HELP QUICK!!!!!! Carrier Preload?

#1

On The Tree

Thread Starter

iTrader: (4)

Join Date: Dec 2009

Location: Versailles, MO

Posts: 165

Likes: 0

Received 0 Likes

on

0 Posts

I'm installing motive 4.10's, and I don't know what the preload of the pinion and carrier is supposed to be. My carrier and pinion preload is 40 in/lbs. Pinion preload is 28in/lbs and backlash is .008. Are all these measurements good? I searched but everyone seems to say different stuff.

#3

TECH Veteran

iTrader: (4)

you didn't state if you're re-using the bearings or have gone with new ones,it makes a difference.

pinion bearing preload w/the used bearings should be about 10 in.lbs.

pinion bearing preload w/ new bearings should be about 20-25 in.lbs.

carrier/pinion preload- pinion preload x ratio = carrier preload

40-28=12 x 4.10 = 49 in.lbs. carrier preload

pinion bearing preload w/the used bearings should be about 10 in.lbs.

pinion bearing preload w/ new bearings should be about 20-25 in.lbs.

carrier/pinion preload- pinion preload x ratio = carrier preload

40-28=12 x 4.10 = 49 in.lbs. carrier preload

#4

On The Tree

Thread Starter

iTrader: (4)

Join Date: Dec 2009

Location: Versailles, MO

Posts: 165

Likes: 0

Received 0 Likes

on

0 Posts

I'm using new bearings, so is the 28in/lbs for the pinion bearing bad. On the writeup I used it said to do 24-32in/lbs. And what is carrier preload supposed to be is 49in/lbs good.

#5

TECH Veteran

iTrader: (4)

28 is OK

49 is 'tight',but setting carrier preload properly sometimes requires a shim(s) that is not 'on hand'. if you got shims to loosen it slightly,I would but that's gonna change the pattern,if it's good now.

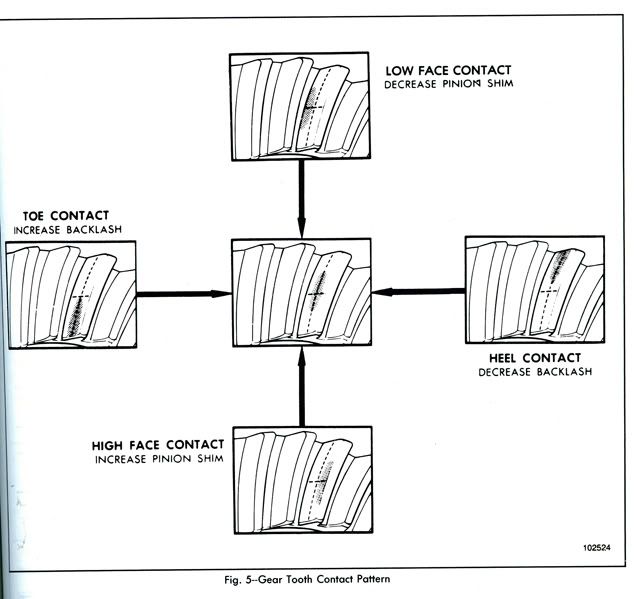

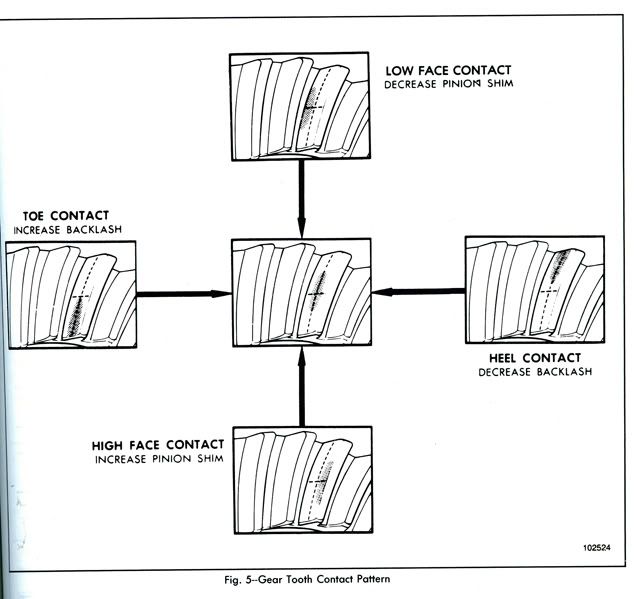

IF it was me and I was getting a good pattern with those preloads and a lash of .008,I would run with that. how's the pattern ?

49 is 'tight',but setting carrier preload properly sometimes requires a shim(s) that is not 'on hand'. if you got shims to loosen it slightly,I would but that's gonna change the pattern,if it's good now.

IF it was me and I was getting a good pattern with those preloads and a lash of .008,I would run with that. how's the pattern ?

#6

On The Tree

Thread Starter

iTrader: (4)

Join Date: Dec 2009

Location: Versailles, MO

Posts: 165

Likes: 0

Received 0 Likes

on

0 Posts

I will post pics of the pattern but I think the preload of the carrier is like way to high because it is hard to turn by hand. I used the stock shims, but I switched the carrier shims because there was absolutely no backlash with the setup I pulled out. Left shim was .024 and right shim was .023, then I switched them to get the backlash of .008.

Trending Topics

#8

TECH Veteran

iTrader: (4)

compound too thick which causes smearing and hides the true pattern,you don't need a lot,a light coat will do.

carrier too tight or too loose,that's the problem with using the original shims and not having a variety on hand to be able to vary them.

4 OEM shims I pulled measured .2315,.2375,.2415,&.2435

you really need a variety of shims to set up a rearend,any change in carrier bearing lenght from the originals will change carrier preload(either looser or tighter) and sometimes you get lucky and it's perfect.

carrier too tight or too loose,that's the problem with using the original shims and not having a variety on hand to be able to vary them.

4 OEM shims I pulled measured .2315,.2375,.2415,&.2435

you really need a variety of shims to set up a rearend,any change in carrier bearing lenght from the originals will change carrier preload(either looser or tighter) and sometimes you get lucky and it's perfect.

#11

On The Tree

Thread Starter

iTrader: (4)

Join Date: Dec 2009

Location: Versailles, MO

Posts: 165

Likes: 0

Received 0 Likes

on

0 Posts

Ok I guess I will go try it right now even though its pitch black outside. How easy should the carrier be to spin. I realize that is a hard question to answer but as of right now it is almost impossible to spin it by hand, when I checked the pattern I had to spin it by the ring gear bolts. Thanks for all your help!

#12

On The Tree

Thread Starter

iTrader: (4)

Join Date: Dec 2009

Location: Versailles, MO

Posts: 165

Likes: 0

Received 0 Likes

on

0 Posts

Ok, I took .002 off of each side, and the shims were pretty easy to push in. I was able to just push them in with my finger(isn't this a no no), with the stock ones I had to hammer them in. Anyway and it was still just has hard to turn the carrier. What I don't understand is why it feels about perfect when i spin it from the yoke, but it won't budge when I try to spin the carrier. Is it possible i need to add a little to each side of the carrier instead of taking away.

What I don't understand is why it feels about perfect when i spin it from the yoke, but it won't budge when I try to spin the carrier. Is it possible i need to add a little to each side of the carrier instead of taking away.

What I don't understand is why it feels about perfect when i spin it from the yoke, but it won't budge when I try to spin the carrier. Is it possible i need to add a little to each side of the carrier instead of taking away.

What I don't understand is why it feels about perfect when i spin it from the yoke, but it won't budge when I try to spin the carrier. Is it possible i need to add a little to each side of the carrier instead of taking away.

#14

TECH Veteran

iTrader: (4)

It's always gonna be hard to spin from the carrier,if your pinion preload is 28 in.lbs.,that's gonna show up as 115 in.lbs.(because of the 4.10:1 ratio operating reverse)=9.5 ft.lbs.

looks like you gotta go in between what you have and what you had,.229 & .239.

you don't spin carrier,you spin pinion.

when you get a 'final',I take a drill motor with the pinion nut socket in the chuck(lot of step down adaptors) coat the gearset with some lube and drive it at drill motor rpm,if something isn't right,you can hear and feel it,such as ring gear not spinning concentrically.

from a GM 7.5 10 bolt manual

looks like you gotta go in between what you have and what you had,.229 & .239.

you don't spin carrier,you spin pinion.

when you get a 'final',I take a drill motor with the pinion nut socket in the chuck(lot of step down adaptors) coat the gearset with some lube and drive it at drill motor rpm,if something isn't right,you can hear and feel it,such as ring gear not spinning concentrically.

from a GM 7.5 10 bolt manual

Last edited by FirstYrLS1Z; 11-19-2010 at 10:59 PM.

#16

On The Tree

Thread Starter

iTrader: (4)

Join Date: Dec 2009

Location: Versailles, MO

Posts: 165

Likes: 0

Received 0 Likes

on

0 Posts

So it's normal that I can't spin the carrier by hand. How come I could spin it relatively easy when I first took it apart, is it because there is no oil on the gears?

#17

TECH Senior Member

iTrader: (96)

Join Date: Aug 2007

Location: Turnin' Wrenches Infractions: 005

Posts: 24,241

Likes: 0

Received 79 Likes

on

70 Posts

No, bearings wear in and get loose. The specs change once the bearings are used. You expect used bearings to spin very freely. New bearings are very tight, as they wear the first few times you drive it, they will loosen up. This creates a lot of heat so drive short distances the first few times.

#18

On The Tree

Thread Starter

iTrader: (4)

Join Date: Dec 2009

Location: Versailles, MO

Posts: 165

Likes: 0

Received 0 Likes

on

0 Posts

Well I put it all back together, I decided to paint it to so it won't be on the road till tomorrow. I stuck with the stock shims switched around setup which gave me .008 backlash and the pattern in the pics above. I was tired of switching shims and checking the pattern just to find out it was screwed up. I figure if it whines like a son of a bitch, I will just buy a fab 9 when tax time comes.

Last edited by cleb; 11-21-2010 at 09:04 AM.

[/IMG]

[/IMG] [/IMG]

[/IMG]  Sometimes they will develop a little whine after a few miles but it shouldn't be much if any.

Sometimes they will develop a little whine after a few miles but it shouldn't be much if any.