How to modify PTK kit to install bigger turbo

#1

The little T4 76mm on my car finally had enough. I inherited it when I bought my STS kit back in 2005 no idea how many miles it had on it then but I put about 30K on it and probably 50 track passes and countless burnouts, mexico runs ect. So I decided to put something on there to make her more competive at the track hense the title.

Modification cost. about 125.

Ebay PTK kit can be had for 500.00

total cost 625 for a T6 hot pipe kit not bad

In order to accomplish this you need

2 tight radius 90 degree 3" mandrels

1 3" turn down

T6 flange

2 3" ID couplers

downpipe flange bought this from www.racepartsolutions.com

5" to 4/3.5/3" cone what ever you decide to use I ran mine into 3.5" and put a cutout at the bottom of the second 90. then plumbed it into the existing 3" down pipe.

I bought everything except the downpipe flange from columbia mandrels

You will need to stand up the radiator to fit the larger turbo no getting around it I had already done this there is plenty of info on the site about this.

Getting started

1. Grab one of the 90s cut it off on both sides right were the 90s start.

2. Pick a end of it, put it in a vice and flatten down two of the sides. so it will now be oval shaped like the flange hole.

3. Weld one of the 3' ID couplers on the other end of your 90

4. Weld the oval shaped end to the flange should look like the pic below when done.

[IMG] [/IMG]

[/IMG]

5. Weld the T6 flange to the 3" turndown make sure its parallel with the pipe. Use a deburring tool to ensure its open.

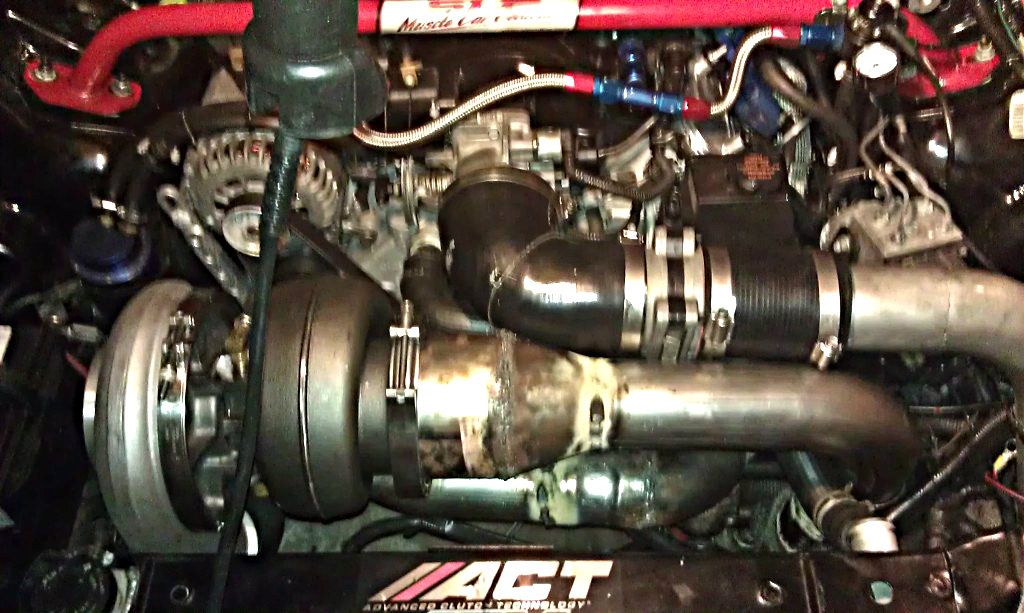

6. Insert the pipe end of your turbo flange and pipe into your recently created 90. Dont weld it yet. Grab your turbo and figure out how it needs to be clocked to fit. My flange ended up being turned to about a 30 degree angle toward the motor for the turbo to fit. I used a S480. Make sure there is enough clearance to re-install the radiator hose to the water pump. by cutting the pipe to the correct length. Then weld the pipe at the 3' ID coupler. should look like the pic below. Highly recommended to help support the heavier weight of the turbo to weld a bracket to the flange and attach it to the upper water pump bolt.

[IMG] [/IMG]

[/IMG]

7. Loosen the V band and remove the original down pipe from the car

9. Cut the V band off after its first 90.

10. Re-attach the PTK down pipe to the exhaust.

11. Grab the last 3" ID coupler and fit it to the cut end of the PTK down pipe make sure it is straight up and down and tack it in place.

12. Remove the down pipe again and weld the rest of the 3" ID coupler

13. Reinstall the down pipe for the last time.

14. Weld the cone transition to the downpipe flange.

15. Bolt the turbo to the flange.

16. Attach the turbo downpipe flange to the turbo.

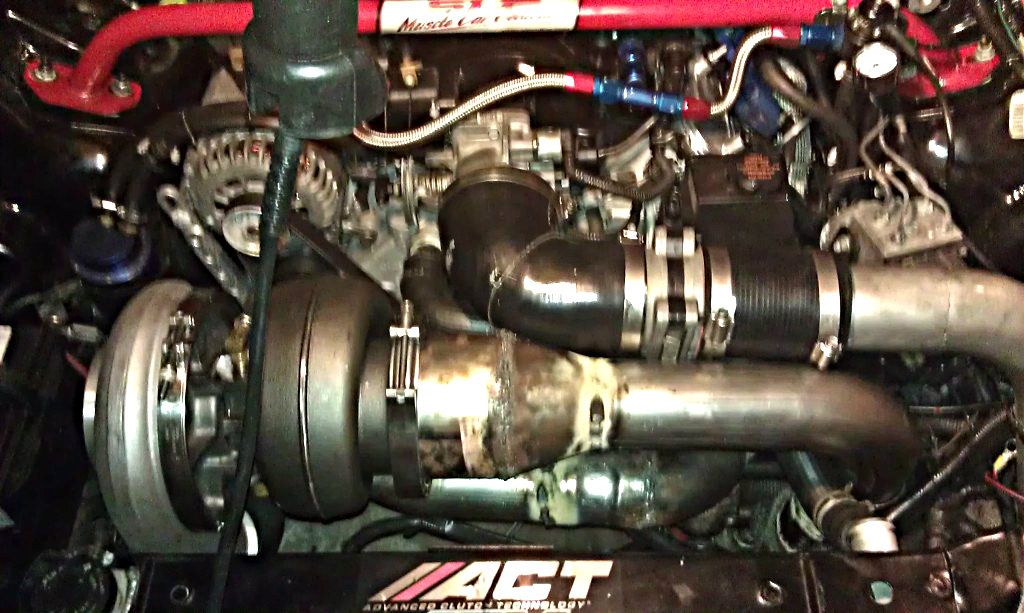

17. Cut the last 90 to fit into the 3" ID coupler and butt against the transition cone.

18. Weld the last 90 to the transition, and weld it to the 3" transition.

[IMG] [/IMG]

[/IMG]

[IMG] [/IMG]

[/IMG]

19. Plumb the compressor into the existing cold pipe setup on your car.

20. Dont forget to wrap the new pipes or ceramacoat them.

Modification cost. about 125.

Ebay PTK kit can be had for 500.00

total cost 625 for a T6 hot pipe kit not bad

In order to accomplish this you need

2 tight radius 90 degree 3" mandrels

1 3" turn down

T6 flange

2 3" ID couplers

downpipe flange bought this from www.racepartsolutions.com

5" to 4/3.5/3" cone what ever you decide to use I ran mine into 3.5" and put a cutout at the bottom of the second 90. then plumbed it into the existing 3" down pipe.

I bought everything except the downpipe flange from columbia mandrels

You will need to stand up the radiator to fit the larger turbo no getting around it I had already done this there is plenty of info on the site about this.

Getting started

1. Grab one of the 90s cut it off on both sides right were the 90s start.

2. Pick a end of it, put it in a vice and flatten down two of the sides. so it will now be oval shaped like the flange hole.

3. Weld one of the 3' ID couplers on the other end of your 90

4. Weld the oval shaped end to the flange should look like the pic below when done.

[IMG]

[/IMG]

[/IMG]5. Weld the T6 flange to the 3" turndown make sure its parallel with the pipe. Use a deburring tool to ensure its open.

6. Insert the pipe end of your turbo flange and pipe into your recently created 90. Dont weld it yet. Grab your turbo and figure out how it needs to be clocked to fit. My flange ended up being turned to about a 30 degree angle toward the motor for the turbo to fit. I used a S480. Make sure there is enough clearance to re-install the radiator hose to the water pump. by cutting the pipe to the correct length. Then weld the pipe at the 3' ID coupler. should look like the pic below. Highly recommended to help support the heavier weight of the turbo to weld a bracket to the flange and attach it to the upper water pump bolt.

[IMG]

[/IMG]

[/IMG]7. Loosen the V band and remove the original down pipe from the car

9. Cut the V band off after its first 90.

10. Re-attach the PTK down pipe to the exhaust.

11. Grab the last 3" ID coupler and fit it to the cut end of the PTK down pipe make sure it is straight up and down and tack it in place.

12. Remove the down pipe again and weld the rest of the 3" ID coupler

13. Reinstall the down pipe for the last time.

14. Weld the cone transition to the downpipe flange.

15. Bolt the turbo to the flange.

16. Attach the turbo downpipe flange to the turbo.

17. Cut the last 90 to fit into the 3" ID coupler and butt against the transition cone.

18. Weld the last 90 to the transition, and weld it to the 3" transition.

[IMG]

[/IMG]

[/IMG][IMG]

[/IMG]

[/IMG]19. Plumb the compressor into the existing cold pipe setup on your car.

20. Dont forget to wrap the new pipes or ceramacoat them.

#3

On The Tree

Join Date: Jan 2012

Location: sydney australia

Posts: 131

Likes: 0

Received 0 Likes

on

0 Posts

#5

I am going to rebuild it once I get a hold of a turbo K member. Wasn't planning on putting a larger turbo on until next year. T4 went to crap so I went ahead and bought the turbo I wanted to run. Should still do better than the little 68mm turbine that was on it.

I used 3" in the list to make it easier for others to follow. my downpipe is 3.5" and at the bottom of the 90 there is a cut out and another transition to 3" to send it through the rest of the exhaust system. I open the cutout at the track. The gate also dumps into the cutout so its essentially dumping to out of the exhaust so it wont play a role in adding more pressure in the downpipe.

I used 3" in the list to make it easier for others to follow. my downpipe is 3.5" and at the bottom of the 90 there is a cut out and another transition to 3" to send it through the rest of the exhaust system. I open the cutout at the track. The gate also dumps into the cutout so its essentially dumping to out of the exhaust so it wont play a role in adding more pressure in the downpipe.

Last edited by Preston99WS6; 07-14-2012 at 09:23 AM.

#6

I get more pics up once I get it all finished, I am wrapping everything up as of now. The turbo will have a blanket too.