Drain line for turbo? oil pan?

#1

Ok, so i have been trying to get all my questions answered on how i want to do my drain line for the turbo. The feed is easy, no big deal.

Ok, so the turbo is high enough to go into the timing cover, which i could do, but id prefer to not pull the crank pulley again, and then there is the oil pan. Which looks way harder then the crank pulley to pull.

So in my research i found a couple people that drill and tap the pan while on the car.

Most say if you greese up the drill bit good, it will collect all of the shavings, and then you can just check it in the pan. and then tap it to what ever size you need, and screw your fitting in and your done.

How many people actually do this? is the oil pan thick enough to tap without any issues? i have found a couple people that have done it and with pics, i guess i just wan to know what people here think.

Thanks, Chris

Ok, so the turbo is high enough to go into the timing cover, which i could do, but id prefer to not pull the crank pulley again, and then there is the oil pan. Which looks way harder then the crank pulley to pull.

So in my research i found a couple people that drill and tap the pan while on the car.

Most say if you greese up the drill bit good, it will collect all of the shavings, and then you can just check it in the pan. and then tap it to what ever size you need, and screw your fitting in and your done.

How many people actually do this? is the oil pan thick enough to tap without any issues? i have found a couple people that have done it and with pics, i guess i just wan to know what people here think.

Thanks, Chris

#2

TECH Senior Member

iTrader: (25)

I did it on my truck, actually twice. The first hole was just below the oil line and I though it was causing problems, so I drilled another hole up higher and it turned out I had another problem with PVC that was unrelated, but have had no issues with any shavings in the pan.

#3

I did it on my truck, actually twice. The first hole was just below the oil line and I though it was causing problems, so I drilled another hole up higher and it turned out I had another problem with PVC that was unrelated, but have had no issues with any shavings in the pan.

Did u tap the pan? or weld a fitting to it. It seems welding would be better, but i dont have a tig, and having it done would require taking the pan off. I just picked up a metric tap set, so may give this a try. I was thinking about going right into the front of the pan underneath the timing cover. Very short, and strait path, with gravity on its side. I guess my biggest concern is the pan being thick enough to get enough threads on it, and im not to worried abotu metal shavings, those should be able to be avoided. Thanks, Chris

#4

TECH Senior Member

iTrader: (25)

On my truck, I drilled and taped the pan on the pass side next to the starter. I used a 90* drill and a 3/4" unibit and drilled it to about 11/16 (didn't drill the last step) and taped it to a 1/2 pipe thread and just used a 5/8 heater hose bung to 1/2 pipe fitting with liquid Teflon on in it. Doesn't leak.

#7

I have drilled and tapped the pan on the car a couple times. I didnt like doing it but I was **** about Bending Q-tips with gobs of valeline and getting in the hole to pick up any shavings. Be sure to use the vaseline on the drill bit and tap and go super slow.

Then for extra measure drain the oil and buy some cheap *** 5 gallon jug of oil and leave the plug out. Pour it in and let it run straight out.

I never had a problem.

Then for extra measure drain the oil and buy some cheap *** 5 gallon jug of oil and leave the plug out. Pour it in and let it run straight out.

I never had a problem.

Trending Topics

#8

Closed Sponsor Account

iTrader: (3)

Join Date: Jun 2007

Location: Boca Raton

Posts: 235

Likes: 0

Received 0 Likes

on

0 Posts

i 99% of the time take the pan off the car then tap it. other then that i fill the engine up with tons of oil so that the level is above where iam drilling, so wheni drill through the oil pushes everything out, but ive only done it once and didnt like it

#9

Ok. Feed is done. Next weekend were gonna get the drain done, and then its all easy bolt on stuff and the car should run...

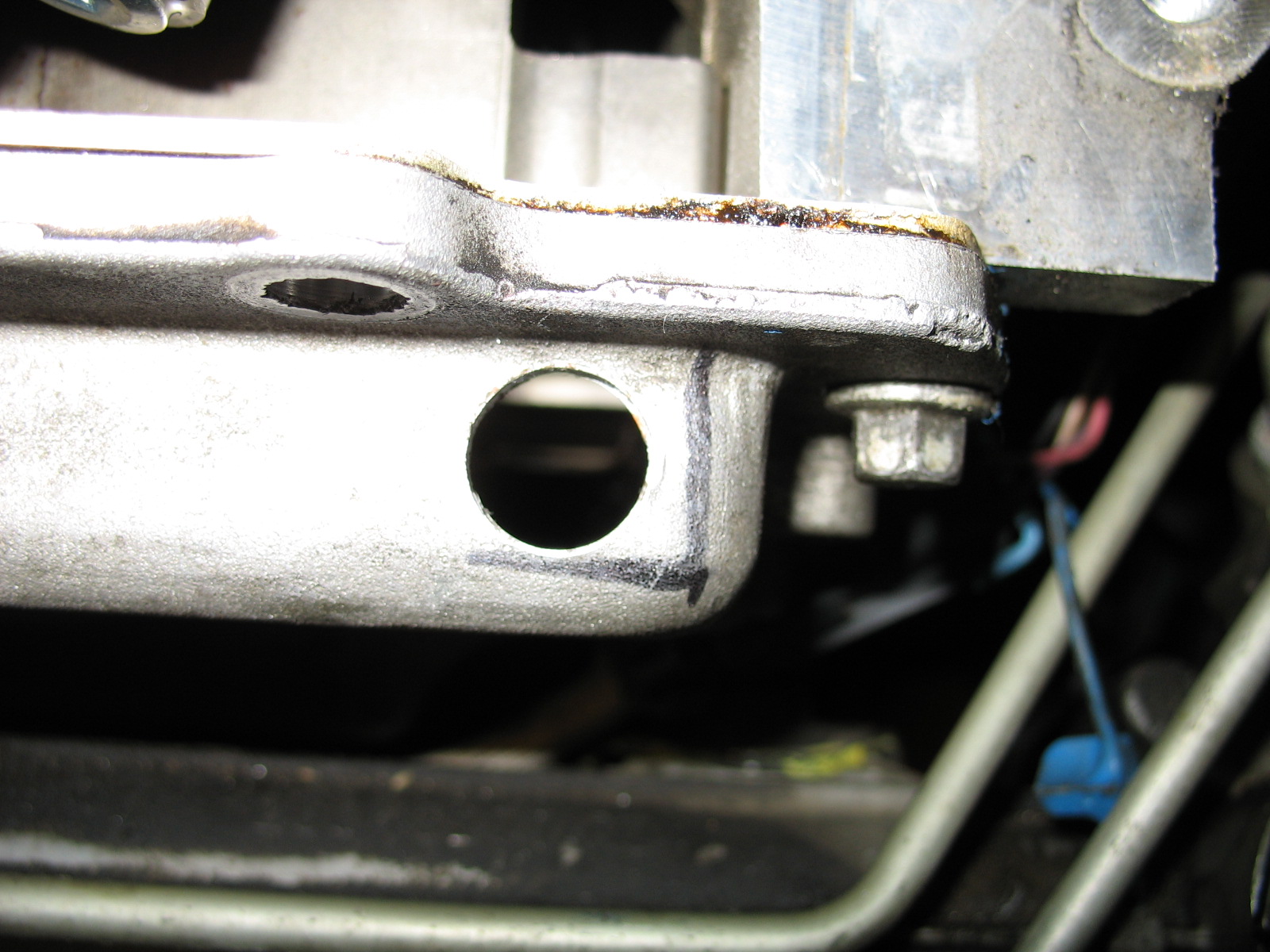

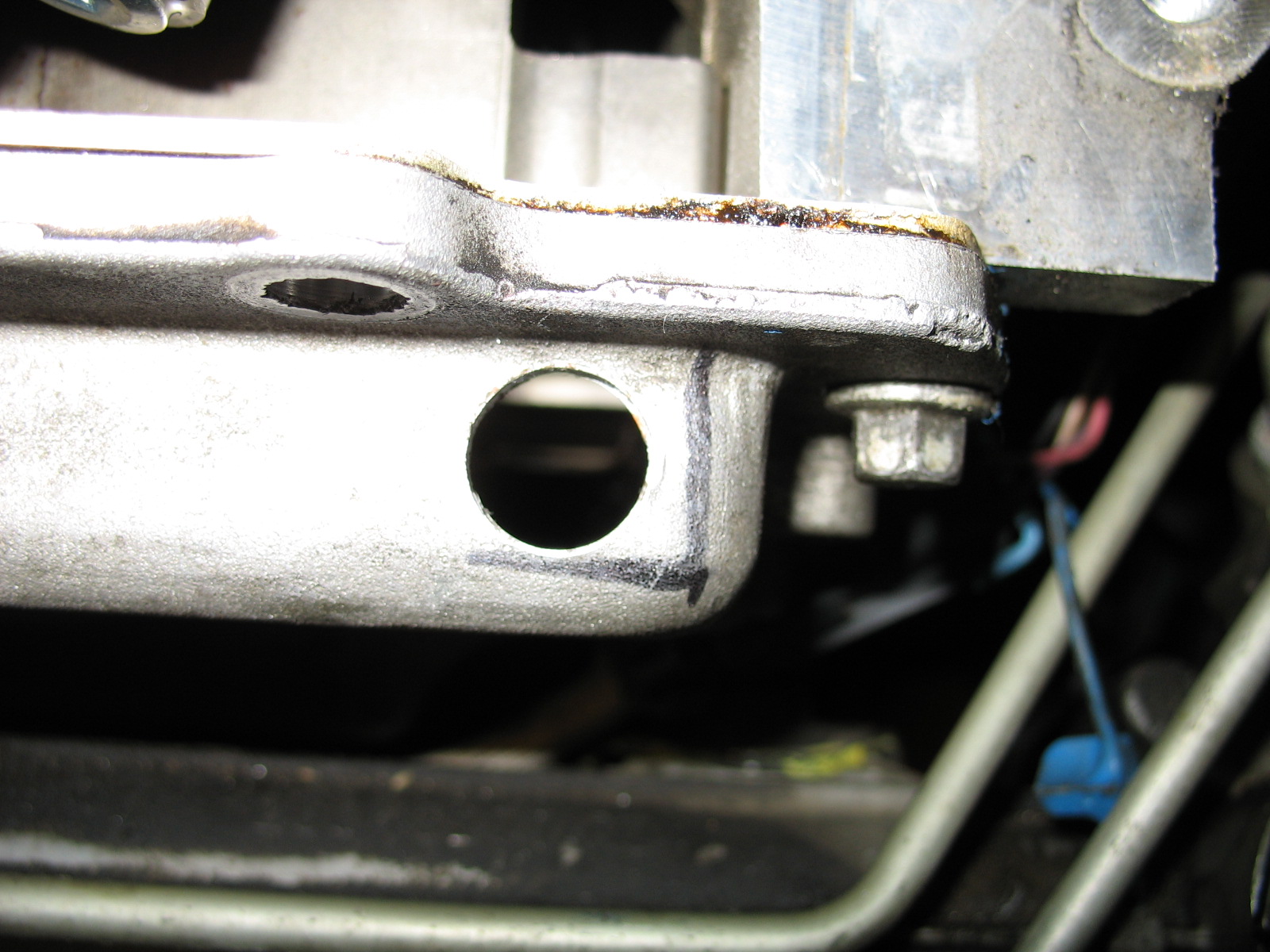

I wanted to do it like this.

But, the nut on the -10 fitting is to big to fit there. Well it will be to close for me to try.

So im thinking about draining to the drivers side of the pan. How high on the pan do i need to go to be above the oil level?

Any pictures would be great. If the passanger side is better, a pic of that would be great. Once this is done, all i should need is a couple hours and the car should start.

Thanks guys, Chris

I wanted to do it like this.

But, the nut on the -10 fitting is to big to fit there. Well it will be to close for me to try.

So im thinking about draining to the drivers side of the pan. How high on the pan do i need to go to be above the oil level?

Any pictures would be great. If the passanger side is better, a pic of that would be great. Once this is done, all i should need is a couple hours and the car should start.

Thanks guys, Chris

#11

On The Tree

iTrader: (89)

Join Date: Mar 2007

Location: Riverside, CA

Posts: 118

Likes: 0

Received 0 Likes

on

0 Posts

i have done over 400 VW Turbo kits since the late eightys and i have often due to turbo placement had to go into the BOTTOM of the oil sump because i couldnt get to a valve cover or the top of the case

- as long as you are using a -10 line and have good "FALL" from the turbo to the pan you WILL NOT have a problem / MOST problems come from having too big a feed line coupled with too small a drain line and a drainage line that turns up or goes parallel for short period -

-when i turbo'd my dune buggy with a 'vet pan i went directly on top of one of the wings

-when i turbo'd my 5.3 truck i went into the BOTTOM of the pan

over 4 years on the buggy and 2 years on the truck

( i would reccomend a -3 feed with a -10 drain )

- as long as you are using a -10 line and have good "FALL" from the turbo to the pan you WILL NOT have a problem / MOST problems come from having too big a feed line coupled with too small a drain line and a drainage line that turns up or goes parallel for short period -

-when i turbo'd my dune buggy with a 'vet pan i went directly on top of one of the wings

-when i turbo'd my 5.3 truck i went into the BOTTOM of the pan

over 4 years on the buggy and 2 years on the truck

( i would reccomend a -3 feed with a -10 drain )

#13

i have done over 400 VW Turbo kits since the late eightys and i have often due to turbo placement had to go into the BOTTOM of the oil sump because i couldnt get to a valve cover or the top of the case

- as long as you are using a -10 line and have good "FALL" from the turbo to the pan you WILL NOT have a problem / MOST problems come from having too big a feed line coupled with too small a drain line and a drainage line that turns up or goes parallel for short period -

-when i turbo'd my dune buggy with a 'vet pan i went directly on top of one of the wings

-when i turbo'd my 5.3 truck i went into the BOTTOM of the pan

over 4 years on the buggy and 2 years on the truck

( i would reccomend a -3 feed with a -10 drain )

- as long as you are using a -10 line and have good "FALL" from the turbo to the pan you WILL NOT have a problem / MOST problems come from having too big a feed line coupled with too small a drain line and a drainage line that turns up or goes parallel for short period -

-when i turbo'd my dune buggy with a 'vet pan i went directly on top of one of the wings

-when i turbo'd my 5.3 truck i went into the BOTTOM of the pan

over 4 years on the buggy and 2 years on the truck

( i would reccomend a -3 feed with a -10 drain )

Thanks for the info, Chris

#14

TECH Apprentice

iTrader: (2)

Join Date: Aug 2006

Location: OKC, OK & Hatteras Island, NC

Posts: 310

Likes: 0

Received 0 Likes

on

0 Posts

So it is ok to just drill and tap the pan? Is the pan thick enough to do this?

Alot of people are saying they have done this on other cars, but can you do this on a F-body's stock pan?

This thread has got my attention. I am currently running a little electric pump, and I do not think it is cutting it. I am getting oil everywhere. leaking under the turbo, in the intake, in the exhaust... Everywhere. I thought the seals were shot in the turbo, but someone said that my turbo does not have seals... It has rings, and they wont leak. Said it could be a bad air filter, or a bad drain line.

Alot of people are saying they have done this on other cars, but can you do this on a F-body's stock pan?

This thread has got my attention. I am currently running a little electric pump, and I do not think it is cutting it. I am getting oil everywhere. leaking under the turbo, in the intake, in the exhaust... Everywhere. I thought the seals were shot in the turbo, but someone said that my turbo does not have seals... It has rings, and they wont leak. Said it could be a bad air filter, or a bad drain line.

#15

So it is ok to just drill and tap the pan? Is the pan thick enough to do this?

Alot of people are saying they have done this on other cars, but can you do this on a F-body's stock pan?

This thread has got my attention. I am currently running a little electric pump, and I do not think it is cutting it. I am getting oil everywhere. leaking under the turbo, in the intake, in the exhaust... Everywhere. I thought the seals were shot in the turbo, but someone said that my turbo does not have seals... It has rings, and they wont leak. Said it could be a bad air filter, or a bad drain line.

Alot of people are saying they have done this on other cars, but can you do this on a F-body's stock pan?

This thread has got my attention. I am currently running a little electric pump, and I do not think it is cutting it. I am getting oil everywhere. leaking under the turbo, in the intake, in the exhaust... Everywhere. I thought the seals were shot in the turbo, but someone said that my turbo does not have seals... It has rings, and they wont leak. Said it could be a bad air filter, or a bad drain line.

I will let you guys know how it goes.

Chris

#17

TECH Apprentice

iTrader: (2)

Join Date: Aug 2006

Location: OKC, OK & Hatteras Island, NC

Posts: 310

Likes: 0

Received 0 Likes

on

0 Posts

Yes people have done it on a stock ls1 oil pan. The picture i posted is one. As far as i know the procharger directions that come with the super charger say to drill and tap the pan. It is not a pressureized line, so if you get 3-4 threads it should be fine. I would some teflon tape, and maybe some sort of gasket maker around it to make sure it doesn't leak. My issue right now is how high in the pan does it need to be. I was going to tap the pan how it is int he picture i posted but a -10 fitting barely fits there, and is so close. im afraid of doing it, so i think im going to do it elsewhere. Im going to do what ever im gonna do on saturday. Once the drain gets done, i should be able to start my car!!!!

I will let you guys know how it goes.

Chris

I will let you guys know how it goes.

Chris

However, it makes sense about only needing a few threads. It wont be pressurized so no need for it. From what I understand, the drain has to be above the oil line.

#18

Yea, i know for sure that the drain line needs to be above the oil, other wise it would not drain, it would build up in the line.

I cant remember where i saw it, but someone was talking about a -8 drain for a supercharger and they tapped the front of the pan, similar to the pic i posted.

Chris

#19

11 Second Club

iTrader: (74)

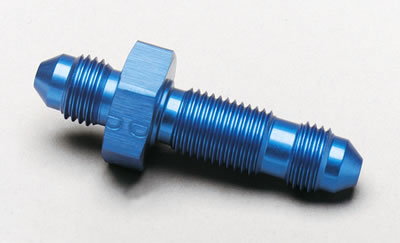

and one of these to go on the inside of it (bulkhead nut)...

A hole was drilled in the block above the oil level on the passengers side just before the pan goes thin toward the front (toward the top right where the pan drops down/where its becomes deeper), then a 10AN tap was run in the hole, then the fitting installed with teflon around the threads. We had to cut off the end of the fitting because it was hitting the pickup tube, but since you have 2 sets of threads it's no big deal. Once the fitting is fitted in the hole, use the bulkhead nut on the inside of the pan to hold the fitting in place so it doesn't try and back out. Thats how they've done it on several cars and it works great.