Nerd Rods: 32 Ford Roadster, Project Acid Test, C6 Suspension, LS, Turbo, Track Toy

#1

Launching!

Thread Starter

Join Date: Jan 2007

Location: Luling TX In the Hot Rod Shop

Posts: 294

Likes: 0

Received 3 Likes

on

3 Posts

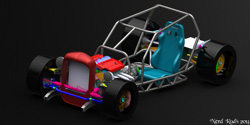

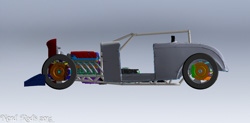

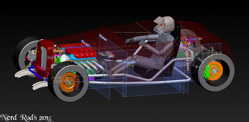

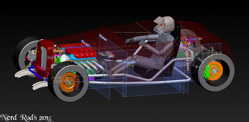

32 Ford Roadster, Project Acid Test, C6 Suspension, LS, Single Turbo, Track Toy

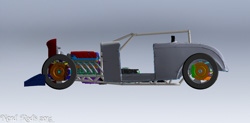

Drawing by my buddy Tyler Richlen

Thought it was about time I introduced a project I’ve been tinkering with for a customer, Dave, for over a year now. Things happened, we got slow, he moved, ideas changed, new manufacturing tools were made available, ect. But finally we’ve locked down the ideas and we’re moving forward. Hit list first then the story bits about what and why we’re doing things or have done things. Like I said this project has a lot of shop evolution as well as technology evolution.

• 1932 Ford Roadster, Fiberglass Hot Rod Jim Body (aka one of our old bodies from before the fire)

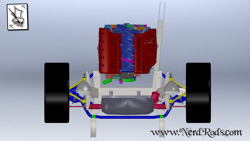

• Nerd Rods Custom Tube Chassis, laser cut and CNC bent, designed in Solidworks

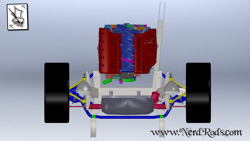

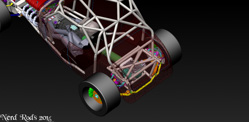

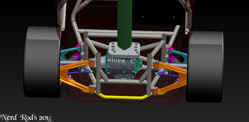

• C6 Z06 Corvette Suspension

• C5 Differential with Nerd Rods (was Hot Rod Jim’s) differential adapter, 4:10 gears, stock limited slip

• 5.3L, Aluminum block, Stock crank, rods and pistons, Texas Speed heads, Holley intake,

• STS Single Turbo, Turbo logic boost controller, 2.5” exhaust, CNC bent custom

• T56 or T6060

• Brakes, still up in the air

• Wheels, 10.5” front with 275’s, 12” rears with 345’s (probably going to go nuts here later on)

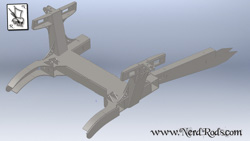

So this party started as a quick project to give Dave a toy while we worked on his 55 project. We were going to use lots of parts off our PT-57 project that were pulled off the older chassis. We’ll just say that and show you these photos of the initial design. We were planning to do everything on a flat laser as that was our primary CNC experience at the time and so this reflects that.

Full Gallery Here http://gallery.nerdrods.com/Customer..._B/Gallery_01/

That was the plan, until he needed to move for work so the project got sidelined. Once he got settled in we had developed a new product based on new technology (new to us at least), a weld it yourself frame kit. So the design evolved to include some CNC cut tubing. At least until our supplier unceremoniously dumped us by trying to triple the price for no explainable reason. So now it was our turn to need to chill while we located new suppliers as well as developed the design to properly utilize the new equipment. Namely we needed the CNC tubing laser to cut the complex parts for our kits. We found two new shops and finally got back into the swing of things but what we found at one of these new laser shops was even more toys. A CNC tubing bender and a CNC tubing laser all under one roof (Don’t ask, they’re not taking on any more work and I’m not supposed to release their info, It took a lot of pleading for them to take on my own projects and they only really took it because I was willing to give them 6-8 week delivery times and supply CAD.)

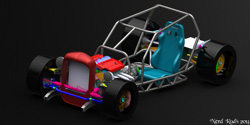

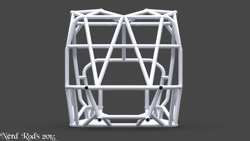

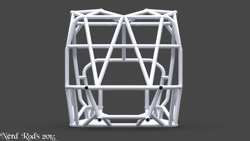

And so the idea of a full CNC tube chassis became feasible, and I did a quick drawing to see if we could make it look cool.

Dave approved and so authorized a 3D scan of the body for the computer so I could really fit the cage and driver in the super confined space of the 1932 Ford Roadster. As so we called Absolute Geometries to do the deed.

Drawing by my buddy Tyler Richlen

Thought it was about time I introduced a project I’ve been tinkering with for a customer, Dave, for over a year now. Things happened, we got slow, he moved, ideas changed, new manufacturing tools were made available, ect. But finally we’ve locked down the ideas and we’re moving forward. Hit list first then the story bits about what and why we’re doing things or have done things. Like I said this project has a lot of shop evolution as well as technology evolution.

• 1932 Ford Roadster, Fiberglass Hot Rod Jim Body (aka one of our old bodies from before the fire)

• Nerd Rods Custom Tube Chassis, laser cut and CNC bent, designed in Solidworks

• C6 Z06 Corvette Suspension

• C5 Differential with Nerd Rods (was Hot Rod Jim’s) differential adapter, 4:10 gears, stock limited slip

• 5.3L, Aluminum block, Stock crank, rods and pistons, Texas Speed heads, Holley intake,

• STS Single Turbo, Turbo logic boost controller, 2.5” exhaust, CNC bent custom

• T56 or T6060

• Brakes, still up in the air

• Wheels, 10.5” front with 275’s, 12” rears with 345’s (probably going to go nuts here later on)

So this party started as a quick project to give Dave a toy while we worked on his 55 project. We were going to use lots of parts off our PT-57 project that were pulled off the older chassis. We’ll just say that and show you these photos of the initial design. We were planning to do everything on a flat laser as that was our primary CNC experience at the time and so this reflects that.

Full Gallery Here http://gallery.nerdrods.com/Customer..._B/Gallery_01/

That was the plan, until he needed to move for work so the project got sidelined. Once he got settled in we had developed a new product based on new technology (new to us at least), a weld it yourself frame kit. So the design evolved to include some CNC cut tubing. At least until our supplier unceremoniously dumped us by trying to triple the price for no explainable reason. So now it was our turn to need to chill while we located new suppliers as well as developed the design to properly utilize the new equipment. Namely we needed the CNC tubing laser to cut the complex parts for our kits. We found two new shops and finally got back into the swing of things but what we found at one of these new laser shops was even more toys. A CNC tubing bender and a CNC tubing laser all under one roof (Don’t ask, they’re not taking on any more work and I’m not supposed to release their info, It took a lot of pleading for them to take on my own projects and they only really took it because I was willing to give them 6-8 week delivery times and supply CAD.)

And so the idea of a full CNC tube chassis became feasible, and I did a quick drawing to see if we could make it look cool.

Dave approved and so authorized a 3D scan of the body for the computer so I could really fit the cage and driver in the super confined space of the 1932 Ford Roadster. As so we called Absolute Geometries to do the deed.

Last edited by rat_rod_russell; 03-22-2015 at 03:41 PM.

#2

Launching!

Thread Starter

Join Date: Jan 2007

Location: Luling TX In the Hot Rod Shop

Posts: 294

Likes: 0

Received 3 Likes

on

3 Posts

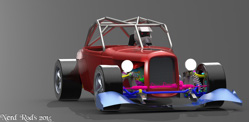

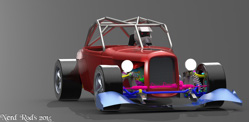

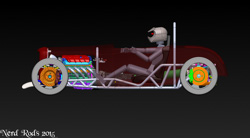

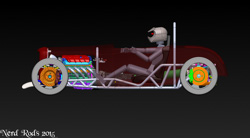

So while I was waiting on the scan data to come back to me someone asked me about fenders. My reply was “No Fender No Problems!” thinking about a set of 345’s up front and some 355’s out back in the long run but then I started looking at some of the old fender shapes and thinking about an areo package. And so I slapped this on the front to look like the old fender shape, it’s just another proof of concept but I think it’s a good looking stat. We’ll come back to this later when I get a chance to play with some CFD (FYI, I have a friend who is willing to let me play with his package and teach me so I will come back to this)

The scan was done and looks awesome! We compressed the hell out of this file so it would load faster so you can see some areas that are not so nice but having the body makes all the difference when fitting inside these tiny old hot rods.

Well, let’s just say my original design had some creative license going for it and after just dropping the body into the computer you can see how badly off I was in several areas.

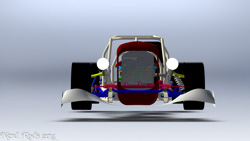

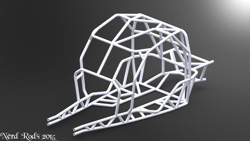

So next I pulled the cage up into place and it all the sudden lots is bad ***-a-re, and so some re design was in order.

After re working the cage shape quite considerably this is basically where I stand.

Any thought or constructive criticism is very very welcome.

Complete Photo Gallery Here,

http://gallery.nerdrods.com/Customer..._B/Gallery_02/

Later

-Russell

The scan was done and looks awesome! We compressed the hell out of this file so it would load faster so you can see some areas that are not so nice but having the body makes all the difference when fitting inside these tiny old hot rods.

Well, let’s just say my original design had some creative license going for it and after just dropping the body into the computer you can see how badly off I was in several areas.

So next I pulled the cage up into place and it all the sudden lots is bad ***-a-re, and so some re design was in order.

After re working the cage shape quite considerably this is basically where I stand.

Any thought or constructive criticism is very very welcome.

Complete Photo Gallery Here,

http://gallery.nerdrods.com/Customer..._B/Gallery_02/

Later

-Russell

#3

Launching!

Thread Starter

Join Date: Jan 2007

Location: Luling TX In the Hot Rod Shop

Posts: 294

Likes: 0

Received 3 Likes

on

3 Posts

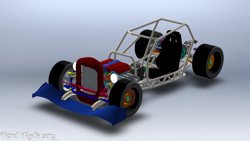

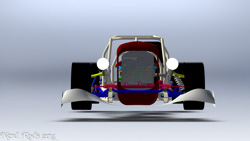

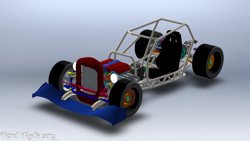

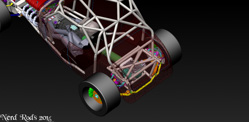

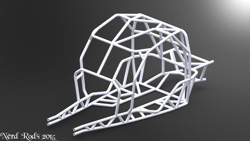

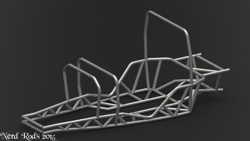

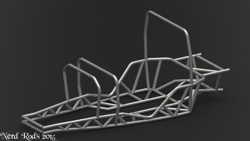

Ok, So this is the last time I’m going to re start this frame design, I promise, maybe……. I sent these photos of the V0.4 frame to Dave (aka the customer) and he, well, probably better to just let you read it.

So there you have it. It’s going to be a race car that might just be street legal for the hell of it. So any suggestions of racing classes will be awesome so I can start looking at specific rules so he can hopefully have some wheel to wheel fun in some class but I’m pretty sure this car will mostly be a track day / time attack tool more than anything. Dave’s a cool guy but he’s also really really damn busy.

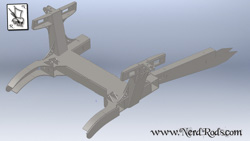

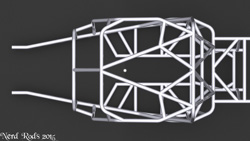

Onto the current design and what’s changed. This is Version 0.4 and so 0.1-0.3 are all scarped for various reasons. The big design change in this one is breaking the frame into a defined top and bottom sections so it can be fabricated in relation to the body. Basically build the bottom half and a good chunk of the top then put the body on the bottom and drop the top half in on top of it and weld the two together. Also remember this was supposed to be a street car with track abilities at this point. Still some fine tuning and I need to take a trip over to use my friends FEA to see where I need to make the fine adjustments and I need to add in a few more bars now for the race version of the chassis.

Later

-Russell @ Nerd Rods

Thanks for all the updates and the oil pump data. The added headroom is not too big of a push but necessary. In order to get this on a track and race, I will need to pass the safety *****. Let's get this set-up for track use first and street legal second. This means a lot of of show stuff goes away and clearly marked safety equipment is plain view. It may end up looking like a cross between a midget and baja 1000 cage by the time its done.

The general requirements that I remember are the helmet has to be at least two inches from any contact point. I will be padding the roll bar with standard dense foam. This should be added to the roll bar calculations for final diameter. What spec do you design the roll cage to for track use?

I will need shoulder harness bars. The harness bar use to be 15 degrees less than the harnesses seat entry point. I didn't see this in the frame pictures. I prefer to use a six point mount. Open cockpit = arm restraints. I'll need a point to attach these. The seat should have enough space for a neck brace and helmet support. Just means the seat angle should consider this. Other non-frame stuff - Easy access to kill switch, front and back tow straps to get a ride off the track. Purple K extinguisher will need to be within reach.

The general requirements that I remember are the helmet has to be at least two inches from any contact point. I will be padding the roll bar with standard dense foam. This should be added to the roll bar calculations for final diameter. What spec do you design the roll cage to for track use?

I will need shoulder harness bars. The harness bar use to be 15 degrees less than the harnesses seat entry point. I didn't see this in the frame pictures. I prefer to use a six point mount. Open cockpit = arm restraints. I'll need a point to attach these. The seat should have enough space for a neck brace and helmet support. Just means the seat angle should consider this. Other non-frame stuff - Easy access to kill switch, front and back tow straps to get a ride off the track. Purple K extinguisher will need to be within reach.

Onto the current design and what’s changed. This is Version 0.4 and so 0.1-0.3 are all scarped for various reasons. The big design change in this one is breaking the frame into a defined top and bottom sections so it can be fabricated in relation to the body. Basically build the bottom half and a good chunk of the top then put the body on the bottom and drop the top half in on top of it and weld the two together. Also remember this was supposed to be a street car with track abilities at this point. Still some fine tuning and I need to take a trip over to use my friends FEA to see where I need to make the fine adjustments and I need to add in a few more bars now for the race version of the chassis.

Later

-Russell @ Nerd Rods

#4

Launching!

Thread Starter

Join Date: Jan 2007

Location: Luling TX In the Hot Rod Shop

Posts: 294

Likes: 0

Received 3 Likes

on

3 Posts

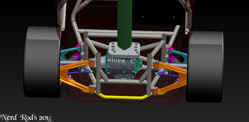

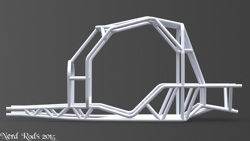

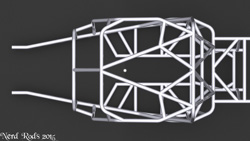

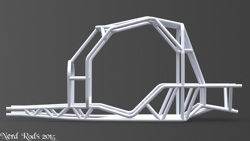

So here's the current plan. We're going to start with this. I'm going to order this half of the chassis with my next order of frames after I finalize the rear suspension pickup points and alignment tabs. We don't have a solid racing class but Time Trials with NASA or other Time Attack stuff looks like what the customer wants to do because of his schedule. This will allow us to get the ergonomics dialed in exactly so everyone can be comfortable then dial the cage roof in from there depending on exact rules and classes we discover at that point.

Gallery

http://gallery.nerdrods.com/Customer..._B/Gallery_03/

This is basically the bottom half that I'll need to get the body on the car. Then we glass the body to the frame and work our way up. Its going to be tight and while looks are very important the ability to drive this car with confidence is even more important.

Later

-Russell

Gallery

http://gallery.nerdrods.com/Customer..._B/Gallery_03/

This is basically the bottom half that I'll need to get the body on the car. Then we glass the body to the frame and work our way up. Its going to be tight and while looks are very important the ability to drive this car with confidence is even more important.

Later

-Russell

#5

TECH Resident

Would your customer buy a FG body to go with this or use a steel one?

That is a neat project. Could be cool if the frame could be modular, so you could add the top cage depending upon your application (even having flanged / bolted mounts vs. welding) say if you want to add the cage for a track event.

As opposed to the single rollbar hoop behind the rear seat, I wonder if it'd look better with a small driver hoop only like in the Cobras. I know you've been through many iterations of design, so I'm not suggesting this change, just kind of thinking out loud for perhaps a project of my own one day.

The trussed rails seem to make a whole lot of sense from a strength to weight standpoint.

Thanks for posting here! I really love your projects

Doug

That is a neat project. Could be cool if the frame could be modular, so you could add the top cage depending upon your application (even having flanged / bolted mounts vs. welding) say if you want to add the cage for a track event.

As opposed to the single rollbar hoop behind the rear seat, I wonder if it'd look better with a small driver hoop only like in the Cobras. I know you've been through many iterations of design, so I'm not suggesting this change, just kind of thinking out loud for perhaps a project of my own one day.

The trussed rails seem to make a whole lot of sense from a strength to weight standpoint.

Thanks for posting here! I really love your projects

Doug

#6

Launching!

Thread Starter

Join Date: Jan 2007

Location: Luling TX In the Hot Rod Shop

Posts: 294

Likes: 0

Received 3 Likes

on

3 Posts

The fiberglass body we scanned a few post up is the one we'll be using for this project so it is fiberglass.

The bolt on cage would not pass tech for most racing classes.

The main hoop is a starting point for the rest of the cage and so it can not be swapped for single hoops. It will look like the earlier photos when it is done. This is just a starting point.

The bolt on cage would not pass tech for most racing classes.

The main hoop is a starting point for the rest of the cage and so it can not be swapped for single hoops. It will look like the earlier photos when it is done. This is just a starting point.