Welding 4" SS V-band onto S475 turbine questions

#1

TECH Regular

Thread Starter

iTrader: (3)

Join Date: Nov 2005

Location: NoCal

Posts: 430

Likes: 0

Received 0 Likes

on

0 Posts

I made a thread regarding this a while back, but now the time has come and i need specific answers so i can provide my welder with all the correct materials. What i plan to do is cut off the 5" V-band and weld on a stainless 4" V-band. I have very limited space in my engine bay and this is the action i have to take to make it work. I will cut on the tape line which is around 4" Dia on the turbine housing, which allows for the V-band to weld on will plenty of surface area. The 4" flange pictured is mild steel, the stainless one will be in next week. Soo for those of you that have done this, my questions are:

-Is the S475 turbine housing cast iron or steel?

-What rod is to be used? Someone mentioned nickel and another mentioned a 309 rod?

-am i crazy to be cutting up a brand new $1200 turbo? LOL

From what i researched, the stainless V-band flange welded with a nickel rod has similar expansion and contraction rates as the cast steel does. Which of course reduces the possibility of it cracking sometime down the road. IS this correct or am i way off?

thanks to all that help!

-Is the S475 turbine housing cast iron or steel?

-What rod is to be used? Someone mentioned nickel and another mentioned a 309 rod?

-am i crazy to be cutting up a brand new $1200 turbo? LOL

From what i researched, the stainless V-band flange welded with a nickel rod has similar expansion and contraction rates as the cast steel does. Which of course reduces the possibility of it cracking sometime down the road. IS this correct or am i way off?

thanks to all that help!

#2

TECH Veteran

iTrader: (7)

isn't the turbine wheel right in that area, been a while since I looked at mine

if it were me, I would make something up to reduce the 5" to 4" right off the back vs cutting the housing-is their a flange that would fit the housing outside dia. but 4"-if not wouldn't be hard to machine one, provide a taper inside like some hose fittings

if it were me, I would make something up to reduce the 5" to 4" right off the back vs cutting the housing-is their a flange that would fit the housing outside dia. but 4"-if not wouldn't be hard to machine one, provide a taper inside like some hose fittings

#3

Nickel rod is what I would use when welding cast iron also pre heat the exhaust housing and dont let it cool quickly when done welding will help it not to crack. but other than that I don't think I'm much help on cutting it off and how that will affect performance.

Trending Topics

#8

TECH Regular

Thread Starter

iTrader: (3)

Join Date: Nov 2005

Location: NoCal

Posts: 430

Likes: 0

Received 0 Likes

on

0 Posts

isn't the turbine wheel right in that area, been a while since I looked at mine

if it were me, I would make something up to reduce the 5" to 4" right off the back vs cutting the housing-is their a flange that would fit the housing outside dia. but 4"-if not wouldn't be hard to machine one, provide a taper inside like some hose fittings

if it were me, I would make something up to reduce the 5" to 4" right off the back vs cutting the housing-is their a flange that would fit the housing outside dia. but 4"-if not wouldn't be hard to machine one, provide a taper inside like some hose fittings

#10

TECH Regular

Thread Starter

iTrader: (3)

Join Date: Nov 2005

Location: NoCal

Posts: 430

Likes: 0

Received 0 Likes

on

0 Posts

heh, i know  evil:

evil:

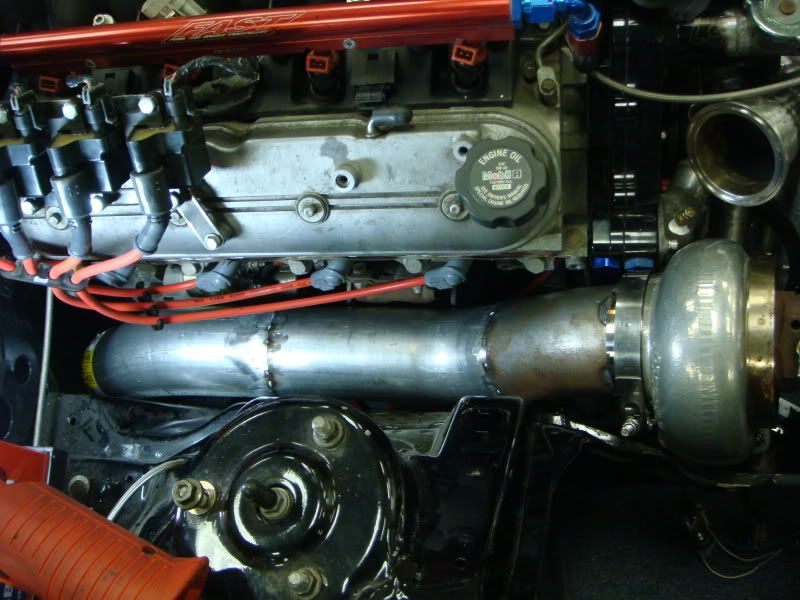

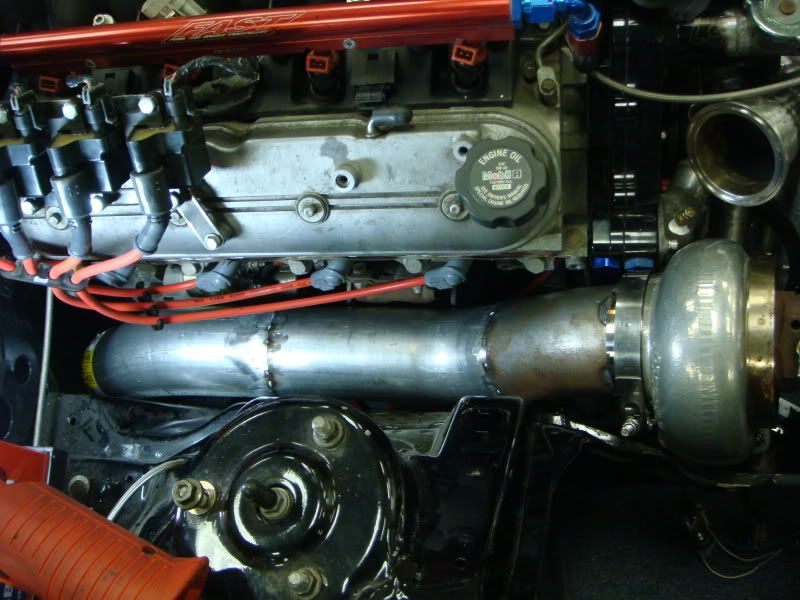

heres an old pic when i had the PT88. kinda hard to tell in this pic, but between the water pump and frame rail is about 4.5" and the 4" DP is very tight through there. Soo if i were to run a 4-5" transition on the S475 it will then move the unit too far forward into the radiator/core support.

evil:

evil:heres an old pic when i had the PT88. kinda hard to tell in this pic, but between the water pump and frame rail is about 4.5" and the 4" DP is very tight through there. Soo if i were to run a 4-5" transition on the S475 it will then move the unit too far forward into the radiator/core support.

#16

TECH Regular

Thread Starter

iTrader: (3)

Join Date: Nov 2005

Location: NoCal

Posts: 430

Likes: 0

Received 0 Likes

on

0 Posts

i will have a 4" SS braided flex section about 18" after the turbo and then the rest of the exhaust under the car will be supported off hangers.