Flamed a TFS 6 bolt head on 28lbs of boost (Pics inside)

#22

12 Second Club

iTrader: (91)

The problem cylinder looks leaner than the surrounding cylinder. May check that out. Mark the injector that came out of that hole and flow it. Or swap it out with the richest looking cylinder on that side at minimum.

I may have done the same at 25lbs and 17* a few weeks ago. I figured it was poor head clamping on my setup. Kinda looked like it had been eating its way to freedom over many runs, so it may not be related. I was using E85 and water/meth inj. No signs of detonation on the plugs, pistons, or CC. LS9 gaskets, china studs torqued to 75lbs once... never retorqued.

]

I may have done the same at 25lbs and 17* a few weeks ago. I figured it was poor head clamping on my setup. Kinda looked like it had been eating its way to freedom over many runs, so it may not be related. I was using E85 and water/meth inj. No signs of detonation on the plugs, pistons, or CC. LS9 gaskets, china studs torqued to 75lbs once... never retorqued.

]

#24

The cylinder is clean from water. That big of hole from water jacket to cylinder he was pulling water in on the intake stroke guaranteed. That is why I suggested checking piston height compared to the rest

Send me Ur scanner and file to zacbrown1307@gmail.com

From the video it blew out down track but that isn't to say it got unseated early and started moving gas and couldn't recover

Send me Ur scanner and file to zacbrown1307@gmail.com

From the video it blew out down track but that isn't to say it got unseated early and started moving gas and couldn't recover

#25

My guess is you will see some funky things with the injector when you flow them. I had all sorts of issues with FIC (Clinic not Connection) and E85 on my 1000WHP EVO. Every few months it seemed they would be out of balance.

Super heavy car too let's not forget. The load on this motor is pretty intense between vehicle weight ant the 4L80E trans. I would move it to a better more consistent fuel for track days and run E85 dialed down on the street.

Super heavy car too let's not forget. The load on this motor is pretty intense between vehicle weight ant the 4L80E trans. I would move it to a better more consistent fuel for track days and run E85 dialed down on the street.

#27

ARP 6 bolt head studs made for Dart Ls Motor , Cometic MLX gaskets.

I did not assemble longblock. Jakson assembled the longblock. No re-torque after heat cycle.

Last edited by transam69230; 09-11-2014 at 12:17 PM.

#28

8 Second Club

iTrader: (4)

Id think with that much duration in the cam, 17* doesn't sound excessive... even at 28lbs. Maybe the timing is ramped in too quickly? Screen shot of timing map? What are you reving to? Can you guess where it let go RPM wise in the logs?

Did you mark the balancer at TDC and verify the timing is 100% accurate? All 3 of my motors needed to be adjusted and re-synced.

Did you mark the balancer at TDC and verify the timing is 100% accurate? All 3 of my motors needed to be adjusted and re-synced.

#31

Get the timing right and run it in 11.4 to 11.8 range. Especially on an A/W IC set up. I think for folks who are non intercooled and relying on the corn to cool the IAT's a bit then perhaps a super fat tune up is worth it.

Super fat on E85 is going to break **** in my view. Lean on E85 is very forgiving provided IAT's are low.

#33

10 Second Club

iTrader: (11)

I keep hearing to run E85 super fat with more timing at higher power levels - I think that is crazy. Super fat on E85 in my view is more likely to have issues.

Get the timing right and run it in 11.4 to 11.8 range. Especially on an A/W IC set up. I think for folks who are non intercooled and relying on the corn to cool the IAT's a bit then perhaps a super fat tune up is worth it.

Super fat on E85 is going to break **** in my view. Lean on E85 is very forgiving provided IAT's are low.

Get the timing right and run it in 11.4 to 11.8 range. Especially on an A/W IC set up. I think for folks who are non intercooled and relying on the corn to cool the IAT's a bit then perhaps a super fat tune up is worth it.

Super fat on E85 is going to break **** in my view. Lean on E85 is very forgiving provided IAT's are low.

#35

8 Second Club

iTrader: (4)

I keep hearing to run E85 super fat with more timing at higher power levels - I think that is crazy. Super fat on E85 in my view is more likely to have issues.

Get the timing right and run it in 11.4 to 11.8 range. Especially on an A/W IC set up. I think for folks who are non intercooled and relying on the corn to cool the IAT's a bit then perhaps a super fat tune up is worth it.

Super fat on E85 is going to break **** in my view. Lean on E85 is very forgiving provided IAT's are low.

Get the timing right and run it in 11.4 to 11.8 range. Especially on an A/W IC set up. I think for folks who are non intercooled and relying on the corn to cool the IAT's a bit then perhaps a super fat tune up is worth it.

Super fat on E85 is going to break **** in my view. Lean on E85 is very forgiving provided IAT's are low.

With timing there is usually a clear do not exceed point. As soon as you stop making large power gains or stop seeing mph gains... stop. I think a lot of people tuning on a dyno tune to this point. Then when they go the track the extra load on the engine causes failures like the OP's. I'd pull 3-5* from the dyno visit if you tuned to the ragged edge timing wise. The weight of the car puts A LOT more load on the motor.

Last edited by Forcefed86; 09-11-2014 at 03:24 PM.

#36

I don't agree with that really. E85 has a huge tuning window. 10.44 to 12.64. (.71 to .86 lambda) Much better off on the rich side of the peak power window IMO. Also helps out if you have one or more lean cylinders.

With timing there is usually a clear do not exceed point. As soon as you stop making large power gains or stop seeing mph gains... stop. I think a lot of people tuning on a dyno tune to this point. Then when they go the track the extra load on the engine causes failures like the OP's. I'd pull 3-5* from the dyno visit if you tuned to the ragged edge timing wise. The weight of the car puts A LOT more load on the motor.

With timing there is usually a clear do not exceed point. As soon as you stop making large power gains or stop seeing mph gains... stop. I think a lot of people tuning on a dyno tune to this point. Then when they go the track the extra load on the engine causes failures like the OP's. I'd pull 3-5* from the dyno visit if you tuned to the ragged edge timing wise. The weight of the car puts A LOT more load on the motor.

Low timing, nice solid 11:4.1 E85 scale is ussually pretty safe. Now if you keep gaining power going from 11:4.1 to 11:2.1 to 11.0.1 etc... then so be it but that is out of the ordinary for sure.

#37

holy **** thats a big stick for a 427 especially with TFS245s and those turbines

#38

On The Tree

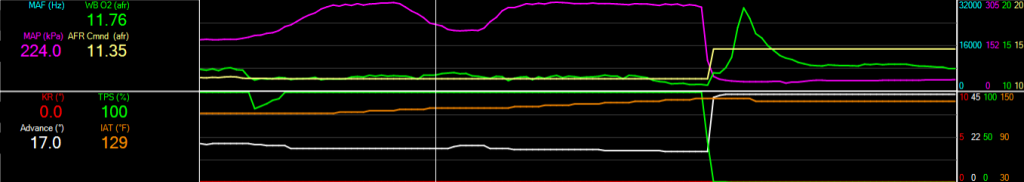

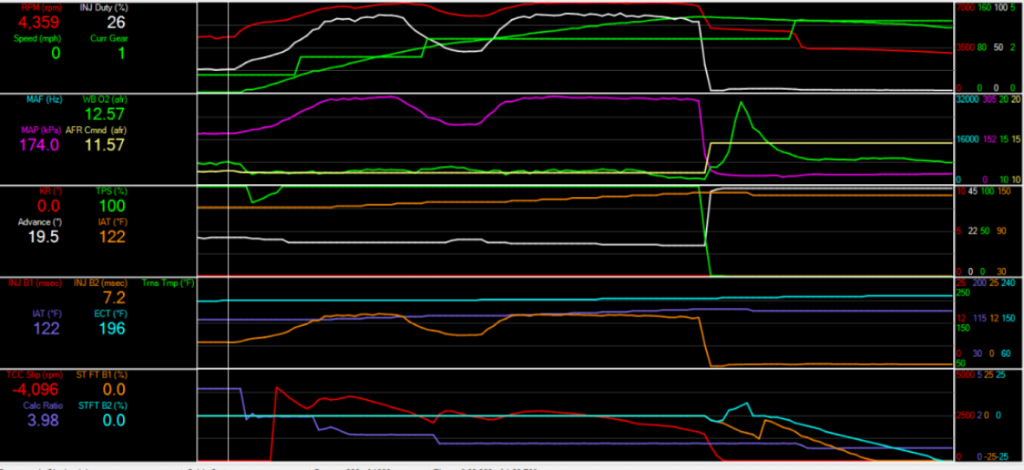

11.5:1 on E85 on gas scale is perfectly fine. No need to go richer. Timing is also not excessive provided that there isn't a horrible backpressure ratio. Now, commanded AFR and actual AFR are 2 different things. Can you post a log showing actual AFR, timing, fuel pressure, voltage and MAP for this pass? What engine management?

#40

11.5:1 on E85 on gas scale is perfectly fine. No need to go richer. Timing is also not excessive provided that there isn't a horrible backpressure ratio. Now, commanded AFR and actual AFR are 2 different things. Can you post a log showing actual AFR, timing, fuel pressure, voltage and MAP for this pass? What engine management?

Stock PCM right now, what to get holley eventually but not in the budget currently for a little bit.