Drag Racing Tire FAQ

#1

Lots of information out there so lets put it in one thread and I will combine it into one post.

OPEN TO ANY DRAG TIRE INFO

Question: What is the approved rim range for tires?

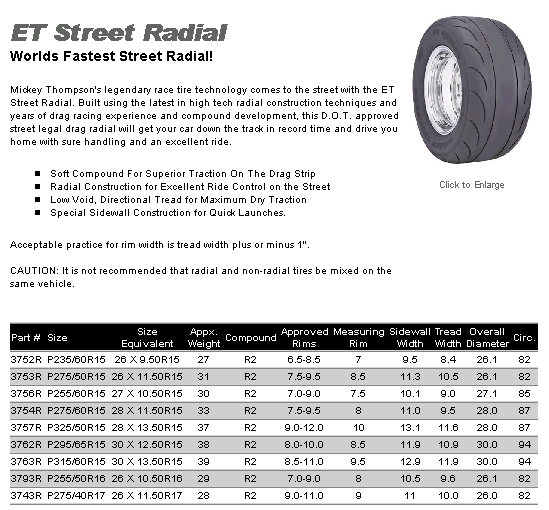

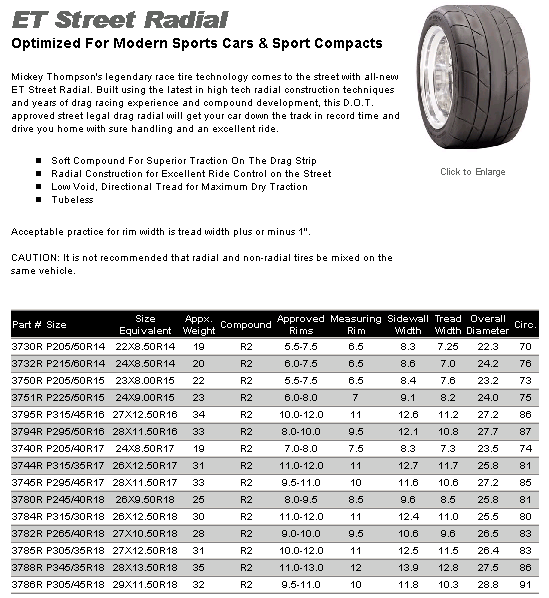

Answer: The approved rim range for race tires is the tread width plus or minus 1.

Note: The sidewall measurement will change with rim width. The rule of thumb is 4/10ths of an inch, over all, for each 1change in rim width.

Question: How much will a drag slick grow?

Answer: Over all diameter will affect the amount of growth that you will have. There are many variables that contribute to tire growth as well. Unless otherwise noted, drag slicks are considered a low growth tire. Slicks will grow approximately 1 to 1 ½ @ 150mph

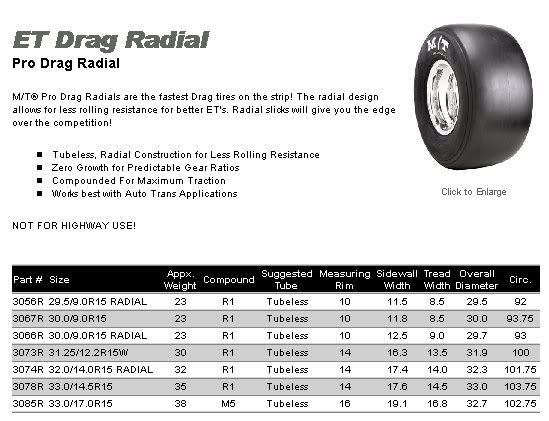

Note: Radial slicks do not grow.

Question: What is the advantage to running a stiff sidewall tire? If there is no stiff sidewall slick in my size what can I do to stiffen the sidewall of my slick?

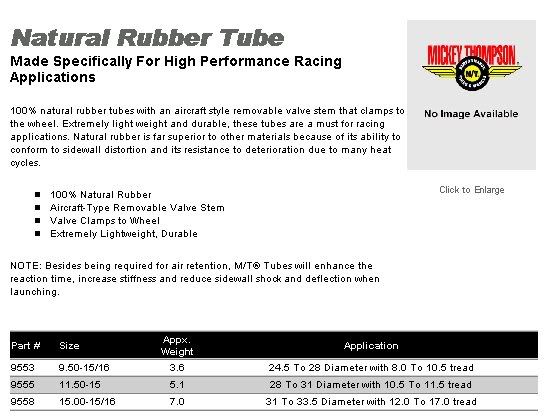

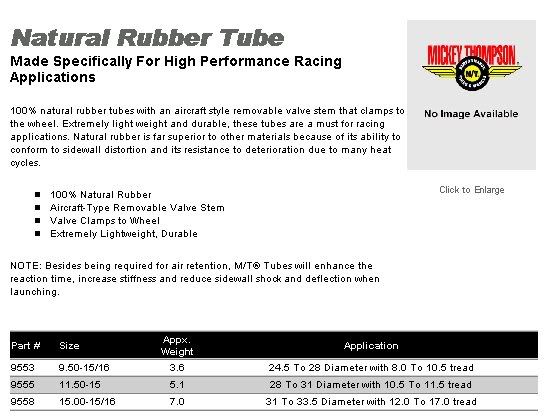

Answer: The advantage of a stiff sidewall is less tire wrap or sidewall distortion, thus reacting better at launch. Note: This is good for heavy cars, or cars with a suspension, that can absorb the initial launch. If you are running a fixed suspension car like a dragster or an altered, you would need the tire to absorb the launch, thus a softer sidewall. There are two ways to stiffen the sidewall. 1. Run tubes to help support the sidewall. 2. Matching the tread width with the wheel width, or going 1 wider on the wheel width, will stiffen the sidewall.

Question: Should I use rim screws with slicks?

Answer: Starting line launches can cause the rim to spin inside the tire. This can be hazardous and should be avoided. If you are not sure your rim is doing this, mark the tire and wheel with a line to gauge tire slippage on the wheel. Check for tire slippage when you check your tire pressure after each pass. If it moves ½ to 1, you should use rim screws. Do not use rim screws on radial tires, unless they move on the rim.

Question: Should my slicks be balanced?

Answer: Yes. Static or Bubble balancing. Dynamic or Spin balancing, a bias ply slick will work best only if the slick does not deform. In racing the tire goes through many changes in shape. Launching, the tire wrinkles and squats. As the car goes towards the top end, the tire begins to egg shape. A static balance assures the tire is balanced around the circumference as it deforms.

Question: Are drag slicks directional?

Answer: Bias ply drag slicks are non directional. New tires that require running directional will have rotation arrows to signify this. Radial tires are directional.

TIRE STORAGE

The useful life of a tire, whether mounted or dismounted, is directly affected by storage conditions. Tires should always be stored indoors in a dark, cool, dry room.

DO

1 Remove the tires from the vehicle.

2. Remove the air from the tires and store them on their side in a cool/dark/dry environment.

3. Place tires in a black plastic bag when stored during the "off-season".

4. Make sure the temperature range in the storage location is between 40-90 degrees Fahrenheit.

DON'T

1. Don't store tires in direct sunlight or near electric motors. (Electric motors emit small amounts of ozone.) Tires need to be protected from light, especially sunlight. Light causes ultraviolet damage by breaking down the rubber compounds. The storeroom should not contain electrical welding or any other equipment that could produce ozone.

2. Don't apply any chemical to tires. It's not necessary and may actually damage the integrity of the tire by breaking down the rubber properties of the tire. Tires must not be allowed to come in contact with oils, greases, solvents, or other petroleum products that cause rubber to soften or deteriorate.

3. Don't store tires in sub-freezing temperatures for any length of time. (The rubber can freeze and may crack as a result.)

OPEN TO ANY DRAG TIRE INFO

Question: What is the approved rim range for tires?

Answer: The approved rim range for race tires is the tread width plus or minus 1.

Note: The sidewall measurement will change with rim width. The rule of thumb is 4/10ths of an inch, over all, for each 1change in rim width.

Question: How much will a drag slick grow?

Answer: Over all diameter will affect the amount of growth that you will have. There are many variables that contribute to tire growth as well. Unless otherwise noted, drag slicks are considered a low growth tire. Slicks will grow approximately 1 to 1 ½ @ 150mph

Note: Radial slicks do not grow.

Question: What is the advantage to running a stiff sidewall tire? If there is no stiff sidewall slick in my size what can I do to stiffen the sidewall of my slick?

Answer: The advantage of a stiff sidewall is less tire wrap or sidewall distortion, thus reacting better at launch. Note: This is good for heavy cars, or cars with a suspension, that can absorb the initial launch. If you are running a fixed suspension car like a dragster or an altered, you would need the tire to absorb the launch, thus a softer sidewall. There are two ways to stiffen the sidewall. 1. Run tubes to help support the sidewall. 2. Matching the tread width with the wheel width, or going 1 wider on the wheel width, will stiffen the sidewall.

Question: Should I use rim screws with slicks?

Answer: Starting line launches can cause the rim to spin inside the tire. This can be hazardous and should be avoided. If you are not sure your rim is doing this, mark the tire and wheel with a line to gauge tire slippage on the wheel. Check for tire slippage when you check your tire pressure after each pass. If it moves ½ to 1, you should use rim screws. Do not use rim screws on radial tires, unless they move on the rim.

Question: Should my slicks be balanced?

Answer: Yes. Static or Bubble balancing. Dynamic or Spin balancing, a bias ply slick will work best only if the slick does not deform. In racing the tire goes through many changes in shape. Launching, the tire wrinkles and squats. As the car goes towards the top end, the tire begins to egg shape. A static balance assures the tire is balanced around the circumference as it deforms.

Question: Are drag slicks directional?

Answer: Bias ply drag slicks are non directional. New tires that require running directional will have rotation arrows to signify this. Radial tires are directional.

TIRE STORAGE

The useful life of a tire, whether mounted or dismounted, is directly affected by storage conditions. Tires should always be stored indoors in a dark, cool, dry room.

DO

1 Remove the tires from the vehicle.

2. Remove the air from the tires and store them on their side in a cool/dark/dry environment.

3. Place tires in a black plastic bag when stored during the "off-season".

4. Make sure the temperature range in the storage location is between 40-90 degrees Fahrenheit.

DON'T

1. Don't store tires in direct sunlight or near electric motors. (Electric motors emit small amounts of ozone.) Tires need to be protected from light, especially sunlight. Light causes ultraviolet damage by breaking down the rubber compounds. The storeroom should not contain electrical welding or any other equipment that could produce ozone.

2. Don't apply any chemical to tires. It's not necessary and may actually damage the integrity of the tire by breaking down the rubber properties of the tire. Tires must not be allowed to come in contact with oils, greases, solvents, or other petroleum products that cause rubber to soften or deteriorate.

3. Don't store tires in sub-freezing temperatures for any length of time. (The rubber can freeze and may crack as a result.)

Last edited by dlove; 06-13-2008 at 01:55 PM.

#2

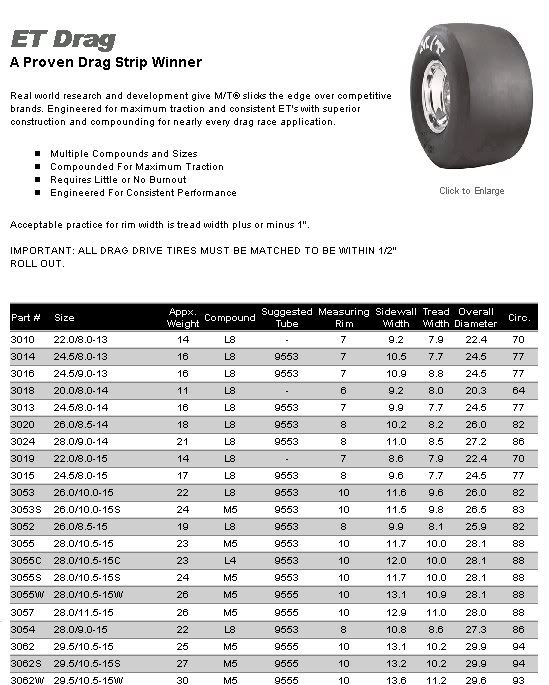

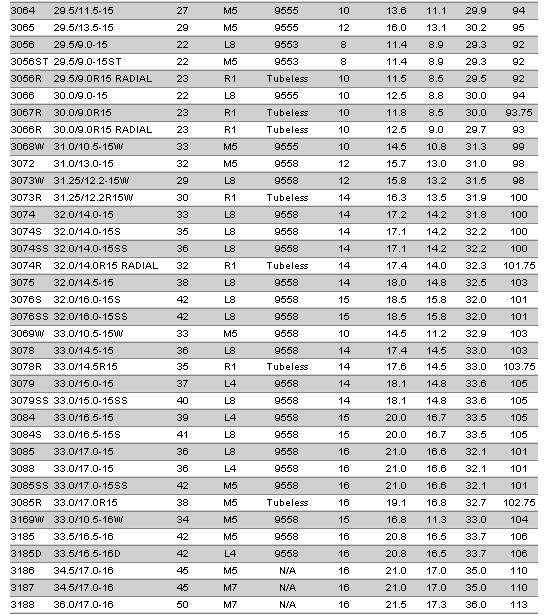

Compounds and Constructions (from MT)

Med............................................... .......................................Soft

B1...M7....M5.................R2....R1...L8....L7. ..............B2.........L4.....M2

B1: For Motorcyles

B2: For Motorcyles

L4: For dragsters, lightweight vehicles, FWD vehicles, & vehicles without rear suspension

L7: For Motorcyles

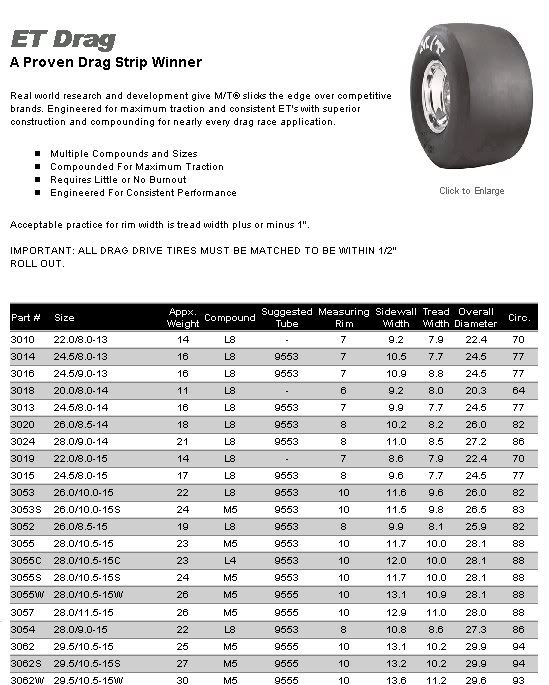

L8: General use compound

M2: For Jr. dragsters

M5: General use compound

M7: High HP general application

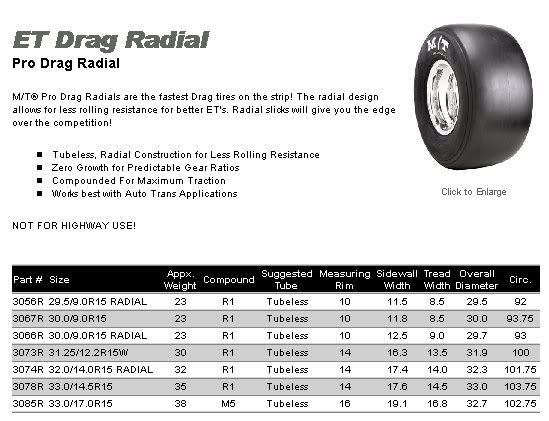

R1: Special compound for ET drag radial

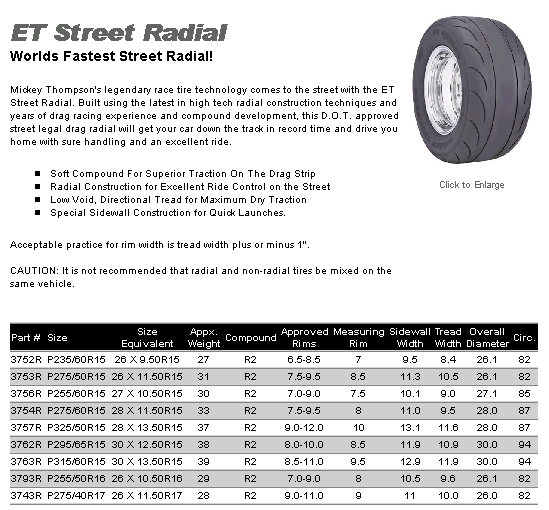

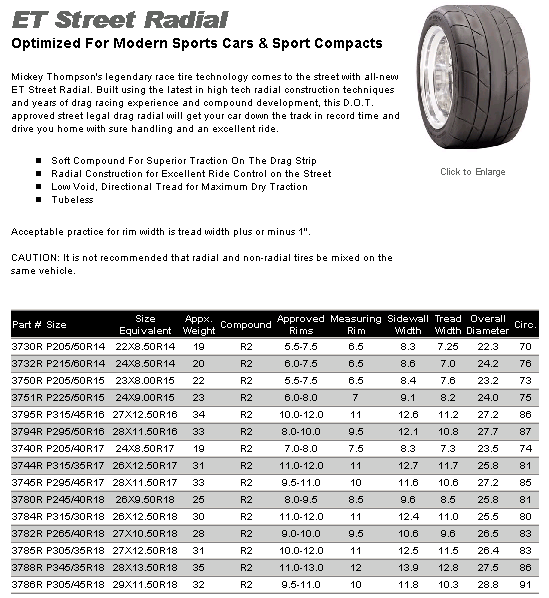

R2: Special compound for ET street radial

ST: Suggest for maual trans (med compound)

W: Extra tread width

S: Stiff sidewall construction, aids in quicker reaction time due to less tire distortion

SS: Super stiff sidewall

C: Sport compact

D: Dragster application

R: Radial construction

Med............................................... .......................................Soft

B1...M7....M5.................R2....R1...L8....L7. ..............B2.........L4.....M2

B1: For Motorcyles

B2: For Motorcyles

L4: For dragsters, lightweight vehicles, FWD vehicles, & vehicles without rear suspension

L7: For Motorcyles

L8: General use compound

M2: For Jr. dragsters

M5: General use compound

M7: High HP general application

R1: Special compound for ET drag radial

R2: Special compound for ET street radial

ST: Suggest for maual trans (med compound)

W: Extra tread width

S: Stiff sidewall construction, aids in quicker reaction time due to less tire distortion

SS: Super stiff sidewall

C: Sport compact

D: Dragster application

R: Radial construction

Last edited by dlove; 04-13-2008 at 09:13 PM.

#4

Helpful Links

Compare tire sizes-

http://www.miata.net/garage/tirecalc.html

Some drag wheel info-

http://www.freewebs.com/casper9t9/dragwheelinfo.htm

Compare tire sizes-

http://www.miata.net/garage/tirecalc.html

Some drag wheel info-

http://www.freewebs.com/casper9t9/dragwheelinfo.htm

Last edited by dlove; 08-12-2008 at 02:40 PM.

#5

Bias Ply Tire: Bias Ply tires are constructed of layers of rubber-coated plies composed of textile cords placed upon each other at approximately 30-45 degree angles. These plies are then wrapped around the bead wires. As a result of a tire being bias in design it will have a circumference that varies from tire to tire. Because of its design a bias tire can expand due to increased air pressure or due to heat generated during use. This allows a team to tune their cars setup and stagger in order to help the car handle better. Bias-ply tires have many limitations. Since the plies were placed at angles to each other, the casing is subjected to strong friction due to inter-ply shearing, which builds up heat and increases tread wear due to a higher slip angle. The positioning of the plies also limits the tire’s ability to provide both superior handling and ride comfort. One big advantage of bias tire is the lower tire cost. Bias tires are also much more tolerant of the set up than radial tires. It is easier to set them up and they are typically easier to drive at the limit of traction. Bias ply tires like higher slip angles, in the area of 3°-5° and work best with less than 1 degree of camber.

DOT: Department of Transportation. Governing body that establishes regulations including tire labeling and performance standards of tires that are run inside the United States on public roads and highways.

DOT Markings: A code molded into the sidewall of a tire signifying that the tire complies with U.S. Department of Transportation motor vehicle safety standards. The DOT code includes an alphanumeric designator, which can also identify the tire's manufacturer, production plant, and date of production and brand.

DOT Tires: Used to refer to street-legal tires that can be purchased by the public, as opposed to racing tires. Many lower-cost forms of racing require use of Department of Transportation (DOT) tires

Footprint: The portion or amount of area of the tread that contacts the road.

Heat Cycle: Refers to the number of times a tire is run up to operating temperature and then allowed to fully cool.

Load Index: An assigned number ranging from 0 to 279 that corresponds to the load carrying capacity of a tire.

Load Range: DOT required specification. Calculation based on pressure, construction and speed. The average load a tire can bear without damage under set specifications

Meats: Slang term for tires. Mostly used in drag racing.

Radial Ply Tire: A type of tire that's constructed with the reinforcing belts sideways (bead to bead) under the tread rather than lengthwise. The cords in the body of a radial tire run at or near 90-degree angles to the centerline of the tread. The combination of stabilizing belts and the radial casing allows the tread and sidewall to act independently. The sidewall flexes easily under load and greater vertical deflection is achieved with radial tires. When negotiating curves and encountering side forces, the independent action of the tread and sidewalls keeps the tread flat on the road. This allows the tire to hold to its path. This results in better overall handling compared to a bias tire. Radials also run cooler than a bias ply tire because there is less friction between the plies inside the tire. But radials tend to demand a much more precise line around each track, whereas bias-ply tires are more forgiving. This is related to the slip angle that each design needs for maximum grip. Radial tires work best at 1-2 degrees of slip and need 2-3 degrees of camber. For the driver this translates into a bigger window of feedback to feel the tire working. The other related factor is the drop off in grip that occurs if the tire is pushed beyond the optimum. For bias ply tires, this tends to be a smooth transition that can be corrected, while with radial tires, the transition can be quite abrupt causing the car to loose control all at once. Radials are much more expensive to produce compared to bias tires.

Rolling Resistance: The measured drag create by a driving surface, the tire, drive train parts, or a combination of all. The lower the rolling resistance, the less energy needed to keep a vehicle moving.

Rollout: The circumference of an inflated tire. The measured distance a tire will cover in one revolution.

Rotation: The changing of tires from front to rear or from side-to-side on a vehicle according to a set pattern; provides even tread wear.

Section Height: The distance between to bead diameter and the outer diameter of the tire. This dimension is usually represented as a percentage of the tread width.

Section Width: The width of the tire at the widest point when mounted on the correct rim. This is typically located somewhere about the midpoint of the sidewall.

Sidewall: That portion of a tire between the tread and the bead.

Slicks: Racing tires having no tread design, in order to get the maximum amount of rubber in contact with the pavement.

TIN: Tire Identification Number. An alphanumeric code mark located usually on the sidewall of a tire to identify a manufacturing batch or date.

Tire: An assembly of rubber, chemicals, fabric and possibly metal, designed to provide traction, cushion road shock and carry a load under varying conditions.

Tire Designation: An alphanumeric code molded into the sidewall of the tire that describes the tire's size, including width, aspect ratio, rim diameter, load index and speed rating. Most designations use the P-Metric system, although racing tires often use non-DOT nomenclature.

Tire Placard: A metal or paper tag permanently affixed to a highway vehicle, which indicates the appropriate tire size and inflation pressures for the vehicle.

Tire Rub: When a tire is coming in contact with part of the car.

Tire Run: The amount of laps or time run during the useful life of a set of tires.

Tire Rule: When a racing series mandates that competitors can run only one "spec" or specified brand of tires. See "Spec."

Tire Shake: A drag racing phenomenon when a loss of traction and/or tire distortion causes the tires to shake violently. Normally, the car becomes out of control and the driver's vision is blurred from the movement. See also back-pedaling.

Tire Softener: A solvent, which is applied to the surface of tires, changes the chemical characteristics of the tread rubber. Sanctioning bodies and most weekly tracks have banned the use of tire softeners because they are based on aromatic hydrocarbons (such as benzene or xylene), which are toxic with repeated exposure. They may also cause damage to the structure of the tire and increase the risk of failure.

Tire Stint: The amount of laps or time run during the useful life of a set of tires.

Tire Wear: The loss of rubber from tire treads due to use.

Tread: The portion of a tire that comes into contact with the road.

Tread Depth: The usable thickness of the tread. Small pinholes, called depth holes, are placed in the tread so tread depth can be measured.

Tread Pattern: This refers to the groove design on the operating surface of a tire. Most patterns are molded into the tread at the factory, but a custom grooved tire is also said to have a tread pattern.

Tread Rib: The tread section that runs around the circumference of the tire separated by the tread grooves.

Tread Width: The width of a tire's tread.

Tread Wear Indicator: Narrow bands, sometimes called "wear bars," that appear across the tread of the tire when only 2/32 inch of treads remains. This applies to DOT type tires.

Wheel Hop: A hopping action of the rear wheels during heavy acceleration. Traction is lost and regained in rapid cycles after power is applied to the rear wheels.

DOT: Department of Transportation. Governing body that establishes regulations including tire labeling and performance standards of tires that are run inside the United States on public roads and highways.

DOT Markings: A code molded into the sidewall of a tire signifying that the tire complies with U.S. Department of Transportation motor vehicle safety standards. The DOT code includes an alphanumeric designator, which can also identify the tire's manufacturer, production plant, and date of production and brand.

DOT Tires: Used to refer to street-legal tires that can be purchased by the public, as opposed to racing tires. Many lower-cost forms of racing require use of Department of Transportation (DOT) tires

Footprint: The portion or amount of area of the tread that contacts the road.

Heat Cycle: Refers to the number of times a tire is run up to operating temperature and then allowed to fully cool.

Load Index: An assigned number ranging from 0 to 279 that corresponds to the load carrying capacity of a tire.

Load Range: DOT required specification. Calculation based on pressure, construction and speed. The average load a tire can bear without damage under set specifications

Meats: Slang term for tires. Mostly used in drag racing.

Radial Ply Tire: A type of tire that's constructed with the reinforcing belts sideways (bead to bead) under the tread rather than lengthwise. The cords in the body of a radial tire run at or near 90-degree angles to the centerline of the tread. The combination of stabilizing belts and the radial casing allows the tread and sidewall to act independently. The sidewall flexes easily under load and greater vertical deflection is achieved with radial tires. When negotiating curves and encountering side forces, the independent action of the tread and sidewalls keeps the tread flat on the road. This allows the tire to hold to its path. This results in better overall handling compared to a bias tire. Radials also run cooler than a bias ply tire because there is less friction between the plies inside the tire. But radials tend to demand a much more precise line around each track, whereas bias-ply tires are more forgiving. This is related to the slip angle that each design needs for maximum grip. Radial tires work best at 1-2 degrees of slip and need 2-3 degrees of camber. For the driver this translates into a bigger window of feedback to feel the tire working. The other related factor is the drop off in grip that occurs if the tire is pushed beyond the optimum. For bias ply tires, this tends to be a smooth transition that can be corrected, while with radial tires, the transition can be quite abrupt causing the car to loose control all at once. Radials are much more expensive to produce compared to bias tires.

Rolling Resistance: The measured drag create by a driving surface, the tire, drive train parts, or a combination of all. The lower the rolling resistance, the less energy needed to keep a vehicle moving.

Rollout: The circumference of an inflated tire. The measured distance a tire will cover in one revolution.

Rotation: The changing of tires from front to rear or from side-to-side on a vehicle according to a set pattern; provides even tread wear.

Section Height: The distance between to bead diameter and the outer diameter of the tire. This dimension is usually represented as a percentage of the tread width.

Section Width: The width of the tire at the widest point when mounted on the correct rim. This is typically located somewhere about the midpoint of the sidewall.

Sidewall: That portion of a tire between the tread and the bead.

Slicks: Racing tires having no tread design, in order to get the maximum amount of rubber in contact with the pavement.

TIN: Tire Identification Number. An alphanumeric code mark located usually on the sidewall of a tire to identify a manufacturing batch or date.

Tire: An assembly of rubber, chemicals, fabric and possibly metal, designed to provide traction, cushion road shock and carry a load under varying conditions.

Tire Designation: An alphanumeric code molded into the sidewall of the tire that describes the tire's size, including width, aspect ratio, rim diameter, load index and speed rating. Most designations use the P-Metric system, although racing tires often use non-DOT nomenclature.

Tire Placard: A metal or paper tag permanently affixed to a highway vehicle, which indicates the appropriate tire size and inflation pressures for the vehicle.

Tire Rub: When a tire is coming in contact with part of the car.

Tire Run: The amount of laps or time run during the useful life of a set of tires.

Tire Rule: When a racing series mandates that competitors can run only one "spec" or specified brand of tires. See "Spec."

Tire Shake: A drag racing phenomenon when a loss of traction and/or tire distortion causes the tires to shake violently. Normally, the car becomes out of control and the driver's vision is blurred from the movement. See also back-pedaling.

Tire Softener: A solvent, which is applied to the surface of tires, changes the chemical characteristics of the tread rubber. Sanctioning bodies and most weekly tracks have banned the use of tire softeners because they are based on aromatic hydrocarbons (such as benzene or xylene), which are toxic with repeated exposure. They may also cause damage to the structure of the tire and increase the risk of failure.

Tire Stint: The amount of laps or time run during the useful life of a set of tires.

Tire Wear: The loss of rubber from tire treads due to use.

Tread: The portion of a tire that comes into contact with the road.

Tread Depth: The usable thickness of the tread. Small pinholes, called depth holes, are placed in the tread so tread depth can be measured.

Tread Pattern: This refers to the groove design on the operating surface of a tire. Most patterns are molded into the tread at the factory, but a custom grooved tire is also said to have a tread pattern.

Tread Rib: The tread section that runs around the circumference of the tire separated by the tread grooves.

Tread Width: The width of a tire's tread.

Tread Wear Indicator: Narrow bands, sometimes called "wear bars," that appear across the tread of the tire when only 2/32 inch of treads remains. This applies to DOT type tires.

Wheel Hop: A hopping action of the rear wheels during heavy acceleration. Traction is lost and regained in rapid cycles after power is applied to the rear wheels.

Last edited by dlove; 04-02-2008 at 02:01 PM.

Trending Topics

#13

FYI...

Per MT on balancing slicks:

"They should be balanced at the running tire pressure a bubble balance is what we prefer. We recommend stick on weight on the back with duct tape over them."

Duct tape is the way to go.

Per MT on balancing slicks:

"They should be balanced at the running tire pressure a bubble balance is what we prefer. We recommend stick on weight on the back with duct tape over them."

Duct tape is the way to go.

#20

I am using the BFG DRs 255/50/16, and have less that 1000 miles on them. I only have 12 passes on them, and they are past the wear bars. How many passes, miles can I expect from DRs in general? For this price, I could have just bought some dedicated slicks and changed them at the track.