Bearing clearance for boosted build

#1

11 Second Club

Thread Starter

iTrader: (3)

Join Date: Apr 2014

Location: St Louis, MO.

Posts: 624

Likes: 0

Received 0 Likes

on

0 Posts

I posted this somewhere else with no luck, so I thought I would try to see if anyone here knows.

It's a gen 4 5.3 and I'm only planning on being around 650-750rwhp. I checked my clearances with oem gm bearings and they were around .0015-.0017. I'm shooting for around .0025 so I called King race bearings about their STDX .001 extra clearance bearings to make sure that would work good on my stock gm crank. He told me that their XP bearings ran about .0005 more clearance than oem bearings and my clearances should be around .002 if I just bought the standard bearings.

I was wondering if anyone can verify that the King XP standard bearings come up around .002 clearances on a stock untouched gm crank? I don't want to buy two sets of each if I don't have to and I don't want to take the chance that the standard isn't actually .0005 and end up with .0015 clearances. On the other hand, I'd hate to buy the STDX standard extra .001 clearance and end up with .003 oil clearances.

If I were to get the extra clearance and I ended up with .003 clearances, then what would the possible problems be that I could run into? And if low oil pressure is the only issue, would a melling 10296 pump it?

It's a gen 4 5.3 and I'm only planning on being around 650-750rwhp. I checked my clearances with oem gm bearings and they were around .0015-.0017. I'm shooting for around .0025 so I called King race bearings about their STDX .001 extra clearance bearings to make sure that would work good on my stock gm crank. He told me that their XP bearings ran about .0005 more clearance than oem bearings and my clearances should be around .002 if I just bought the standard bearings.

I was wondering if anyone can verify that the King XP standard bearings come up around .002 clearances on a stock untouched gm crank? I don't want to buy two sets of each if I don't have to and I don't want to take the chance that the standard isn't actually .0005 and end up with .0015 clearances. On the other hand, I'd hate to buy the STDX standard extra .001 clearance and end up with .003 oil clearances.

If I were to get the extra clearance and I ended up with .003 clearances, then what would the possible problems be that I could run into? And if low oil pressure is the only issue, would a melling 10296 pump it?

Last edited by Deeohgie69; 09-28-2016 at 05:42 PM.

#2

TECH Addict

iTrader: (9)

I also have a Gen 4 5.3 I'm beginning to build for boost also in the 700 rwhp range and from the info I've read you want to use stock style bearings with a stock crank shaft, guys who use high zoot bearings on stock cranks end up having problems.

Its also suggested to run the stock clearances designed for the stock crank which the most popular clearances seem to be .002 on the rods and mains and .004 for end play.

So perhaps some Clevite bearings and still use the H/V oil pump which my plan is to buy the GM HV unit and then port it because its cheaper and will clear a double roller chain without modification.

Its also suggested to run the stock clearances designed for the stock crank which the most popular clearances seem to be .002 on the rods and mains and .004 for end play.

So perhaps some Clevite bearings and still use the H/V oil pump which my plan is to buy the GM HV unit and then port it because its cheaper and will clear a double roller chain without modification.

#3

11 Second Club

Thread Starter

iTrader: (3)

Join Date: Apr 2014

Location: St Louis, MO.

Posts: 624

Likes: 0

Received 0 Likes

on

0 Posts

That may be a route to look into for me. I've been reading thread after thread looking for this info and anything about it for 3 days now and it just doesn't seem to be out there.

So I guess now my question would be, what bearings do you guys recommend for a stock gen 4 iron 5.3 with a stock crank unpolished or anything? It's a really low mileage motor, so I've torn it apart to regap the rings and put new bearings in and run it like it is. I hadn't read that about the stock crank is best with stock clearances. I guess all the stuff I've read is for forged motors.

So clevite H series standard bearings is what you'd run?

So I guess now my question would be, what bearings do you guys recommend for a stock gen 4 iron 5.3 with a stock crank unpolished or anything? It's a really low mileage motor, so I've torn it apart to regap the rings and put new bearings in and run it like it is. I hadn't read that about the stock crank is best with stock clearances. I guess all the stuff I've read is for forged motors.

So clevite H series standard bearings is what you'd run?

#5

11 Second Club

Thread Starter

iTrader: (3)

Join Date: Apr 2014

Location: St Louis, MO.

Posts: 624

Likes: 0

Received 0 Likes

on

0 Posts

So are the XP bearings not recommend for oem cranks?

The following users liked this post:

Homer_Simpson (04-10-2023)

#7

11 Second Club

Thread Starter

iTrader: (3)

Join Date: Apr 2014

Location: St Louis, MO.

Posts: 624

Likes: 0

Received 0 Likes

on

0 Posts

What bearing brand would be good for my type of build? Which is basically just a gen 4 iron 5.3, stock bottom end with flat top 5.3 pistons.

Last edited by Deeohgie69; 09-28-2016 at 05:43 PM.

Trending Topics

#8

Yeah I'm just trying to learn this side of it so I'm not really that familiar with it yet. I guess I read where everyone throws these junkyard motors in and they live. I figured I'd at least pull it apart and throw some bearings in and gap the rings. My last motor had the King xp series bearings but it was for a .010 undersized crank. I saw everyone ran bugger clearances and thought the King xp STDX extra clearance would work out good so I thought I'd see if anyone had ran them.

What bearing brand would be good for my type of build? Which is basically just a gen 4 iron 5.3, stock bottom end with flat top 5.3 pistons.

What bearing brand would be good for my type of build? Which is basically just a gen 4 iron 5.3, stock bottom end with flat top 5.3 pistons.

#11

11 Second Club

Thread Starter

iTrader: (3)

Join Date: Apr 2014

Location: St Louis, MO.

Posts: 624

Likes: 0

Received 0 Likes

on

0 Posts

That's good to hear. I just ordered the melling 10296 with my bearings, so hopefully mine will measure out around that too. What oil pressures are you seeing hot? I will probably give the blue spring a go in mine since I've read a lot of people are saying they went with it.

#12

8 Second Truck Club

iTrader: (32)

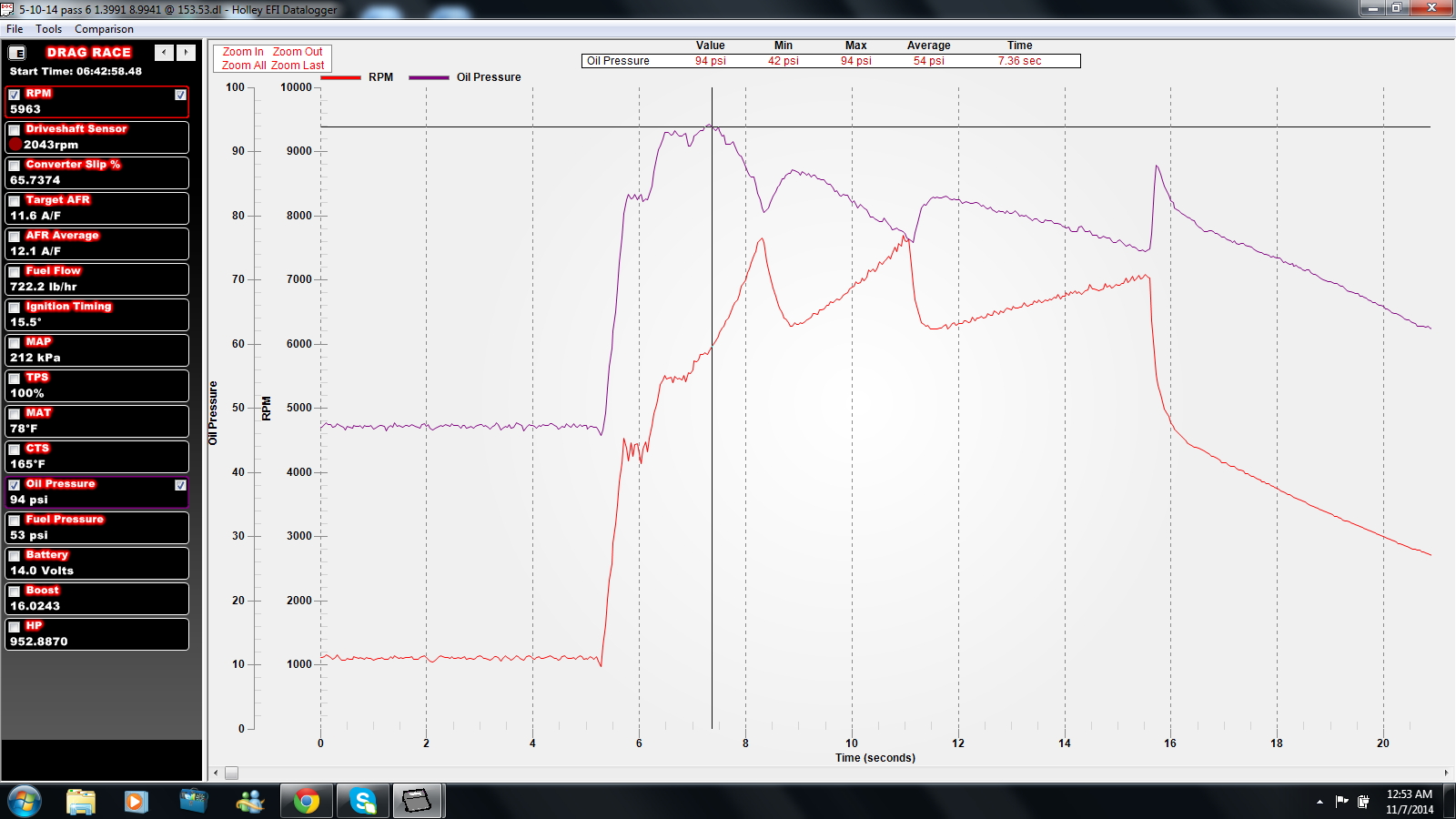

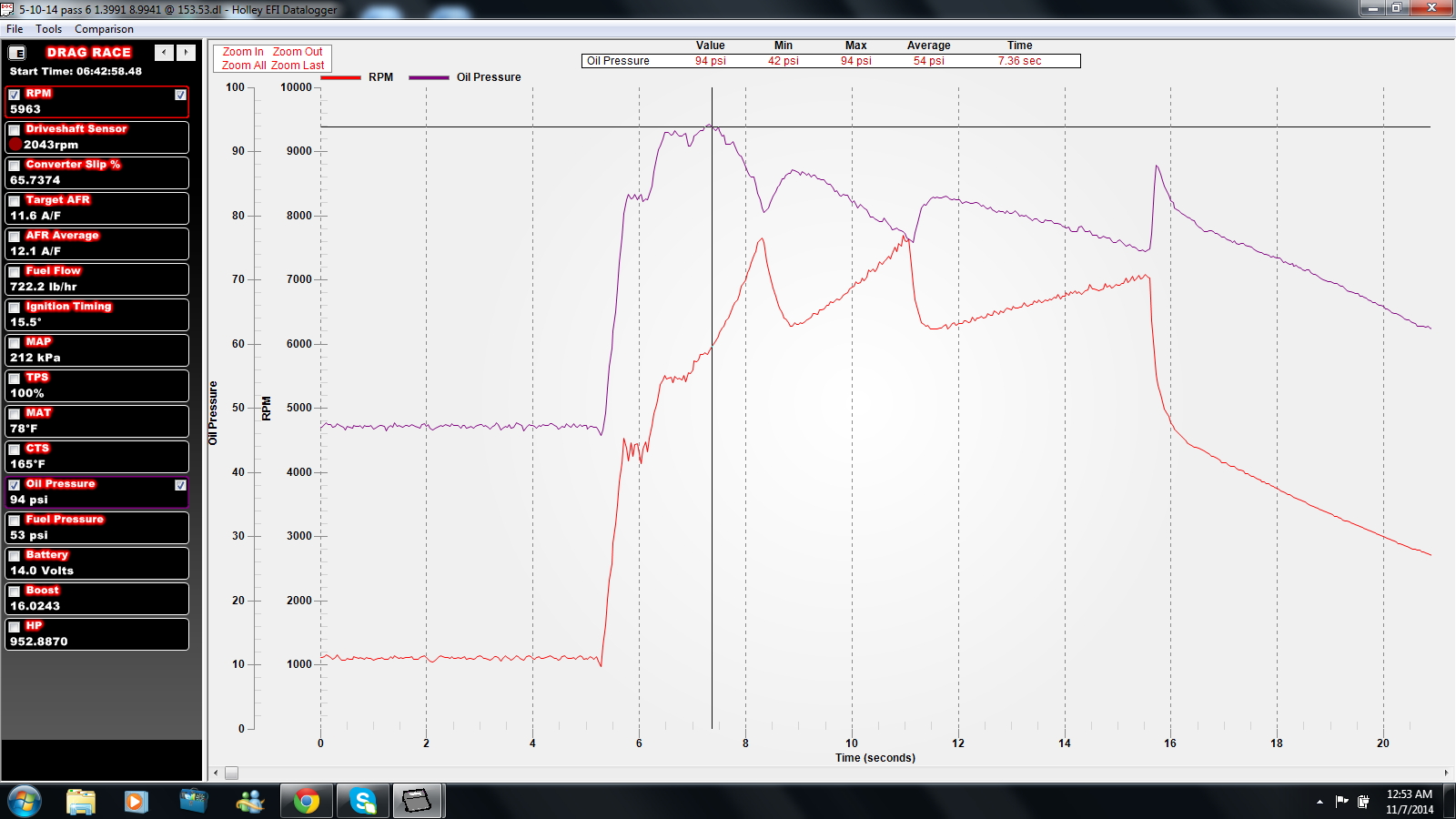

Hot idle is around 50 psi if I remember right. I've posted this screen shot many times for similar threads, so I guess I'll do it here as well:

This is probably the most perfect and classic example of the characteristics of the factory wet sump oiling system of an ls motor. It starts having issues around 6000 rpm give or take 500 rpm. So to recap, rod/main clearance is 0.0027", pump is a melling 10296 with the big pressure spring, oil is Royal Purple XPR 20w/50, engine was at operating water temp (probably close to 175*. You can see the idle around 48-50 psi, then the spike to 95 psi coming off the trans brake, pressure falls to around 75-80 psi at the shift, then picks back up and falls off again. This screen shot is a data log showing rpm and oil pressure only with Y axis' for both. Obviously the red line is rpm and the purple line is oil press.

This is probably the most perfect and classic example of the characteristics of the factory wet sump oiling system of an ls motor. It starts having issues around 6000 rpm give or take 500 rpm. So to recap, rod/main clearance is 0.0027", pump is a melling 10296 with the big pressure spring, oil is Royal Purple XPR 20w/50, engine was at operating water temp (probably close to 175*. You can see the idle around 48-50 psi, then the spike to 95 psi coming off the trans brake, pressure falls to around 75-80 psi at the shift, then picks back up and falls off again. This screen shot is a data log showing rpm and oil pressure only with Y axis' for both. Obviously the red line is rpm and the purple line is oil press.

The following users liked this post:

Homer_Simpson (04-10-2023)

#20

11 Second Club

Thread Starter

iTrader: (3)

Join Date: Apr 2014

Location: St Louis, MO.

Posts: 624

Likes: 0

Received 0 Likes

on

0 Posts

Yeah I didn't want to chance it so I went with the stdx extra .001 clearance. I figured that I would rather have .003 than be too tight.

Yeah let me know what psi you get with it. I'm hoping to be somewhere around .0028 or so with mine. Going to assemble the bottom end tonight and if I can get time off this weekend, then I'll have it up and running. I'll post what I got with the 10296 and the blue spring once it's running.