GT500 M122 on a cathedral head build in a Grand Prix 2+2

#1

This project started because I was going to design & fab a cathedral blower intake. Was planning to take an independent study mastercam machining class for my engineering degree this fall. Due to bureaucracy that class got cut so I ended up with 2/3rds the parts so I am proceeding anyways.

So anyways!

I have a RWD l67 swapped 4th gen firebird. There is a TON of m90 blowers for sale for under $100 and thought it would be real cool to splice a Thunderbird supercoupe m90 on the front and 3800 m90 on the back to make an m180 of sorts. All the money is in LS stuff now so thought there would be a market for some blower splice kits and a nice manifold.

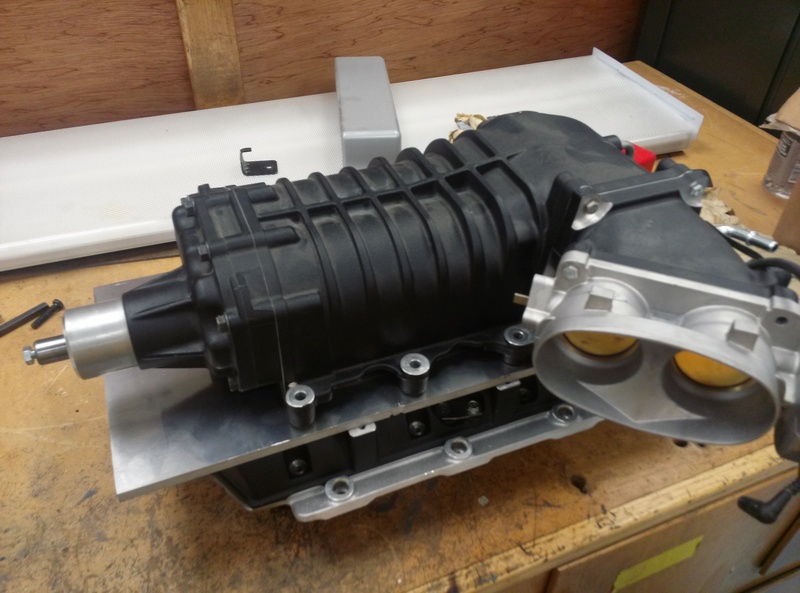

Scrapped that idea when I found a really low mile GT500 M122 a few hours away and picked that up instead. Also bought a 99-00 6.0, a 5.3 for some jigging, and other miscellaneous parts.

6.0 in my rainier

Took the heads off to make sure it was nice and since I am changing heads.

Other stack of junk

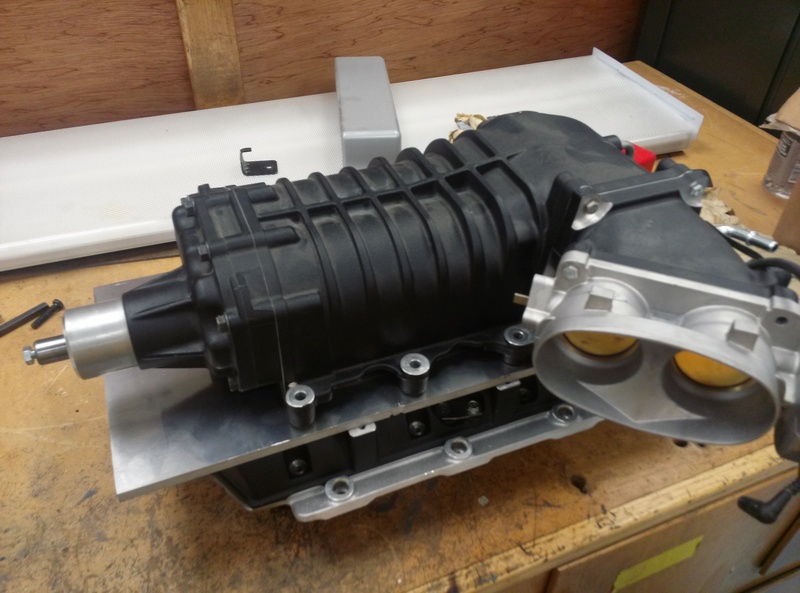

And then I found a magnacharger LIM pair so I bought that.

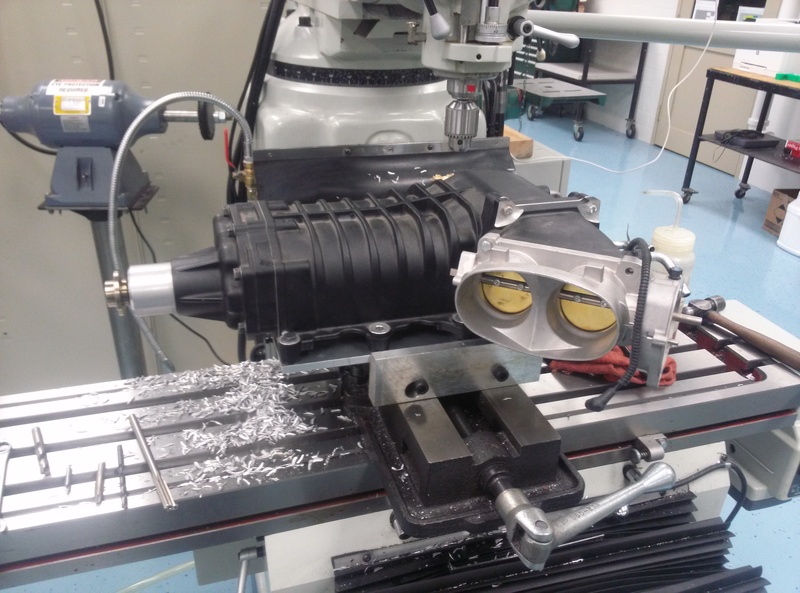

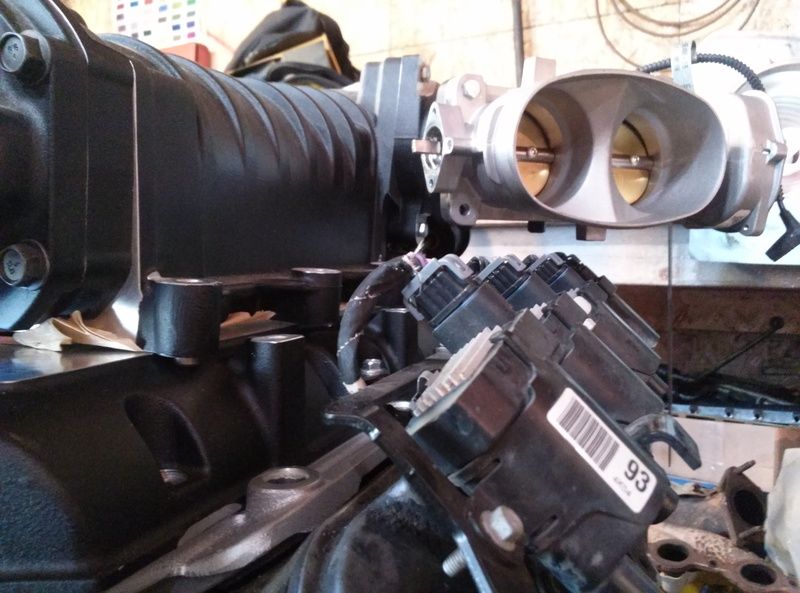

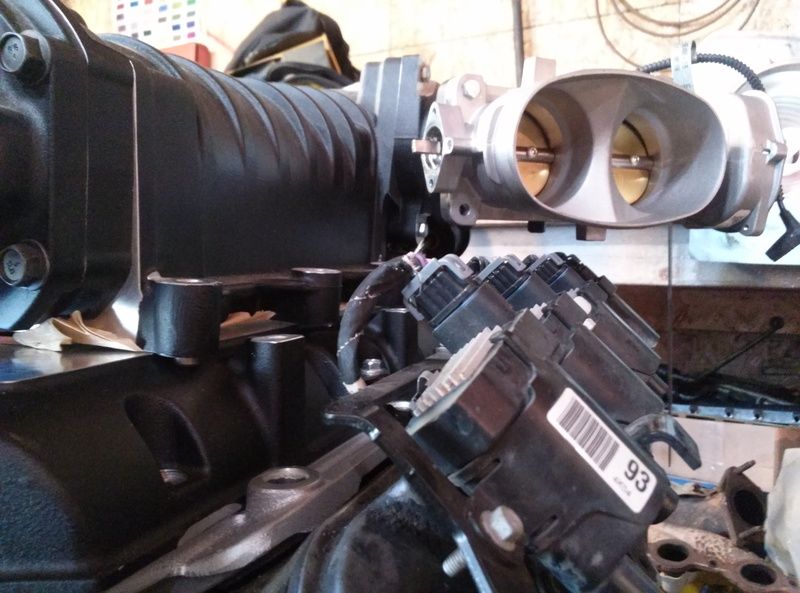

Running the stock GT500 tb actuated by GM stepper and TPS.

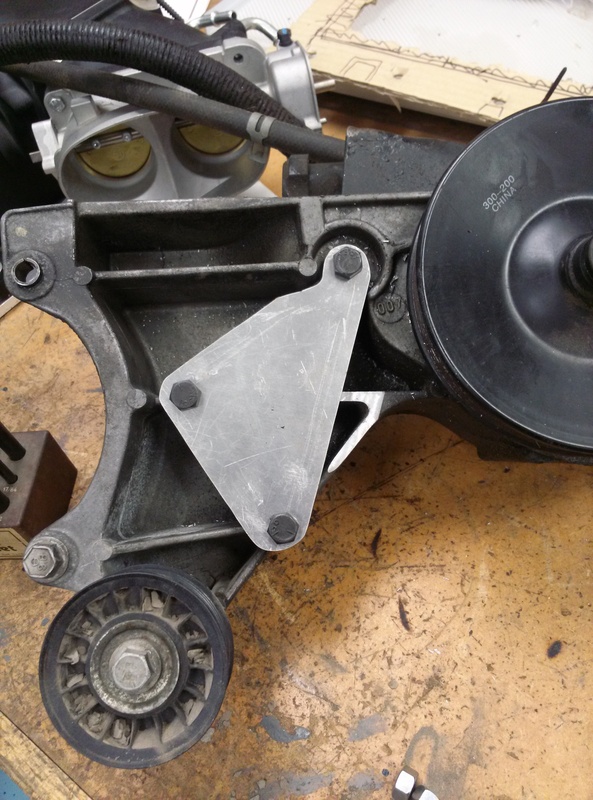

Got some space to make up

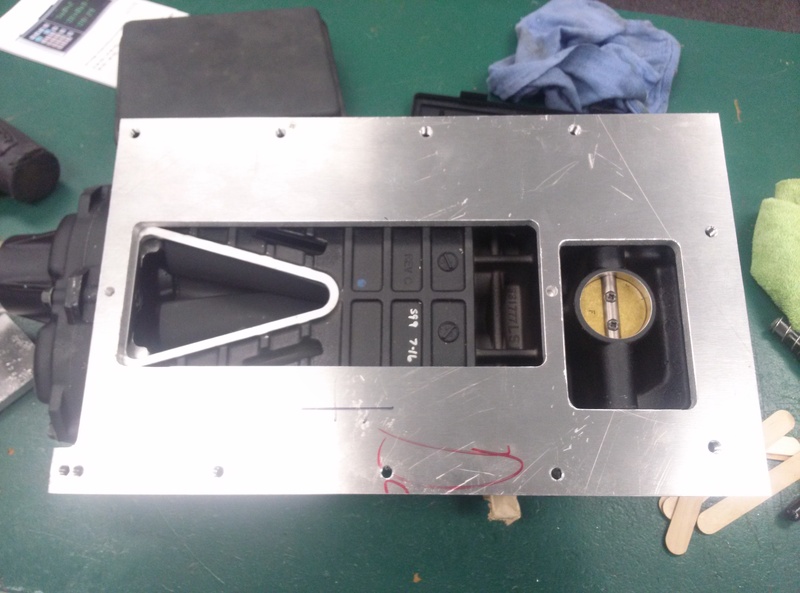

Current plan is to build an adapter plate between the maggie intake and blower, adapt the factory GM DBW controls to the ford TB, and solve the drive system problems. I don't have a car for this yet. I'm thinking c4 vette right now though backed with a T56.

More to follow in the coming months.

So anyways!

I have a RWD l67 swapped 4th gen firebird. There is a TON of m90 blowers for sale for under $100 and thought it would be real cool to splice a Thunderbird supercoupe m90 on the front and 3800 m90 on the back to make an m180 of sorts. All the money is in LS stuff now so thought there would be a market for some blower splice kits and a nice manifold.

Scrapped that idea when I found a really low mile GT500 M122 a few hours away and picked that up instead. Also bought a 99-00 6.0, a 5.3 for some jigging, and other miscellaneous parts.

6.0 in my rainier

Took the heads off to make sure it was nice and since I am changing heads.

Other stack of junk

And then I found a magnacharger LIM pair so I bought that.

Running the stock GT500 tb actuated by GM stepper and TPS.

Got some space to make up

Current plan is to build an adapter plate between the maggie intake and blower, adapt the factory GM DBW controls to the ford TB, and solve the drive system problems. I don't have a car for this yet. I'm thinking c4 vette right now though backed with a T56.

More to follow in the coming months.

Last edited by Gutless; 11-28-2015 at 08:08 PM.

#3

Neat build, I am definitely curious to see what car you stuff it in. I was heavily interested in stuffing a maggie in my f-body, but just couldn't come to the compromise of hacking up the cowl. The sound of those when you get on the pedal though is unmatched IMO.

#6

The only problem with the ZF is I end up in nomans land with flywheels and clutches. A zf would be awesome but parts like mentioned are tough. Part of me is thinking LT1 t56 since I already have the long crank.

Big reason I am wanting a C4 is I want something that can stop and turn for under 5,000. Plus C4's are worth stupid money for what they are really. Any other RWD IRS 80's car is 1-2 grand (944 porche, FC) but I cant find a semi decent C4 for under 5 around here, and they are all autos.

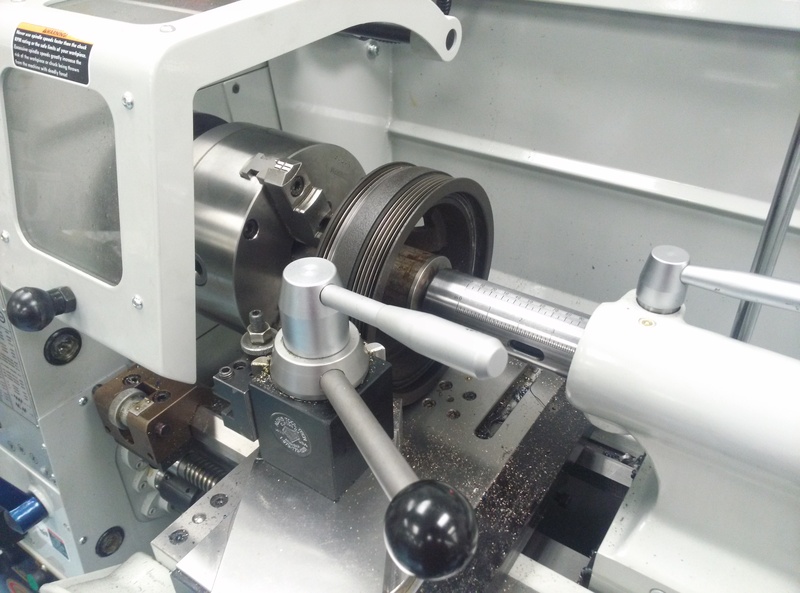

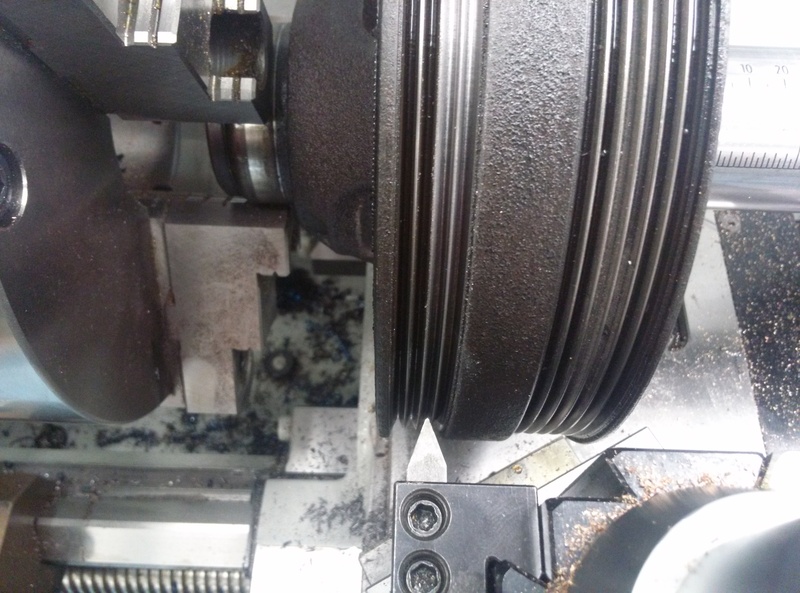

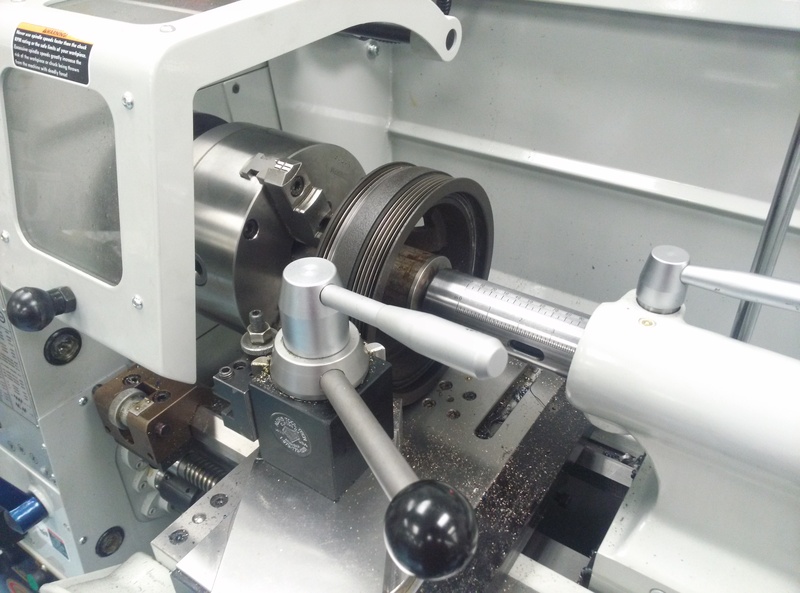

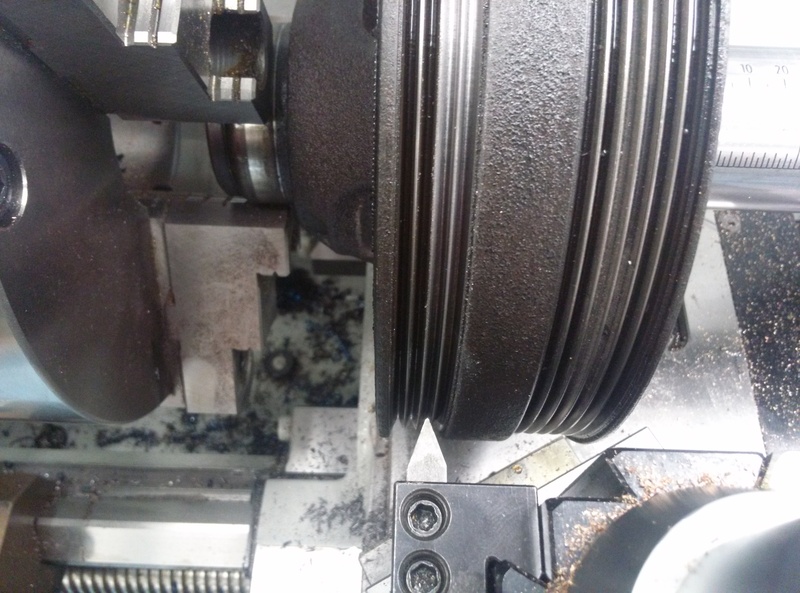

Today's progress-

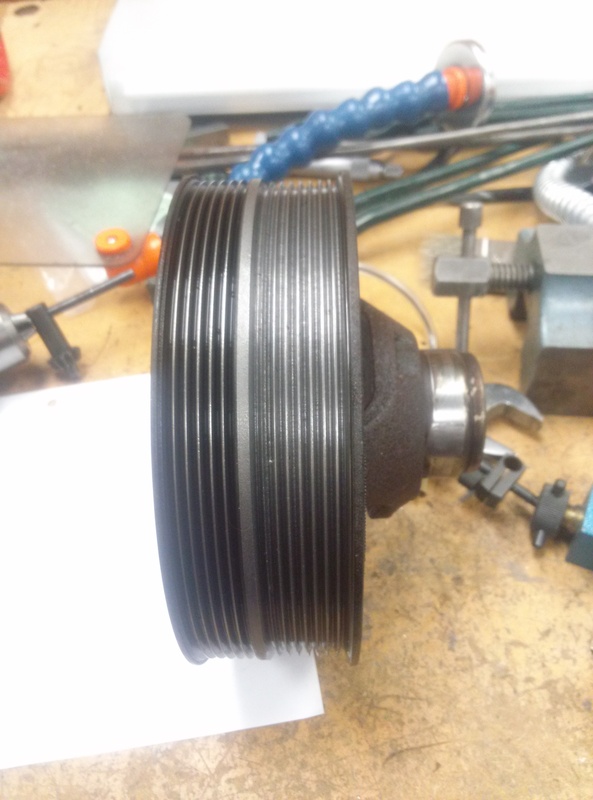

Spent 3 hours doing tooling for the 8 rib truck ballancer. Didn't have a live center that fit the hole in the truck pulley so I had to build a larger center cone. Ground a HSS 40 degree tool to add onto the AC belt. The idea is to move the AC pump to the front drive set and run an 8 rib belt off the AC side of the truck ballancer.

Got it in

Here goes nothing!

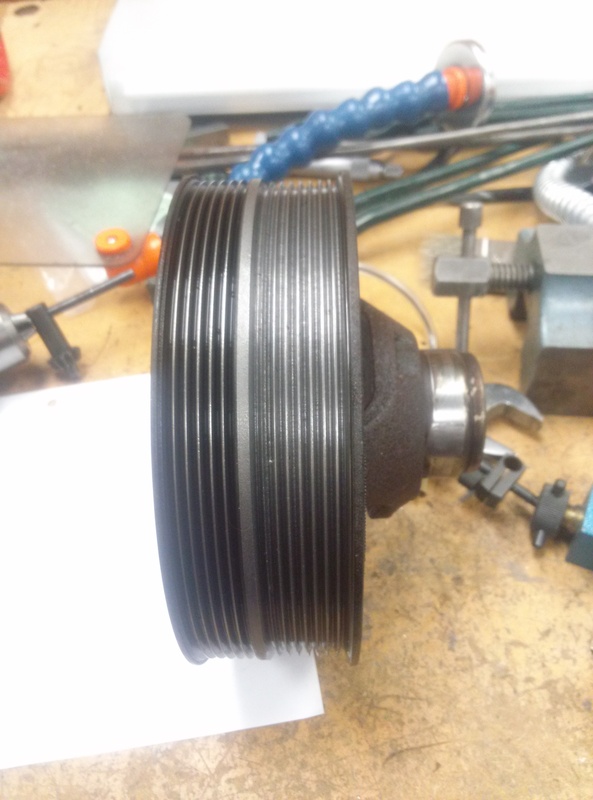

Not bad!

This weekend's task if I get ambitious is to start dimensioning out the adapter plate.

Big reason I am wanting a C4 is I want something that can stop and turn for under 5,000. Plus C4's are worth stupid money for what they are really. Any other RWD IRS 80's car is 1-2 grand (944 porche, FC) but I cant find a semi decent C4 for under 5 around here, and they are all autos.

Today's progress-

Spent 3 hours doing tooling for the 8 rib truck ballancer. Didn't have a live center that fit the hole in the truck pulley so I had to build a larger center cone. Ground a HSS 40 degree tool to add onto the AC belt. The idea is to move the AC pump to the front drive set and run an 8 rib belt off the AC side of the truck ballancer.

Got it in

Here goes nothing!

Not bad!

This weekend's task if I get ambitious is to start dimensioning out the adapter plate.

Trending Topics

#8

TECH Resident

iTrader: (2)

Join Date: Jun 2013

Location: Wichita, KS

Posts: 755

Likes: 0

Received 0 Likes

on

0 Posts

I know it would have cost you more, but you may have wanted to try that same modification with a corvette balancer, as it moves everything back closer to the engine by, I think, about 1.5".

#9

Sorry guys. I didnt consider the cost of repairs or part accessibility which is definitely considerable.

My bad.

The ones i have seen never really broke so....

Sorry for the mislead. It wasnt intended.

My experience with them on early modified Zr1s was positive for the most part. Hence why i posted.

My bad.

The ones i have seen never really broke so....

Sorry for the mislead. It wasnt intended.

My experience with them on early modified Zr1s was positive for the most part. Hence why i posted.

#10

Problem with the vette balancer is that it might almost be too close and not give me the room between the water pump and block to get the belt around the water pump pulley and snout.

Today's progress

Menards only had 6 M8X30 countersunk cap screws so I gotta get 4 more but I did countersink my valley cover bolts

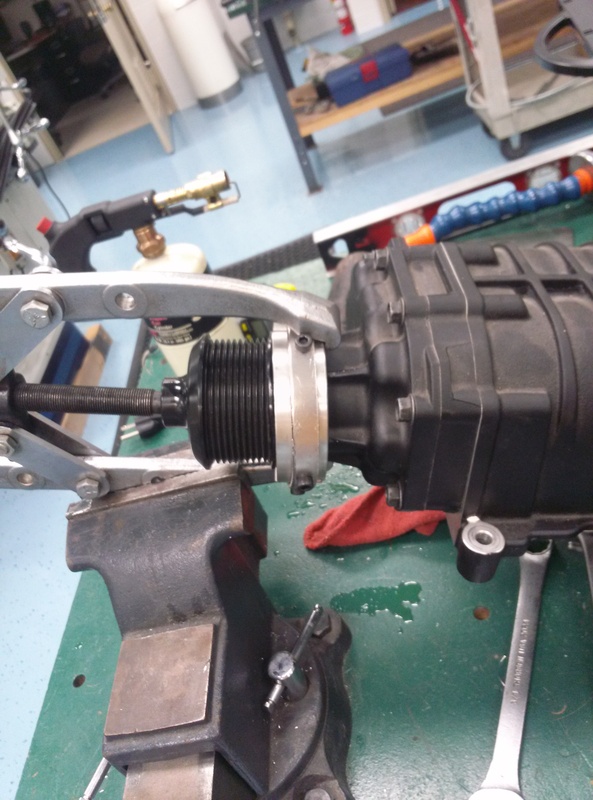

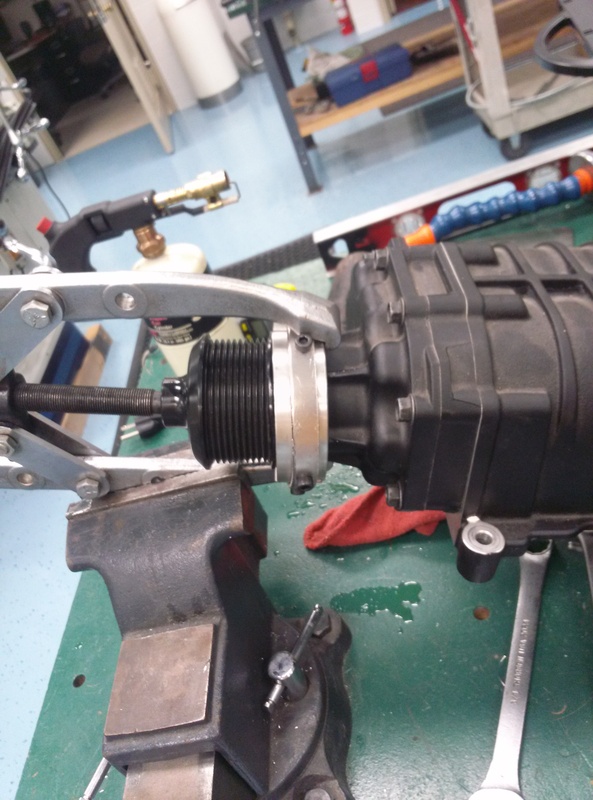

Getting the old pulley off was a bitch and a half. Tried the 3 jaw at home and it started bending the flange. Went to college and stuck the big 2 jaw in the vice and reefed on it. Bent the thing worse. Found a piece of scrap aluminum and cut 1/3rd out of it to use as a force spreader. Reefed on it again and bent it more. Heated the shaft up to 400 degrees and sprayed some oil on it, put a breaker bar on and bent the pulley more. Admitted I needed a 360 degree ring so I bent a piece of aluminum on my knee and stitched the ring together with some 1/4x20 cap screws. Put the whole ring on and and reefed on it again and it finally came off. Better than spending the $150 on the purchased ones. Yeah I screwed the pulley up but I gotta build my own anyways.

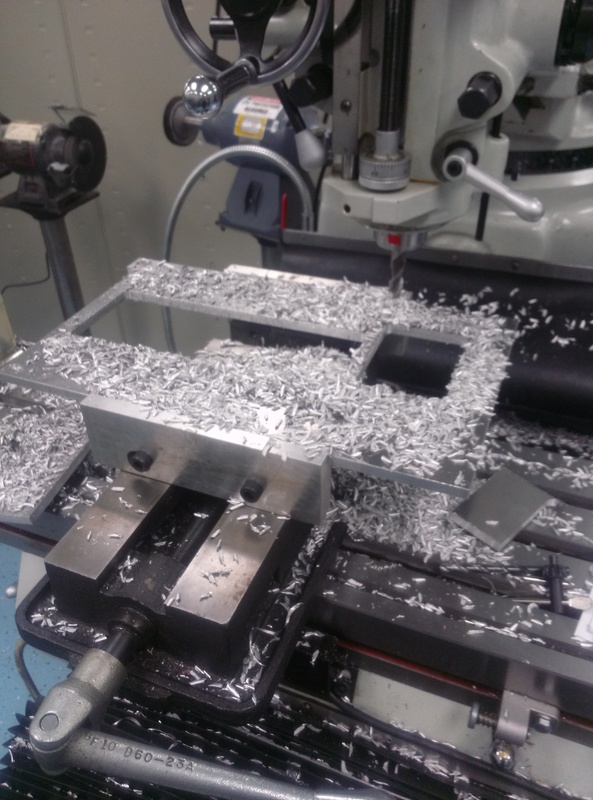

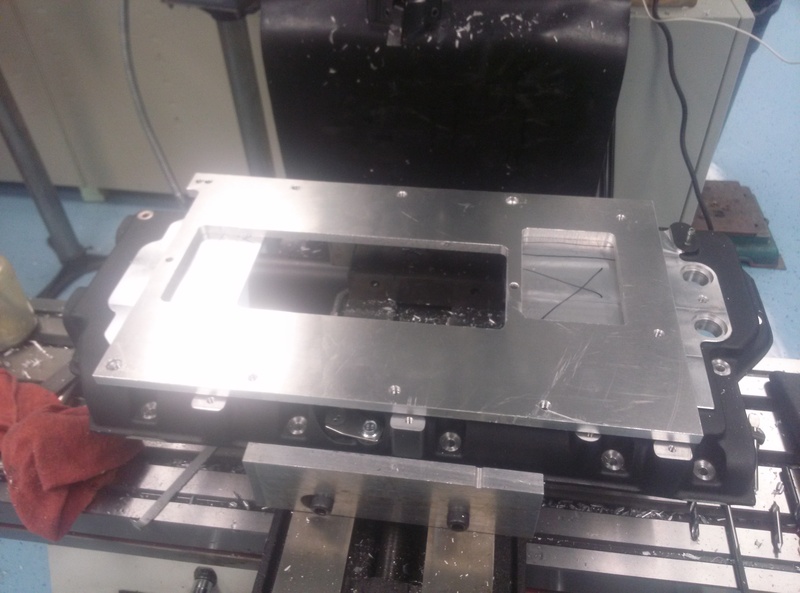

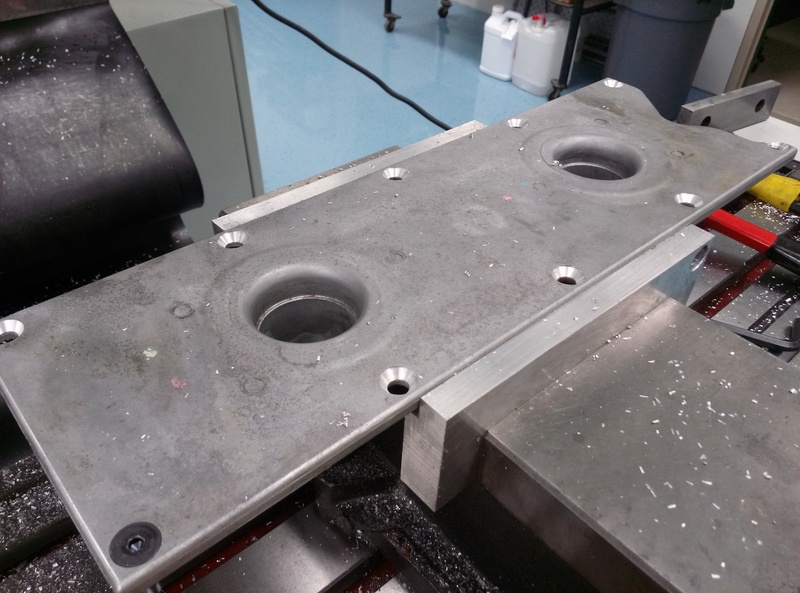

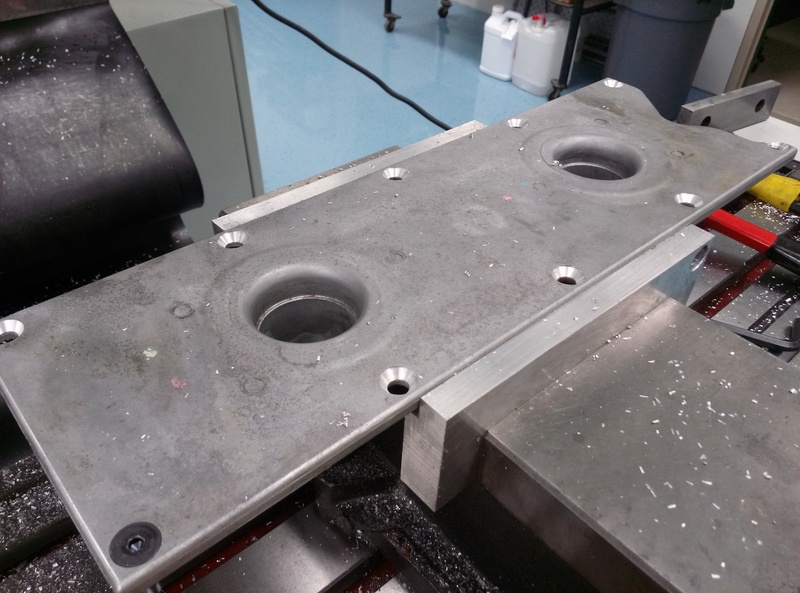

And I cut my 3/8 thick adapter plate. Id like 1/2" but 3/8" should do. Havn't decided if I am manually machining the plate or doing it in the Haas.

Pulley solution is going to be me buying another full modular setup for my m90 firebird. Ive got a 2.8" and want to step to a 2.6". That way I get a spare hub to push onto the big m122 and a 2.6" for the fbird. Top top- M90's and m122's both have a .780 diam pulley drive shaft. From there I'll just build my own upper pulley with the correct drive offset.

Today's progress

Menards only had 6 M8X30 countersunk cap screws so I gotta get 4 more but I did countersink my valley cover bolts

Getting the old pulley off was a bitch and a half. Tried the 3 jaw at home and it started bending the flange. Went to college and stuck the big 2 jaw in the vice and reefed on it. Bent the thing worse. Found a piece of scrap aluminum and cut 1/3rd out of it to use as a force spreader. Reefed on it again and bent it more. Heated the shaft up to 400 degrees and sprayed some oil on it, put a breaker bar on and bent the pulley more. Admitted I needed a 360 degree ring so I bent a piece of aluminum on my knee and stitched the ring together with some 1/4x20 cap screws. Put the whole ring on and and reefed on it again and it finally came off. Better than spending the $150 on the purchased ones. Yeah I screwed the pulley up but I gotta build my own anyways.

And I cut my 3/8 thick adapter plate. Id like 1/2" but 3/8" should do. Havn't decided if I am manually machining the plate or doing it in the Haas.

Pulley solution is going to be me buying another full modular setup for my m90 firebird. Ive got a 2.8" and want to step to a 2.6". That way I get a spare hub to push onto the big m122 and a 2.6" for the fbird. Top top- M90's and m122's both have a .780 diam pulley drive shaft. From there I'll just build my own upper pulley with the correct drive offset.

#13

#16

Mill is a South Bend 1028. Almost brand new. It's not mine but I totally wish it was. Pnuematic tool change, power Z axis, 3hp.

Motor was going to go into a C4 vette. An 86 2+2 came up for sale a few hours away. I like and have a history with G bodies so it was an easy decision. Kinda aero so it will be kinda okay with my road race goal with it. Car is rock solid and needs a little dent repair. Blew the engine in 97 and been sitting since. Mice got in the interior so it needs some work. G body #4 for me. Yikes!

Again, the 5.3 rainier kicks ***. Towed the car like it wasn't even there. 200K in MN and it still has rockers. Never could say that about a 99-06 GM pickup.

In other news, the engine is getting closer. The blower pulley kinda lines up. Still need to get the idler and tensioner done for the blower belt.

Motor was going to go into a C4 vette. An 86 2+2 came up for sale a few hours away. I like and have a history with G bodies so it was an easy decision. Kinda aero so it will be kinda okay with my road race goal with it. Car is rock solid and needs a little dent repair. Blew the engine in 97 and been sitting since. Mice got in the interior so it needs some work. G body #4 for me. Yikes!

Again, the 5.3 rainier kicks ***. Towed the car like it wasn't even there. 200K in MN and it still has rockers. Never could say that about a 99-06 GM pickup.

In other news, the engine is getting closer. The blower pulley kinda lines up. Still need to get the idler and tensioner done for the blower belt.