Is this the correct way to set up a manual boost controler APS!

#1

TECH Fanatic

Thread Starter

iTrader: (59)

Join Date: Jan 2007

Location: Pittsburgh,Pa

Posts: 1,736

Likes: 0

Received 0 Likes

on

0 Posts

Ok guys

Is this how i should set up my manual boost controler on my APS TT camaro?

http://www.youtube.com/watch?v=EhJtXGSmROs

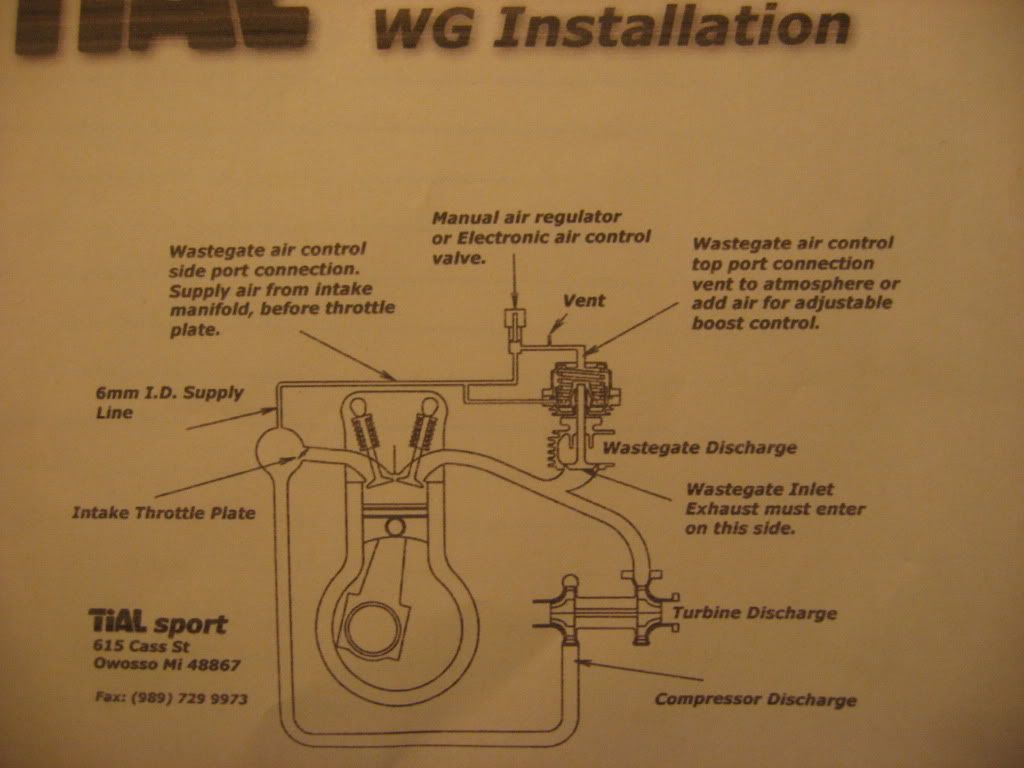

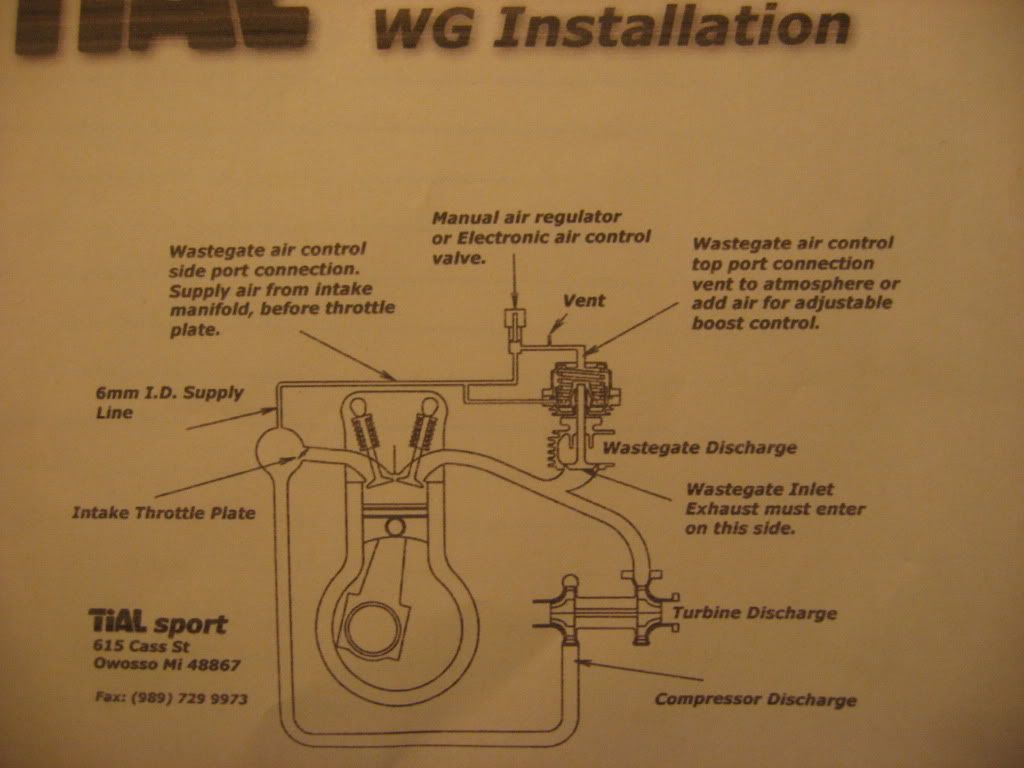

I ran the boost referanced line from the front of my LG turbo (nipple in compressor outlet) to the bottom of the W/G like in these pics .From what ive read,,,this just assaist the spring opening anyways?,,, To keep lines from being cut everywhere ,i ran a line from a nipple that i welded into my (mass air flow delete pipe) (before throttle body of coarse! ) which then goes into the bottom of my manual boost controler and then out of the side of my boost controler which then tees off to both of my waste gates tops

Is this how i should set up my manual boost controler on my APS TT camaro?

http://www.youtube.com/watch?v=EhJtXGSmROs

I ran the boost referanced line from the front of my LG turbo (nipple in compressor outlet) to the bottom of the W/G like in these pics .From what ive read,,,this just assaist the spring opening anyways?,,, To keep lines from being cut everywhere ,i ran a line from a nipple that i welded into my (mass air flow delete pipe) (before throttle body of coarse! ) which then goes into the bottom of my manual boost controler and then out of the side of my boost controler which then tees off to both of my waste gates tops

Last edited by barnat; 06-25-2010 at 12:07 AM.

#4

TECH Fanatic

Thread Starter

iTrader: (59)

Join Date: Jan 2007

Location: Pittsburgh,Pa

Posts: 1,736

Likes: 0

Received 0 Likes

on

0 Posts

The only differance between the way mine is hooked up and the diagrams above is that im bitting of of my (mass air flow delete pipe) for the boost referance for the boost controler which shouldnt make a bit of differance IMO Just makes for less lines and connections

The way i had it hooked up before was that i was using manifold pressure which was (aft the throttle body ) for the boost controler and it was leaving the side of my boost controler and going into the bottoms of my APS W/G's and it wasnt working either

From what ive found,,, Both were wrong LOL

Im actually pulling my APS W/G's as we speak and will be pulling these 10 psi springs and putting in some 12 psi springs and adjusting up from there with my manual boost controler. 12 psi should be about perfect of the street and i can adjust up to say 15psi for the track or my local flash light drags when they come around.Im putting down 633RWHP right now on 10psi so 12 should be just about right for the street says the little bear LOL

Last edited by barnat; 06-25-2010 at 12:04 AM.

#5

On The Tree

iTrader: (1)

By some of your wording I could not quite understand how you routed your lines but I will post the right way and hopefully you did that.

Boost line will go from both turbo compressor outlets, or somewhere else in the pressurized cold side, to the bottoms of their corresponding wastegates. Then you will tee into each boost line from each turbo take these two additional boost lines and tee them together into 1 boost line and take this line into your boost controller valve and then back out of it then tee it back out to two lines again to go to both wastegates at the top.

With the valve on the boost controller fully closed (test by blowing through it) you will be running off of just WG spring pressure. As you open the valve, and thus put more boost resistance on the top of the WG diaphragm, your boost will increase in proportion. Hope this helps.

Boost line will go from both turbo compressor outlets, or somewhere else in the pressurized cold side, to the bottoms of their corresponding wastegates. Then you will tee into each boost line from each turbo take these two additional boost lines and tee them together into 1 boost line and take this line into your boost controller valve and then back out of it then tee it back out to two lines again to go to both wastegates at the top.

With the valve on the boost controller fully closed (test by blowing through it) you will be running off of just WG spring pressure. As you open the valve, and thus put more boost resistance on the top of the WG diaphragm, your boost will increase in proportion. Hope this helps.

Last edited by rocket5979; 06-24-2010 at 11:31 PM.

#6

TECH Fanatic

Thread Starter

iTrader: (59)

Join Date: Jan 2007

Location: Pittsburgh,Pa

Posts: 1,736

Likes: 0

Received 0 Likes

on

0 Posts

By some of your wording I could not quite understand how you routed your lines but I will post the right way and hopefully you did that.

Boost line will go from both turbo compressor outlets, or somewhere else in the pressurized cold side before TB, to the bottoms of their corresponding wastegates. Then you will tee into each boost line from each turbo take these two additional boost lines and tee them together into 1 boost line and take this line into your boost controller valve and then back out of it then tee it back out to two lines again to go to both wastegates at the top.

With the valve on the boost controller fully closed (test by blowing through it) you will be running off of just WG spring pressure. As you open the valve, and thus put more boost resistance on the top of the WG diaphragm, your boost will increase in proportion. Hope this helps.

Boost line will go from both turbo compressor outlets, or somewhere else in the pressurized cold side before TB, to the bottoms of their corresponding wastegates. Then you will tee into each boost line from each turbo take these two additional boost lines and tee them together into 1 boost line and take this line into your boost controller valve and then back out of it then tee it back out to two lines again to go to both wastegates at the top.

With the valve on the boost controller fully closed (test by blowing through it) you will be running off of just WG spring pressure. As you open the valve, and thus put more boost resistance on the top of the WG diaphragm, your boost will increase in proportion. Hope this helps.

More or less instead of teeing off of the turbo like in the diagram above and like you said ,,,i just moved down the pressure side some (right before the throttle body) to feed the boost controler.

This way its a 1 piece hose on each of the turbos . A one piece hose going from my (mass air flow delete pipe) to my boost controler and a one piece hose with 1 tee that goes from my boost controler to the tops of both my wastegates

Last edited by barnat; 06-24-2010 at 11:41 PM.

#7

On The Tree

iTrader: (1)

Instead of teeing like you said off of the tubo ,,,I just bit off of my (mass air flow delete pipe)which is still before the throttle body to work my boost controller which i then ran lines from it to the tops of my W/G's. Im still running lines from the turbos to the bottoms of my W/G's too, i just bit off of another area on the pressure side to run my boost controller. Less lines and teeing and what have you.

More or less instead of teeing off of the turbo like in the diagram above and like you said ,,,i just moved down the pressure side some (right before the throttle body) to feed the boost controler.

This way its a 1 piece hose on each of the turbos . A one piece hose going from my (mass air flow delete pipe) to my boost controler and a one piece hose with 1 tee that goes from my boost controler to the tops of both my wastegates

More or less instead of teeing off of the turbo like in the diagram above and like you said ,,,i just moved down the pressure side some (right before the throttle body) to feed the boost controler.

This way its a 1 piece hose on each of the turbos . A one piece hose going from my (mass air flow delete pipe) to my boost controler and a one piece hose with 1 tee that goes from my boost controler to the tops of both my wastegates

Your method should be fine. As long as the bottom of the WG senses actual boost and the BC can send a proportionable amount of boost pressure to push against the top then you will be fine.

Trending Topics

#8

TECH Fanatic

Thread Starter

iTrader: (59)

Join Date: Jan 2007

Location: Pittsburgh,Pa

Posts: 1,736

Likes: 0

Received 0 Likes

on

0 Posts

#9

TECH Enthusiast

Join Date: Jan 2004

Location: New Zealand

Posts: 608

Likes: 0

Received 0 Likes

on

0 Posts

some manual boost controllers actually act as a bleed off valve and just plumb into existing wastegate line and bleed off some of the boost ref line pressure to atomsphere causing gate to open later.

#10

TECH Fanatic

Thread Starter

iTrader: (59)

Join Date: Jan 2007

Location: Pittsburgh,Pa

Posts: 1,736

Likes: 0

Received 0 Likes

on

0 Posts

I think wheather your running a boost controler or not the top of the waste gate has to be vented anyways for the diafram inside to move.My Tial 38mms had brass filter breathers on the tops of them .My Forge manual boost controler also has 2 tiny breather holes built into it

#11

On The Tree

iTrader: (1)

I think wheather your running a boost controler or not the top of the waste gate has to be vented anyways for the diafram inside to move.My Tial 38mms had brass filter breathers on the tops of them .My Forge manual boost controler also has 2 tiny breather holes built into it

#12

TECH Veteran

iTrader: (17)

Join Date: Mar 2009

Location: Indy

Posts: 4,220

Likes: 0

Received 0 Likes

on

0 Posts

Im going to bring this back, i have a hallman controller, and plumbed it per what i thought should work.

Manifold to lower port on Gate, then took the 1/8"npt on the compressor housing to the controller to the top of the gate. This seemed to work best.

But for ***** i plumbed it per their instructions which is exactly what JohnV posted, and i noticed that the boost took a touch longer tobuild and was finiky.

Now, Something i want to know, Does the top of the gate HAVE to be vented, IE, the small bleeder hole in controller, seems counteractive, if it is infact connected to the compressor housing of the turbo and is infact connected to your coldside piping, which is vented by a blow off valve, that tells me the wastegate is vented per all that BS.

So, having a small hole in the nipple bleeding off air, seems to be counter productive, any thoughts, or am i complete jack ***!

EDIT: and i am a complete jack ***, because you wouldnt have anywhere for the extra air your trying to control to go. oops.

Manifold to lower port on Gate, then took the 1/8"npt on the compressor housing to the controller to the top of the gate. This seemed to work best.

But for ***** i plumbed it per their instructions which is exactly what JohnV posted, and i noticed that the boost took a touch longer tobuild and was finiky.

Now, Something i want to know, Does the top of the gate HAVE to be vented, IE, the small bleeder hole in controller, seems counteractive, if it is infact connected to the compressor housing of the turbo and is infact connected to your coldside piping, which is vented by a blow off valve, that tells me the wastegate is vented per all that BS.

So, having a small hole in the nipple bleeding off air, seems to be counter productive, any thoughts, or am i complete jack ***!

EDIT: and i am a complete jack ***, because you wouldnt have anywhere for the extra air your trying to control to go. oops.

Last edited by JAX04; 04-01-2011 at 10:27 AM.

#13

TECH Fanatic

Thread Starter

iTrader: (59)

Join Date: Jan 2007

Location: Pittsburgh,Pa

Posts: 1,736

Likes: 0

Received 0 Likes

on

0 Posts

For the life of me i just couldn't get mine to work correctly and after talking with my tuner and taking his advice lol i just install a little bigger W/G spring and left it alone. Its that much less **** to go bad on my ride to ruin my day!

#14

TECH Veteran

iTrader: (17)

Join Date: Mar 2009

Location: Indy

Posts: 4,220

Likes: 0

Received 0 Likes

on

0 Posts

oddly enough, i decided last night to just run the compressor line straight to the bottom port on the gate and it opens at between zero and 1 psi on my boost gauge, i here it plain as day. Freaking 5.3 spring in the gate. surely i dont have that large of a pressure drop across this intercooler. very weird.

Im going to go back to putting it on the top of the gate and seeing how it goes.

#17

12 Second Club

iTrader: (13)

Hey Barnat, if you are still following this. A couple questions for you.

1. What brand/model number manual boost controller are you guys using? There are so many, and I obviously want one that will be of good quality.

2. I kinda had the same deal as you barnat, I dynoed my car on the stock WG springs at 7.5psi. The dyno read from the intake manifold that I made 7.0psi, so I guess we lose 0.5 through our intercooler, which is fine. I was actually going to set up my lines exactly like how you said. Reference the tubing before the throttle body and then send that through a MBC, and then "Y" off and go to each wastegate. Does this sound the same as yours?

3. I hear some talk about that you don't want to use a MBC to go that far above your spring rating, otherwise you could have a couple problems. So my question is, if I stay on the 7.5psi spring, would I be ok to MBC up to around 14?

4. LAST question. Where are you getting your springs for your wastegate from? lol

Thanks in advance for answers.

1. What brand/model number manual boost controller are you guys using? There are so many, and I obviously want one that will be of good quality.

2. I kinda had the same deal as you barnat, I dynoed my car on the stock WG springs at 7.5psi. The dyno read from the intake manifold that I made 7.0psi, so I guess we lose 0.5 through our intercooler, which is fine. I was actually going to set up my lines exactly like how you said. Reference the tubing before the throttle body and then send that through a MBC, and then "Y" off and go to each wastegate. Does this sound the same as yours?

3. I hear some talk about that you don't want to use a MBC to go that far above your spring rating, otherwise you could have a couple problems. So my question is, if I stay on the 7.5psi spring, would I be ok to MBC up to around 14?

4. LAST question. Where are you getting your springs for your wastegate from? lol

Thanks in advance for answers.