Rod bolts

#1

TECH Apprentice

Thread Starter

06, 6.0, rod bolt torque. Do you all do the 15 ft lbs, and then 73 degrees? All I have is 1 of those torq angle deals where you have to support the rod against something solid and hope nothing moves. I still have the stk rod bolts, would you recommend ARP's since I got it down? I hate to mess with them with out having the big end cked after installing the bolts. I pulled the pistons to regap rings. Opinions please.

#3

TECH Apprentice

Thread Starter

I've done the eye ball deal. I was talking about the gauge moving, or the rod that holds it. It's kinda a screwed up deal trying to use it. I guess on the bolts you do one at a time and shouldn't affect the big end of the rod. Do you just go to a dealer, or you got a link?

#4

On The Tree

Join Date: Aug 2011

Location: Somewhere, VA

Posts: 105

Likes: 0

Received 0 Likes

on

0 Posts

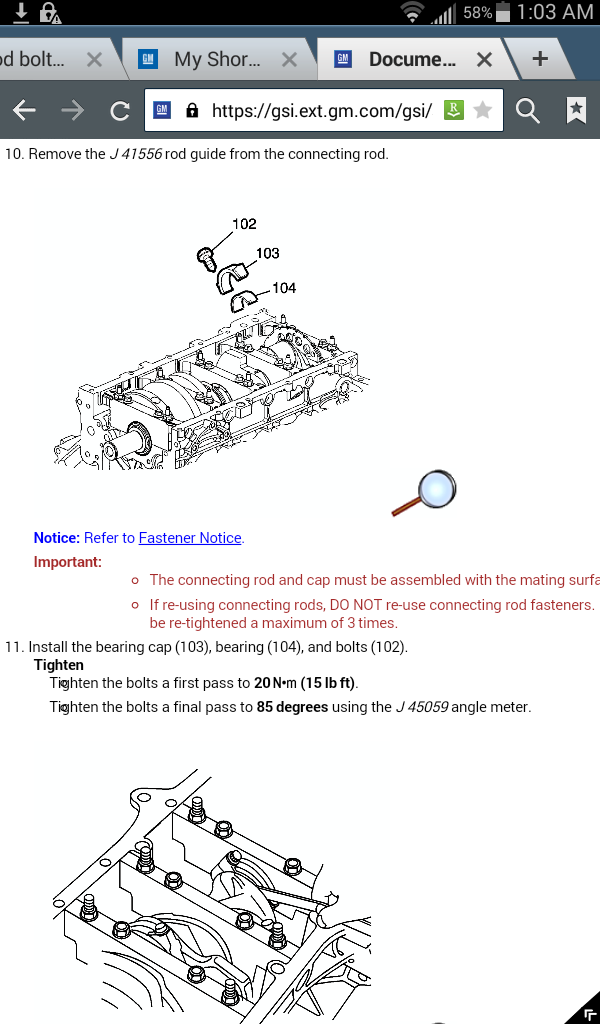

I had a link, but with the newer style rods with the floating wrist pins, it should be 15ft lbs of torque initially and then 85 degrees. Ive heard of people reusing the stock rod bolts a few times with out problems.

#5

TECH Apprentice

Thread Starter

Mine has the floating pins, good to know. I found a couple of deals on ebay. Factory bolts sold separately, I sent them a message and asked about a price on 16. I'll call a dealer tomorrow and see what my cost is.

Trending Topics

#11

TECH Apprentice

Thread Starter

If its 85, then thats great. I'll go 90 and be done. I'd rather put new in it the way my luck goes. I'll ck tooley out, that's where I'm going to order my spring kit. Thanks for the info.

#14

TECH Apprentice

iTrader: (2)

A low torque + angle is a far more reliable method of obtaining the correct stretch on almost any fastener than a single higher torque rating. The angle of the treads and rotation can be fairly accurately predicted compared to the mating surface finish, thread lubrication, etc, that can have as much as a 50% influence on actual stretch for a single high torque value.

A straight torque number on a bolt will result in a much wider variation in final stretched length than any possible movement in the angle meter. The best method is to actually measure the bolt stretch, but that isn't really practical with most bolted joints.

A straight torque number on a bolt will result in a much wider variation in final stretched length than any possible movement in the angle meter. The best method is to actually measure the bolt stretch, but that isn't really practical with most bolted joints.