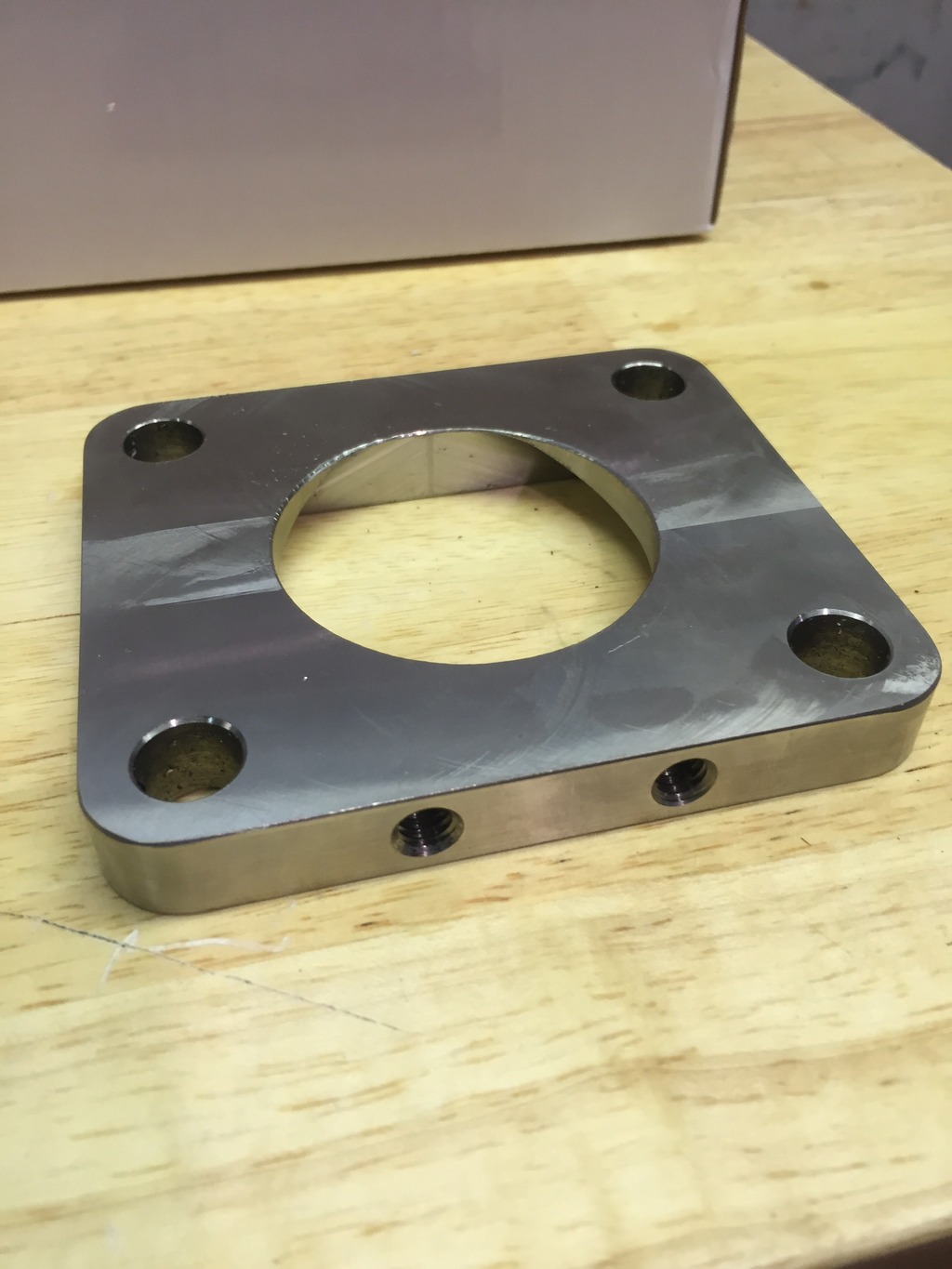

Check out these T4 flanges I had made

#1

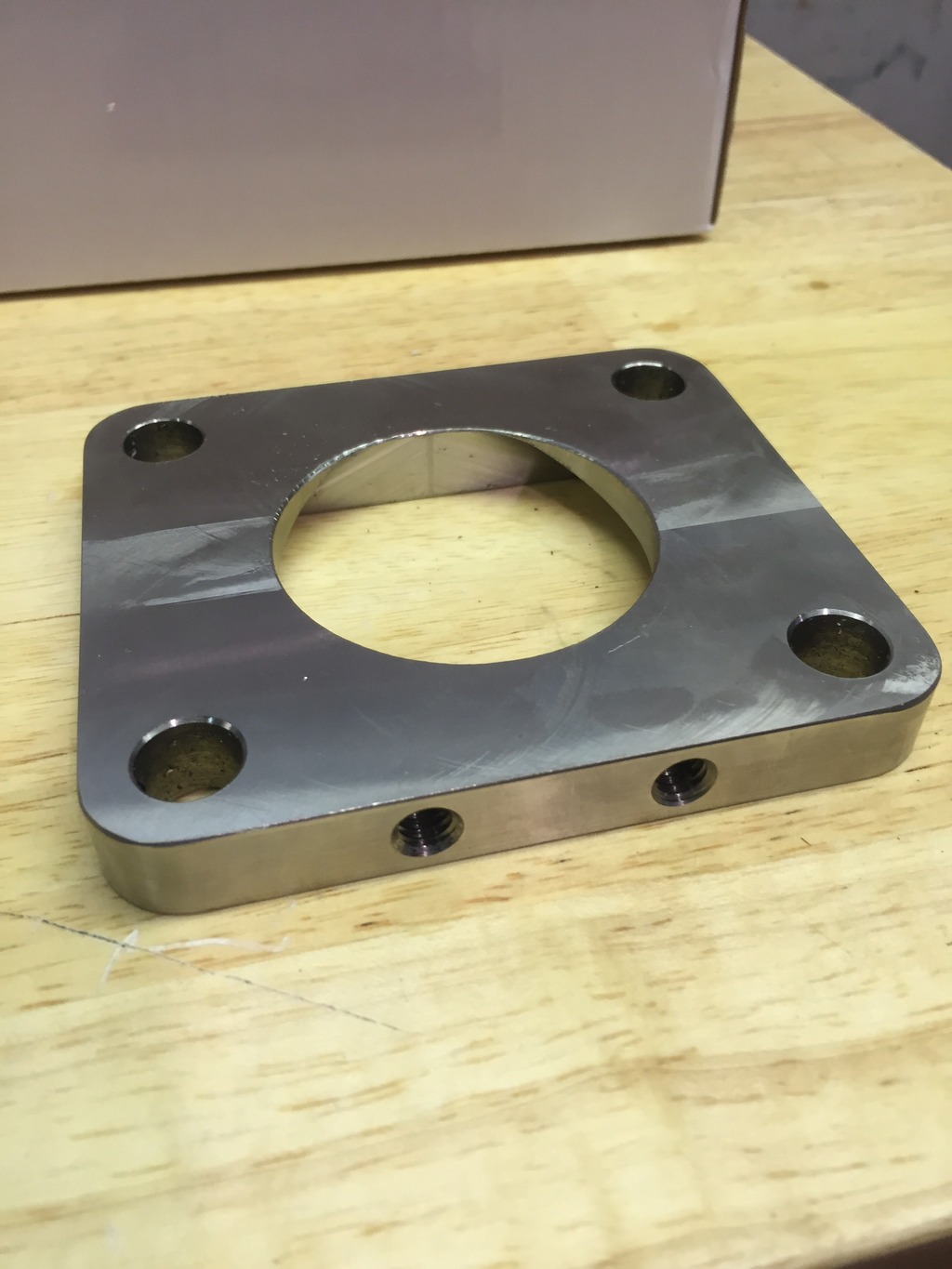

So we were having issues getting 2inch schedule 10 to merge with a t4 flange for my twin setup. Short of cutting the piping in half and widening the pipe, it wasn't going to look good. So I had a machinist friend come by and get some ideas of what we were trying to accomplish.

And this is what he came up with

The transition is too short to really do anything, but it looks sick and made our life way easier

Holes for bracing

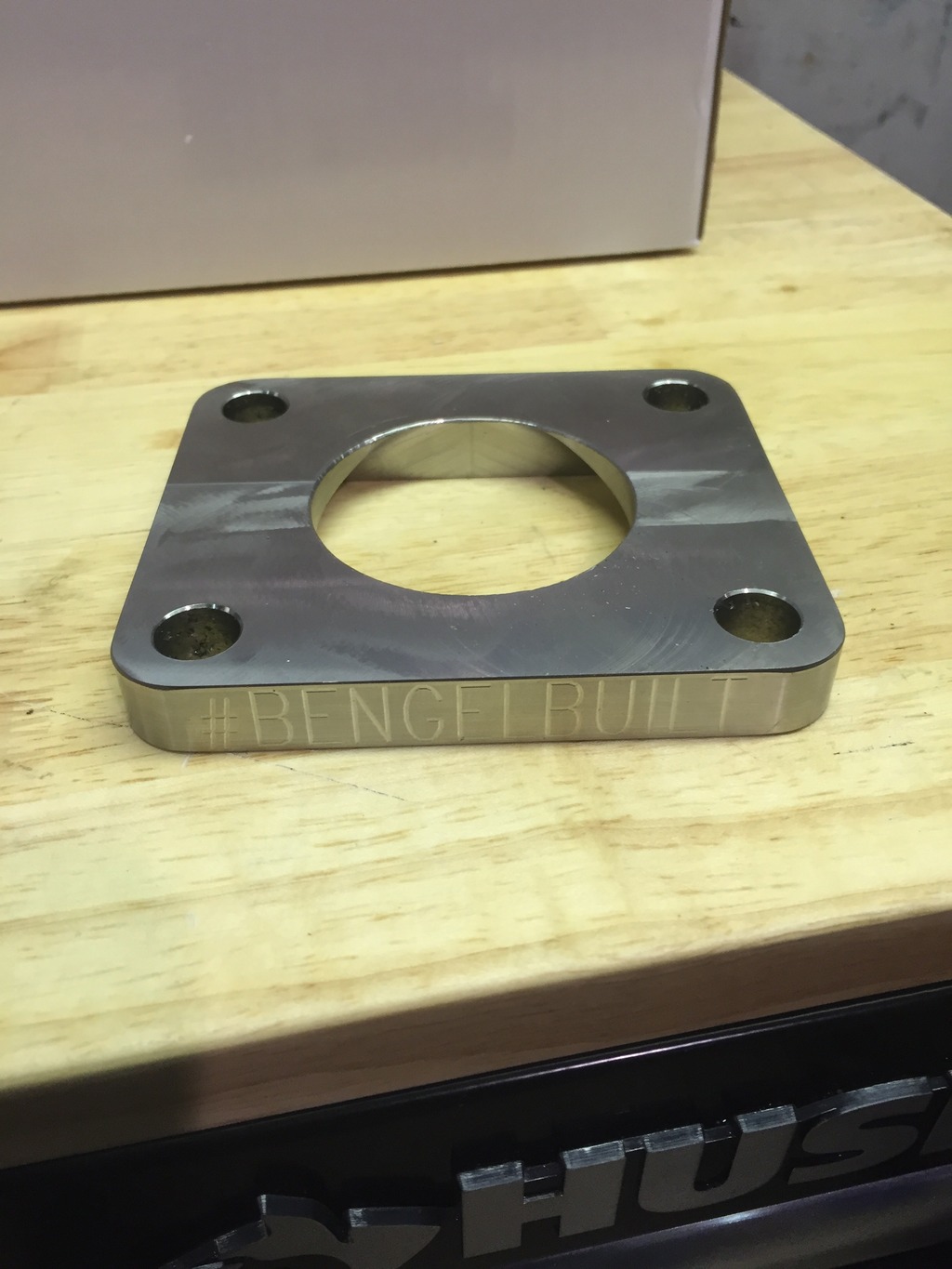

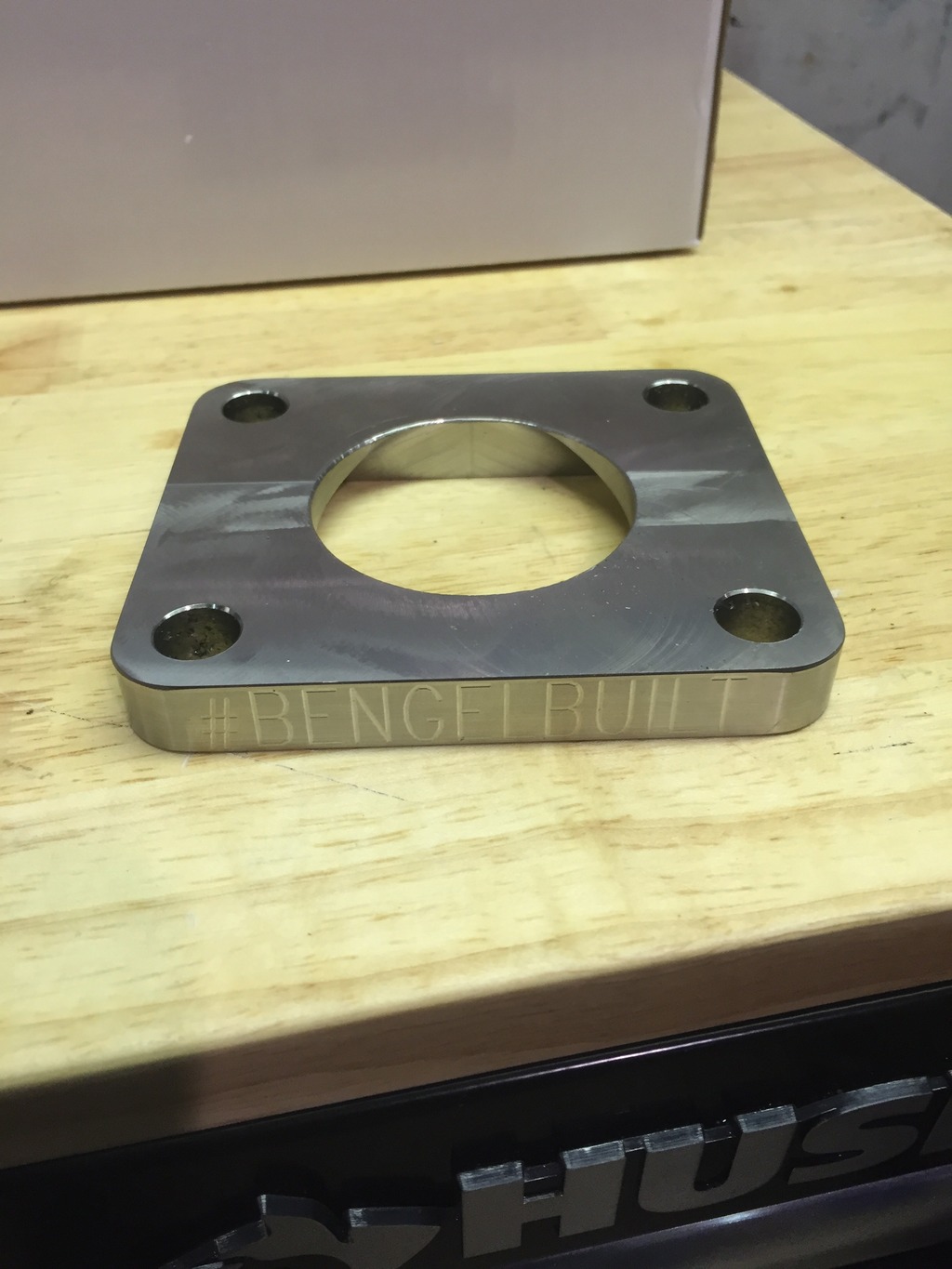

And this is what he came up with

The transition is too short to really do anything, but it looks sick and made our life way easier

Holes for bracing

Trending Topics

#12

9 Second Club

Support holes could be handy, but really, all that machining on the turbo side is a waste of time.

A simple round hole flange is perfectly fine and easier for most as they want to weld round pipe into them.

A simple round hole flange is perfectly fine and easier for most as they want to weld round pipe into them.

#18

TECH Fanatic