TT 408 numbers

#61

TECH Enthusiast

iTrader: (13)

Join Date: Nov 2005

Location: Pittsburgh PA

Posts: 665

Likes: 0

Received 0 Likes

on

0 Posts

Depends on if you half fill with aluminum heads or iron for heat dissipatation. LOL

Look at non lsx x275 turbo cars that are running bottom 4s to the 8th at 170 plus. All aluminum heads regardless of motor platform.

If your hell bent on iron heads do it and report back. My hunch is you will knock or break something because of the heat retention with a normal, traditional boosted ls tuneup.

Look at non lsx x275 turbo cars that are running bottom 4s to the 8th at 170 plus. All aluminum heads regardless of motor platform.

If your hell bent on iron heads do it and report back. My hunch is you will knock or break something because of the heat retention with a normal, traditional boosted ls tuneup.

Now part of that might be lack of availability in iron tho. Aluminum is lighter anf easier to machine and port. And its lighter. Hence why alot of iron heads are being phased out, even in sbc world. Only ppl who run iron seem to be in classes that specify iron only.

There arent many iron lsx heads are there? Wasnt it only like 1-2 years in production in super early truck motors? And they werent real good to begin with. Anyone making aftermarket iron cores?

#62

8 Second Club

iTrader: (4)

Plenty of iron headed cars making BIG power. They are using race castings with thick decks though. Tom Vaught over on theturboforums ran a 406 Pontiac at over 38lbs of boost with Iron heads/block for 3 years without ever pulling a head off. He also ran no head gasket…trapping mid 190’s in a 3000lb chassis.

I wouldn’t worry about the Iron causing detonation/performance loss. That’s been beat to death over the years. Still no valid proof to back up one is better than the other. Heat retention isn’t necessarily a bad thing and more IGN lead isn’t always a good thing. That aside there aren’t any decent iron castings out there for an LS I’m aware of. I’d go with the thickest deck 6-bolt alum head you could find and a nice aftermarket block/crank if you want reliability. 1300whp on OEM anything will be far from reliable IMO.

Lots of those “1000 HP” super cars really aren’t putting up great times. I think you’d be surprised how well your car would do if you got a clean pass with enough gear as it sits. Racing 1500ft isn’t going to generate much more heat than a ¼ mile run. Are you planning on half mile stuff too?

I wouldn’t worry about the Iron causing detonation/performance loss. That’s been beat to death over the years. Still no valid proof to back up one is better than the other. Heat retention isn’t necessarily a bad thing and more IGN lead isn’t always a good thing. That aside there aren’t any decent iron castings out there for an LS I’m aware of. I’d go with the thickest deck 6-bolt alum head you could find and a nice aftermarket block/crank if you want reliability. 1300whp on OEM anything will be far from reliable IMO.

Lots of those “1000 HP” super cars really aren’t putting up great times. I think you’d be surprised how well your car would do if you got a clean pass with enough gear as it sits. Racing 1500ft isn’t going to generate much more heat than a ¼ mile run. Are you planning on half mile stuff too?

#63

Plenty of iron headed cars making BIG power. They are using race castings with thick decks though. Tom Vaught over on theturboforums ran a 406 Pontiac at over 38lbs of boost with Iron heads/block for 3 years without ever pulling a head off. He also ran no head gasket…trapping mid 190’s in a 3000lb chassis.

I wouldn’t worry about the Iron causing detonation/performance loss. That’s been beat to death over the years. Still no valid proof to back up one is better than the other. Heat retention isn’t necessarily a bad thing and more IGN lead isn’t always a good thing. That aside there aren’t any decent iron castings out there for an LS I’m aware of. I’d go with the thickest deck 6-bolt alum head you could find and a nice aftermarket block/crank if you want reliability. 1300whp on OEM anything will be far from reliable IMO.

Lots of those “1000 HP” super cars really aren’t putting up great times. I think you’d be surprised how well your car would do if you got a clean pass with enough gear as it sits. Racing 1500ft isn’t going to generate much more heat than a ¼ mile run. Are you planning on half mile stuff too?

I wouldn’t worry about the Iron causing detonation/performance loss. That’s been beat to death over the years. Still no valid proof to back up one is better than the other. Heat retention isn’t necessarily a bad thing and more IGN lead isn’t always a good thing. That aside there aren’t any decent iron castings out there for an LS I’m aware of. I’d go with the thickest deck 6-bolt alum head you could find and a nice aftermarket block/crank if you want reliability. 1300whp on OEM anything will be far from reliable IMO.

Lots of those “1000 HP” super cars really aren’t putting up great times. I think you’d be surprised how well your car would do if you got a clean pass with enough gear as it sits. Racing 1500ft isn’t going to generate much more heat than a ¼ mile run. Are you planning on half mile stuff too?

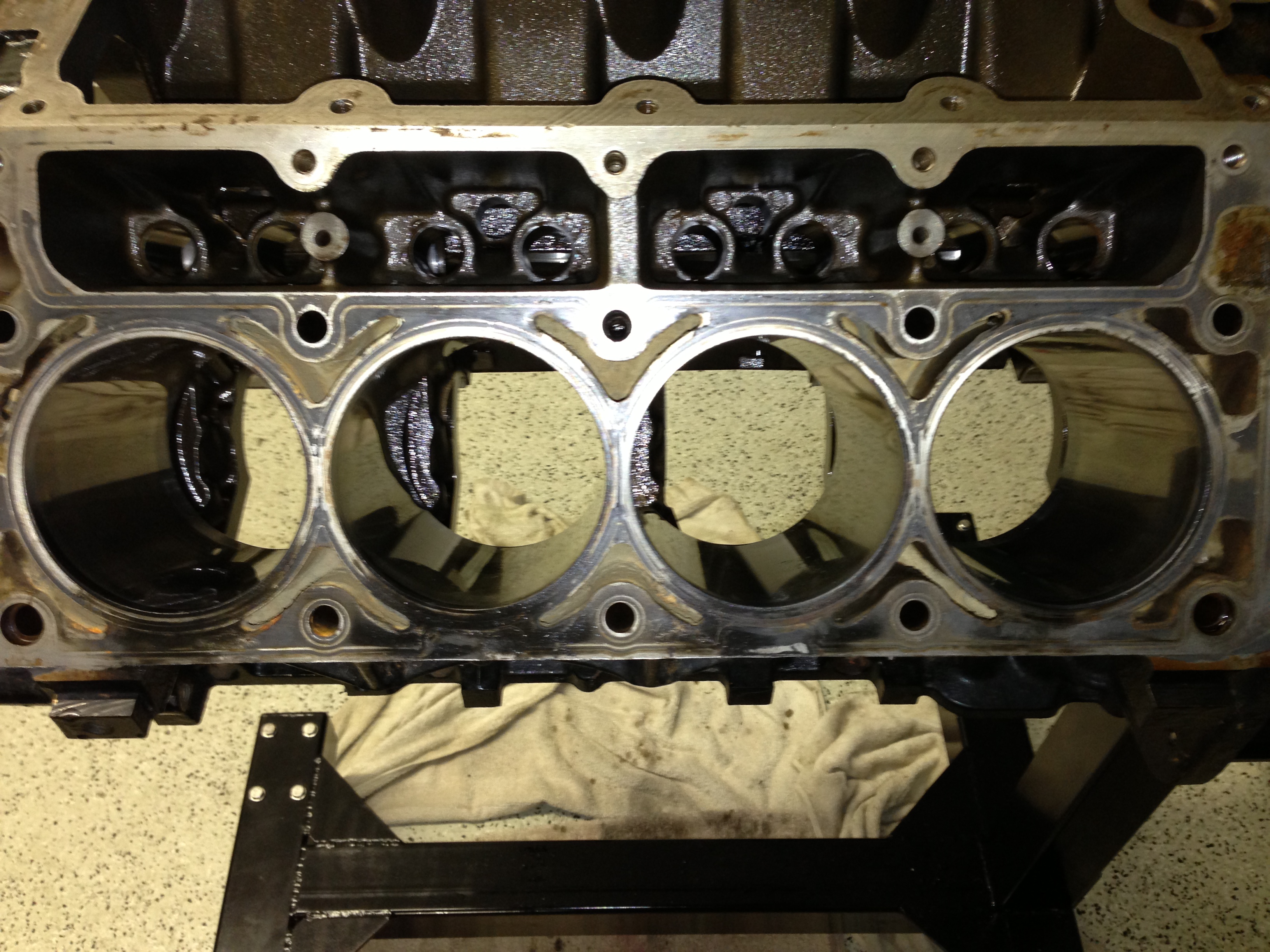

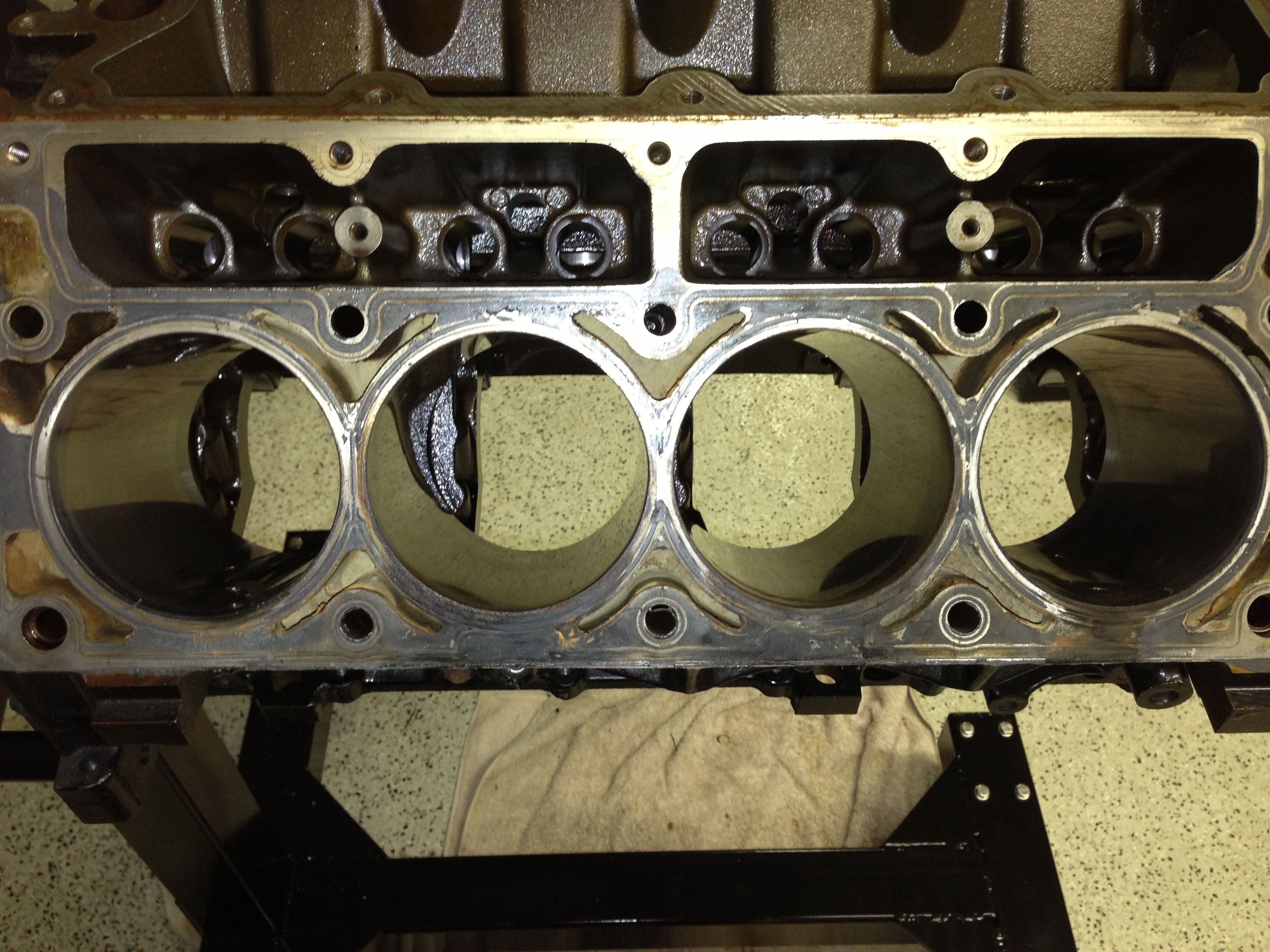

Interesting to hear that. Yes 1/2 mile and more are on the horizon for me in the future. I spoke with Erik @ HKE for an hour or so about all this last night and his response about 4 bolt heads lifting was mostly tune related. He also suggested a process that strengthens the corner of the bores (water jackets) I posted about this in another thread a few months ago and no one seemed to pay attention. His theory is when the motor is making big power and the cylinders start to flex and the deck Becomes distorted it is happening at these areas with no support. This is where the head is actually lifting. He seems to think with the right tuning and attention to detail 1300 on a 4 bolt is very possible. With that said im not sure i want to take it there.. The constant risk of failure in the event of even the slightest change steers me away. After all the dust clears with block modifications/Crank/Studs etc. A 6 bolt block could be had and done with less trouble.

#65

Interesting to hear that. Yes 1/2 mile and more are on the horizon for me in the future. I spoke with Erik @ HKE for an hour or so about all this last night and his response about 4 bolt heads lifting was mostly tune related. He also suggested a process that strengthens the corner of the bores (water jackets) I posted about this in another thread a few months ago and no one seemed to pay attention. His theory is when the motor is making big power and the cylinders start to flex and the deck Becomes distorted it is happening at these areas with no support. This is where the head is actually lifting. He seems to think with the right tuning and attention to detail 1300 on a 4 bolt is very possible. With that said im not sure i want to take it there.. The constant risk of failure in the event of even the slightest change steers me away. After all the dust clears with block modifications/Crank/Studs etc. A 6 bolt block could be had and done with less trouble.

Be interesting to know how many deck issues/distortion and head sealing issues (may not be lifting?) are on cars with mounts vs plates.

#68

9 Second Club

I dont think he's done any long duration pulls yet ? The last event was just 1500ft I think, so barely more than the standard 1/4

#69

And why do you think this ?

I just don't see a drop in CR making more power at this point, not without a lot more boost. At 25/26 I'm sure I'm reaching the limits of what these 4 bolts can hold. Sure lower SCR will allow you to run more but at what point do returns diminish? I don't know the awnser to that.

I dont think he's done any long duration pulls yet ? The last event was just 1500ft I think, so barely more than the standard 1/4

I just don't see a drop in CR making more power at this point, not without a lot more boost. At 25/26 I'm sure I'm reaching the limits of what these 4 bolts can hold. Sure lower SCR will allow you to run more but at what point do returns diminish? I don't know the awnser to that.

I dont think he's done any long duration pulls yet ? The last event was just 1500ft I think, so barely more than the standard 1/4

#72

Im talking about pinning the bores not the sleeves, well a sleeve would be the same concept so yes. You are providing rigidity for the deck/upper cylinder bores. You have to obviously drill/tap these first. Set your plugs/mill/deck plate and bore like normal as this will distort the bores.

#73

Im talking about pinning the bores not the sleeves, well a sleeve would be the same concept so yes. You are providing rigidity for the deck/upper cylinder bores. You have to obviously drill/tap these first. Set your plugs/mill/deck plate and bore like normal as this will distort the bores.

#74

everyone can agree tq is a good measure of average cylinder pressure

average cylinder pressure across one powerstroke delivers TQ

we have a cylinder pressure clamp limit with the 4 bolt deck, we know this

how do we make more HP without pushing past our clamp limit? RPM

lets say you take two engines the same size, both we limit to lets say 1000 ftlbs of tq

engine 1 tq curve is lower, it makes our 1000ftlbs at 6000rpm...... it develops 1142hp

engine 2 tq curve we shift higher but still the same 1000ftlbs, but at 7500 rpm.... it develops 1428hp

at higher rpm we have less dwell time at peak cylinder pressures too vs lower

#75

look at the SBF, it has been around forever, it is almost identical in head design, deck layout, borespacing, and fasteners

big power is made, how??

look at the small displacement motors with 4 bolt decks, they make big power and clamp, how?

We know we dont want cylinder pressure over X during a single power cycle to keep things sealed up. so how do we make more power? we dont add pressure, we just add more power cycles for a given amount of time

this is why timing plays a huge roll.... average cylinder pressure across the full power stroke may not change much with a modest change in timing

but peak pressures move a ton, very easy to unseat the gasket

big power is made, how??

look at the small displacement motors with 4 bolt decks, they make big power and clamp, how?

We know we dont want cylinder pressure over X during a single power cycle to keep things sealed up. so how do we make more power? we dont add pressure, we just add more power cycles for a given amount of time

this is why timing plays a huge roll.... average cylinder pressure across the full power stroke may not change much with a modest change in timing

but peak pressures move a ton, very easy to unseat the gasket

#78

ha

everyone can agree tq is a good measure of average cylinder pressure

average cylinder pressure across one powerstroke delivers TQ

we have a cylinder pressure clamp limit with the 4 bolt deck, we know this

how do we make more HP without pushing past our clamp limit? RPM

lets say you take two engines the same size, both we limit to lets say 1000 ftlbs of tq

engine 1 tq curve is lower, it makes our 1000ftlbs at 6000rpm...... it develops 1142hp

engine 2 tq curve we shift higher but still the same 1000ftlbs, but at 7500 rpm.... it develops 1428hp

at higher rpm we have less dwell time at peak cylinder pressures too vs lower

everyone can agree tq is a good measure of average cylinder pressure

average cylinder pressure across one powerstroke delivers TQ

we have a cylinder pressure clamp limit with the 4 bolt deck, we know this

how do we make more HP without pushing past our clamp limit? RPM

lets say you take two engines the same size, both we limit to lets say 1000 ftlbs of tq

engine 1 tq curve is lower, it makes our 1000ftlbs at 6000rpm...... it develops 1142hp

engine 2 tq curve we shift higher but still the same 1000ftlbs, but at 7500 rpm.... it develops 1428hp

at higher rpm we have less dwell time at peak cylinder pressures too vs lower