Round 2 on my 87, Custom ehxaust, crossmember, installed cutout. LOTS OF PICS!!

#1

Hey everyone. I just thought I would post some pictures of the second round of modifications to my 87. Among other things, the big project was my exhaust. The y-pipe was a mess. It had leaks and hung way too low. And it was just not good. So, I wanted to build a new crossmember, a y-pipe to go along with it, and also add a cut out.

Im going to let the pictures do most of the talking. I got to drive her around today for the first time in about a month. The new y-pipe seems good to go. No noises, no leaks so far, and the cut out is funnn!!!! I love that thing. I wired it up to a vert top switch from the 99 donor car that I had.

First, a pic of the old y-pipe, and also how close to the ground it hung. This was a hawks conversion y-pipe. I had to cut it up and re-weld it just to get it to fit. And even then it would hit on everything I drove over and was just generally a mess.

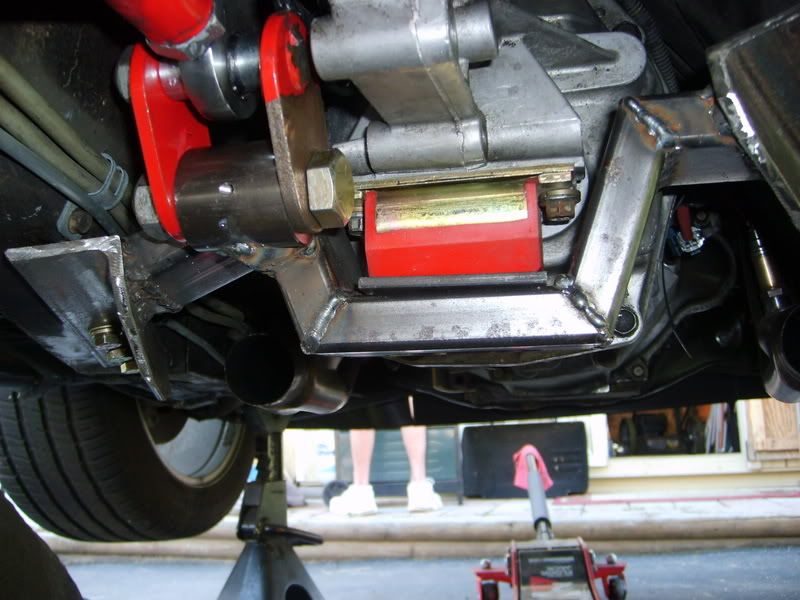

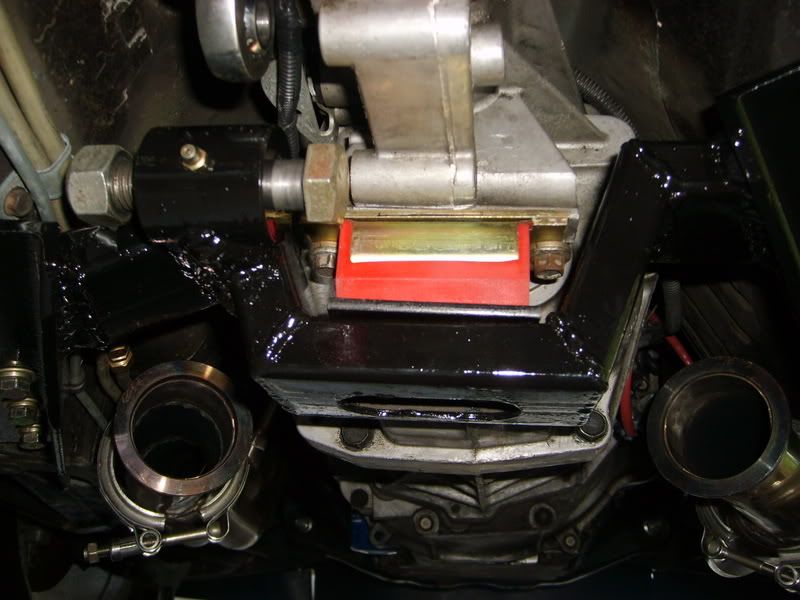

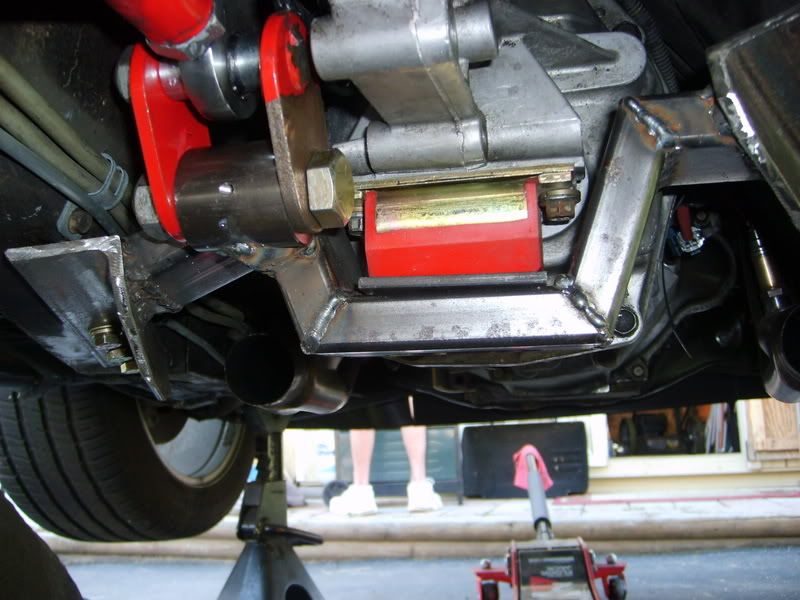

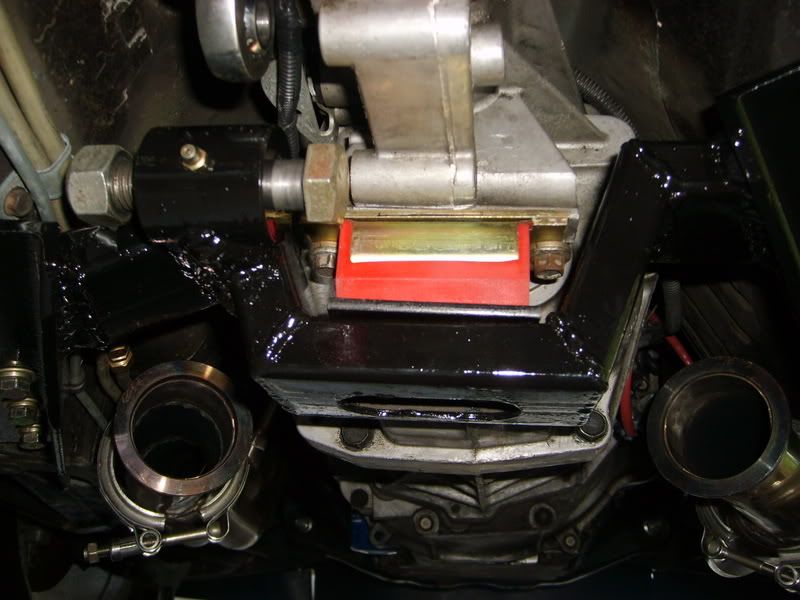

Ok, Now some pictures of the crossmember to start things off. This was fun to make. Turned out pretty good. Should be PLENTY strong.

Now for the y-pipe. First, everything started with some v-clamps. Those are the clamps I chose to work with, and Im glad I did. They work perfectly, and so far they have lived up to the hype of not needing gaskets or anything.

After a lot of cutting and fitting and tacking, I ended up with this. This is before I tacked on the cut out pipe and rear clamps.

This is after finish welding. No MIG welds here...

Im going to let the pictures do most of the talking. I got to drive her around today for the first time in about a month. The new y-pipe seems good to go. No noises, no leaks so far, and the cut out is funnn!!!! I love that thing. I wired it up to a vert top switch from the 99 donor car that I had.

First, a pic of the old y-pipe, and also how close to the ground it hung. This was a hawks conversion y-pipe. I had to cut it up and re-weld it just to get it to fit. And even then it would hit on everything I drove over and was just generally a mess.

Ok, Now some pictures of the crossmember to start things off. This was fun to make. Turned out pretty good. Should be PLENTY strong.

Now for the y-pipe. First, everything started with some v-clamps. Those are the clamps I chose to work with, and Im glad I did. They work perfectly, and so far they have lived up to the hype of not needing gaskets or anything.

After a lot of cutting and fitting and tacking, I ended up with this. This is before I tacked on the cut out pipe and rear clamps.

This is after finish welding. No MIG welds here...

#2

Here are some pics after its all together. How it all fits and all that jazz...

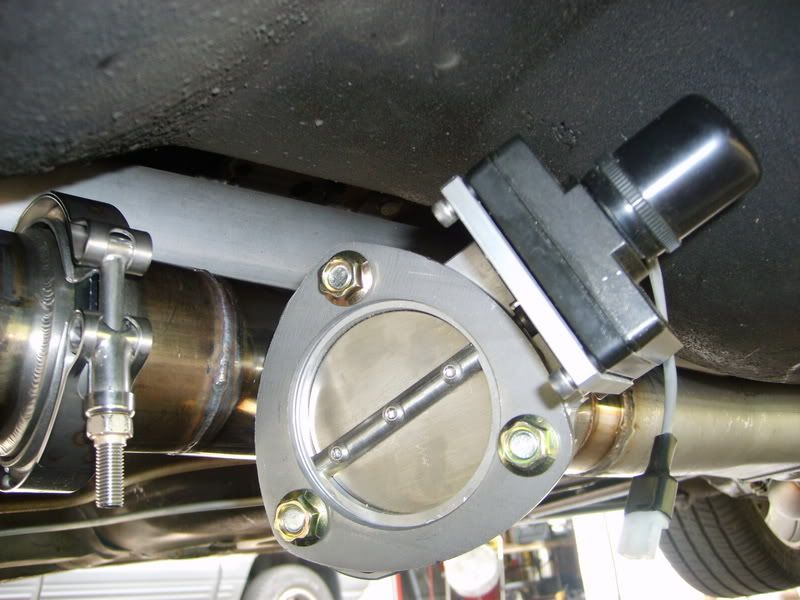

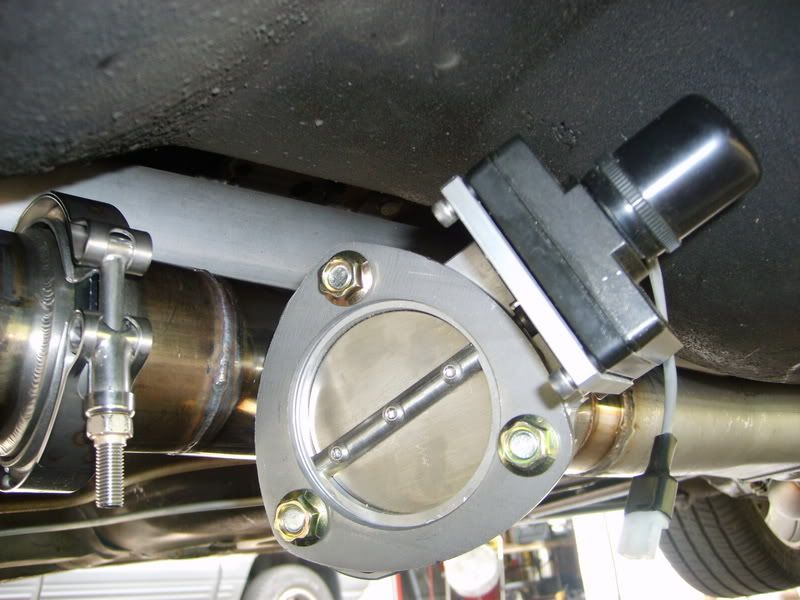

Cut out with a flange installed ready for fitting a turn down. The valve opens up so that it would blow onto the floor. SO I made a simple quick turn down for it.

Now just some overall pics...

Alittle better clearance...

Questions/comments encouraged!

Justin

Cut out with a flange installed ready for fitting a turn down. The valve opens up so that it would blow onto the floor. SO I made a simple quick turn down for it.

Now just some overall pics...

Alittle better clearance...

Questions/comments encouraged!

Justin

#5

Thanks guys! Yeah most of the welds are pretty decent. The little turn down on the cut out came out like crap, because I was so excited and in a hurry to finish, I forgot to turn the gas on the welder when I started.

Im sitting there like why is this thing welding so bad. Then it hit me after I already had booger welds all over it. So I turned on the gas and burnt over it all. Since it was just a turn down, it didnt need to seal or anything. So I didnt worry about it.

Im going to check for leaks today and catch all the small ones that Im sure that I have. Ill report back. So far, I dont think those v-clamps are leaking at all. Those clamps are awesome!!!

Justin

Im sitting there like why is this thing welding so bad. Then it hit me after I already had booger welds all over it. So I turned on the gas and burnt over it all. Since it was just a turn down, it didnt need to seal or anything. So I didnt worry about it.

Im going to check for leaks today and catch all the small ones that Im sure that I have. Ill report back. So far, I dont think those v-clamps are leaking at all. Those clamps are awesome!!!

Justin

Trending Topics

#10

For some of the work I used a crappy *** Clarke 130 MIG. For the TIG welds, I went to a local machine shop. I kind of made friends with their main welder, and we talked about it, and he actually taught me how to TIG. He let me practice on some scrap til I could get a decent looking weld. Then he did some and I did a couple. If you look in person, you can tell which ones are his and which are mine. He's a cool dude. Even welded support pieces across the "Y" so it didnt flex/shift during the heat cycling of welding. Not sure what the TIG machine was exactly. It was a Miller. One of their smaller 220 machines.

I was going to MIG the whole exhaust. I can get great beads in thicker flat steal. And on mild exhaust. But the entire exhaust is stainless, with the some mild mixed in. So right there you gotta have the 309 wire, which I have. But its just a general pain to get it to look good. Cost me quite a few bucks for the welders time and all, but worth it, because if I can ever get a TIG, Ill be able to jump right on it. If only the garage had 220....

The wooden ramps were a god send! It started out on those, then the rear got jacked up. Then I had to put the front on stands because I was making adjustable steering stops. But they really shine when lowering the car all the way. My jack doesnt get stuck under the car anymore Put the front wheels down, lower the rear with a jack, back her down.

Put the front wheels down, lower the rear with a jack, back her down.

Thanks for the feedback fellas! I still have some ticking goin on... Im not sure if its still an exhaust leak up front, or leaky headers, or just valvetrain noise. I put on new GM header gaskets. Torqued the bolts. And used stage 8 locking bolts with the locks installed. Anyone think I should pull all the locks off and give them alittle tighten? The thing runs great...just that darn ticking gets annoying sometimes.

Justin

I was going to MIG the whole exhaust. I can get great beads in thicker flat steal. And on mild exhaust. But the entire exhaust is stainless, with the some mild mixed in. So right there you gotta have the 309 wire, which I have. But its just a general pain to get it to look good. Cost me quite a few bucks for the welders time and all, but worth it, because if I can ever get a TIG, Ill be able to jump right on it. If only the garage had 220....

The wooden ramps were a god send! It started out on those, then the rear got jacked up. Then I had to put the front on stands because I was making adjustable steering stops. But they really shine when lowering the car all the way. My jack doesnt get stuck under the car anymore

Put the front wheels down, lower the rear with a jack, back her down.

Put the front wheels down, lower the rear with a jack, back her down.Thanks for the feedback fellas! I still have some ticking goin on... Im not sure if its still an exhaust leak up front, or leaky headers, or just valvetrain noise. I put on new GM header gaskets. Torqued the bolts. And used stage 8 locking bolts with the locks installed. Anyone think I should pull all the locks off and give them alittle tighten? The thing runs great...just that darn ticking gets annoying sometimes.

Justin

#11

TECH Fanatic

iTrader: (52)

Join Date: May 2004

Location: Kingsland, GA

Posts: 1,354

Likes: 0

Received 0 Likes

on

0 Posts

Damn! That looks good! I may have to do that if my way doesn't work out. I plan on getting some dr gas oval tubing and cramming it in the trans tunnell all the way down. Mufflers will go where rear seat *** pans used to be bubbled down. But I'm not that far yet...I still have to fabricate my headers

#13

I made the crossmember from scratch. 1/4" thick 1.5" or 2" angle, and 1"x3"x1/8" rectangular tubing. I used 3 mount holes per side. And I got the parts to hook up the torque arm right from spohn.

The v-clamps came from summit. They are Dynatech clamps. Mild flanges with stainless clamps. Wanted all stainless but they were $$$$$$$. They didnt come with the pipe welded on. The pipes were welded on so that I could attach them to the end of the headers, and it made tacking the rest easier.

fast377: I was looking into oval tubing for awhile. the thought of having to cut and fit that stuff kinda had me worried. Round is much easier and much more forgiving. That would be cool if you got that to work though.

Justin

The v-clamps came from summit. They are Dynatech clamps. Mild flanges with stainless clamps. Wanted all stainless but they were $$$$$$$. They didnt come with the pipe welded on. The pipes were welded on so that I could attach them to the end of the headers, and it made tacking the rest easier.

fast377: I was looking into oval tubing for awhile. the thought of having to cut and fit that stuff kinda had me worried. Round is much easier and much more forgiving. That would be cool if you got that to work though.

Justin

#14

TECH Fanatic

iTrader: (52)

Join Date: May 2004

Location: Kingsland, GA

Posts: 1,354

Likes: 0

Received 0 Likes

on

0 Posts

I'll find out in a couple of weeks if it will work. I know I have a TON of room around the output shaft with the spohn cross member...it's around the torque arm where I am worried. But I'm turning the oval pipe vertical (long up and down short side to side) to run along side the drive shaft. But if that doesn't work out, at least I know your way does...again well done!

#20

Thanks for the compliments guys!

Not off topic at all. They are made by Dynatech. I got mine from summit...seemed to be the best price and fastest shipping. They are steel flanges and stainless clamps.

J.

Originally Posted by SheldonZ28

Completely off topic, but are those band clamps made by clampco?

J.