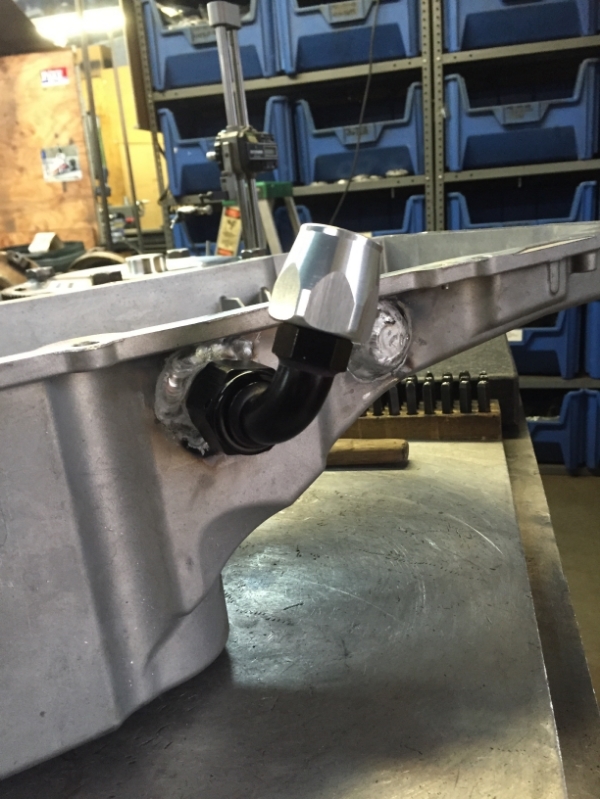

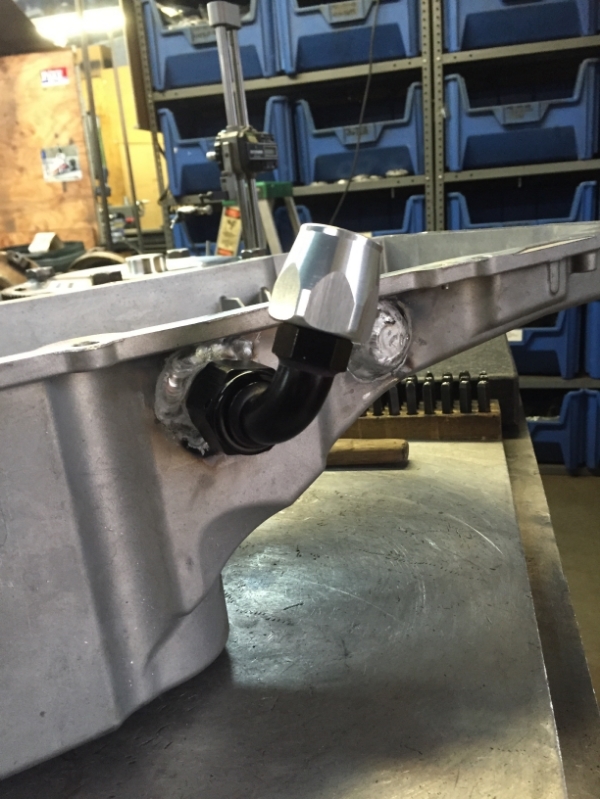

Tapping oil pan.

#3

On The Tree

iTrader: (1)

Join Date: Oct 2009

Location: Philly, PA

Posts: 198

Likes: 0

Received 0 Likes

on

0 Posts

My car is a G-body so probably different than what you're doing. The first bung I welded in turned out to be against the subframe. I closed it up and stepped up to a -12 and moved it back a bank. It's fine where it is but in reality after having the car 90% complete I see that I would have been better off going back to the next bank back. That would have allowed me to run the hose on a straighter path instead of making bends or curves in the line.

#7

I bought a metric to a/n adapter and used the oil level sensor hole. You guys see a problem with using this setup? I use -12 return line that definitely flows downward. I hope not or the engine has to come out again.

Trending Topics

#10

That will not work because the oil level sensor is below the oil level so the oil will not drain back into the pan. You'll need to move it up higher on the pan.

#11

Uh oh. Another member has done it on 2 builds. Said it worked with -12 drain which is what i have. I thought there may be a problem. Should have gone with my gut instinct and had the bung welded. ****, i just dropped the motor back in too.

#12

TECH Apprentice

Just run it like you have it. Iv seen other people have it there no issues too. If you have excessive smoke or something then switch things up, but no sense in going back now