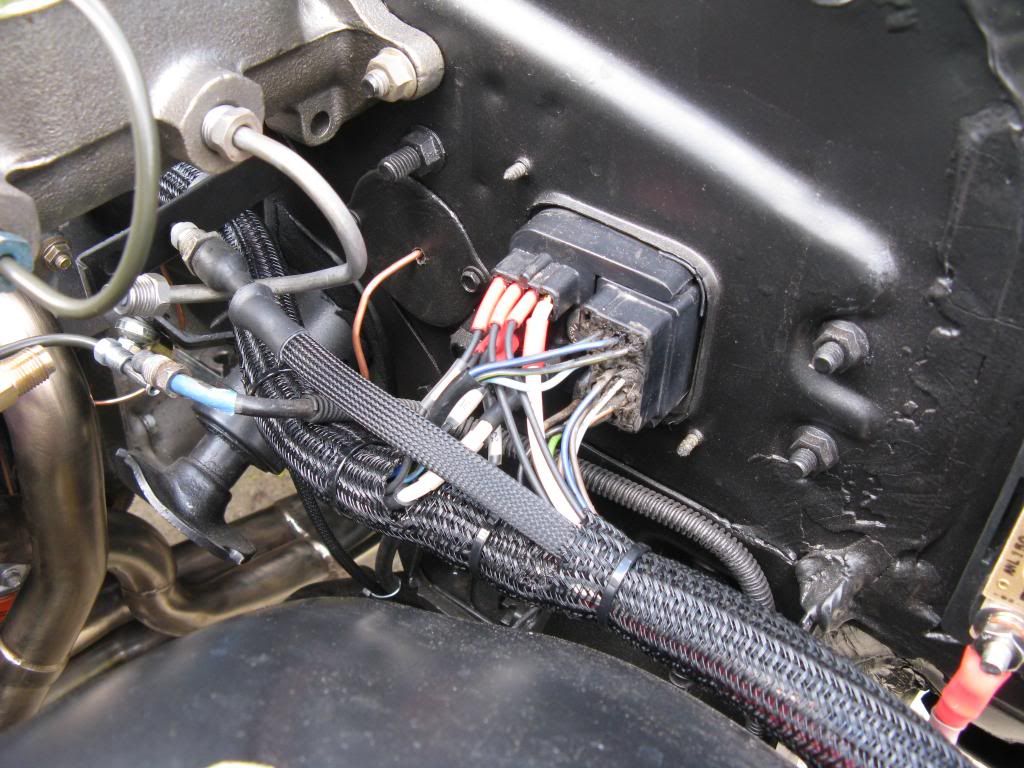

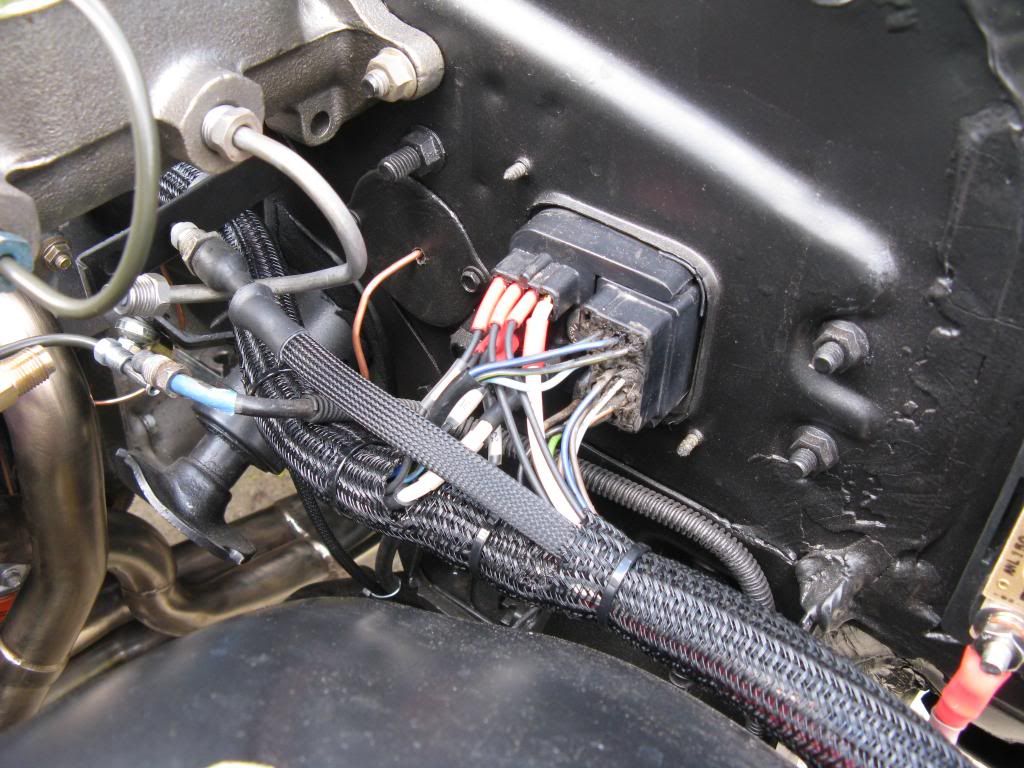

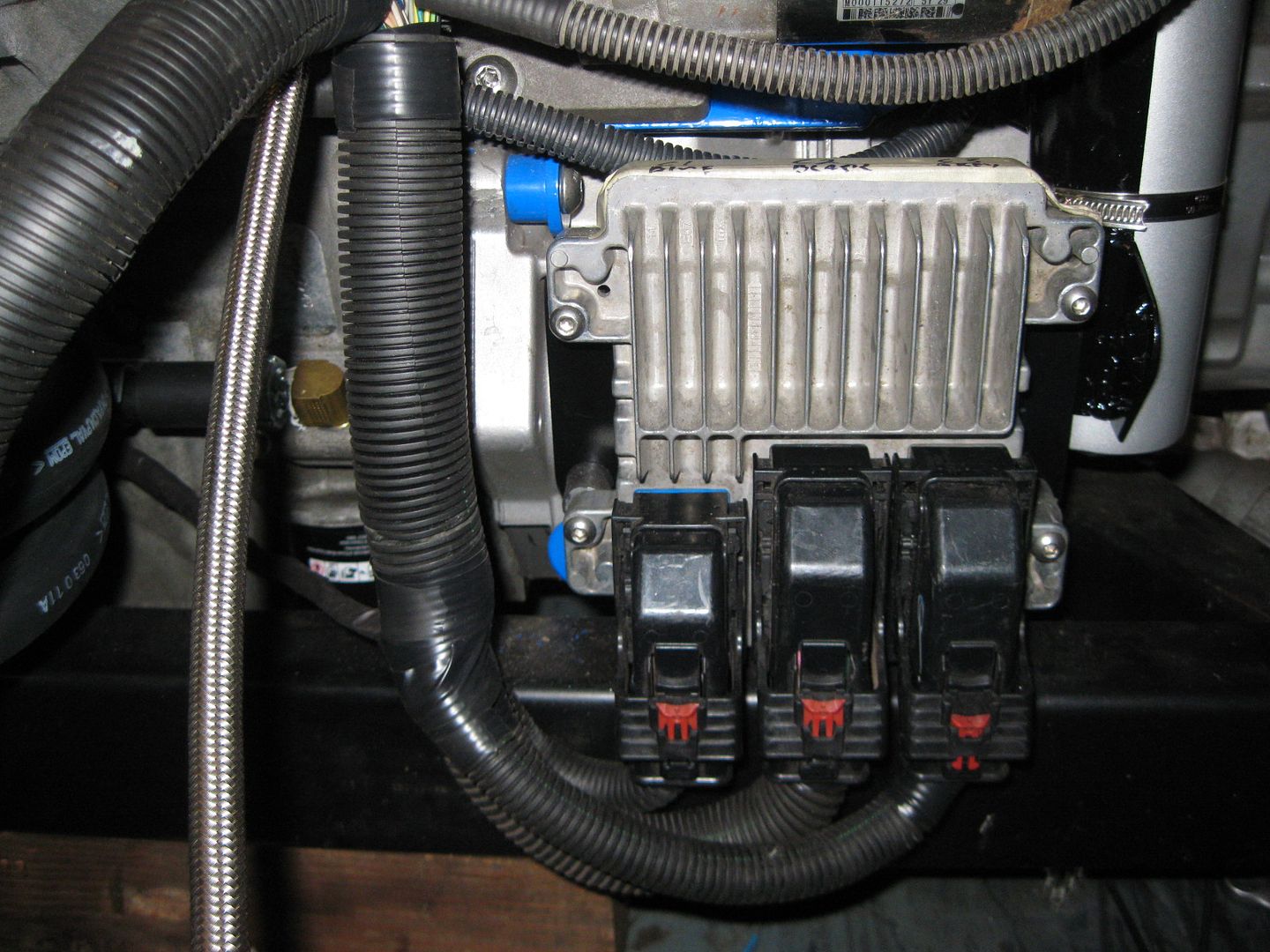

When the harness is small or on the top side of the engine, I prefer to use heat shrink tubing to keep the harness bulk minimized so it is easier to hide behind items. The wires that go to the individual sensors are heat shrunk first, then when they come together I tape them in place, then slide on the next section of heat shrink. Like this:

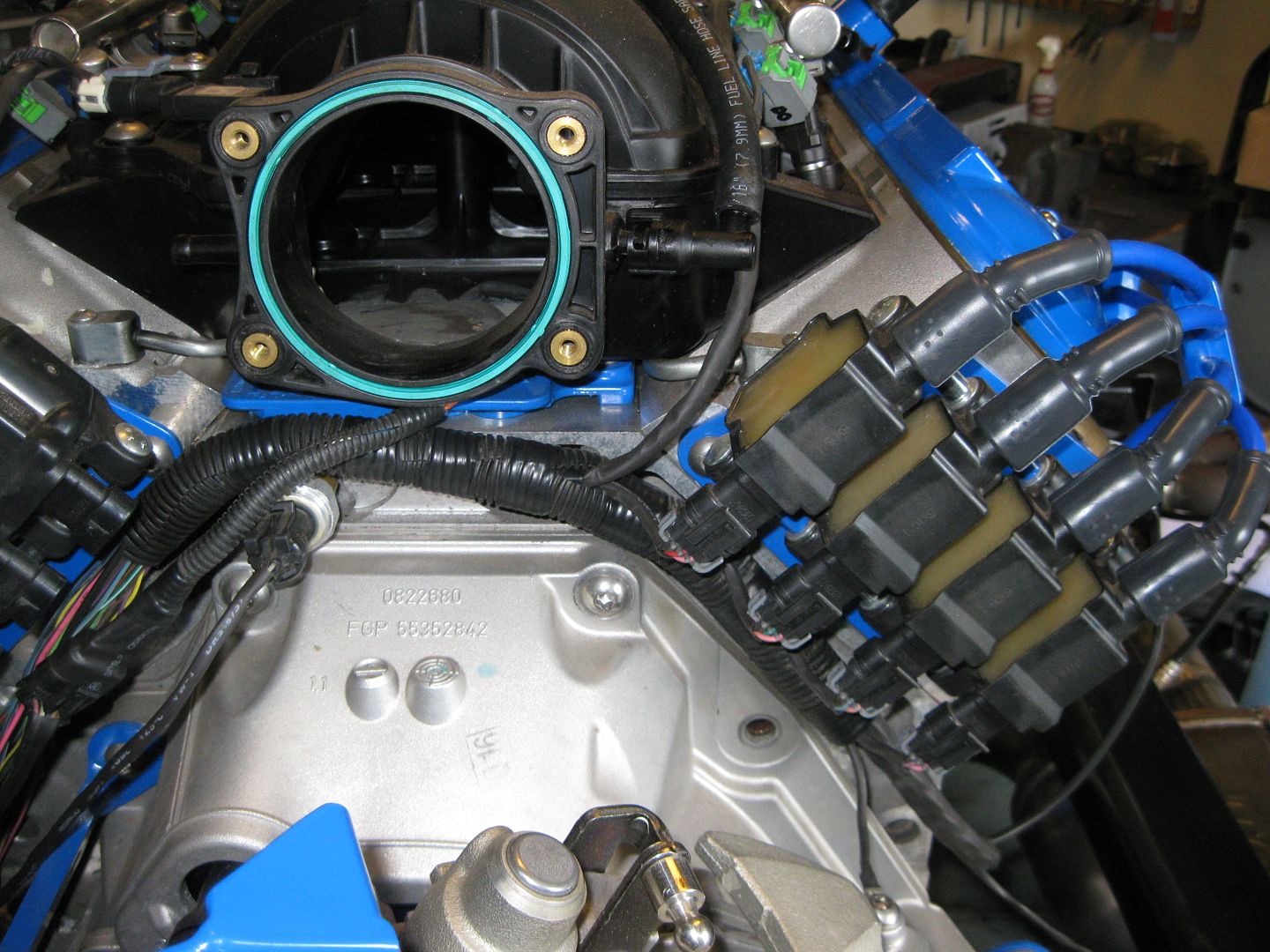

For the injector harness, I took the heat shrink tube for the main run and cut diamond notches in it so I could slide the injector wires into it.

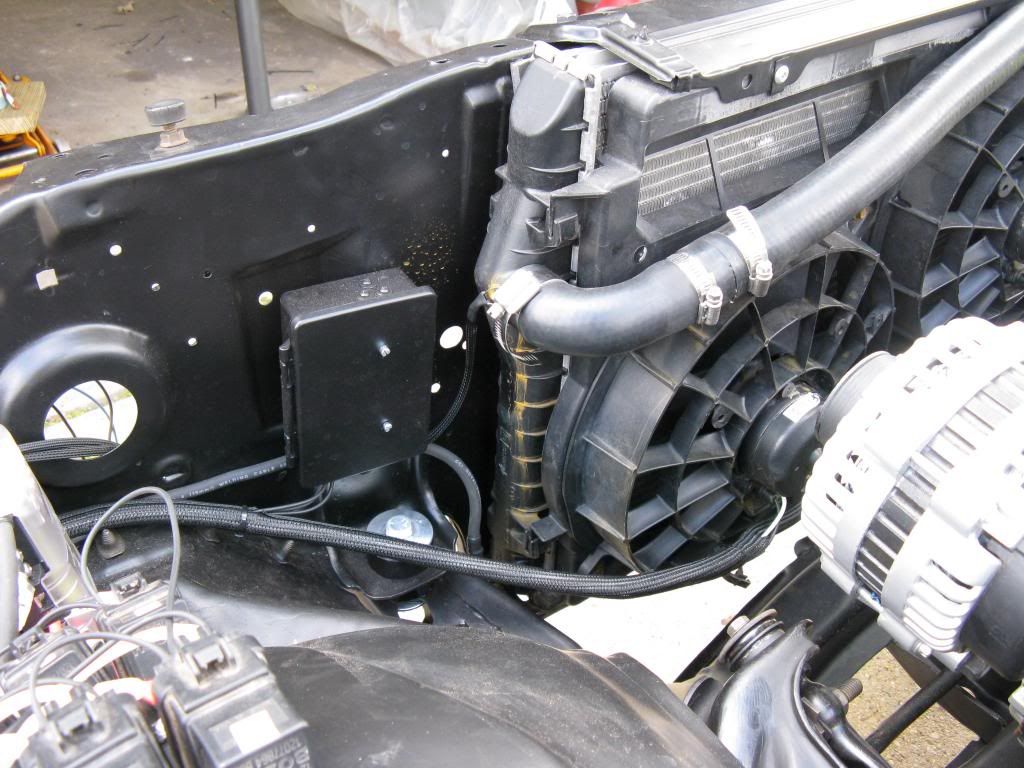

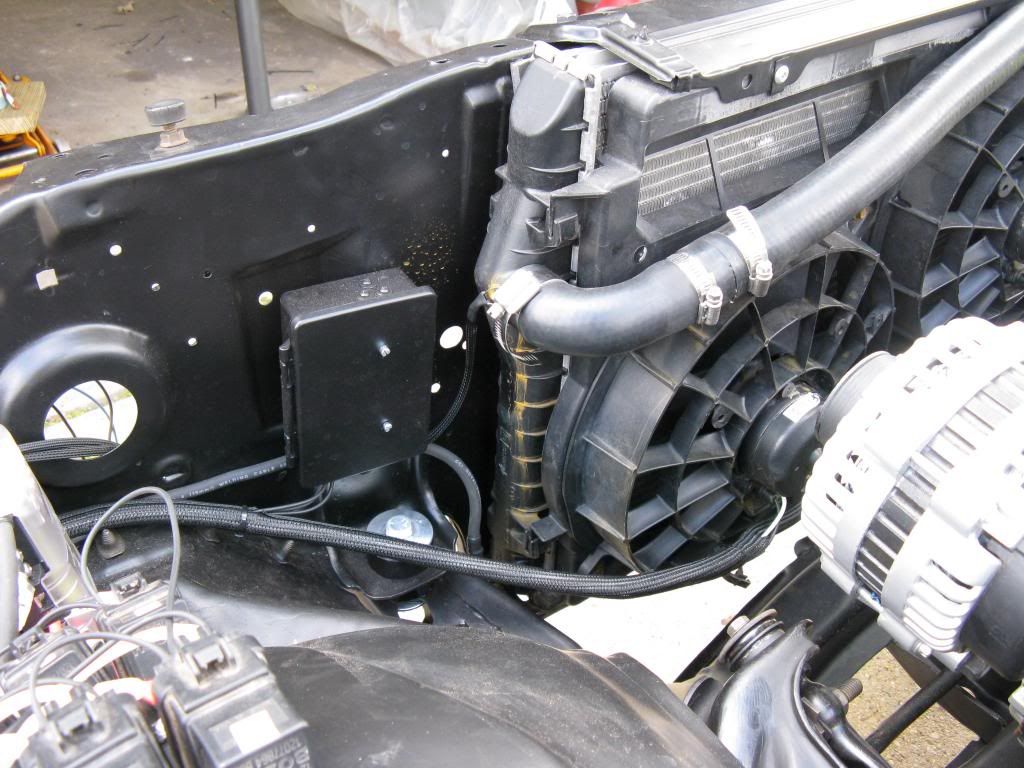

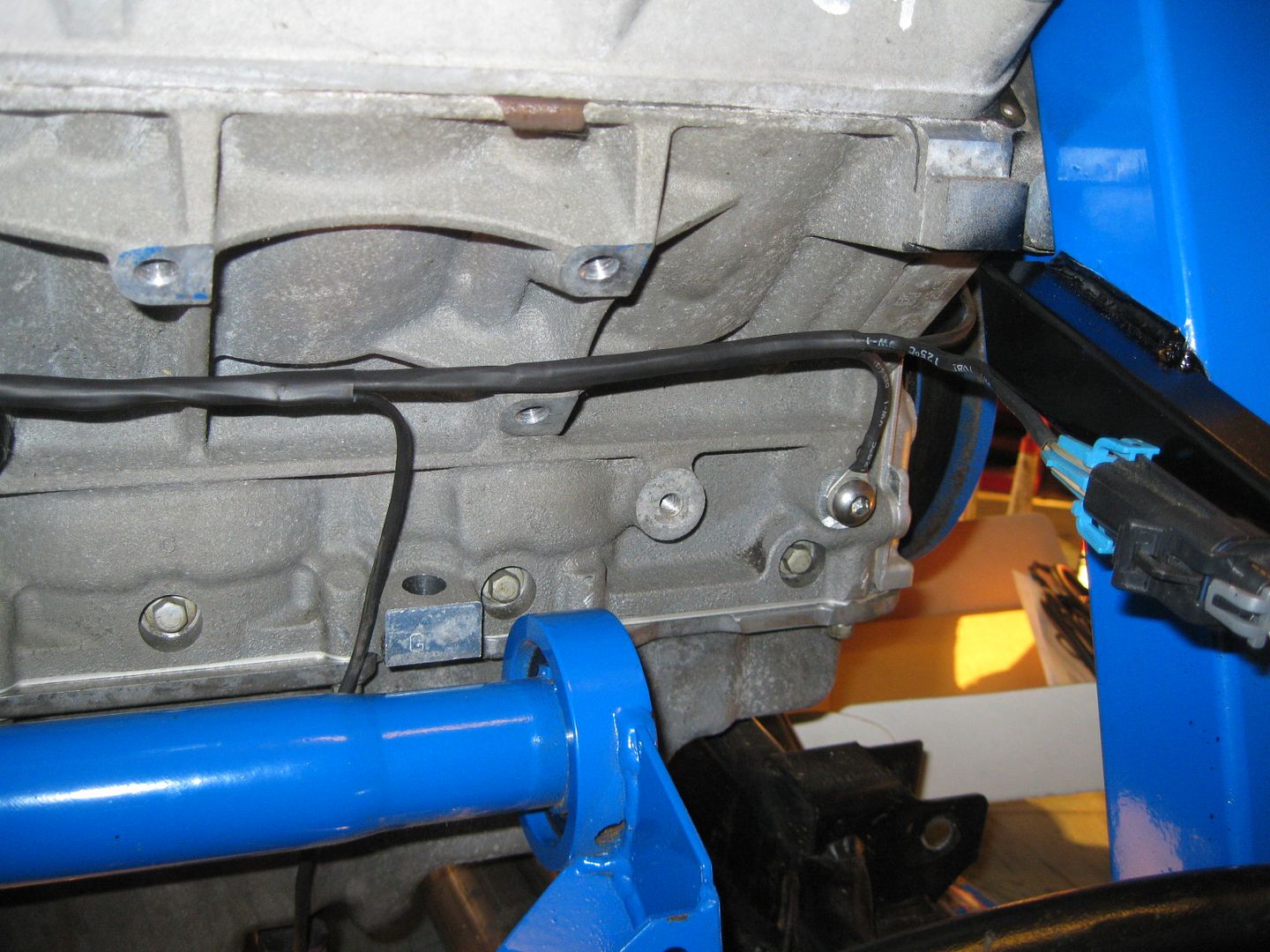

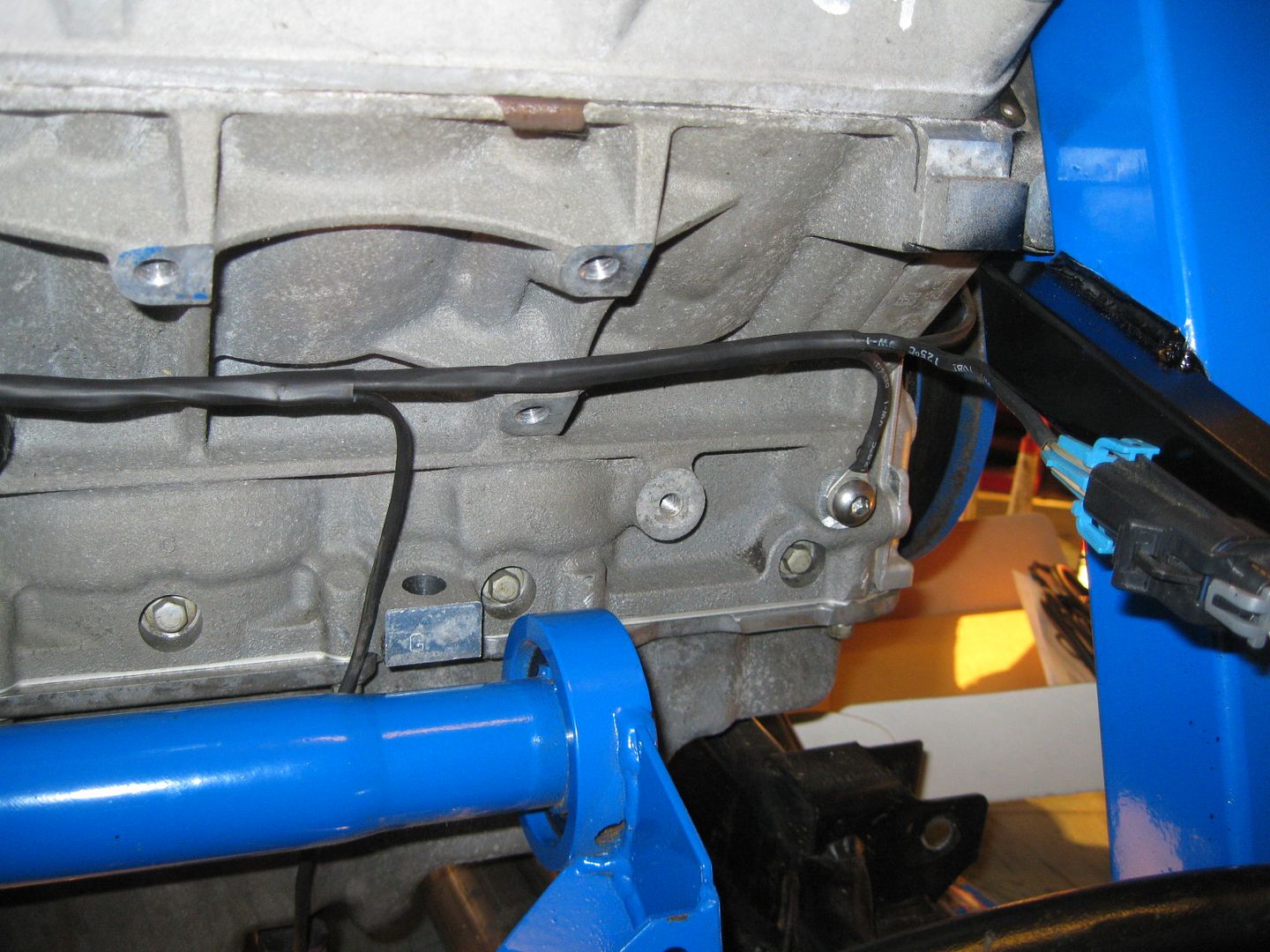

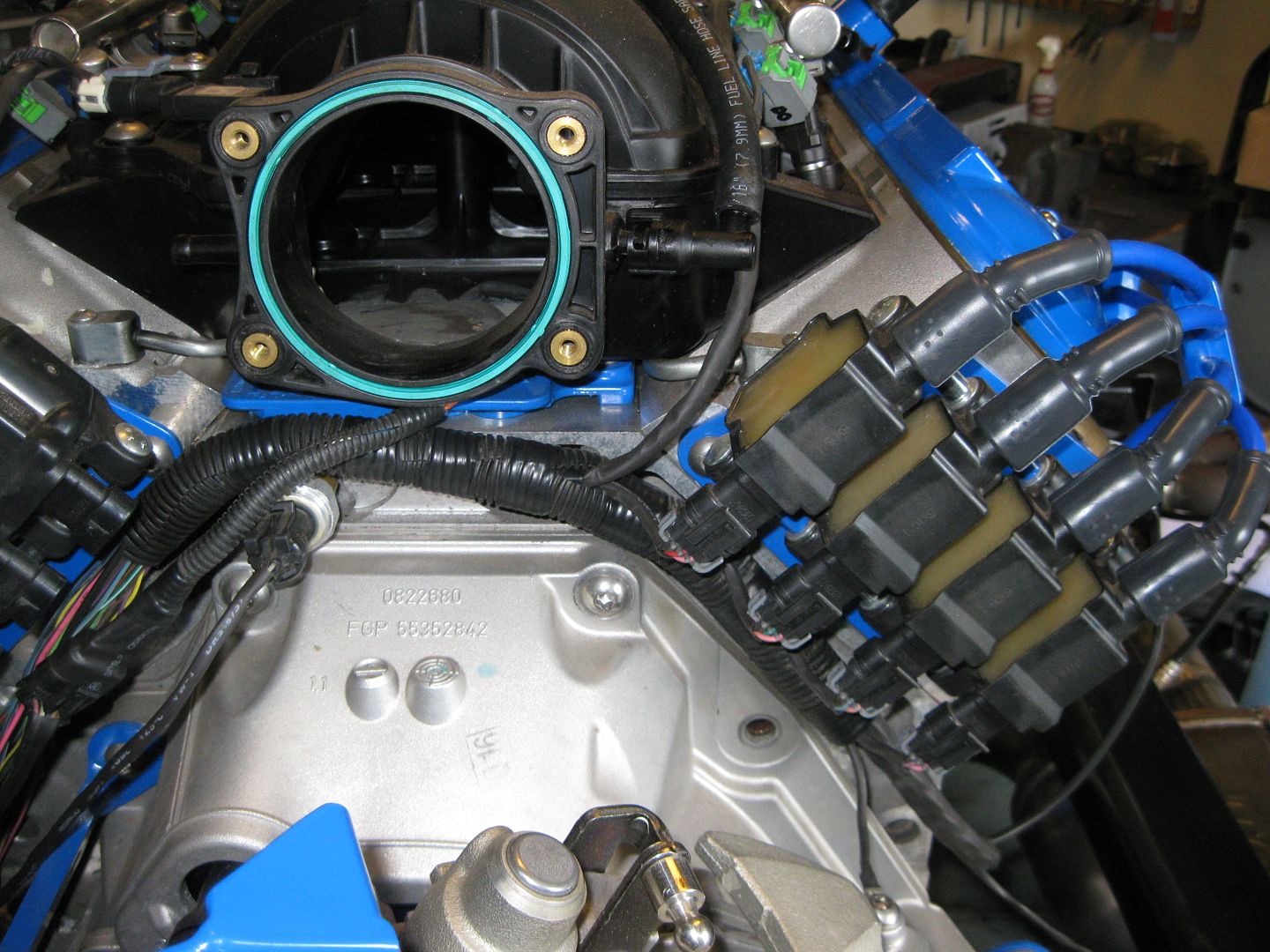

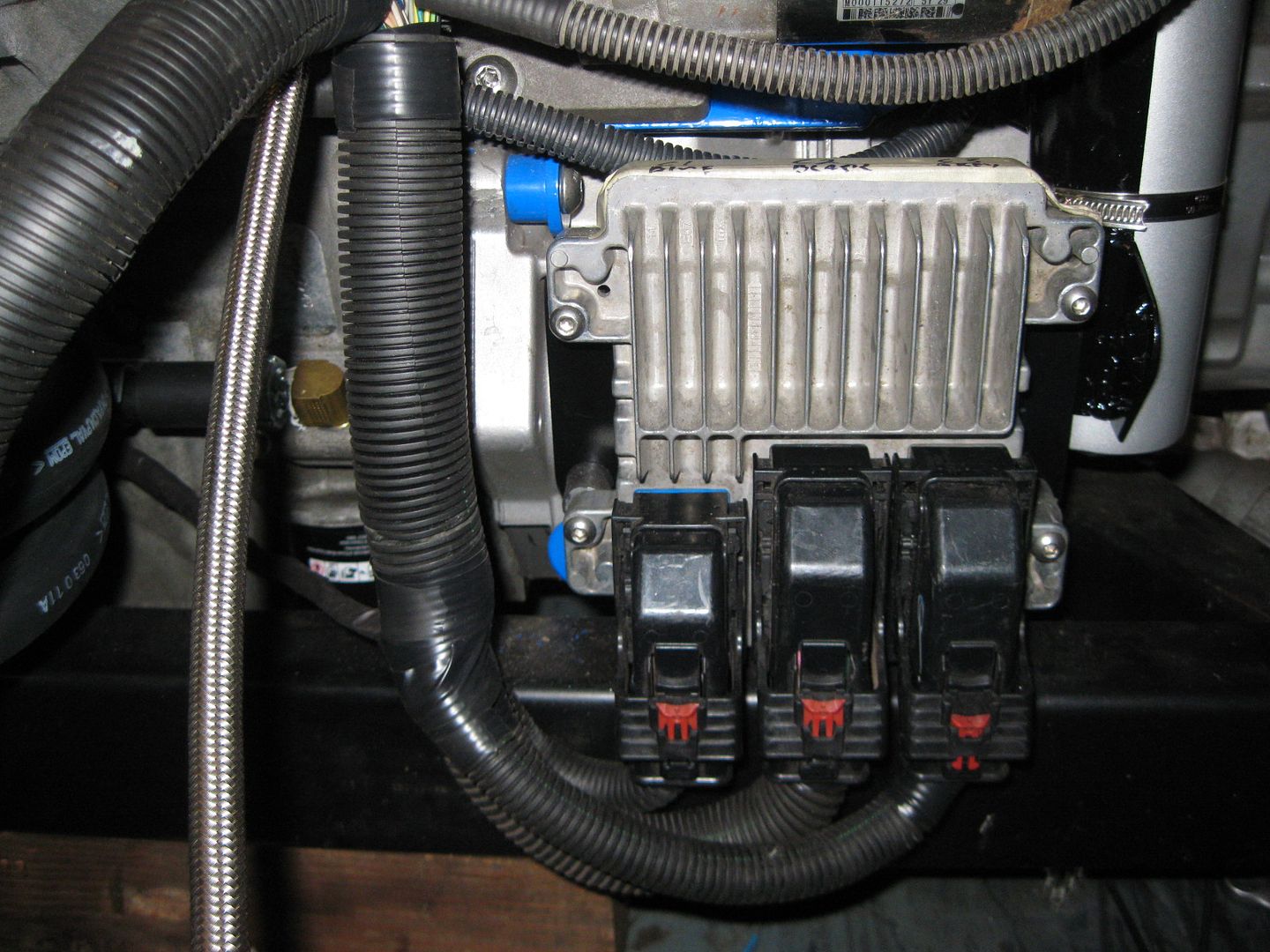

When the harness becomes large, I prefer split loom and then run the heat shrink wires out the seam where they are needed and tape the loom to keep it shut. I try to keep this section of harness hidden (like under my relocated coils and throttle body):

When loomed sections meet, I try to keep these in hidden areas and tape the transition:

For the injector harness, I took the heat shrink tube for the main run and cut diamond notches in it so I could slide the injector wires into it.

When the harness becomes large, I prefer split loom and then run the heat shrink wires out the seam where they are needed and tape the loom to keep it shut. I try to keep this section of harness hidden (like under my relocated coils and throttle body):

When loomed sections meet, I try to keep these in hidden areas and tape the transition:

#5

fieroguru, thanks for posting. I've looked at your build many times for ideas. You pulled off a really clean wiring job. I didn't realize that was heat shrink; I thought it was harness tape. I've thought about doing wyes with loom in a similar way, capping loom with heat shrink on the two branches then adding a larger shrink over them both from the larger loom.

Last edited by -TheBandit-; 06-23-2013 at 12:06 PM.

#6

I assume you used heat shrink over all new wire? And not over any splices also.

Good idea, but probably a pain if something was to happen to a solder or crimp splice and it needed to be repaired. A lot of heat shrink to remove. How stiff is that BTW?

I attempted the same once, but I took a long strip of heat shrink and sliced it up to a bunch of thin sleeves. So every 5in or so was a little strip of heat shrink holding the harness together.

Got tired of doing that and went back to using tape every couple inches. I just felt like I was wasting time and heat shrink.

Good idea, but probably a pain if something was to happen to a solder or crimp splice and it needed to be repaired. A lot of heat shrink to remove. How stiff is that BTW?

I attempted the same once, but I took a long strip of heat shrink and sliced it up to a bunch of thin sleeves. So every 5in or so was a little strip of heat shrink holding the harness together.

Got tired of doing that and went back to using tape every couple inches. I just felt like I was wasting time and heat shrink.

#7

TECH Resident

iTrader: (1)

Sure using shrink wrap will make any wiring issue (if I have any) more difficult to fix, but I would rather take that chance than have to see a large bulky harness on the top side of my swap every single time I pop the hood.

The heat shrink firms the harness up, but it is still flexible enough to move it around and push on the connectors. I have had the fuel injector rail off a few times swapping out/cleaning injectors and didn't have any issue snaking the harness out and back into place.

Trending Topics

#8

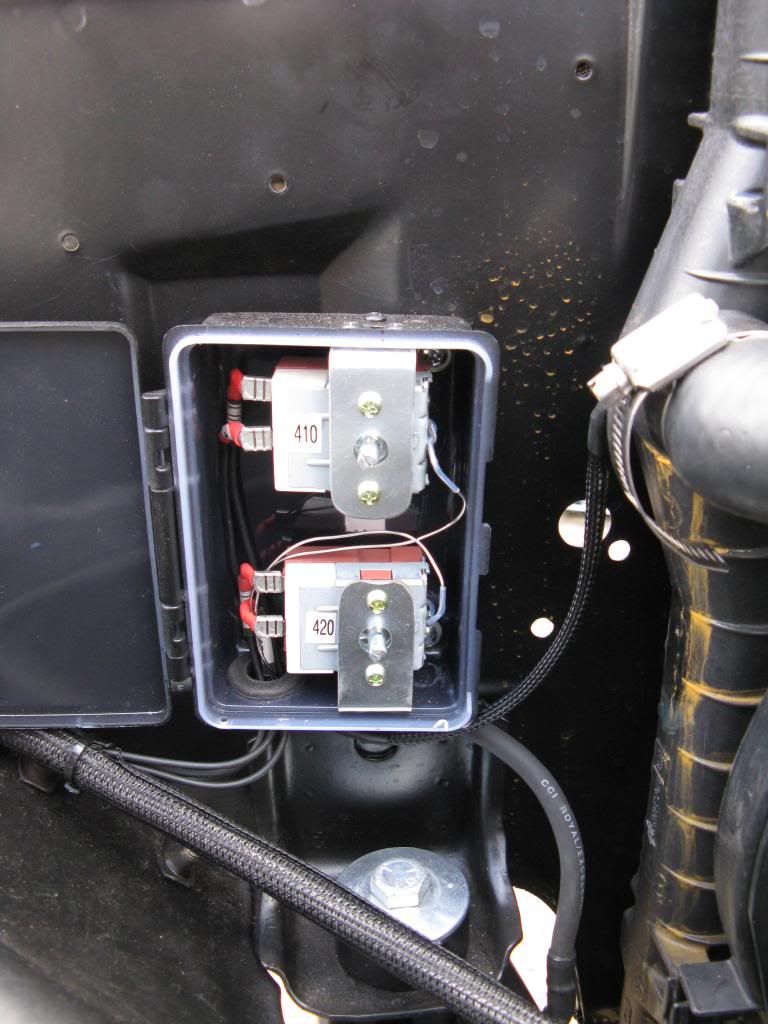

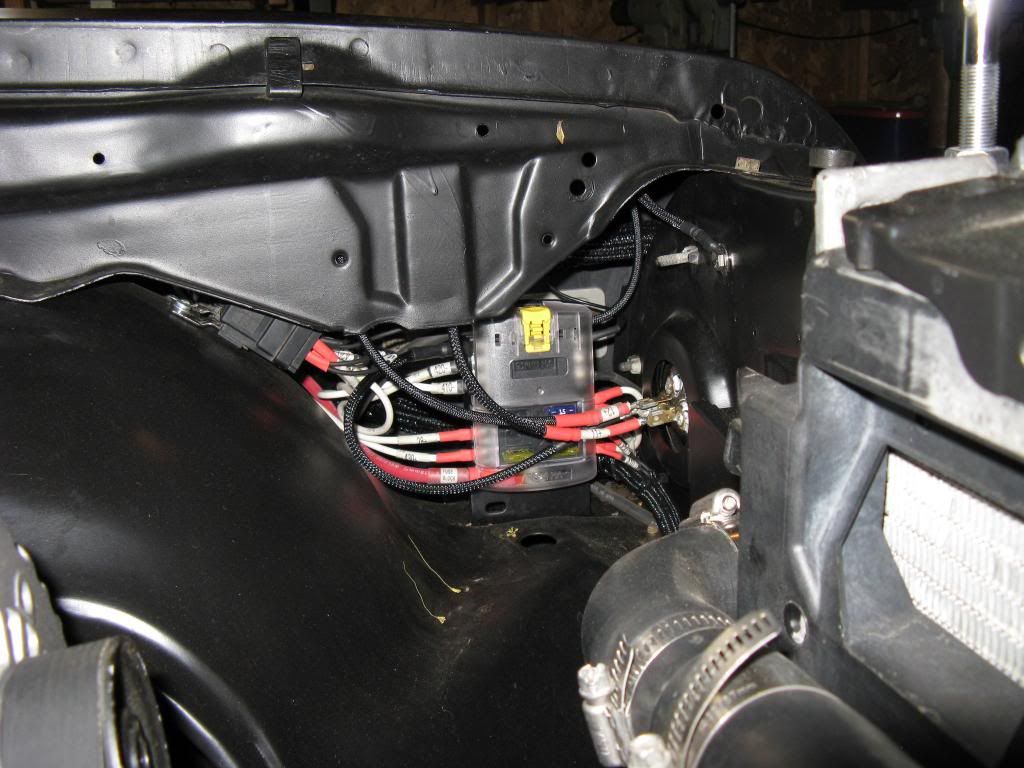

Here is my first attempt at 1-in, 3-out wye. Each smaller run was loomed with Techflex F6 and standard 2:1 heat shrink was used to finish the ends. Then I wrapped the larger run with non-adhesive harness wrap, loomed it, and put a larger piece of 2:1 heat shrink over it and the 3 smaller runs, leaving some of the smaller heat shrink exposed. This turned out okay, but I think it could be done better. I don't like how the larger heat shrink necks down at the transition from larger loom. It may have been better if the larger loom overlapped the smaller looms and heat shrink over all 3 without any of the smaller heat shrink showing.

#9

I bought a bunch of assorted heat shrink about 1 year ago with the idea that to do what FieroGuru did. Lets just say I am not that savvy with wiring and HAD to buy Techflex F6 split woven wrap. I just love the quality workmanship DSE does. ($$$$$$)

I wish they had a heat shrink tape to wrap junctions or ends or wrap like -TheBANDIT- did. I am assuming Clint(bandit) depined the pigtails to get the heat shrink into position.

Either way, Fieroguru and BANDIT did great work.

I wish they had a heat shrink tape to wrap junctions or ends or wrap like -TheBANDIT- did. I am assuming Clint(bandit) depined the pigtails to get the heat shrink into position.

Either way, Fieroguru and BANDIT did great work.

#10

I did have one end depinned so I could slip the heat shrink over. The metripack type connectors are very easy to depin and you could do one at a time if you're worried about mixing them up. You can even put the two heat shrink tubes on (without shrinking them) before slipping the wire into the split loom.

#11

TECH Enthusiast

iTrader: (8)

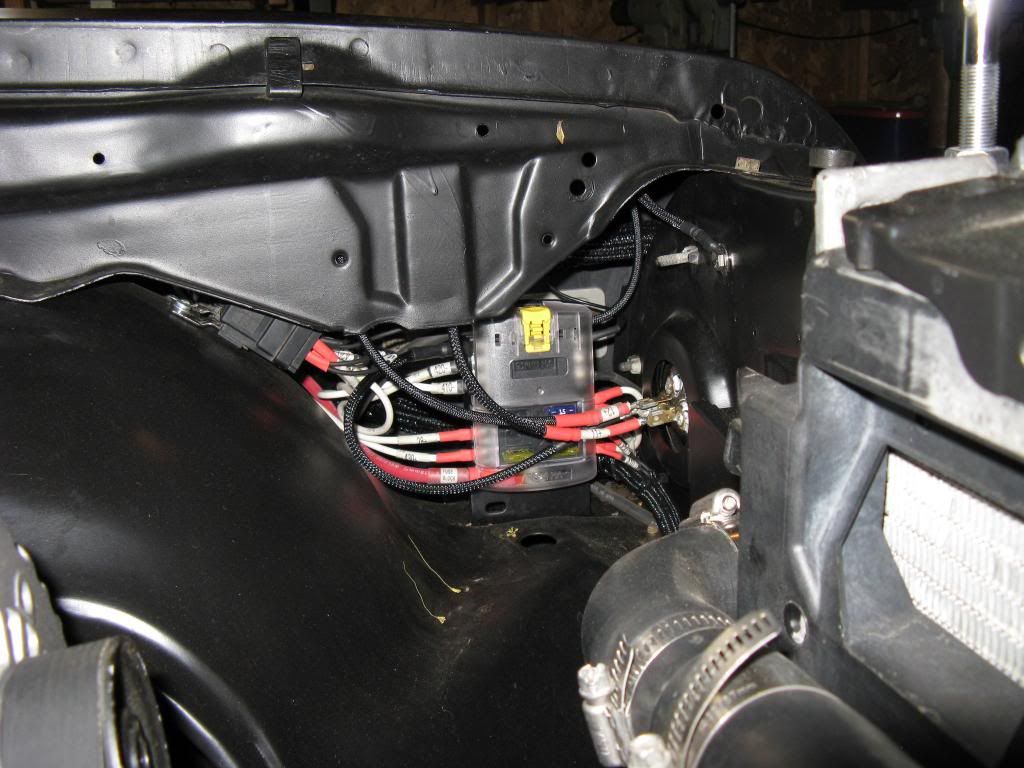

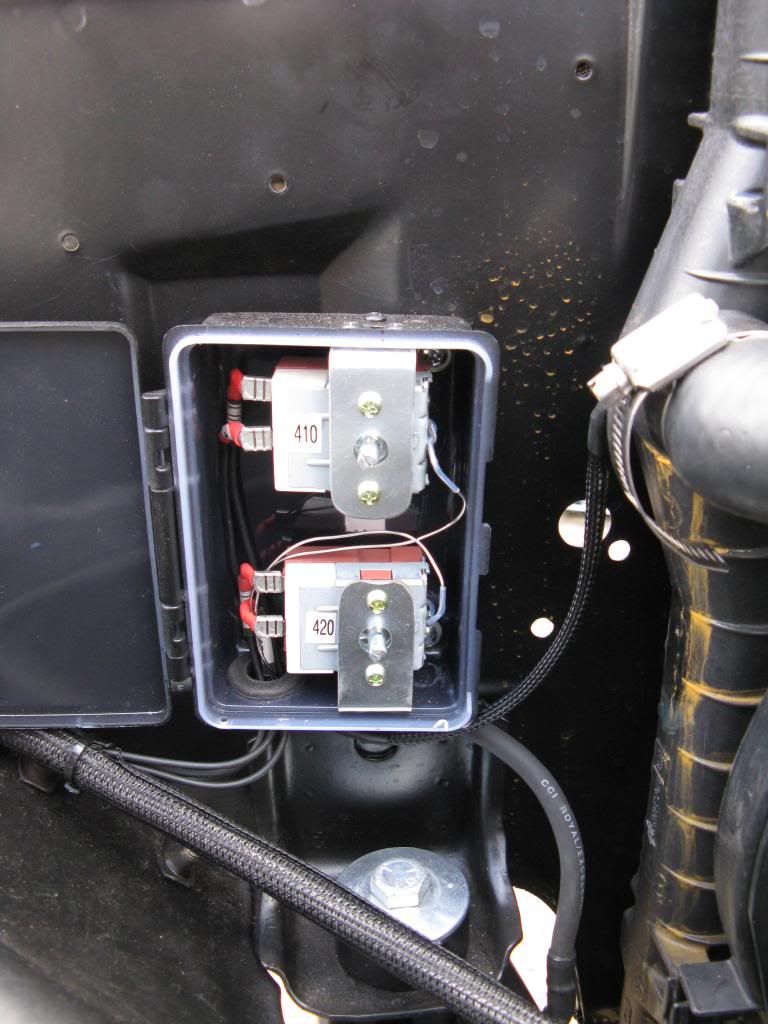

Hey Bandit, I used the same F6 split loom, and man it was worth every extra penny! I too debated how to terminate and break out wires: heat shrink VS tape VS harness tape VS zip ties. For me in the end, ease of service was more important then perfect appearance. I wanted to be able to add and remove wires without major hassle. I went the same route as BCZEE did and used zipties. I also found that making a slit at the split in the loom with a soldering iron made for a very clean breakout. The soldering iron was also the best way to cut the loom to avoid ugly fraying ends. They actually make a hot knife tool but I'm not dropping hard earned bankroll on oddity tools like that! Here are a few pics of different parts of my harness.