Variable speed fuel pump via holley(or any stand alone ems)

#1

Just gonna share this because it blows my mind people dont do this, or they have a standalone and still buy a 400dollar PWM pump controller.. Or worse a voltage controller

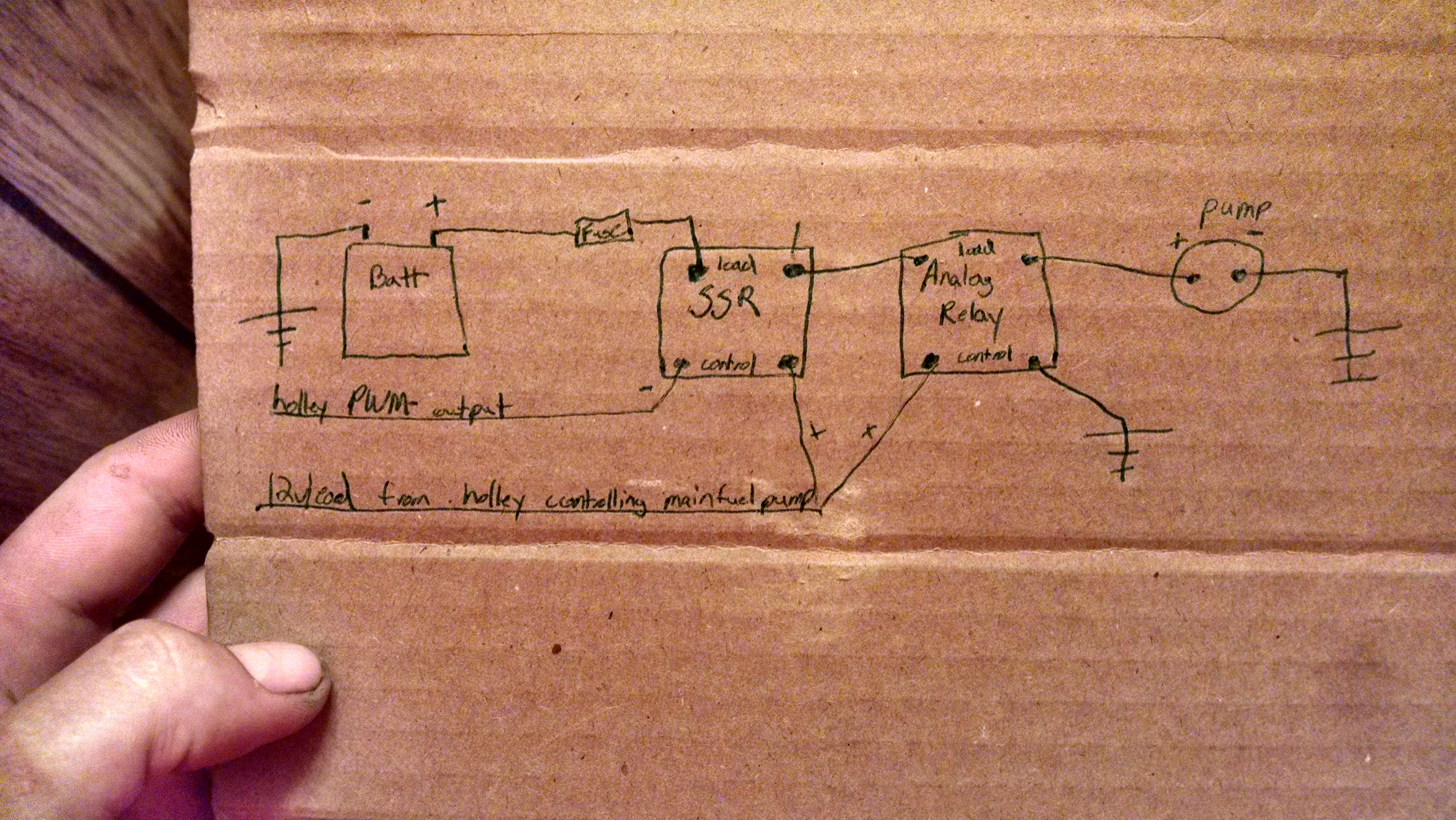

This was done with a single wire from the ECU, and one output.

And 20$ I for a SSR and heat sink + some thermal grease

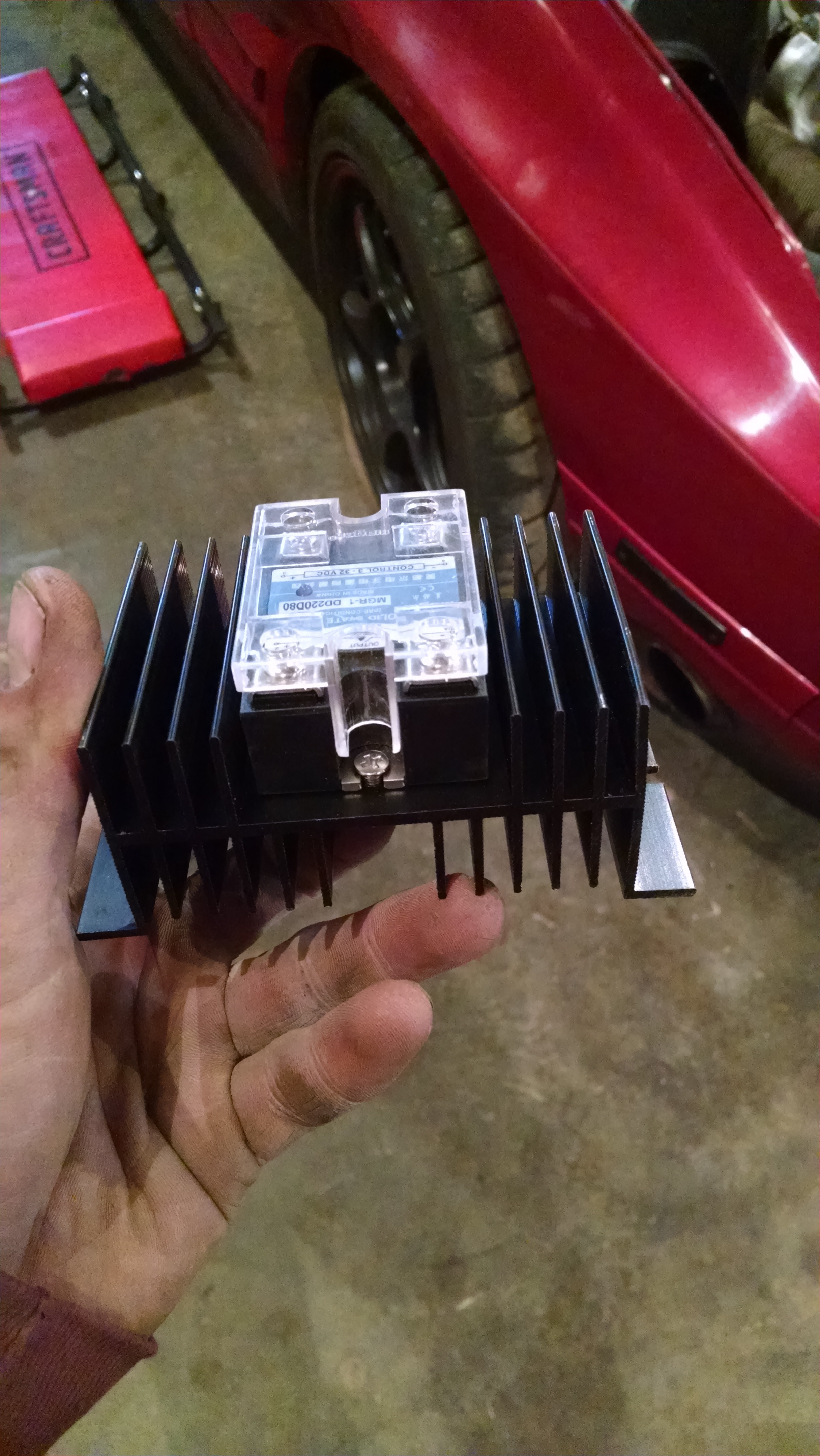

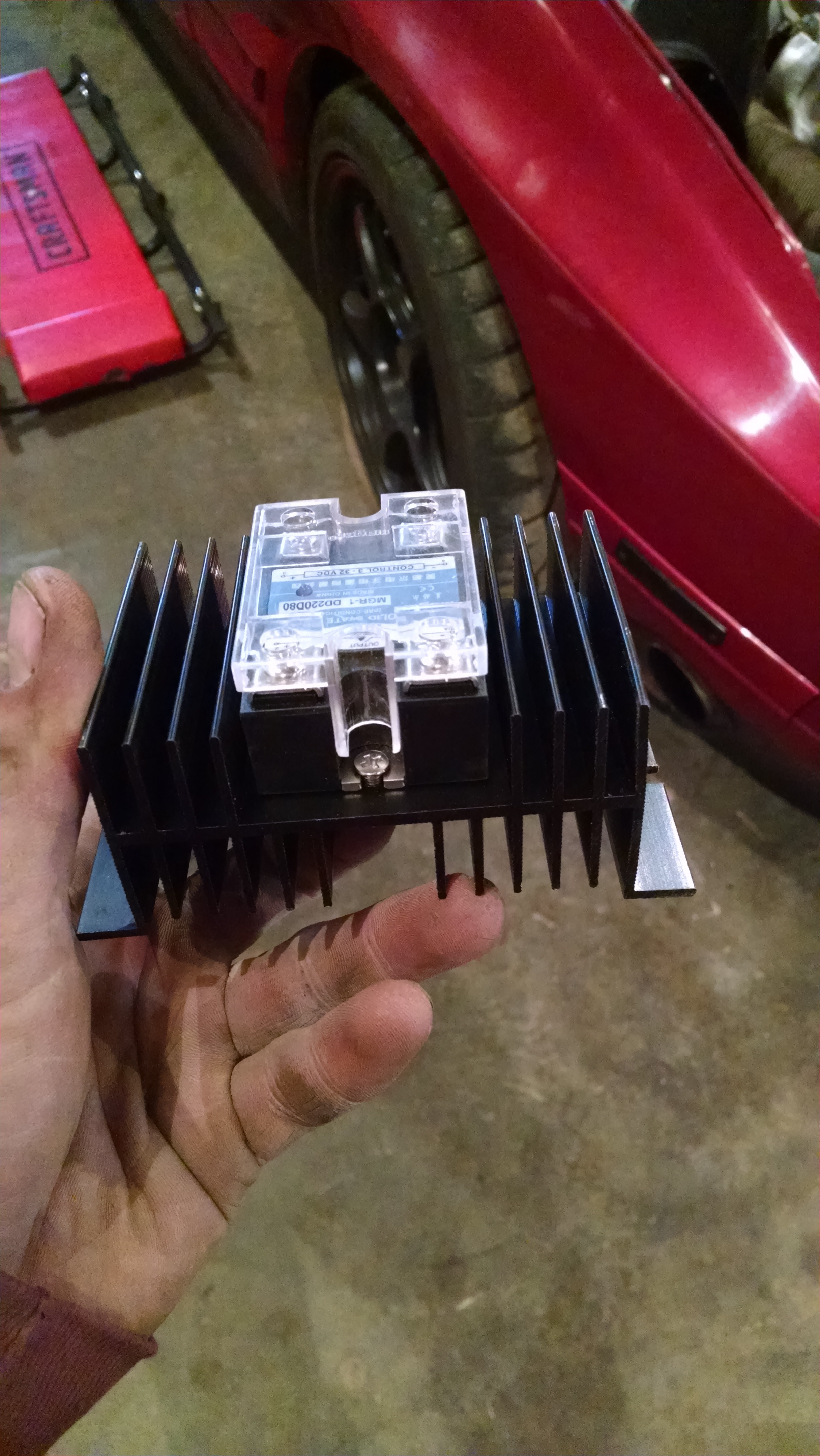

Here we have an 80 amp DC SSR and a large heat sink

Wired up

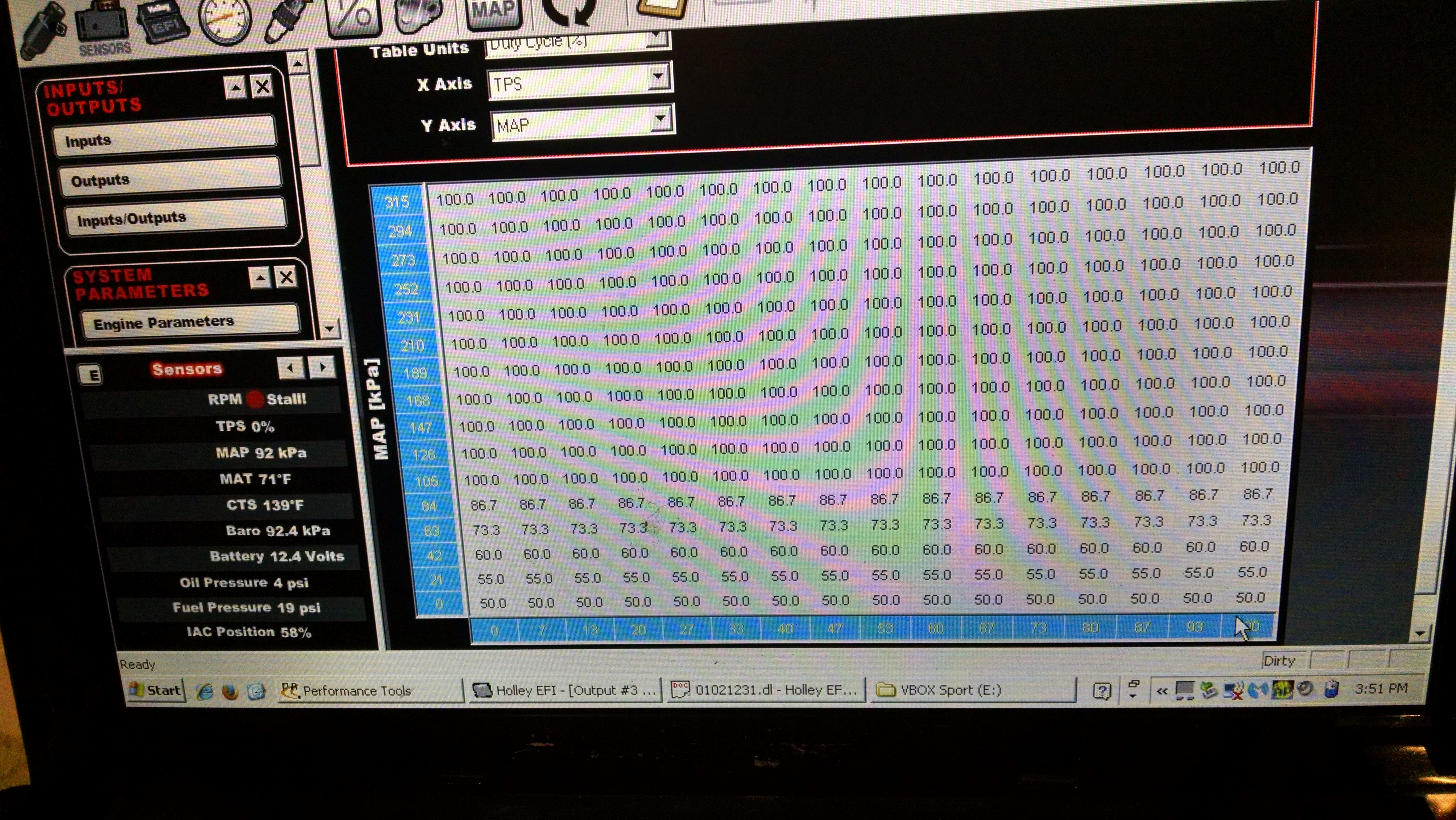

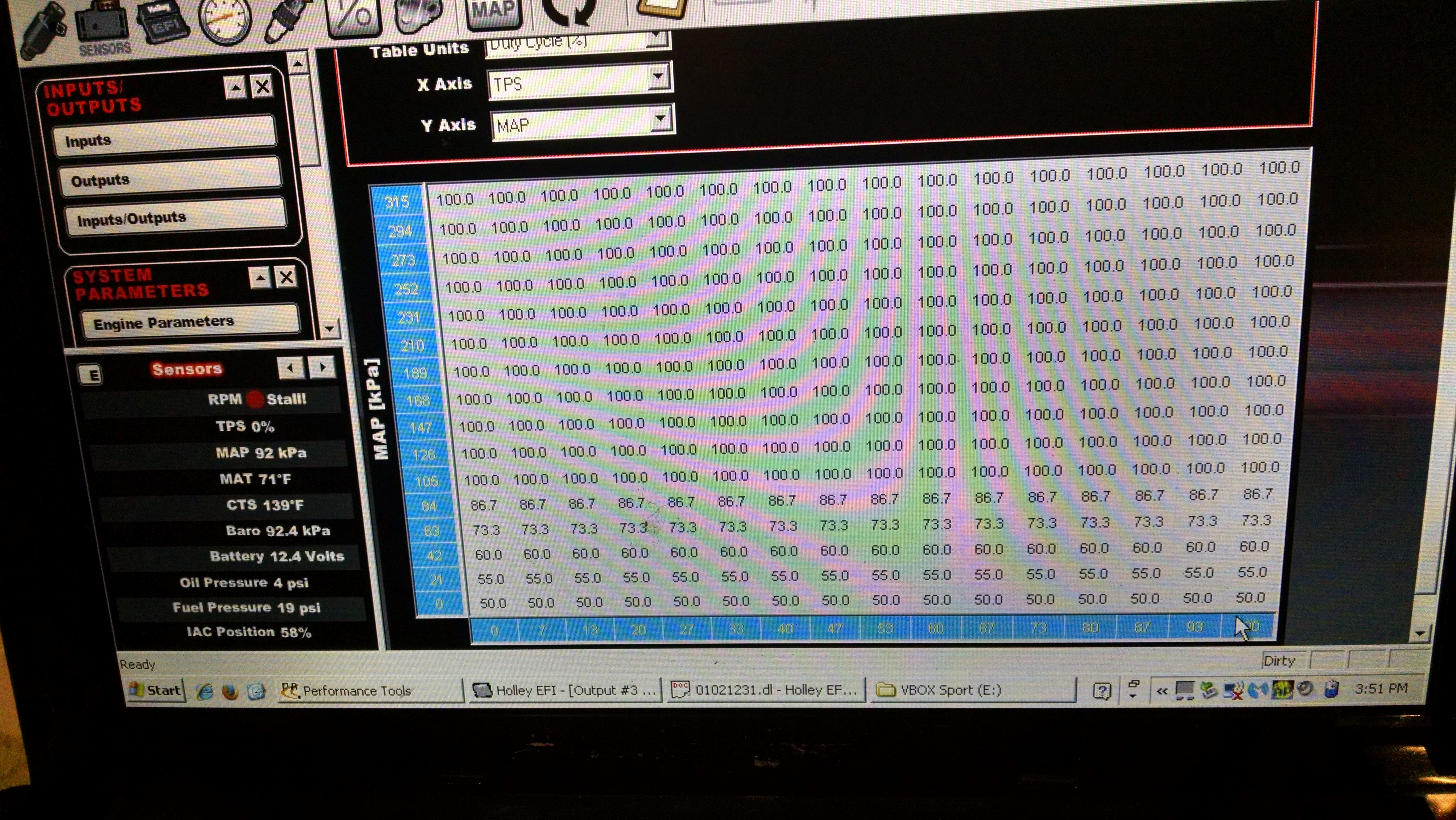

Here is an example if how you can setup to control, very simple and lots of options

And here is a vid to show operation. This was setup against TPS, to vary from 60-100% duty cycle just to illustrate. In real I vary it vs MAP

The camera gives the tone difference but doesn't catch the full decrease in noise. It's impressive, less noise, less heat in the fuel, and less wear of the pump

This was done with a single wire from the ECU, and one output.

And 20$ I for a SSR and heat sink + some thermal grease

Here we have an 80 amp DC SSR and a large heat sink

Wired up

Here is an example if how you can setup to control, very simple and lots of options

And here is a vid to show operation. This was setup against TPS, to vary from 60-100% duty cycle just to illustrate. In real I vary it vs MAP

The camera gives the tone difference but doesn't catch the full decrease in noise. It's impressive, less noise, less heat in the fuel, and less wear of the pump

#2

9 Second Club

I know people who have done it for cooling fans, water pumps and fuel pumps, but the electronic bods I speak to often say only certain SSR's can handle this type of operation.

I've never seen a dummies guide as to what should be done from a 100% electronics point of view, as opposed to what can easily be done but may not be correct.

Here's one with the SSR bolted to a small alloy heat sink and then to the vehicle chassis and effectively use that as a larger heat sink.

But some they say some SSR's have high losses, or do not switch correctly or fast enough and may not be suitable for this type of job. I've never had a straight answer as to which ones are best to use though.

One guy used a Crydom SSR on his, but I also noticed he had a small resistor across the input connections. Not sure why on this. See pic

I keep meaning to try it, but laziness and a working system just hasnt given me the incentive to do so. If I do ever add that 3rd pump, I will just PWM all 3 though. I dont quite need that yet.

PWM control also offers the option of full closed loop pressure control with no regulator and a dead end system, which means all the capacity of the pumps will get used, and none wasted returning fuel to the tank.

What sort of frequency is the Holley outputing the PWM at ? Most seem higher is better, in the 10-20khz range.

I've never seen a dummies guide as to what should be done from a 100% electronics point of view, as opposed to what can easily be done but may not be correct.

Here's one with the SSR bolted to a small alloy heat sink and then to the vehicle chassis and effectively use that as a larger heat sink.

But some they say some SSR's have high losses, or do not switch correctly or fast enough and may not be suitable for this type of job. I've never had a straight answer as to which ones are best to use though.

One guy used a Crydom SSR on his, but I also noticed he had a small resistor across the input connections. Not sure why on this. See pic

I keep meaning to try it, but laziness and a working system just hasnt given me the incentive to do so. If I do ever add that 3rd pump, I will just PWM all 3 though. I dont quite need that yet.

PWM control also offers the option of full closed loop pressure control with no regulator and a dead end system, which means all the capacity of the pumps will get used, and none wasted returning fuel to the tank.

What sort of frequency is the Holley outputing the PWM at ? Most seem higher is better, in the 10-20khz range.

Last edited by stevieturbo; 06-21-2015 at 06:37 AM.

#3

8 Second Club

iTrader: (4)

Pretty slick.

Does the Holley not have and adjustable frequency to run the SSR at? I had planned to do this with my 4303 as well, but I couldn't get a straight answer from the Magna fuel guys about a "safe" freq. to run their pumps at. I have a drop down Hz menu ranging from 11.1 hz to 250hz. Also an option called variable Freq. Then a Load VS RPM table with 0-100% input options.

I was afraid I'd hurt the pump in someway if I didn't operate it at the proper Hz.

Does the Holley not have and adjustable frequency to run the SSR at? I had planned to do this with my 4303 as well, but I couldn't get a straight answer from the Magna fuel guys about a "safe" freq. to run their pumps at. I have a drop down Hz menu ranging from 11.1 hz to 250hz. Also an option called variable Freq. Then a Load VS RPM table with 0-100% input options.

I was afraid I'd hurt the pump in someway if I didn't operate it at the proper Hz.

#4

TECH Senior Member

iTrader: (7)

I have some experience, but as it relates to the cooling fan. On my Cougar build, I have the Dominator ECU and I am using a C6 Corvette fan controller and fan. The C6 fan controller wants to see 128hz. I have a PWM- off the Dominator varying the speed of the cooling fan. It works awesome. I see no reason why this same set-up can't be used to control a fuel pump. The C6 fan is rates at 400 watts, which works out to about 32 amps at 12 volts. I am pretty sure that most fuel pumps won't draw that much.

The PWM table on the Dominator can be configured with different X and Y axes. For fan control I have CTS vs. MPH. For fuel pump control you can have MAP vs ???

Here is a video of the fan control.

Andrew

The PWM table on the Dominator can be configured with different X and Y axes. For fan control I have CTS vs. MPH. For fuel pump control you can have MAP vs ???

Here is a video of the fan control.

Andrew

The following users liked this post:

grocerygetter83 (01-08-2021)

#5

TECH Senior Member

iTrader: (7)

Pretty slick.

Does the Holley not have and adjustable frequency to run the SSR at? I had planned to do this with my 4303 as well, but I couldn't get a straight answer from the Magna fuel guys about a "safe" freq. to run their pumps at. I have a drop down Hz menu ranging from 11.1 hz to 250hz. Also an option called variable Freq. Then a Load VS RPM table with 0-100% input options.

I was afraid I'd hurt the pump in someway if I didn't operate it at the proper Hz.

Does the Holley not have and adjustable frequency to run the SSR at? I had planned to do this with my 4303 as well, but I couldn't get a straight answer from the Magna fuel guys about a "safe" freq. to run their pumps at. I have a drop down Hz menu ranging from 11.1 hz to 250hz. Also an option called variable Freq. Then a Load VS RPM table with 0-100% input options.

I was afraid I'd hurt the pump in someway if I didn't operate it at the proper Hz.

Rotary1307, what frequency did you input into the software, your screen shot just missed that...

Andrew

#6

9 Second Club

Pretty slick.

Does the Holley not have and adjustable frequency to run the SSR at? I had planned to do this with my 4303 as well, but I couldn't get a straight answer from the Magna fuel guys about a "safe" freq. to run their pumps at. I have a drop down Hz menu ranging from 11.1 hz to 250hz. Also an option called variable Freq. Then a Load VS RPM table with 0-100% input options.

I was afraid I'd hurt the pump in someway if I didn't operate it at the proper Hz.

Does the Holley not have and adjustable frequency to run the SSR at? I had planned to do this with my 4303 as well, but I couldn't get a straight answer from the Magna fuel guys about a "safe" freq. to run their pumps at. I have a drop down Hz menu ranging from 11.1 hz to 250hz. Also an option called variable Freq. Then a Load VS RPM table with 0-100% input options.

I was afraid I'd hurt the pump in someway if I didn't operate it at the proper Hz.

#7

OK I drove 200miles on a cruise yesterday, lots of on off power. It all worked very well, I can't hear the pump driving around and idling now, very happy with that

You definitely need a good heat sink for the relay, it would overheat without a doubt if it was insufficient

This relay is rated for 80amps continuous if it has the proper thermal protection

I played around with the frequency from 60hz up to 250hz, I didn't try way high like the stevie said. I was just winging it

From the naked eye and ear I couldn't tell a difference in function in that range, all seemed the same in pump characteristics .

I have another setup I plan to use fory cooling fans.

If anyone has a better understanding of where the frequency should be set I am all ears. I do believe the holley will go quite high

Seemed flawless over the weekend though

You definitely need a good heat sink for the relay, it would overheat without a doubt if it was insufficient

This relay is rated for 80amps continuous if it has the proper thermal protection

I played around with the frequency from 60hz up to 250hz, I didn't try way high like the stevie said. I was just winging it

From the naked eye and ear I couldn't tell a difference in function in that range, all seemed the same in pump characteristics .

I have another setup I plan to use fory cooling fans.

If anyone has a better understanding of where the frequency should be set I am all ears. I do believe the holley will go quite high

Seemed flawless over the weekend though

Trending Topics

#9

9 Second Club

I know some ecu's require a flyback diode if they dont already have this internally, but that's more for inductive loads, which an SSR isnt really ?

Good thread here, although not specifically about SSR's...Max can go a bit OTT but he's an incredibly smart guy.

http://www.pistonheads.com/gassing/topic.asp?t=916550

Good thread here, although not specifically about SSR's...Max can go a bit OTT but he's an incredibly smart guy.

http://www.pistonheads.com/gassing/topic.asp?t=916550

#13

I know some ecu's require a flyback diode if they dont already have this internally, but that's more for inductive loads, which an SSR isnt really ?

Good thread here, although not specifically about SSR's...Max can go a bit OTT but he's an incredibly smart guy.

http://www.pistonheads.com/gassing/topic.asp?t=916550

Good thread here, although not specifically about SSR's...Max can go a bit OTT but he's an incredibly smart guy.

http://www.pistonheads.com/gassing/topic.asp?t=916550

Is this basically what Max has done? If so I wonder if there is not an OEM part available?

#14

9 Second Club

Max built his own closed loop controller for 3 pumps. ie one lift pump and 2 high pressure pumps to be configured as a dead end system with no regulator.

Later in the thread some people do seem to be suggesting a speed controller from a Range Rover is a simple PWM item, but seems it can only handle around 10A, so not really up to the job for some of the high flow pumps.

The SSR clearly isnt the perfect solution for everything to be technically correct, but it is by far the easiest solution, and whether perfect or not it does work.

I'm not that electronic savvy, so cant say what the actual downsides are and whether it just poses risk to the SSR itself, or the motors being switched by it.

Later in the thread some people do seem to be suggesting a speed controller from a Range Rover is a simple PWM item, but seems it can only handle around 10A, so not really up to the job for some of the high flow pumps.

The SSR clearly isnt the perfect solution for everything to be technically correct, but it is by far the easiest solution, and whether perfect or not it does work.

I'm not that electronic savvy, so cant say what the actual downsides are and whether it just poses risk to the SSR itself, or the motors being switched by it.

#17

TECH Senior Member

iTrader: (7)

How much was your SSR?

Andrew

#20

Max built his own closed loop controller for 3 pumps. ie one lift pump and 2 high pressure pumps to be configured as a dead end system with no regulator.

Later in the thread some people do seem to be suggesting a speed controller from a Range Rover is a simple PWM item, but seems it can only handle around 10A, so not really up to the job for some of the high flow pumps.

The SSR clearly isnt the perfect solution for everything to be technically correct, but it is by far the easiest solution, and whether perfect or not it does work.

I'm not that electronic savvy, so cant say what the actual downsides are and whether it just poses risk to the SSR itself, or the motors being switched by it.

Later in the thread some people do seem to be suggesting a speed controller from a Range Rover is a simple PWM item, but seems it can only handle around 10A, so not really up to the job for some of the high flow pumps.

The SSR clearly isnt the perfect solution for everything to be technically correct, but it is by far the easiest solution, and whether perfect or not it does work.

I'm not that electronic savvy, so cant say what the actual downsides are and whether it just poses risk to the SSR itself, or the motors being switched by it.

It's a shame these none return systems haven't picked up in the after market world. Would make installs much simpler and allow some very clever fuelling strategies (thinking high octane / meth delivery along with normal fuel down a single line) with a super near installation.