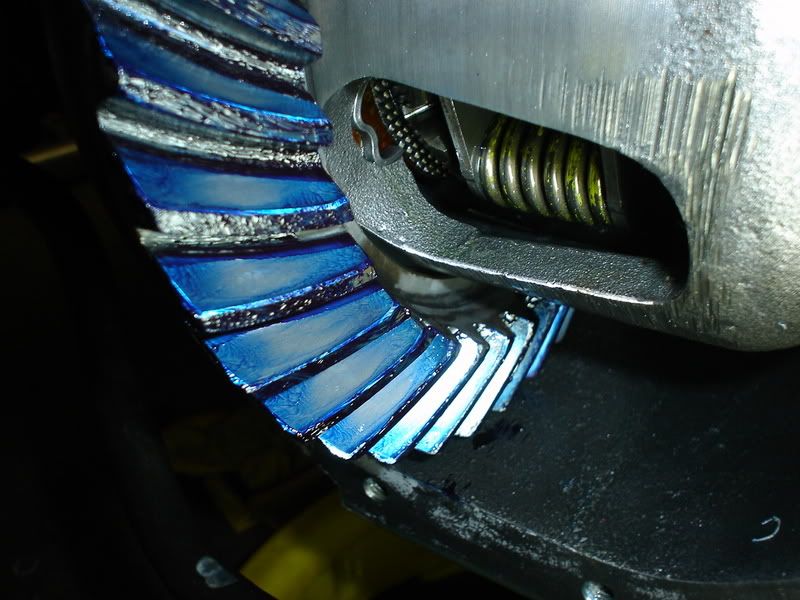

Pics of my 12 bolt's gear contact pattern

#2

TECH Fanatic

iTrader: (1)

Join Date: Jul 2005

Location: Earth

Posts: 1,682

Likes: 0

Received 0 Likes

on

0 Posts

I am not gonna tell you whether that looks good or not...for that I didn't pay enough attention when they did the rear end segment on Horsepower TV, but I am curious to see that you have a 99 model year car, with an Auburn differential....at least I am guessing that's what it is due to the springs I see in rear end.

#5

Originally Posted by MannyZ28

I am not gonna tell you whether that looks good or not...for that I didn't pay enough attention when they did the rear end segment on Horsepower TV, but I am curious to see that you have a 99 model year car, with an Auburn differential....at least I am guessing that's what it is due to the springs I see in rear end.

Not sure what the backlash is set to exactly. My dial indicator is missing the magnet base and rods.

#6

yeah, that pattern looks pretty good to me. Nice and centered from face to flank (maybe a little deep) and has a good fat contact pattern from heel to toe. IMO a nicely centered pattern from face to flank is most important and then get the backlash set right. After that there isn't much left to do. That pattern doesn't look like it should cause excessive noise. If the noise is excessive, maybe it's got too much pinion preload or a bearing is gone?

If you're really worried about it you could get the high dollar pinion depth gauge and get the pinion depth on the money. Even the $20 ratech pinion depth tool works okay if used correctly.

If you're really worried about it you could get the high dollar pinion depth gauge and get the pinion depth on the money. Even the $20 ratech pinion depth tool works okay if used correctly.

Trending Topics

#8

Originally Posted by turbotko

yeah, that pattern looks pretty good to me. Nice and centered from face to flank (maybe a little deep) and has a good fat contact pattern from heel to toe. IMO a nicely centered pattern from face to flank is most important and then get the backlash set right. After that there isn't much left to do. That pattern doesn't look like it should cause excessive noise. If the noise is excessive, maybe it's got too much pinion preload or a bearing is gone?

If you're really worried about it you could get the high dollar pinion depth gauge and get the pinion depth on the money. Even the $20 ratech pinion depth tool works okay if used correctly.

If you're really worried about it you could get the high dollar pinion depth gauge and get the pinion depth on the money. Even the $20 ratech pinion depth tool works okay if used correctly.

#9

14 Second Truck Club

iTrader: (36)

Join Date: Oct 2004

Location: Chicago, Il

Posts: 2,633

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by thunderdan74

The coast pattern looks good, but the drive pattern is running diagonal and abruptly contacting the mid heel. I'm getting .016 backlash and 15 in/lbs of pinion and carrier preload.

#10

TECH Fanatic

Originally Posted by thunderdan74

It makes a lot of noise, but only during cruise at around 65ish.

I think she's got too much backlash and needs a thinner pinion shim.

What do you think of the pattern, guys?

I think she's got too much backlash and needs a thinner pinion shim.

What do you think of the pattern, guys?

1. Drive is a little too deep, unless... you are beating on it at the strip constantly. A little deep will help combat tooth deflection from launching... but its runs the risk of making noise in a street car during cruise.

2. Coast is nice and centered, but with 0.016" lash and light pinion preload... it explains your noise. If it were around 0.010" lash like you would want it... it would be way, way too deep and coast would dive in toe.

Not knowing yet what manufacturer you are using... I would only take a stab at saying that you need to take out a loose 0.002 to a tight 0.003" in pinion depth and shoot for around 0.010" lash.

A centered coast really doesnt add anything to the set-up... but it does help in controlling coast noise. Drive is way more important than coast and when you cant get a textbook pattern... set for drive and hope coast doesnt make too much noise.

I would also an oil based paint over that of Dyechem... and only paint about six teeth. Then do a concentraited roll over the six tooth area before you roll it over two to three times (360). The dry wipe-off will tell you more about the pattern than the painted area alone. That, and it will show you what is going on around two other places on the ring gear... for example, if you have runout problems or if something isnt seated correctly. Dont forget to measure the lash at the other points of direct wipe-off... so that you keep the pattern you are looking at in comparison all the way around.

Originally Posted by gollum

All aftermarket race gears whine even when set up perfectly. Isn't that an aftermarket 12 bolt rearend.

The only noticeable difference in any of the aftermarket or OEM sets is (with the exception of Richmonds material hardness), the quality of finish machining... which doesnt effect anything in terms of noise.

Originally Posted by mzoomora

You need to cut that backlash in about 1/2 and you will need more pinion preload also.

On another note, new bearing pinion pre-load should be 35 roll inch pounds... and used bearing pre-load is right about 16 in/lbs rolling. I dont think that is an issue.

Last edited by chicane; 04-28-2007 at 03:33 PM.

#12

14 Second Truck Club

iTrader: (36)

Join Date: Oct 2004

Location: Chicago, Il

Posts: 2,633

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by chicane

I dont know about half !? But keep it between 0.009 to 0.012" when using 90 weight lube.

On another note, new bearing pinion pre-load should be 35 roll inch pounds... and used bearing pre-load is right about 16 in/lbs rolling. I dont think that is an issue.

As for the bearings, that was just matter of fact. Although improper preload can cause noise, he has enough where it shouldnt be an issue. He did also say pinion and carrier preload, which I hope doesnt mean he is trying to measure them together with the carrier in place.

#13

Simply set your pinion depth to the numbers scribed on your pinion then set your backlash. Are there any pinion depth numbers scribed on pinion? I know OEM and AAM gears do not have this luxery.

My past set of 4.11 Motive's where set up exactly to pinion depth scribe marks but they still whined...WTF?

My past set of 4.11 Motive's where set up exactly to pinion depth scribe marks but they still whined...WTF?

Last edited by gollum; 04-29-2007 at 08:35 AM.

#14

Originally Posted by chicane

What gear manufacturer is this we are dealing with ??

1. Drive is a little too deep, unless... you are beating on it at the strip constantly. A little deep will help combat tooth deflection from launching... but its runs the risk of making noise in a street car during cruise.

2. Coast is nice and centered, but with 0.016" lash and light pinion preload... it explains your noise. If it were around 0.010" lash like you would want it... it would be way, way too deep and coast would dive in toe.

Not knowing yet what manufacturer you are using... I would only take a stab at saying that you need to take out a loose 0.002 to a tight 0.003" in pinion depth and shoot for around 0.010" lash.

A centered coast really doesnt add anything to the set-up... but it does help in controlling coast noise. Drive is way more important than coast and when you cant get a textbook pattern... set for drive and hope coast doesnt make too much noise.

I would also an oil based paint over that of Dyechem... and only paint about six teeth. Then do a concentraited roll over the six tooth area before you roll it over two to three times (360). The dry wipe-off will tell you more about the pattern than the painted area alone. That, and it will show you what is going on around two other places on the ring gear... for example, if you have runout problems or if something isnt seated correctly. Dont forget to measure the lash at the other points of direct wipe-off... so that you keep the pattern you are looking at in comparison all the way around.

Uhmm... no. The fact of the matter is, that they dont.... if set-up correctly. And I am interested in what you mean by 'race' gears. Are you talking about 9210 series material "pro" sets ?? Because if you are talking about 8620 material sets... the OEM gears are no different than that of AAM, USGear, Percision, Motive etc, etc. Richmonds are the only manufacturer that does have an attribute to their sets, that do increase the possibility of noise... and that is because they Rockwell out very, very hard... and it changes the natural resonant frequency... which in most cases makes they sing.

The only noticeable difference in any of the aftermarket or OEM sets is (with the exception of Richmonds material hardness), the quality of finish machining... which doesnt effect anything in terms of noise.

I dont know about half !? But keep it between 0.009 to 0.012" when using 90 weight lube.

On another note, new bearing pinion pre-load should be 35 roll inch pounds... and used bearing pre-load is right about 16 in/lbs rolling. I dont think that is an issue.

1. Drive is a little too deep, unless... you are beating on it at the strip constantly. A little deep will help combat tooth deflection from launching... but its runs the risk of making noise in a street car during cruise.

2. Coast is nice and centered, but with 0.016" lash and light pinion preload... it explains your noise. If it were around 0.010" lash like you would want it... it would be way, way too deep and coast would dive in toe.

Not knowing yet what manufacturer you are using... I would only take a stab at saying that you need to take out a loose 0.002 to a tight 0.003" in pinion depth and shoot for around 0.010" lash.

A centered coast really doesnt add anything to the set-up... but it does help in controlling coast noise. Drive is way more important than coast and when you cant get a textbook pattern... set for drive and hope coast doesnt make too much noise.

I would also an oil based paint over that of Dyechem... and only paint about six teeth. Then do a concentraited roll over the six tooth area before you roll it over two to three times (360). The dry wipe-off will tell you more about the pattern than the painted area alone. That, and it will show you what is going on around two other places on the ring gear... for example, if you have runout problems or if something isnt seated correctly. Dont forget to measure the lash at the other points of direct wipe-off... so that you keep the pattern you are looking at in comparison all the way around.

Uhmm... no. The fact of the matter is, that they dont.... if set-up correctly. And I am interested in what you mean by 'race' gears. Are you talking about 9210 series material "pro" sets ?? Because if you are talking about 8620 material sets... the OEM gears are no different than that of AAM, USGear, Percision, Motive etc, etc. Richmonds are the only manufacturer that does have an attribute to their sets, that do increase the possibility of noise... and that is because they Rockwell out very, very hard... and it changes the natural resonant frequency... which in most cases makes they sing.

The only noticeable difference in any of the aftermarket or OEM sets is (with the exception of Richmonds material hardness), the quality of finish machining... which doesnt effect anything in terms of noise.

I dont know about half !? But keep it between 0.009 to 0.012" when using 90 weight lube.

On another note, new bearing pinion pre-load should be 35 roll inch pounds... and used bearing pre-load is right about 16 in/lbs rolling. I dont think that is an issue.

#17

14 Second Truck Club

iTrader: (36)

Join Date: Oct 2004

Location: Chicago, Il

Posts: 2,633

Likes: 0

Received 0 Likes

on

0 Posts

Torque arms are almost like a tuning fork, they magnify almost all the sounds. It is also a hatchback, which manes the passenger compartment is directly over the axle similar to vans which are more prone to hearing the gear noise.