log manifold ideas

#1

On The Tree

Thread Starter

iTrader: (1)

Join Date: Jul 2006

Posts: 188

Likes: 0

Received 0 Likes

on

0 Posts

***disclaimer: my Microsoft Paint skills are terrible***

***disclaimerII: I did do a search***

first off, I'm working on a 78 Malibu twin turbo build and want to run a header or log setup as opposed to a stock manifold setup. one reason for this is that in forward and down configuration, I don't think any fit, and I don't like the look of the up and forward so much. That being said I have sketched a couple ideas and would like to know some info on if anyone has done anything like this before.

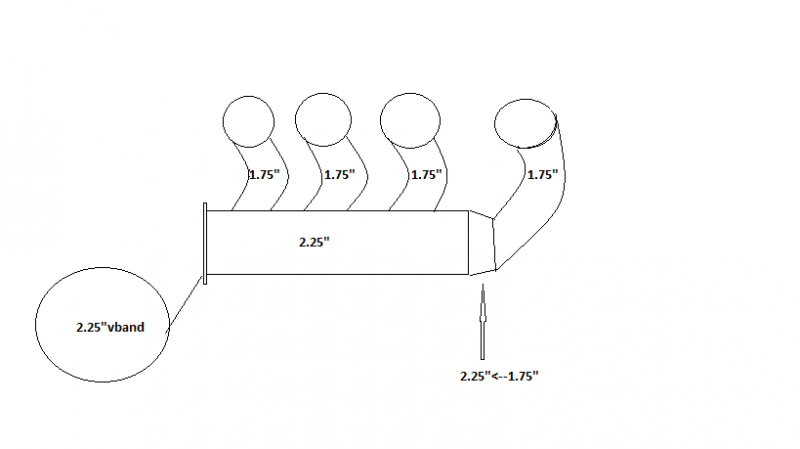

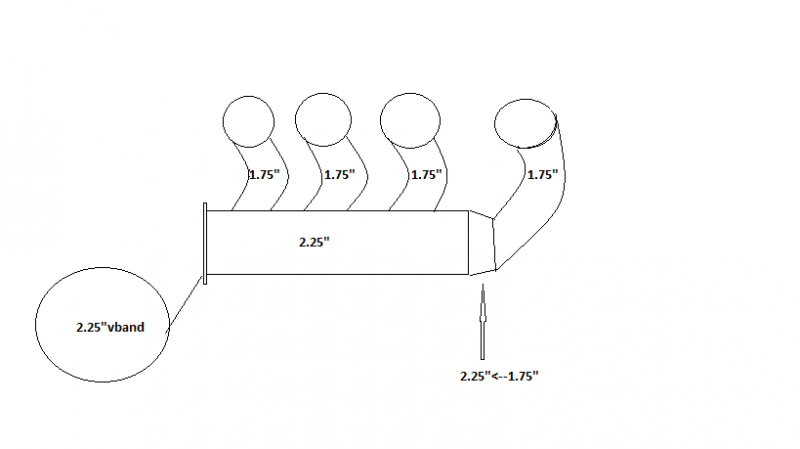

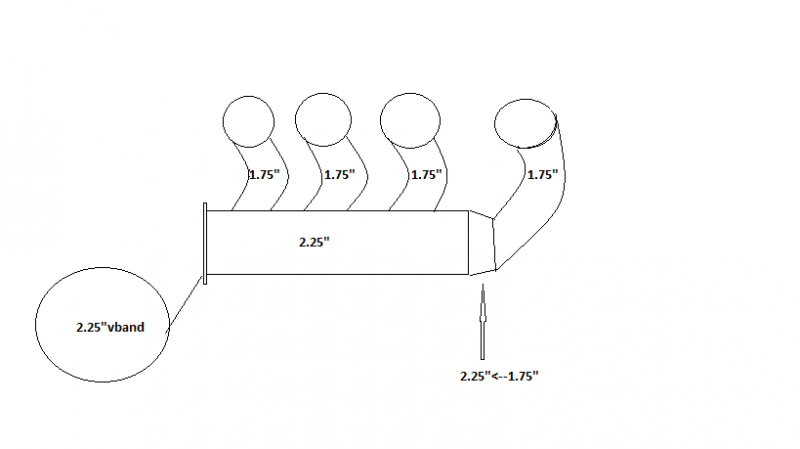

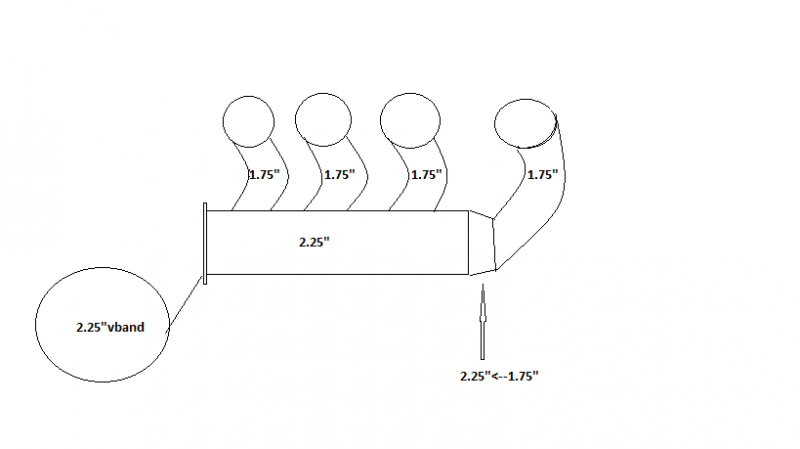

-first one-

I know this is a common setup for log manifolds.

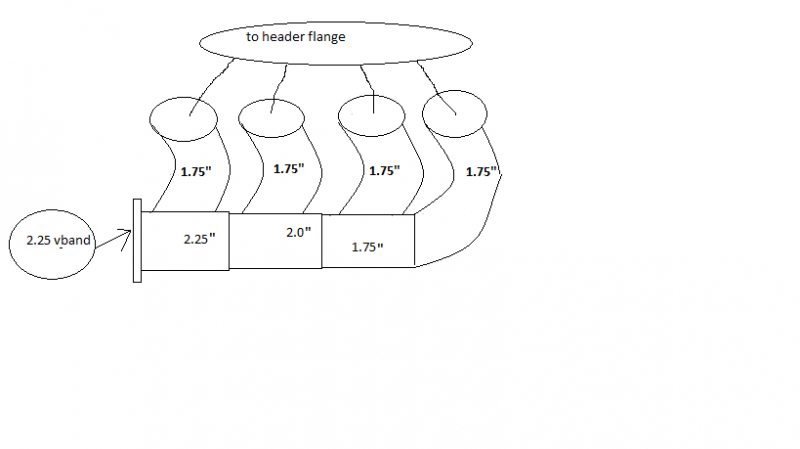

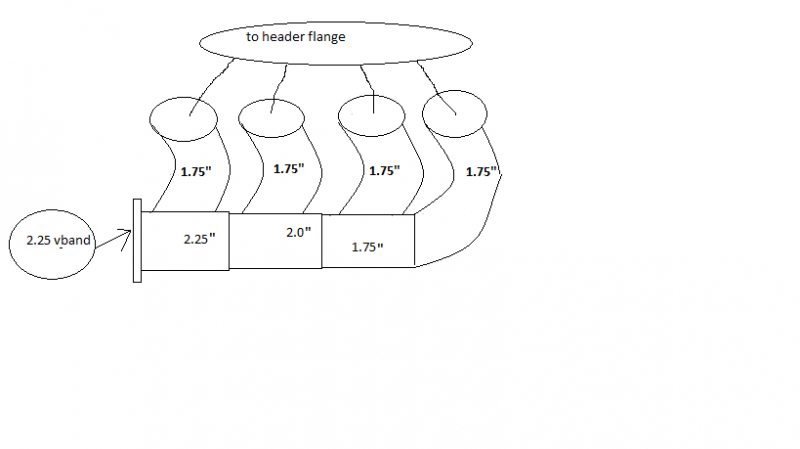

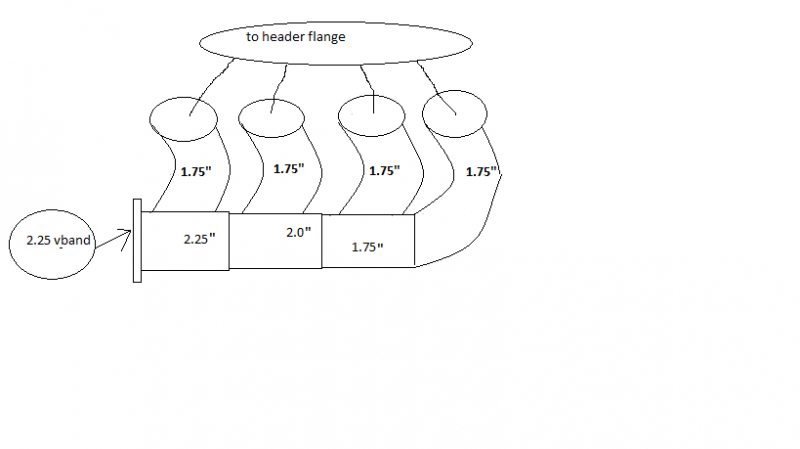

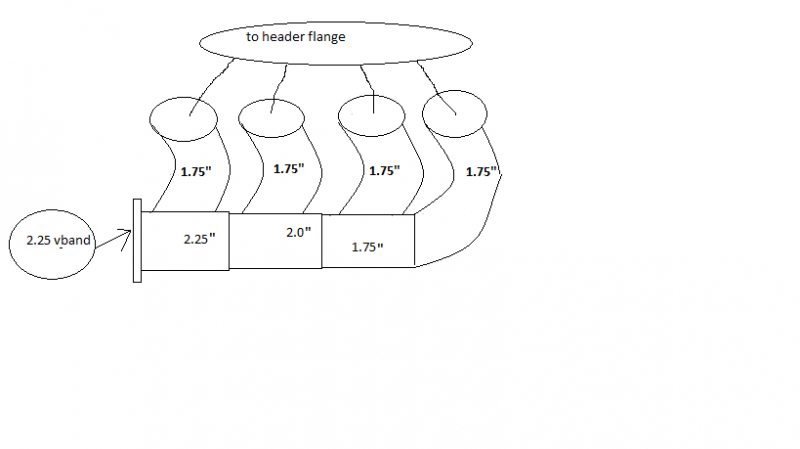

-second one-

Wondering if something like this (similar to a stepped header idea) would keep velocity up more (quicker spool etc), of if it would even amount to a damn.

edit* perhaps change the 1.75" primary tubes to 1.625(1 5/8)"?

I have a tig welder and am getting decently handy with it so the fab shouldn't be an issue so much.

Which would perform better or am i wasting my time?

Thanks

***disclaimerII: I did do a search***

first off, I'm working on a 78 Malibu twin turbo build and want to run a header or log setup as opposed to a stock manifold setup. one reason for this is that in forward and down configuration, I don't think any fit, and I don't like the look of the up and forward so much. That being said I have sketched a couple ideas and would like to know some info on if anyone has done anything like this before.

-first one-

I know this is a common setup for log manifolds.

-second one-

Wondering if something like this (similar to a stepped header idea) would keep velocity up more (quicker spool etc), of if it would even amount to a damn.

edit* perhaps change the 1.75" primary tubes to 1.625(1 5/8)"?

I have a tig welder and am getting decently handy with it so the fab shouldn't be an issue so much.

Which would perform better or am i wasting my time?

Thanks

#2

TECH Fanatic

iTrader: (20)

***disclaimer: my Microsoft Paint skills are terrible***

***disclaimerII: I did do a search***

first off, I'm working on a 78 Malibu twin turbo build and want to run a header or log setup as opposed to a stock manifold setup. one reason for this is that in forward and down configuration, I don't think any fit, and I don't like the look of the up and forward so much. That being said I have sketched a couple ideas and would like to know some info on if anyone has done anything like this before.

-first one-

I know this is a common setup for log manifolds.

-second one-

Wondering if something like this (similar to a stepped header idea) would keep velocity up more (quicker spool etc), of if it would even amount to a damn.

edit* perhaps change the 1.75" primary tubes to 1.625(1 5/8)"?

I have a tig welder and am getting decently handy with it so the fab shouldn't be an issue so much.

Which would perform better or am i wasting my time?

Thanks

***disclaimerII: I did do a search***

first off, I'm working on a 78 Malibu twin turbo build and want to run a header or log setup as opposed to a stock manifold setup. one reason for this is that in forward and down configuration, I don't think any fit, and I don't like the look of the up and forward so much. That being said I have sketched a couple ideas and would like to know some info on if anyone has done anything like this before.

-first one-

I know this is a common setup for log manifolds.

-second one-

Wondering if something like this (similar to a stepped header idea) would keep velocity up more (quicker spool etc), of if it would even amount to a damn.

edit* perhaps change the 1.75" primary tubes to 1.625(1 5/8)"?

I have a tig welder and am getting decently handy with it so the fab shouldn't be an issue so much.

Which would perform better or am i wasting my time?

Thanks

A 1.5 primary will have almost a 2 inch od. The main section of the log should be 2 inch pipe which I believe will have an od of 2.5 inch. You can get a really nice deep weld on the manifolds and they'll last forever.

4000 years from now when archaeologists are digging through the ruins of your garage the manifold will still be intact.

#4

On The Tree

Thread Starter

iTrader: (1)

Join Date: Jul 2006

Posts: 188

Likes: 0

Received 0 Likes

on

0 Posts

Do yourself a favor and do the manifold with sch 40 or sch 10 pipe elbows.

A 1.5 primary will have almost a 2 inch od. The main section of the log should be 2 inch pipe which I believe will have an od of 2.5 inch. You can get a really nice deep weld on the manifolds and they'll last forever.

4000 years from now when archaeologists are digging through the ruins of your garage the manifold will still be intact.

A 1.5 primary will have almost a 2 inch od. The main section of the log should be 2 inch pipe which I believe will have an od of 2.5 inch. You can get a really nice deep weld on the manifolds and they'll last forever.

4000 years from now when archaeologists are digging through the ruins of your garage the manifold will still be intact.

I get the longevity standpoint, but will 2" ID support enough hp to run 8.50's @3300lbs? .25" seems really damn thick for a tubing wall

#7

9 Second Club

Join Date: Dec 2010

Location: Michigan

Posts: 147

Likes: 0

Received 0 Likes

on

0 Posts

Here ya go. This question gets asked a ton. I made a set and pics are in the following thread

https://ls1tech.com/forums/forced-in...-question.html

https://ls1tech.com/forums/forced-in...-question.html

Trending Topics

#8

Truck Sponsor

iTrader: (11)

Join Date: Sep 2006

Location: Wichita Falls Tx.

Posts: 3,122

Likes: 0

Received 0 Likes

on

0 Posts

***disclaimer: my Microsoft Paint skills are terrible***

***disclaimerII: I did do a search***

first off, I'm working on a 78 Malibu twin turbo build and want to run a header or log setup as opposed to a stock manifold setup. one reason for this is that in forward and down configuration, I don't think any fit, and I don't like the look of the up and forward so much. That being said I have sketched a couple ideas and would like to know some info on if anyone has done anything like this before.

-first one-

I know this is a common setup for log manifolds.

-second one-

Wondering if something like this (similar to a stepped header idea) would keep velocity up more (quicker spool etc), of if it would even amount to a damn.

edit* perhaps change the 1.75" primary tubes to 1.625(1 5/8)"?

I have a tig welder and am getting decently handy with it so the fab shouldn't be an issue so much.

Which would perform better or am i wasting my time?

Thanks

***disclaimerII: I did do a search***

first off, I'm working on a 78 Malibu twin turbo build and want to run a header or log setup as opposed to a stock manifold setup. one reason for this is that in forward and down configuration, I don't think any fit, and I don't like the look of the up and forward so much. That being said I have sketched a couple ideas and would like to know some info on if anyone has done anything like this before.

-first one-

I know this is a common setup for log manifolds.

-second one-

Wondering if something like this (similar to a stepped header idea) would keep velocity up more (quicker spool etc), of if it would even amount to a damn.

edit* perhaps change the 1.75" primary tubes to 1.625(1 5/8)"?

I have a tig welder and am getting decently handy with it so the fab shouldn't be an issue so much.

Which would perform better or am i wasting my time?

Thanks

Your first design is fine.

I would use weld L's sch 40 and call it good.

#9

On The Tree

Thread Starter

iTrader: (1)

Join Date: Jul 2006

Posts: 188

Likes: 0

Received 0 Likes

on

0 Posts

Shawnc16 - can I get some more pics of your manifolds? Since I don't need the step design for my goals, that's actually the exact design I had in mind lol. So I need what? Hate to pick your brain that hard, but I'm still new to fabbing stuff. Looks like 10 els (1.5"?) And some 2"id sch10/40?

Thanks everyone

Thanks everyone

#11

10 Second Club

iTrader: (2)

Join Date: Oct 2004

Location: Orange Co. New York

Posts: 441

Likes: 0

Received 0 Likes

on

0 Posts

I had the exact same problems with my single T4 Chevelle build, no OE manifolds would clear forward and down. And I too really didn't want up and over exhaust pipes, don't like the look at all. Not knocking anyone else's setup just don't want that look. I made the exact logs in pic 1, worked out perfectly. Ill try to post some pics for ya.

#12

On The Tree

Thread Starter

iTrader: (1)

Join Date: Jul 2006

Posts: 188

Likes: 0

Received 0 Likes

on

0 Posts

None clear foreward and down. Only up and forward I like are the Obx or whatever brand headers that I'm not paying for. I really hoped truck manifolds would work. But really, just got a new tig and want to play factors into this as well.

#16

9 Second Club

Join Date: Dec 2010

Location: Michigan

Posts: 147

Likes: 0

Received 0 Likes

on

0 Posts

Honestly I don't remember exactly how much.

10 short radius 1.5" els.

2 2" to 1.5" reducers

4' of 2" pipe

2' of 1.5" pipe

1/2" SS flanges

2.25" V Bands

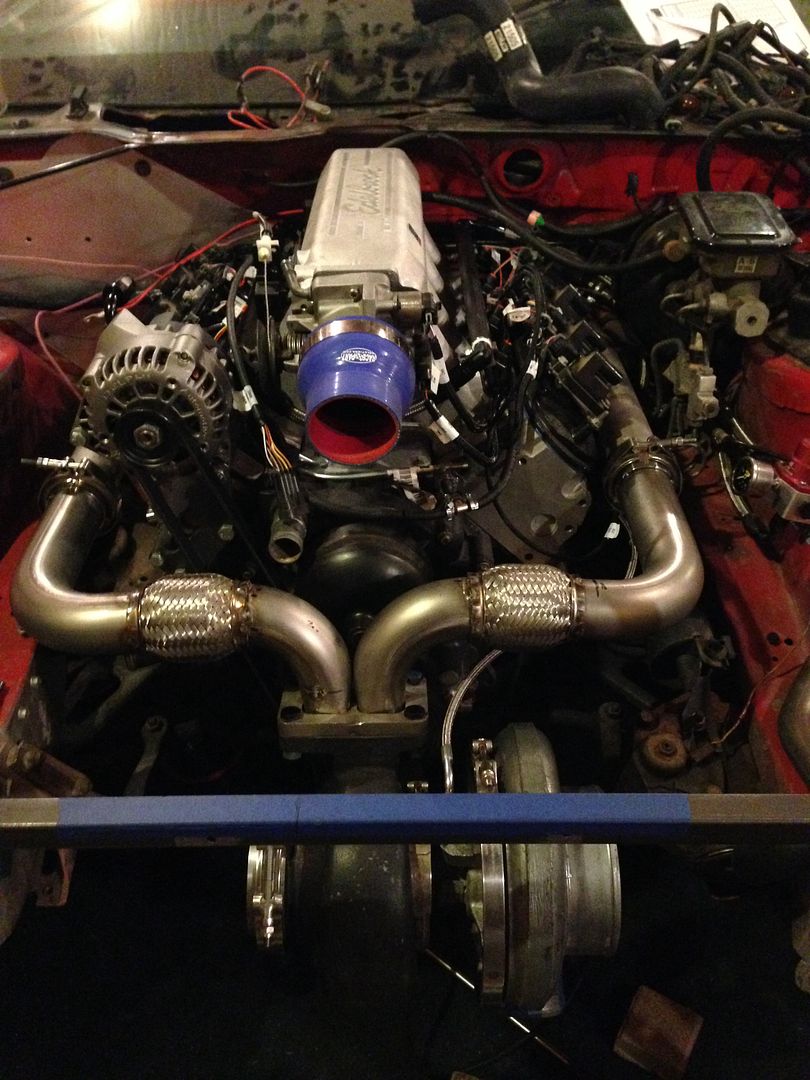

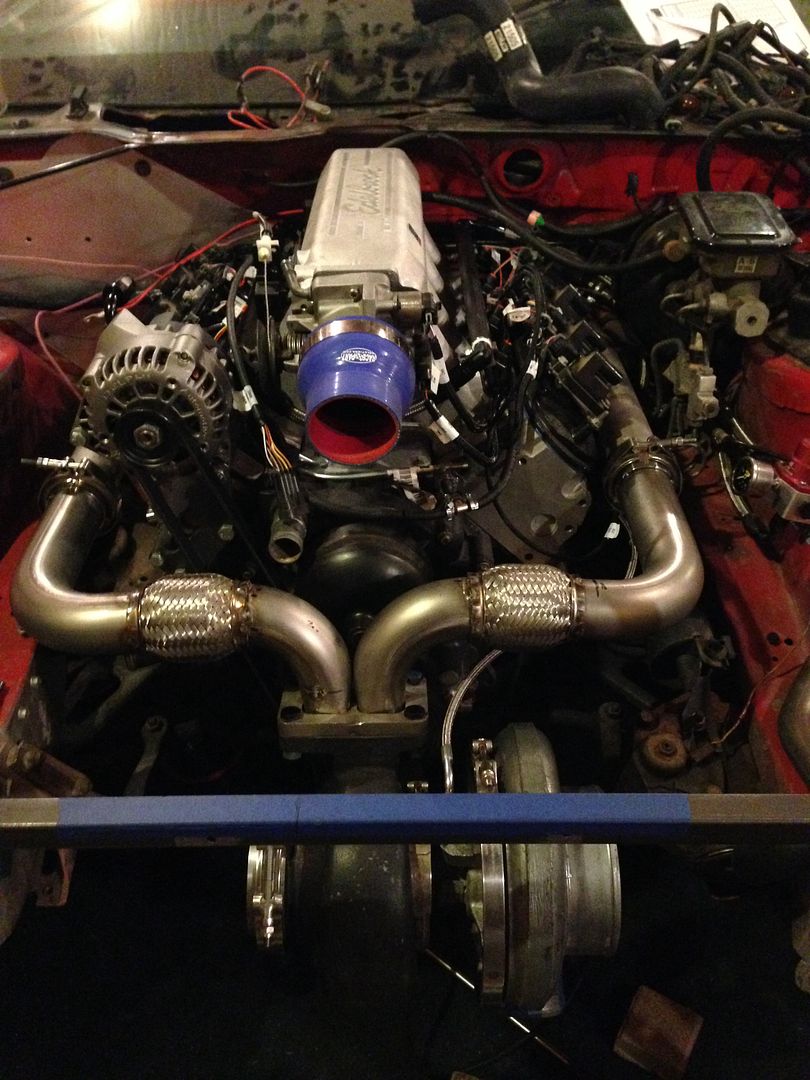

I don't see why they wouldn't fit. Here is a pic in my 3rd gen chassis. I'm not running power steering so, I couldn't tell you if it would clear or not.

10 short radius 1.5" els.

2 2" to 1.5" reducers

4' of 2" pipe

2' of 1.5" pipe

1/2" SS flanges

2.25" V Bands

I don't see why they wouldn't fit. Here is a pic in my 3rd gen chassis. I'm not running power steering so, I couldn't tell you if it would clear or not.

#19

10 Second Club

iTrader: (2)

Join Date: Oct 2004

Location: Orange Co. New York

Posts: 441

Likes: 0

Received 0 Likes

on

0 Posts

[QUOTE=turbotater1;18172756]just for reference truck manifolds can be modified for down and forward and have power steering. this pic is pre wastegate

What type of welding did you use for the v-bands,mig,tig/stainless,stick/cast rod?

What type of welding did you use for the v-bands,mig,tig/stainless,stick/cast rod?