MY Real Street 275 build

#741

TECH Fanatic

iTrader: (18)

I think they are helping a lot yes. We will have this combo 60' better than the old combo in no time. Had the track been there Friday night the 60' would of been well into the 1.24-1.28 range.

My nitrous combo best 60' was 1.28 and would consistently go 1.29-1.31. The cam only combo best 60' was 1.29 and would consistently go 1.30-1.33.

Going to make a torque arm adjustment to attempt to plant the tire a little harder initially and see where it takes us.

My nitrous combo best 60' was 1.28 and would consistently go 1.29-1.31. The cam only combo best 60' was 1.29 and would consistently go 1.30-1.33.

Going to make a torque arm adjustment to attempt to plant the tire a little harder initially and see where it takes us.

1.24 would be booking

#744

Staging Lane

Join Date: Oct 2004

Location: In the garage

Posts: 89

Likes: 0

Received 0 Likes

on

0 Posts

On the stock glide cases. It's isn't really the hp that cracks the case as much as it is the line pressure. With a stock case, 180psi is pretty safe but once running low 5's that may not be enough pressure to keep high gear clutches in it. Once high gear starts slipping you need more line pressure. I ran mine as high as 210psi without cracking the case but you never know when it's going to give up. With an aftermarket case you can go 230+ safely. One local car I tune runs 5 teens at 141 with a stock 1.76 gear set and stock case. I cover my eyes every time it leaves the line. That last outing with it, it spun out on the top end of the track and tapped the wall. I knew it had busted the trans but it pushed out the lokar dipstick.

On your converter, it won't hurt to short shift it with the power turned down. Once you turn the power up, the rpm drop will work it's way back where it needs to be. Sometimes that large rpm drop can knock the tires off so if we have the power backed down, we just short shift where the rpm drops 800-1200 range.

On your converter, it won't hurt to short shift it with the power turned down. Once you turn the power up, the rpm drop will work it's way back where it needs to be. Sometimes that large rpm drop can knock the tires off so if we have the power backed down, we just short shift where the rpm drops 800-1200 range.

#745

On the stock glide cases. It's isn't really the hp that cracks the case as much as it is the line pressure. With a stock case, 180psi is pretty safe but once running low 5's that may not be enough pressure to keep high gear clutches in it. Once high gear starts slipping you need more line pressure. I ran mine as high as 210psi without cracking the case but you never know when it's going to give up. With an aftermarket case you can go 230+ safely. One local car I tune runs 5 teens at 141 with a stock 1.76 gear set and stock case. I cover my eyes every time it leaves the line. That last outing with it, it spun out on the top end of the track and tapped the wall. I knew it had busted the trans but it pushed out the lokar dipstick.

On your converter, it won't hurt to short shift it with the power turned down. Once you turn the power up, the rpm drop will work it's way back where it needs to be. Sometimes that large rpm drop can knock the tires off so if we have the power backed down, we just short shift where the rpm drops 800-1200 range.

On your converter, it won't hurt to short shift it with the power turned down. Once you turn the power up, the rpm drop will work it's way back where it needs to be. Sometimes that large rpm drop can knock the tires off so if we have the power backed down, we just short shift where the rpm drops 800-1200 range.

I want to thank you first for a bad to the bone converter! This thing is stupid tight and efficient. I know once I start pouring the power to it that it won't drop nearly as much as it does now on the shift and that the more RPM I turn it the tighter it's going to become and the more it will drop on the shift.

I had thought about short shifting it around 6800-7000 just to make it slip more and not drop as much, but haven't tried it yet. I'm going to start playing with shift points once we start putting some real power to it. Right now I have the shift light set at 7100.

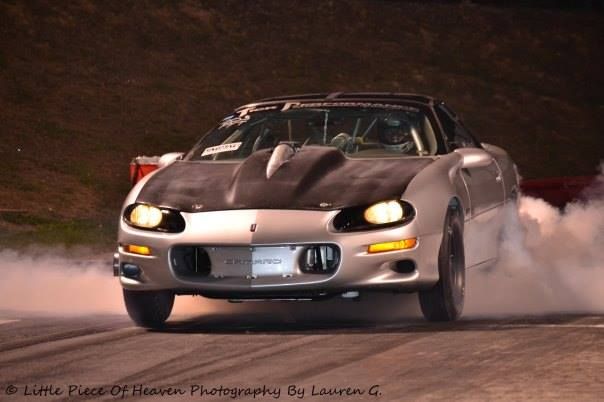

Here are some more pictures from the same album that Stephen posted the picture from.

#747

Staging Lane

Join Date: Oct 2004

Location: In the garage

Posts: 89

Likes: 0

Received 0 Likes

on

0 Posts

7000-7100 is a good shift point at your current power level which is just getting the bugs out of the car.

What you want to watch is the rpm it falls to on the gear change. Right now yours is 5800 which is what we will call the true flash stall at your current power level. If you put 4 degrees of timing in it and it makes more power, that 5800 rpm point may become 6000-6100. As you add timing, boost and fine tune the a/f ratio you will see this rpm drop point increase which tells you the engine is putting more power to the converter which in turn drives the true flash stall higher. Cranked up, the fall back rpm may be 6400-6600 for example and you can adjust your shift point to that. We will then evaluate the slip and see if the motor is happy in that 7800-6600 range. If the motor likes rpm you can loosen the converter to get the flash to 7000 and then shift at 8200..etc. That's where the testing comes in, to see what rpm the turbo can keep up with, if that works well with the cam and optimize the converter to get the motor into that sweet spot for the duration of the pass.

Just for another example. The US car I drove was tested with several different turbo's....same converter just to see the effects the turbo had.

The 47-80mm, drove the flash stall to 6200

The 47-88 drove it to 6600

The LF85 drove it to 7000. The LF85 made the same boost as the 47-88 but the backpressure was cut in half and the car easily picked up 200hp.

What you want to watch is the rpm it falls to on the gear change. Right now yours is 5800 which is what we will call the true flash stall at your current power level. If you put 4 degrees of timing in it and it makes more power, that 5800 rpm point may become 6000-6100. As you add timing, boost and fine tune the a/f ratio you will see this rpm drop point increase which tells you the engine is putting more power to the converter which in turn drives the true flash stall higher. Cranked up, the fall back rpm may be 6400-6600 for example and you can adjust your shift point to that. We will then evaluate the slip and see if the motor is happy in that 7800-6600 range. If the motor likes rpm you can loosen the converter to get the flash to 7000 and then shift at 8200..etc. That's where the testing comes in, to see what rpm the turbo can keep up with, if that works well with the cam and optimize the converter to get the motor into that sweet spot for the duration of the pass.

Just for another example. The US car I drove was tested with several different turbo's....same converter just to see the effects the turbo had.

The 47-80mm, drove the flash stall to 6200

The 47-88 drove it to 6600

The LF85 drove it to 7000. The LF85 made the same boost as the 47-88 but the backpressure was cut in half and the car easily picked up 200hp.

#748

7000-7100 is a good shift point at your current power level which is just getting the bugs out of the car.

What you want to watch is the rpm it falls to on the gear change. Right now yours is 5800 which is what we will call the true flash stall at your current power level. If you put 4 degrees of timing in it and it makes more power, that 5800 rpm point may become 6000-6100. As you add timing, boost and fine tune the a/f ratio you will see this rpm drop point increase which tells you the engine is putting more power to the converter which in turn drives the true flash stall higher. Cranked up, the fall back rpm may be 6400-6600 for example and you can adjust your shift point to that. We will then evaluate the slip and see if the motor is happy in that 7800-6600 range. If the motor likes rpm you can loosen the converter to get the flash to 7000 and then shift at 8200..etc. That's where the testing comes in, to see what rpm the turbo can keep up with, if that works well with the cam and optimize the converter to get the motor into that sweet spot for the duration of the pass.

Just for another example. The US car I drove was tested with several different turbo's....same converter just to see the effects the turbo had.

The 47-80mm, drove the flash stall to 6200

The 47-88 drove it to 6600

The LF85 drove it to 7000. The LF85 made the same boost as the 47-88 but the backpressure was cut in half and the car easily picked up 200hp.

What you want to watch is the rpm it falls to on the gear change. Right now yours is 5800 which is what we will call the true flash stall at your current power level. If you put 4 degrees of timing in it and it makes more power, that 5800 rpm point may become 6000-6100. As you add timing, boost and fine tune the a/f ratio you will see this rpm drop point increase which tells you the engine is putting more power to the converter which in turn drives the true flash stall higher. Cranked up, the fall back rpm may be 6400-6600 for example and you can adjust your shift point to that. We will then evaluate the slip and see if the motor is happy in that 7800-6600 range. If the motor likes rpm you can loosen the converter to get the flash to 7000 and then shift at 8200..etc. That's where the testing comes in, to see what rpm the turbo can keep up with, if that works well with the cam and optimize the converter to get the motor into that sweet spot for the duration of the pass.

Just for another example. The US car I drove was tested with several different turbo's....same converter just to see the effects the turbo had.

The 47-80mm, drove the flash stall to 6200

The 47-88 drove it to 6600

The LF85 drove it to 7000. The LF85 made the same boost as the 47-88 but the backpressure was cut in half and the car easily picked up 200hp.

I really don't see this turbo with the hydraulic I have in it now making good power much past 7400-7500 so we'll probably focus in on that 6300-7500rpm range the most.

Thanks for all your help so far Dusty and anyone looking to get a bad *** PTC converter should definitely talk to you!

#749

Staging Lane

Join Date: Oct 2004

Location: In the garage

Posts: 89

Likes: 0

Received 0 Likes

on

0 Posts

The converter you did for the orange car flashes 6300-6400 and falls back to 6400 on the shift from a 7200-7400rpm shift point. We're pouring the coals to it a lot earlier and a lot harder than I have so far on mine. It's sagging a little bit where the converter grabs the motor when it launches and pulls it down 100rpm or so, but we're working on that too. It also weighs 220lbs. more than mine and has a 3.73 gear versus my 4.10 so it's slipping a lot more as well due to load.

I really don't see this turbo with the hydraulic I have in it now making good power much past 7400-7500 so we'll probably focus in on that 6300-7500rpm range the most.

Thanks for all your help so far Dusty and anyone looking to get a bad *** PTC converter should definitely talk to you!

I really don't see this turbo with the hydraulic I have in it now making good power much past 7400-7500 so we'll probably focus in on that 6300-7500rpm range the most.

Thanks for all your help so far Dusty and anyone looking to get a bad *** PTC converter should definitely talk to you!

#750

Nice work brother and you are right about PTC, I have around a 5000 stall that Kurt Urban put in this car... 1.34 on the rear tires off the food break flashing from idle first pass

#751

The converter you did for the orange car flashes 6300-6400 and falls back to 6400 on the shift from a 7200-7400rpm shift point. We're pouring the coals to it a lot earlier and a lot harder than I have so far on mine. It's sagging a little bit where the converter grabs the motor when it launches and pulls it down 100rpm or so, but we're working on that too. It also weighs 220lbs. more than mine and has a 3.73 gear versus my 4.10 so it's slipping a lot more as well due to load.

I really don't see this turbo with the hydraulic I have in it now making good power much past 7400-7500 so we'll probably focus in on that 6300-7500rpm range the most.

Thanks for all your help so far Dusty and anyone looking to get a bad *** PTC converter should definitely talk to you!

I really don't see this turbo with the hydraulic I have in it now making good power much past 7400-7500 so we'll probably focus in on that 6300-7500rpm range the most.

Thanks for all your help so far Dusty and anyone looking to get a bad *** PTC converter should definitely talk to you!

#752

After working on the power management we've started to fine tune the tune up with fueling and timing. Leaning it out has helped the sag tremendously so far, but it's still just slightly there.

Going to keep working on bringing the boost in faster and if need be we will give it some more timing in those sections.

I have Fast XFI 2.0 on the car. I'm utilizing it for data logging, boost control and engine management.

#753

5.40@136 over the weekend at Shadyside Dragway.

1.33 60'

3.62 330'

5.40 660'

136 mph

Ignition issues are back... Car is unable to be raced in its current state. I honestly don't know what to do. We've tried shielding wires, tried new "fancy" plug wires, we moved coils away from the wiring harness, put a piece of plate steel in front of the wiring harness that was then bolted to the valve cover and then we ran a copper ground wire from the bolt holding it to the valve cover and grounded it to the cylinder head.

Car is unable to be raced in its current state. I honestly don't know what to do. We've tried shielding wires, tried new "fancy" plug wires, we moved coils away from the wiring harness, put a piece of plate steel in front of the wiring harness that was then bolted to the valve cover and then we ran a copper ground wire from the bolt holding it to the valve cover and grounded it to the cylinder head.

That worked for one pass and allowed us to go from a 5.45 to a 5.40. Then the next pass when I tried to bring the boost in faster off the line it immediately cut off on the starting line. Didn't even move 5'.

It seems that if I keep the boost ramp slow which equates to about a 1.33-1.37 60' and a 5.40-5.45 pass it doesn't shut off. If I try to turn it up any higher than that it shuts off.

Really frustrated with this Fast system. We have another car that we race and it has a Holley system on it. Wires are just as close to the coils as mine are and it has no problems whatsoever. It is wired in the exact same fashion as my car is. The same person wired both cars and did nothing different in terms of grounds or power leads.

I've talked to a lot of people that have had the exact same issues with their Fast system and it just makes me wonder why Fast hasn't fixed this issue yet. They gave me a 10 item list of things to check and fix, but every person I've talked to that had problems told me they gave them the same list and nothing really worked.

It seems to only be related to Fast systems that use individual coil on plug ignition systems. Guys with distributors don't seem to have this problem from the Fast system.

Just thought I'd update the thread even though it's not really "good news". I didn't want this thread to only be all "roses and posies" and to show you guys the good and the bad that comes with building a race car. Hopefully we'll get it figured out.

The only real "good news" to share is that I still have more power that can be put to this thing. The MPH it put up this weekend with the tune up I had in it shows a lot of promise. I have no doubts in my mind at all after seeing how it ran this weekend that 5.0's and 138-139mph is just around the corner if we can fix this bug that's holding us back currently.

1.33 60'

3.62 330'

5.40 660'

136 mph

Ignition issues are back...

Car is unable to be raced in its current state. I honestly don't know what to do. We've tried shielding wires, tried new "fancy" plug wires, we moved coils away from the wiring harness, put a piece of plate steel in front of the wiring harness that was then bolted to the valve cover and then we ran a copper ground wire from the bolt holding it to the valve cover and grounded it to the cylinder head.

Car is unable to be raced in its current state. I honestly don't know what to do. We've tried shielding wires, tried new "fancy" plug wires, we moved coils away from the wiring harness, put a piece of plate steel in front of the wiring harness that was then bolted to the valve cover and then we ran a copper ground wire from the bolt holding it to the valve cover and grounded it to the cylinder head. That worked for one pass and allowed us to go from a 5.45 to a 5.40. Then the next pass when I tried to bring the boost in faster off the line it immediately cut off on the starting line. Didn't even move 5'.

It seems that if I keep the boost ramp slow which equates to about a 1.33-1.37 60' and a 5.40-5.45 pass it doesn't shut off. If I try to turn it up any higher than that it shuts off.

Really frustrated with this Fast system. We have another car that we race and it has a Holley system on it. Wires are just as close to the coils as mine are and it has no problems whatsoever. It is wired in the exact same fashion as my car is. The same person wired both cars and did nothing different in terms of grounds or power leads.

I've talked to a lot of people that have had the exact same issues with their Fast system and it just makes me wonder why Fast hasn't fixed this issue yet. They gave me a 10 item list of things to check and fix, but every person I've talked to that had problems told me they gave them the same list and nothing really worked.

It seems to only be related to Fast systems that use individual coil on plug ignition systems. Guys with distributors don't seem to have this problem from the Fast system.

Just thought I'd update the thread even though it's not really "good news". I didn't want this thread to only be all "roses and posies" and to show you guys the good and the bad that comes with building a race car. Hopefully we'll get it figured out.

The only real "good news" to share is that I still have more power that can be put to this thing. The MPH it put up this weekend with the tune up I had in it shows a lot of promise. I have no doubts in my mind at all after seeing how it ran this weekend that 5.0's and 138-139mph is just around the corner if we can fix this bug that's holding us back currently.

#757

9 Second Club

iTrader: (9)

^^^ yeah Martin deserved a fully equipped Holley Dominator system.

It sucks to have issues like that. When we first installed the Holley system we had issues with truck shutting down once we would hit it with a good amount of boost. All we did to fix it is change firmware and bam it worked like a chap. But we did have that issue for a few weeks until a buddy have us a heads up on that problem.

It sucks to have issues like that. When we first installed the Holley system we had issues with truck shutting down once we would hit it with a good amount of boost. All we did to fix it is change firmware and bam it worked like a chap. But we did have that issue for a few weeks until a buddy have us a heads up on that problem.

#758

5.40@136 over the weekend at Shadyside Dragway.

1.33 60'

3.62 330'

5.40 660'

136 mph

Ignition issues are back... Car is unable to be raced in its current state. I honestly don't know what to do. We've tried shielding wires, tried new "fancy" plug wires, we moved coils away from the wiring harness, put a piece of plate steel in front of the wiring harness that was then bolted to the valve cover and then we ran a copper ground wire from the bolt holding it to the valve cover and grounded it to the cylinder head.

Car is unable to be raced in its current state. I honestly don't know what to do. We've tried shielding wires, tried new "fancy" plug wires, we moved coils away from the wiring harness, put a piece of plate steel in front of the wiring harness that was then bolted to the valve cover and then we ran a copper ground wire from the bolt holding it to the valve cover and grounded it to the cylinder head.

That worked for one pass and allowed us to go from a 5.45 to a 5.40. Then the next pass when I tried to bring the boost in faster off the line it immediately cut off on the starting line. Didn't even move 5'.

It seems that if I keep the boost ramp slow which equates to about a 1.33-1.37 60' and a 5.40-5.45 pass it doesn't shut off. If I try to turn it up any higher than that it shuts off.

Really frustrated with this Fast system. We have another car that we race and it has a Holley system on it. Wires are just as close to the coils as mine are and it has no problems whatsoever. It is wired in the exact same fashion as my car is. The same person wired both cars and did nothing different in terms of grounds or power leads.

I've talked to a lot of people that have had the exact same issues with their Fast system and it just makes me wonder why Fast hasn't fixed this issue yet. They gave me a 10 item list of things to check and fix, but every person I've talked to that had problems told me they gave them the same list and nothing really worked.

It seems to only be related to Fast systems that use individual coil on plug ignition systems. Guys with distributors don't seem to have this problem from the Fast system.

Just thought I'd update the thread even though it's not really "good news". I didn't want this thread to only be all "roses and posies" and to show you guys the good and the bad that comes with building a race car. Hopefully we'll get it figured out.

The only real "good news" to share is that I still have more power that can be put to this thing. The MPH it put up this weekend with the tune up I had in it shows a lot of promise. I have no doubts in my mind at all after seeing how it ran this weekend that 5.0's and 138-139mph is just around the corner if we can fix this bug that's holding us back currently.

1.33 60'

3.62 330'

5.40 660'

136 mph

Ignition issues are back...

Car is unable to be raced in its current state. I honestly don't know what to do. We've tried shielding wires, tried new "fancy" plug wires, we moved coils away from the wiring harness, put a piece of plate steel in front of the wiring harness that was then bolted to the valve cover and then we ran a copper ground wire from the bolt holding it to the valve cover and grounded it to the cylinder head.

Car is unable to be raced in its current state. I honestly don't know what to do. We've tried shielding wires, tried new "fancy" plug wires, we moved coils away from the wiring harness, put a piece of plate steel in front of the wiring harness that was then bolted to the valve cover and then we ran a copper ground wire from the bolt holding it to the valve cover and grounded it to the cylinder head. That worked for one pass and allowed us to go from a 5.45 to a 5.40. Then the next pass when I tried to bring the boost in faster off the line it immediately cut off on the starting line. Didn't even move 5'.

It seems that if I keep the boost ramp slow which equates to about a 1.33-1.37 60' and a 5.40-5.45 pass it doesn't shut off. If I try to turn it up any higher than that it shuts off.

Really frustrated with this Fast system. We have another car that we race and it has a Holley system on it. Wires are just as close to the coils as mine are and it has no problems whatsoever. It is wired in the exact same fashion as my car is. The same person wired both cars and did nothing different in terms of grounds or power leads.

I've talked to a lot of people that have had the exact same issues with their Fast system and it just makes me wonder why Fast hasn't fixed this issue yet. They gave me a 10 item list of things to check and fix, but every person I've talked to that had problems told me they gave them the same list and nothing really worked.

It seems to only be related to Fast systems that use individual coil on plug ignition systems. Guys with distributors don't seem to have this problem from the Fast system.

Just thought I'd update the thread even though it's not really "good news". I didn't want this thread to only be all "roses and posies" and to show you guys the good and the bad that comes with building a race car. Hopefully we'll get it figured out.

The only real "good news" to share is that I still have more power that can be put to this thing. The MPH it put up this weekend with the tune up I had in it shows a lot of promise. I have no doubts in my mind at all after seeing how it ran this weekend that 5.0's and 138-139mph is just around the corner if we can fix this bug that's holding us back currently.

My XFI/XIM sets a CAM and CRANK code every pass.

Doesn't matter if on the track or dyno.

I have LS1 coils as well.

I feel your pain because I'm dealing with basically the very same issue as you.

Last edited by Firehawk441; 10-14-2014 at 06:52 AM.

#759

8 Second Truck Club

iTrader: (32)

Man, I've been there too. Hope you get it worked out.

I had a very similar issue with the holley and we tried all this **** like you are (thinking it was noise) and none of it worked. Finally figured out that once the power was turned up, the crank started flexing just enough to get the reluctor out of shape. The fix was to put an msd 4x wheel on the front.

Can you log the crank signal when this happens?

I had a very similar issue with the holley and we tried all this **** like you are (thinking it was noise) and none of it worked. Finally figured out that once the power was turned up, the crank started flexing just enough to get the reluctor out of shape. The fix was to put an msd 4x wheel on the front.

Can you log the crank signal when this happens?