Dual Walbro 450s with stock bucket COMPLETE

#42

TECH Addict

iTrader: (1)

I did mine about a month ago I guess and here's a couple quick tips.

The filters on the bottom of the pump should face the same direction. If the face out in oops site directions you will never get the pump back in I pointed both of mine to the rear.

For a Y I used these nice 3/8 stainless tig welded fittings made for coca cola machines and they work great and are very cheap and easy to fit in the bucket.

It was $8 for 10 on ebay

The filters on the bottom of the pump should face the same direction. If the face out in oops site directions you will never get the pump back in I pointed both of mine to the rear.

For a Y I used these nice 3/8 stainless tig welded fittings made for coca cola machines and they work great and are very cheap and easy to fit in the bucket.

It was $8 for 10 on ebay

#46

On The Tree

iTrader: (4)

Hey guys, just discovered the brand new pump I got for my h/c/I LQ4 isn't gonna cut it and pretty much need to go with twin 450s like this setup y'all are making. I have already ran 3/8" stainless line and -6AN fittings attached at each end. Would 3/8" and -6AN fittings be capable of flowing enough fuel for this twin 450 setup? Would like to keep hard stainless lines under the car running from the tank to the engine bay but no one makes 1/2" stainless hard fuel line. Shooting for 500 rwhp and e85 capability.

Last edited by JCS94; 03-13-2017 at 07:57 PM.

#51

On The Tree

iTrader: (4)

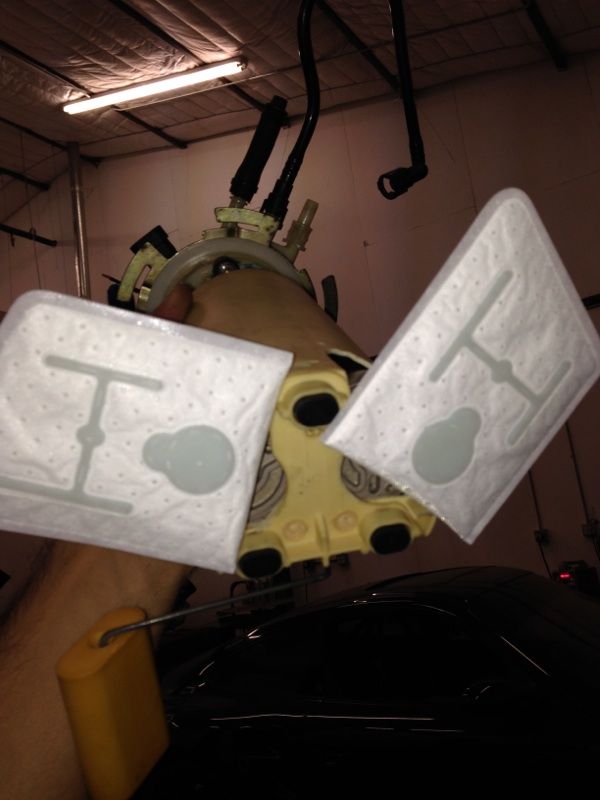

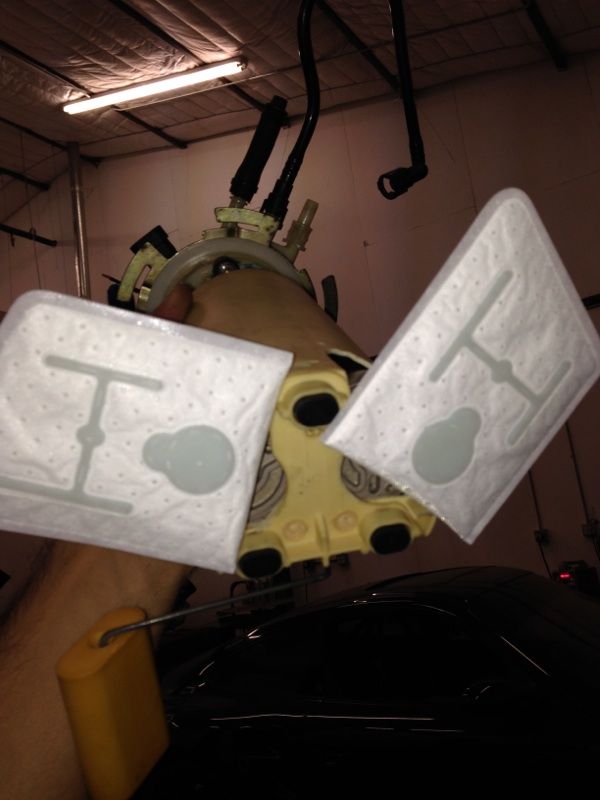

I searched high and low on how to make these pumps work on an Fbody (2001) or if it was even possible with the factory tank and factory hanger/bucket and had no luck. So I took it upon myself to make a thread to show it's possible/doable to get these to fit with small modifications and a lot of patience. The hardest part was fitting the socks into the tank as the plastic part holding the sock on to the pump has almost no give or flex to it. Pair that with the bottoms of the 450's being wide at the bottom, and you're in for a hell of a fight to get it into the tank, but its 100% doable.

I wired them so they both run at the same time, no hobbs switch. And I ended up moving the relays into the spare tire well since I decided to relocate my battery as well. Here are a few pics I took along the way.

I wired them so they both run at the same time, no hobbs switch. And I ended up moving the relays into the spare tire well since I decided to relocate my battery as well. Here are a few pics I took along the way.

#52

TECH Resident

Thread Starter

iTrader: (16)

Join Date: Mar 2006

Location: dfw

Posts: 985

Likes: 0

Received 0 Likes

on

0 Posts

So for you guys that are running the dual setup, how do you hold them in place inside the bucket? And when you cut the bottom out, did you cut out the part where the Venturi tube connected to the bucket? And did you cut out the hole where the original single pump mounted on the top of the bucket?

Gotta man handle them a bit to get them to squeeze together and then play a game of Operation to get it into the tank opening itself without knocking the socks off.

That was the substantially harder part.

That was the substantially harder part.Don't have the answer as to where the bucket was cut since I sent the bucket off to be done by someone who is a lot more precise than myself and a lot more patient. Maybe he will chime in.

#53

TT-TECH Veteran

iTrader: (29)

I cut out everything inside the bucket and then going one pump at a time cut the bottom holes/notches. I don't give a **** about anything the factory fuel system was doing or there for. I made it do what I wanted basically. I used Teflon coated fuel rated wire in the tank and submersible ethanol rated hose are the only things I will tell you to be sure of. I guess a lot of you guys trying to do this yourself are not very mechanically experienced or don't have a good imagination to figure this stuff out. Its not hard just don't be afraid to think outside the box. GL!

#54

On The Tree

iTrader: (4)

I cut out everything inside the bucket and then going one pump at a time cut the bottom holes/notches. I don't give a **** about anything the factory fuel system was doing or there for. I made it do what I wanted basically. I used Teflon coated fuel rated wire in the tank and submersible ethanol rated hose are the only things I will tell you to be sure of. I guess a lot of you guys trying to do this yourself are not very mechanically experienced or don't have a good imagination to figure this stuff out. Its not hard just don't be afraid to think outside the box. GL!

#55

TECH Addict

iTrader: (1)

Originally Posted by Nitroused383

A single 450 will do what you want. I made 830 rwhp on the stock feed line which is 3/8 with e85. Dual 450 will do around 1100 rwhp on e85.

#56

TT-TECH Veteran

iTrader: (29)

I wasn't talking directly to anyone person. And maybe I should have said engineering custom parts to make stuff work. And I wasn't trying to belittle anyone, but I know it comes off like that sorry for that. I am older than most ppl and so naturally usually have done a lot more than a lot because of simple years, but not all.

#57

TECH Fanatic

iTrader: (5)

Join Date: Aug 2007

Location: colorado springs Elevation: 6035 ft

Posts: 1,053

Likes: 0

Received 1 Like

on

1 Post

So I'm stuffing dual 450's into My stock tank/bucket and I noticed everyone is jamming everything into the bucket. My y block is to big for this so I am going to run the dual 3/8 hoses out of the bucket and then y them on top of the gas tank. Anybody see any reason why I shouldn't do this?

#58

So I see you put both fuel pump connectors through the top of the pump so you no longer use the one fuel connector and connect the pumps straight to relays?

Whew! Thanks man, I'm sure someone will find something wrong with it or could be done better which is what I like about these threads. It's First time doing something like this, I'm usually the person reading the write ups and trying what's known and proven to work! The other solution to make these fit was a $700 setup from a sponsor on here thats drop in and go, but I ordered these pumps and THEN saw that there was a drop in solution. Regardless, I saved $400 give or take.