Twin BW S366 on 427LSX?

#21

TECH Addict

iTrader: (6)

Well that honestly depends on the amount of boost planned as well as the purpose of the vehicle. It sounds like it is more of a straight drag set up. Surprisingly enough, backpressure will be an issue towards redline depending on the amount of boost run. It is not horrible with the .91 but at the same time if he plans too run a ton of boost it might benefit from a larger ar turbine housing. As stated above, rrunning 17 psi at 7000 rpms it will be closing in on 30 psi of backpressure. Will it work? Sure. Is it optimal? Not really.

#23

TECH Addict

iTrader: (6)

Actually you can calculate a good guestimate. I spoke with one of the engineers at Full Race who works closely with the Borg Warner engineers and he said from their findings it has been very close to reality. Did you look at the link I put up or just throwing out a blanket statement?

#26

TECH Addict

iTrader: (6)

Actually if you look at macthbot most of that is taken into account. But the bottom line is you will still have to flow x amount of air through a y sized turbine no matter the compression, valve events or or post turbine exhaust. I never clamed it was exact, but it has been pretty darn accurate in the vehicles I have played with.

#28

FormerVendor

iTrader: (3)

Housing size has little to no effect on the actual maximum drive pressure created. Turbine wheel size does. Changing the housing's aspect ratio serves to change the rpm in which that maximum drive pressure number is reached. Basically in simple terms, it "shapes" the curve.

For a given turbine wheel size, changing to a tighter AR housing will create more low end torque, quicker spool and overall more under the curve power. Changing to a looser AR housing will create less low end, slower spooling and generally less under the curve power.

The turbine wheel is the choke point. Thus it is what dictates maximum back pressure. This is why I always like to run the largest turbine wheel needed for a given engine size and the tightest ar housing possible. What this does is it lowers maximum drive pressure(also known as back pressure), but keeps spool time down to a minimum. If you can generate your maximum drive pressure as soon as possible in the rpm range, but it's at a low enough boost pressure to drive pressure ratio to remain at the turbo's highest efficiency you've got a winner.

Combine this with a camshaft that takes into account all of these specifics and also boosts drive pressure at a low RPM to achieve the fastest spool time possible without adding to maximum drive pressure as to not choke the turbine and you've nailed the perfect turbo set-up.

Hope this helps!

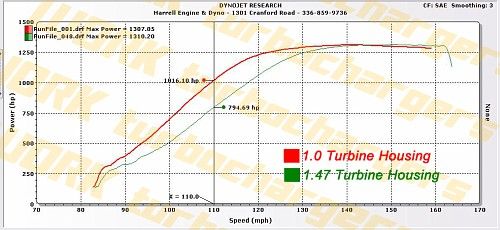

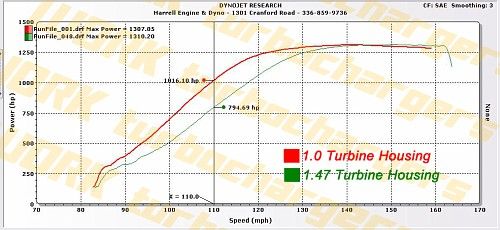

Case in point....here is a dyno graph that shows what I am talking about. This dyno graph is from a local X275 car with a BWS588 which is a 112mm turbine wheel. This is on a 358 cubic inch SBF engine.

As you can see the looser AR housing did nothing for top end. All it did was kill under the curve power. IMO the only reason you'd ever do something like this is if you just couldn't keep a car from going on the bumper at the track, a high profile roll racing car that needs to always hook on the street or if you cannot get down the track due to the turbo's creating drive pressure so fast that it blows the tires off.

As far as the OP's question, I think your turbo selection is fine although I would of liked to of seen you go with a S400 frame for a larger turbine wheel and tighter AR housing selection, but you'll have no issues at all lighting those turbo's with the engine you have.

I would also be happy to specify a camshaft for you if you do not already have one in mind or ground.

For a given turbine wheel size, changing to a tighter AR housing will create more low end torque, quicker spool and overall more under the curve power. Changing to a looser AR housing will create less low end, slower spooling and generally less under the curve power.

The turbine wheel is the choke point. Thus it is what dictates maximum back pressure. This is why I always like to run the largest turbine wheel needed for a given engine size and the tightest ar housing possible. What this does is it lowers maximum drive pressure(also known as back pressure), but keeps spool time down to a minimum. If you can generate your maximum drive pressure as soon as possible in the rpm range, but it's at a low enough boost pressure to drive pressure ratio to remain at the turbo's highest efficiency you've got a winner.

Combine this with a camshaft that takes into account all of these specifics and also boosts drive pressure at a low RPM to achieve the fastest spool time possible without adding to maximum drive pressure as to not choke the turbine and you've nailed the perfect turbo set-up.

Hope this helps!

Case in point....here is a dyno graph that shows what I am talking about. This dyno graph is from a local X275 car with a BWS588 which is a 112mm turbine wheel. This is on a 358 cubic inch SBF engine.

As you can see the looser AR housing did nothing for top end. All it did was kill under the curve power. IMO the only reason you'd ever do something like this is if you just couldn't keep a car from going on the bumper at the track, a high profile roll racing car that needs to always hook on the street or if you cannot get down the track due to the turbo's creating drive pressure so fast that it blows the tires off.

As far as the OP's question, I think your turbo selection is fine although I would of liked to of seen you go with a S400 frame for a larger turbine wheel and tighter AR housing selection, but you'll have no issues at all lighting those turbo's with the engine you have.

I would also be happy to specify a camshaft for you if you do not already have one in mind or ground.

#29

Damn. Not only did you put up a thread questioning my turbo selection for you on the bullet.... you put one up here too....

Starting to think you dont have any faith in me Jason.....

Martin.... dont you have some Na cam to design somewhere instead of trying to steal my guys?? Jesus... lol

Starting to think you dont have any faith in me Jason.....

Martin.... dont you have some Na cam to design somewhere instead of trying to steal my guys?? Jesus... lol

#31

9 Second Club

iTrader: (10)

I've seen 6262's make 1200 rwhp on a 427. Some people act like you need 200 lb/min of air to make 1000 rwhp lol. Those lambos are making 1500 + rwhp with twin 6766's. Some of these billet 66mm turbos will flow 94lbs of air a piece!

Here is a dyno graph from a badass 427 build from National Speed. 2010 Camaro, 6262's, 4l80e pump gas tune up. Here is the build thread https://ls1tech.com/forums/forced-in...0-1-200hp.html

Here is a dyno graph from a badass 427 build from National Speed. 2010 Camaro, 6262's, 4l80e pump gas tune up. Here is the build thread https://ls1tech.com/forums/forced-in...0-1-200hp.html

Hey guys, apologies for the delay in updates and responses over the past month or so. Life at the shop became extremely hectic with this car running over on scheduled time, and it needing to get wrapped up and to Eric. Things are starting to get back to a stabilized level, and the NZ1200 has left on the truck en route to Kansas City.

A few pictures of the completed vehicle with Eric Berry's vehicle and wheel stripes, cleaned up and heading home;

The final Level-IV power setting dyno graph. 17psi, low ignition timing (15degrees), 11.5:1 air:fuel ratio across the loaded board, tuned for 91octane...

(between 1,290-1,300hp and 1,190-1,200ftlbs at the engine. So NZ1200 is a little underrated)

A few pictures of the completed vehicle with Eric Berry's vehicle and wheel stripes, cleaned up and heading home;

The final Level-IV power setting dyno graph. 17psi, low ignition timing (15degrees), 11.5:1 air:fuel ratio across the loaded board, tuned for 91octane...

(between 1,290-1,300hp and 1,190-1,200ftlbs at the engine. So NZ1200 is a little underrated)

Last edited by Nitroused383; 05-24-2013 at 05:43 AM.

#32

FormerVendor

iTrader: (3)

Damn. Not only did you put up a thread questioning my turbo selection for you on the bullet.... you put one up here too....

Starting to think you dont have any faith in me Jason.....

Martin.... dont you have some Na cam to design somewhere instead of trying to steal my guys?? Jesus... lol

Starting to think you dont have any faith in me Jason.....

Martin.... dont you have some Na cam to design somewhere instead of trying to steal my guys?? Jesus... lol

#34

Starting to think you dont have any faith in me Jason.....

I posted them both before I spoke with you.... They just looked so small when I got them....all I could think was that you thought I was putting them on this

instead of this...

#35

Bahahahahahaha thats hilarious.

Nah i remember what that are going on.... amd i remember how concerned we are about packaging.

If you end up maxing those out...we have the billet wheels too..

You also gotta remember the "73"mm turbine is an 82/73 wheel...

Thats the same size wheel as the smallest wheel thats available in the 400 chassis...

Make 1600 horsepower at the crank with those.... then we will talk about bigger units.

Nah i remember what that are going on.... amd i remember how concerned we are about packaging.

If you end up maxing those out...we have the billet wheels too..

You also gotta remember the "73"mm turbine is an 82/73 wheel...

Thats the same size wheel as the smallest wheel thats available in the 400 chassis...

Make 1600 horsepower at the crank with those.... then we will talk about bigger units.

#38

TECH Addict

iTrader: (6)

Just remember it is very dependent on the combination and the turbine of the turbo that is on the motor. If smaller was always better they would only make small ar housings, lol. The above is on a LARGE turbine and a not so large motor. If you have smallish turbines, sometimes the larger turbine housing can help out a bunch.

As Martin stated the turbine housing is used to shift where maximum drive pressure is reached. It needs to be used as such. If you have smallish turbine wheels, sometimes moving the curve out will help. However with a monster turbine wheel on a not so monster motor such as the one in the dyno graph, I can't really imagine why they would have put a 1.47 ar turbine housing on it in the first place unless it was the only one available.

Now this can also go the other way. If you have a smallish turbine wheel on a larger motor, you need every advantage you can get to shift it out. I have at times gone to a larger housing and lost very little under the curve and gained a good bit of top end if the housing was choking the motor. This is just another tool, but Martin is correct in saying to use the smallest AR that works. Figuring out which turbine housing that is for each combination is the key Ultimately sizing the turbo to the motor is the most important step. Turbine AND turbine housing need to be sized accordingly.

Ultimately sizing the turbo to the motor is the most important step. Turbine AND turbine housing need to be sized accordingly.

As Martin stated the turbine housing is used to shift where maximum drive pressure is reached. It needs to be used as such. If you have smallish turbine wheels, sometimes moving the curve out will help. However with a monster turbine wheel on a not so monster motor such as the one in the dyno graph, I can't really imagine why they would have put a 1.47 ar turbine housing on it in the first place unless it was the only one available.

Now this can also go the other way. If you have a smallish turbine wheel on a larger motor, you need every advantage you can get to shift it out. I have at times gone to a larger housing and lost very little under the curve and gained a good bit of top end if the housing was choking the motor. This is just another tool, but Martin is correct in saying to use the smallest AR that works. Figuring out which turbine housing that is for each combination is the key

Ultimately sizing the turbo to the motor is the most important step. Turbine AND turbine housing need to be sized accordingly.

Ultimately sizing the turbo to the motor is the most important step. Turbine AND turbine housing need to be sized accordingly.

#39

FormerVendor

iTrader: (3)

Just remember it is very dependent on the combination and the turbine of the turbo that is on the motor. If smaller was always better they would only make small ar housings, lol. The above is on a LARGE turbine and a not so large motor. If you have smallish turbines, sometimes the larger turbine housing can help out a bunch.

As Martin stated the turbine housing is used to shift where maximum drive pressure is reached. It needs to be used as such. If you have smallish turbine wheels, sometimes moving the curve out will help. However with a monster turbine wheel on a not so monster motor such as the one in the dyno graph, I can't really imagine why they would have put a 1.47 ar turbine housing on it in the first place unless it was the only one available.

Now this can also go the other way. If you have a smallish turbine wheel on a larger motor, you need every advantage you can get to shift it out. I have at times gone to a larger housing and lost very little under the curve and gained a good bit of top end if the housing was choking the motor. This is just another tool, but Martin is correct in saying to use the smallest AR that works. Figuring out which turbine housing that is for each combination is the key Ultimately sizing the turbo to the motor is the most important step. Turbine AND turbine housing need to be sized accordingly.

Ultimately sizing the turbo to the motor is the most important step. Turbine AND turbine housing need to be sized accordingly.

As Martin stated the turbine housing is used to shift where maximum drive pressure is reached. It needs to be used as such. If you have smallish turbine wheels, sometimes moving the curve out will help. However with a monster turbine wheel on a not so monster motor such as the one in the dyno graph, I can't really imagine why they would have put a 1.47 ar turbine housing on it in the first place unless it was the only one available.

Now this can also go the other way. If you have a smallish turbine wheel on a larger motor, you need every advantage you can get to shift it out. I have at times gone to a larger housing and lost very little under the curve and gained a good bit of top end if the housing was choking the motor. This is just another tool, but Martin is correct in saying to use the smallest AR that works. Figuring out which turbine housing that is for each combination is the key

Ultimately sizing the turbo to the motor is the most important step. Turbine AND turbine housing need to be sized accordingly.

Ultimately sizing the turbo to the motor is the most important step. Turbine AND turbine housing need to be sized accordingly.Valve overlap also influences drive pressure and I use it to my advantage in all turbo combinations.