'03 S-10 Build

#21

TECH Enthusiast

iTrader: (5)

If you go to

"S-10 Forum > Engine and Drivetrain Tech > LSx Discussion > 6.0 swap parts"

You will find every thing your needing including part number. Its a wealth of info. I was going to do the same thing with my truck but I decided to but a 4th gen instead.

Your 4.3 radiator will work,the motor should sit into the same location as the 4.3 and bolt up to your 4L60. Everything from you trans back should stay in its same location. If you take it easy the trams/rear end will last for a while giving you time/money to beef them up. If your slick you can find a 8.5 out of a standard shift S-10 which should hold up.

"S-10 Forum > Engine and Drivetrain Tech > LSx Discussion > 6.0 swap parts"

You will find every thing your needing including part number. Its a wealth of info. I was going to do the same thing with my truck but I decided to but a 4th gen instead.

Your 4.3 radiator will work,the motor should sit into the same location as the 4.3 and bolt up to your 4L60. Everything from you trans back should stay in its same location. If you take it easy the trams/rear end will last for a while giving you time/money to beef them up. If your slick you can find a 8.5 out of a standard shift S-10 which should hold up.

#22

TECH Apprentice

Thread Starter

Well did more cleaning in the shop. Tools everywhere, that kind of thing.

Ordered my A/C compressor kit, fuel rail regulator. Now looking for a set of GM quick release lines to mate to the existing S-10 compression fittings at the back of the block. I'll run a '99 Silverado fuel pump to get the required 58lbs of pressure. This is all the correct fuel system that the donor truck had, just in a smaller package.

Also pulled the 4L60 off of the 4.3 and cleaned it up some. Grabbed my '00 LS1 converter and made an attempt to bolt it to the 5.3 (was test fitting the engine & trans into the truck). Mates up fine to the flex plate, so I stuck the converter into the trans to bolt everything up.

Now having an issue with the converter. When I put it in the trans last night (thought I had it seated fully - 2 clunks & rotating the pump) but as I was doing the draw down over the pins, it wouldn't seat to the block. Obvious stopping point before causing damage to the pump as the engine wouldn't rotate with a breaker bar on the balancer.

Took it apart, seemed to be seated. Same result. Right now I have the trans separated again. Will pull the converter out and rotate it 180* and start over. The converter is a 2000 LS1 from a Z/28. This is the one for the dished flywheel.

Thoughts?

Ordered my A/C compressor kit, fuel rail regulator. Now looking for a set of GM quick release lines to mate to the existing S-10 compression fittings at the back of the block. I'll run a '99 Silverado fuel pump to get the required 58lbs of pressure. This is all the correct fuel system that the donor truck had, just in a smaller package.

Also pulled the 4L60 off of the 4.3 and cleaned it up some. Grabbed my '00 LS1 converter and made an attempt to bolt it to the 5.3 (was test fitting the engine & trans into the truck). Mates up fine to the flex plate, so I stuck the converter into the trans to bolt everything up.

Now having an issue with the converter. When I put it in the trans last night (thought I had it seated fully - 2 clunks & rotating the pump) but as I was doing the draw down over the pins, it wouldn't seat to the block. Obvious stopping point before causing damage to the pump as the engine wouldn't rotate with a breaker bar on the balancer.

Took it apart, seemed to be seated. Same result. Right now I have the trans separated again. Will pull the converter out and rotate it 180* and start over. The converter is a 2000 LS1 from a Z/28. This is the one for the dished flywheel.

Thoughts?

#23

TECH Apprentice

Thread Starter

Figured it out. The LS1 converter is 3/8" deeper in the input snout than the 4.3 converter. Going to see if the V-8 bellhouse is deeper than the V-6/SBC unit. Think my buddy has one at his shop.

#24

TECH Apprentice

Thread Starter

I was able to source a 5.3 bellhouse. Yes it is deeper than the SBC/4.3 unit.

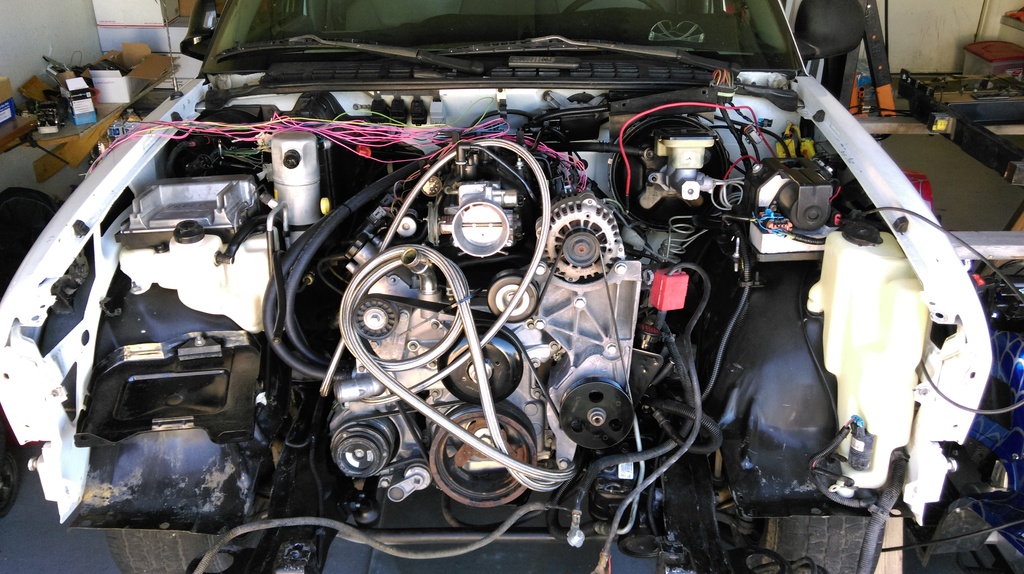

Over the weekend I got more stuff done, prior to the honey-do list. Found out that I do have to tilt the cab back to install the complete engine/trans. But then was able to get more of the hook-up's taken tare of. Have to drill new mounting holes on the throttle linkage bracket. Right now it won't close the TB to the idle position. Also need a cruise control tab to mount the cable to the TB.

Got the new core support roughed out. Radiator drops right in. Now I have to fill the lower section and build the support shelf at the very bottom. Plus other boxing of cut areas. Almost done with it.

Made several trips to the parts store to get the serp belt. When using the truck accessories and smaller dorman pulley, the correct length is 70".

Still on the list:

Cut the coil brackets to relocate the rear coils.

Have the bellhousing swapped (bolts have to be heated to break them loose)

More cleaning and painting

Build the exhaust

So still aways from final hook-up's. But the wire harness is being built now and they will do the reflash to get us up and running. My guess is since this is a stock set-up, the tune should be right on for an LS1 cammed 5.3.

Over the weekend I got more stuff done, prior to the honey-do list. Found out that I do have to tilt the cab back to install the complete engine/trans. But then was able to get more of the hook-up's taken tare of. Have to drill new mounting holes on the throttle linkage bracket. Right now it won't close the TB to the idle position. Also need a cruise control tab to mount the cable to the TB.

Got the new core support roughed out. Radiator drops right in. Now I have to fill the lower section and build the support shelf at the very bottom. Plus other boxing of cut areas. Almost done with it.

Made several trips to the parts store to get the serp belt. When using the truck accessories and smaller dorman pulley, the correct length is 70".

Still on the list:

Cut the coil brackets to relocate the rear coils.

Have the bellhousing swapped (bolts have to be heated to break them loose)

More cleaning and painting

Build the exhaust

So still aways from final hook-up's. But the wire harness is being built now and they will do the reflash to get us up and running. My guess is since this is a stock set-up, the tune should be right on for an LS1 cammed 5.3.

#25

TECH Apprentice

Thread Starter

Photos of where I'm at currently. Picked up some steel last nite to finish the frame notch. Going to get that done and the bell housing switched out tonight.

#28

TECH Apprentice

Thread Starter

I swapped to the smaller pulley. clears by about 3/8 to 7/16 inch at the adjuster nut.

Tonight I finished the notch. looks like I need to open up the front by 3/8 inch to gain clearance. may need to relocate the idler by about 1/4 inch. Truck will need an alignment anyway.

Tonight I finished the notch. looks like I need to open up the front by 3/8 inch to gain clearance. may need to relocate the idler by about 1/4 inch. Truck will need an alignment anyway.

#32

TECH Apprentice

Thread Starter

Running into an issue with the A/C pump. hitting the idler arm. Could bring it forward about 1/8 inch before it hits the sway bar. I am running the stock rubber 2.8 lower mounts. I am going to try a set of SS396 lowers that I have. Still may have to get urethane lowers.

Any ideas ?

Any ideas ?

#33

TECH Fanatic

iTrader: (20)

Running into an issue with the A/C pump. hitting the idler arm. Could bring it forward about 1/8 inch before it hits the sway bar. I am running the stock rubber 2.8 lower mounts. I am going to try a set of SS396 lowers that I have. Still may have to get urethane lowers.

Any ideas ?

Any ideas ?

I should mention my compressor is a sanden 508 in the low mount position with a bracket by Alan somethingorother... probably in my build thread.

#34

Running into an issue with the A/C pump. hitting the idler arm. Could bring it forward about 1/8 inch before it hits the sway bar. I am running the stock rubber 2.8 lower mounts. I am going to try a set of SS396 lowers that I have. Still may have to get urethane lowers.

Any ideas ?

Any ideas ?

The finished product is a little harder to see being all black, but here that is:

#37

TECH Apprentice

Thread Starter

Not too much to report. I was able to get the bell housing swapped for the 5.3 unit. Now should be able to bolt in the LS1 converter and get the trans to mate to the engine.

Made a big mess with the trans oil left in the tranny, opps.

Then had to speak at a Dining Out for my old unit, Christmas tree on Sunday....and the list goes on and on. Try to sneak out this evening to mate the engine/trans & converter, we'll see on that one.

Made a big mess with the trans oil left in the tranny, opps.

Then had to speak at a Dining Out for my old unit, Christmas tree on Sunday....and the list goes on and on. Try to sneak out this evening to mate the engine/trans & converter, we'll see on that one.

#38

TECH Apprentice

Thread Starter

Nothing done again. We did X-mas stuff.

Tonight the plan is to marry up the trans & engine. Have to figure a way to sling everything for install. Going to drill a 3/8 hole in the fuel rail bracket thingy that bolts to the driver side head. That will get the chain off the firewall, and make the chain easy to remove with the engine in place.

Also have to lift the cab to be able to slide in the assembled engine/trans. Still waiting to get the wire harness & ECU back. Also have to build the fuel lines and detail out the engine compartment. At least the list keeps getting "shorter".

This weekend I need to body work the core support to finish mount the radiator/condenser. Have the materials to do it, just need to get out there and make it happen. Sunday we get more snow, then bitter cold.

Tonight the plan is to marry up the trans & engine. Have to figure a way to sling everything for install. Going to drill a 3/8 hole in the fuel rail bracket thingy that bolts to the driver side head. That will get the chain off the firewall, and make the chain easy to remove with the engine in place.

Also have to lift the cab to be able to slide in the assembled engine/trans. Still waiting to get the wire harness & ECU back. Also have to build the fuel lines and detail out the engine compartment. At least the list keeps getting "shorter".

This weekend I need to body work the core support to finish mount the radiator/condenser. Have the materials to do it, just need to get out there and make it happen. Sunday we get more snow, then bitter cold.

#39

TECH Apprentice

Thread Starter

Anyone have an idea where to mount the MAF? Using a stock 5 bar, right now it is mocked up at the 90* elbow towards the driver side, long tube follows, then a cone filter in the stock location.

I have heard that this will be fine, I need to move it to the middle of the pipe. Have to let the harness builder know so the wires are the right length.

I have heard that this will be fine, I need to move it to the middle of the pipe. Have to let the harness builder know so the wires are the right length.