Tig welding formed collectors to primaries

#1

Hey guys, i'm looking for a little bit of assistance on how to tig a formed collector to primaries for a set of custom manifolds i'm building.

i've got the collector stars welded to the primaries and i wanted to weld up about 1/2 inch or so to help fill in the gap between the collectors and primaries. i've practiced on a good amount of spare tubing, but can't seem to get it to work.

I've got a couple of pics of the manifold/collectors and the areas i'm needing help with.

i can get some pics of the test pieces i've failed miserably on.

Any help or suggestions on the process, amperage, technique, etc would be greatly appreciated.

I'm using an AHP Alpha Tig 200

# 17 torch

#10 gas lens (have a Furick Fupa kit coming in this week for better coverage and stick out)

25cfh argon

1/16" ceriated tungsten between .25" and .5" stick out

tried several settings between 40-60 amps

.035 308L filler

i've got the collector stars welded to the primaries and i wanted to weld up about 1/2 inch or so to help fill in the gap between the collectors and primaries. i've practiced on a good amount of spare tubing, but can't seem to get it to work.

I've got a couple of pics of the manifold/collectors and the areas i'm needing help with.

i can get some pics of the test pieces i've failed miserably on.

Any help or suggestions on the process, amperage, technique, etc would be greatly appreciated.

I'm using an AHP Alpha Tig 200

# 17 torch

#10 gas lens (have a Furick Fupa kit coming in this week for better coverage and stick out)

25cfh argon

1/16" ceriated tungsten between .25" and .5" stick out

tried several settings between 40-60 amps

.035 308L filler

#2

I do what your wanting to do quite often. Build up the area on the outside of the star so you can seal weld the collector on. Practice, is use a smaller cup, like in the 6 or 7 range with a gas lens. You can stick the tungsten out quite a bit. Amperage seams right, but I'd change the filler to 309. The 308 is hard to work with and mainly used on 304 for its polishing reasons

#3

TECH Senior Member

iTrader: (25)

personally I'd pie slice that collector and get a better fit.

try turning your amps down to like 32-35

also try turning you gas down. i'll use 15cfh on thin stainless. purging or using a weld backer like solar flux is a must.

turn down and slow it down. you are moving too fast and going too hot.

the weld is still hot enough that when your gas shield moves past it, the chromium precipitates out. that's what the greyish mild steel looking welds come from.

try turning your amps down to like 32-35

also try turning you gas down. i'll use 15cfh on thin stainless. purging or using a weld backer like solar flux is a must.

turn down and slow it down. you are moving too fast and going too hot.

the weld is still hot enough that when your gas shield moves past it, the chromium precipitates out. that's what the greyish mild steel looking welds come from.

#6

Launching!

iTrader: (5)

Join Date: Dec 2014

Location: Jim Thorpe Pa

Posts: 211

Likes: 0

Received 0 Likes

on

0 Posts

Use a 6 or 7 cup as stated before. You don't need the gas turned up that high, shouldn't need to be over 15. Concentrate your arc on the header tubes and as you add the filler work the arc towards the collector. This will stop you from melting the collector away like in your pics. On the big gap you may be able to heat it up a bit and use a punch or a 3/8 extension and a hammer to bend it a little closer.

#7

Launching!

iTrader: (7)

Originally Posted by vinceI

Use a 6 or 7 cup as stated before. You don't need the gas turned up that high, shouldn't need to be over 15. Concentrate your arc on the header tubes and as you add the filler work the arc towards the collector. This will stop you from melting the collector away like in your pics. On the big gap you may be able to heat it up a bit and use a punch or a 3/8 extension and a hammer to bend it a little closer.

Trending Topics

#8

Launching!

iTrader: (1)

Join Date: Jun 2012

Location: Daytona Beach

Posts: 265

Likes: 0

Received 0 Likes

on

0 Posts

I have an Alphatig as well and I ONLY run the E3 purple band tungsten. I have tried every type of tungsten they make and the E3 has been the best, period. Like mentioned above, slow down and jack the post flow. It sucks using a lot of gas but on stainless its a must. I would also use the 309L filler as well. Good job.

#9

I'm different from most here- but I would crank up the cover gas. run the regulator wide open. 3/32 tungsten with a really long point on it. I use red or purple.

first I would take two scrap tubes and lay them side by side, place the collector on the end of them and hammer the corner down in the tubes to get a better fit.

then I'd weld from the star up the tube to tube gaps to about a 1/4" past where the collector covers. this will also buildup the valley to meet the collector better. like say the collector slips a 1/4" over the ends of the tubes, weld up a 1/2". This also guarantees no flow will exit through the tube to tube gaps. use a bigger rod here- like a 1/16. this upweld would protrude from the circumferential weld around the collector.

you're definitely burning too hot but by cranking the gas it will help a little. you may back down on the amps though- just play with it.

first I would take two scrap tubes and lay them side by side, place the collector on the end of them and hammer the corner down in the tubes to get a better fit.

then I'd weld from the star up the tube to tube gaps to about a 1/4" past where the collector covers. this will also buildup the valley to meet the collector better. like say the collector slips a 1/4" over the ends of the tubes, weld up a 1/2". This also guarantees no flow will exit through the tube to tube gaps. use a bigger rod here- like a 1/16. this upweld would protrude from the circumferential weld around the collector.

you're definitely burning too hot but by cranking the gas it will help a little. you may back down on the amps though- just play with it.

#11

8 Second Club

iTrader: (19)

Originally Posted by truckdoug

my experience is that by cranking the gas yes you will add a cooling effect to the weld but you'll also set up a convection current that will pull oxygen into the weld area, again leading to a grey overcooked weld.

sharp tungsten, short arc, move fast

sharp tungsten, short arc, move fast

#12

Have you ever seen the smoke tests done with a gas lens?

The key to getting better color out of stainless is more gas- not less. Also for welds to be x-ray'd it's always best to crank the gas.

Not here to argue, just have 100s of hours of TIG time and work in an industry of full pen, 100% RT inspection. Not a single person will recommend less cover gas.

#15

TECH Regular

iTrader: (1)

Join Date: Jun 2005

Location: The Woodlands, TX

Posts: 445

Likes: 0

Received 0 Likes

on

0 Posts

I guess I can't get behind this rationale.

Have you ever seen the smoke tests done with a gas lens?

The key to getting better color out of stainless is more gas- not less. Also for welds to be x-ray'd it's always best to crank the gas.

Not here to argue, just have 100s of hours of TIG time and work in an industry of full pen, 100% RT inspection. Not a single person will recommend less cover gas.

Have you ever seen the smoke tests done with a gas lens?

The key to getting better color out of stainless is more gas- not less. Also for welds to be x-ray'd it's always best to crank the gas.

Not here to argue, just have 100s of hours of TIG time and work in an industry of full pen, 100% RT inspection. Not a single person will recommend less cover gas.

I also have thousands of hours of TIG time in an industry of full pen 100% RT inspection. I have worked with guys that crank their regulators wide open all the time, and I have tried their way and mine enough to know that opening the regulator that far is just wasting gas. I can get just as good coverage welding pipe with my gas set at 15-18 as anybody welding with their regulator wide open. Based on my personal experience, I agree with truckdoug and oscs.

More gas coverage is rarely correct, the correct amount of gas flow/coverage is always correct.

#17

Yes, at work people mess with each other and jacked my flow up! If it's a calm environment I'll run in the 15-20cfh range and if I'm outside i may end up in the 25-30cfh range

I find it funny the OP has not responded yet

I find it funny the OP has not responded yet

#19

If you're arc is moving it sounds like its too long.

#20

Thanks guys for all the input. Sorry i haven't been back since posting this, wrapping up holiday travels and sick kiddos have kept me out of the garage. I just refilled my argon and got a bunch of scrap 304 from a local metal supply for more practicing.

I'll add a few comments from the feedback left.

i've been told to move faster and turn it up a little rather than slow down and lower the amps. i've tried lowering the amps down to 30-35, but i can't get it puddle before it overheats and turns gray. I'll mess with it a little more when i get out and practice again.

i'll lower the gas flow to 15-20cfh and try some more

forgot to mention i have post flow set at 7 seconds.

also forgot, i am back purging or using solar flux on the back of the welds. i was using more of the solar flux as my tank was getting low. now that it's filled, i'll be be doing more purging.

i'll try some 309L filler

picked up some E3 1/16 and 3/32 tungstens to see how this machine reacts compared to the ceriated and 2% thoriated i've used in the past

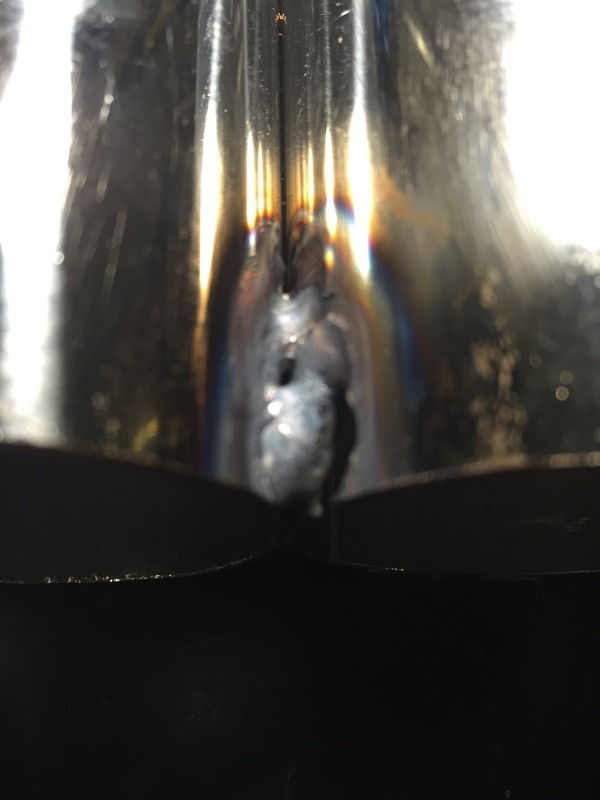

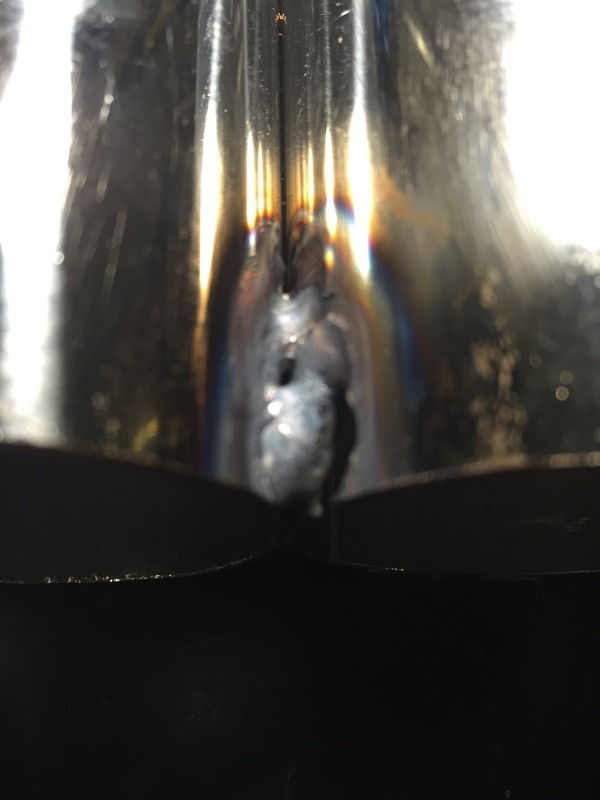

Here the pics i mentioned that didn't work out to well when i tested

on both of the examples above, i tried welding towards the collector star like so

i guess i should have been going the opposite way like this

Thanks again for all the help so far

I'll add a few comments from the feedback left.

i've been told to move faster and turn it up a little rather than slow down and lower the amps. i've tried lowering the amps down to 30-35, but i can't get it puddle before it overheats and turns gray. I'll mess with it a little more when i get out and practice again.

i'll lower the gas flow to 15-20cfh and try some more

forgot to mention i have post flow set at 7 seconds.

also forgot, i am back purging or using solar flux on the back of the welds. i was using more of the solar flux as my tank was getting low. now that it's filled, i'll be be doing more purging.

i'll try some 309L filler

picked up some E3 1/16 and 3/32 tungstens to see how this machine reacts compared to the ceriated and 2% thoriated i've used in the past

Here the pics i mentioned that didn't work out to well when i tested

on both of the examples above, i tried welding towards the collector star like so

i guess i should have been going the opposite way like this

Thanks again for all the help so far

Last edited by 91 240; 12-06-2016 at 11:19 AM.