Help Fix My Noisy A/C Clutch

#22

Just picked up a 02' Z28 A4. The car has been very well maintained but it had been sitting for almost a year before I bought it.

When the A/C is *off*, there is constant noise coming from the compressor clutch. I guess you could say it almost sounds like a hiss. The sound goes away immediately after I turn on the A/C and of course the sound returns when I turn the A/C off.

I'm not familiar with the operation of the clutch, could I damage anything by simply spraying some lubricant right into the front of the clutch?

When the A/C is *off*, there is constant noise coming from the compressor clutch. I guess you could say it almost sounds like a hiss. The sound goes away immediately after I turn on the A/C and of course the sound returns when I turn the A/C off.

I'm not familiar with the operation of the clutch, could I damage anything by simply spraying some lubricant right into the front of the clutch?

#23

On The Tree

Thread Starter

Join Date: Jun 2009

Location: Derry, NH

Posts: 142

Likes: 0

Received 0 Likes

on

0 Posts

So I went and picked up the A/C Clutch Bearing today, it was like $20 bucks. I also borrowed a "A/C Clutch Puller". I obviously want to do this without breaking the refrigerant lines open so this is what did.

Removed the belt.

Removed the 4 bolts holding the compressor to the bracket.

Dropped the Sway bar.

Doing those 3 things I was able to pull the compressor down and out of the way enough to get the Clutch pulley puller onto it. Well the puller they gave me was only a 2 jaw and I could not get the damn thing to stay on the pulley. I will try it again with a 3 jaw puller tomorrow. For now I put everything back together minus the belt so it's at least silent for now!

But yes, you definitely need a tool to pull the clutch off the compressor and it seems like you should be able to do it without taking off the refrigerant lines. I will find out if another tool is needed for the bearing tomorrow or Sunday.

Removed the belt.

Removed the 4 bolts holding the compressor to the bracket.

Dropped the Sway bar.

Doing those 3 things I was able to pull the compressor down and out of the way enough to get the Clutch pulley puller onto it. Well the puller they gave me was only a 2 jaw and I could not get the damn thing to stay on the pulley. I will try it again with a 3 jaw puller tomorrow. For now I put everything back together minus the belt so it's at least silent for now!

But yes, you definitely need a tool to pull the clutch off the compressor and it seems like you should be able to do it without taking off the refrigerant lines. I will find out if another tool is needed for the bearing tomorrow or Sunday.

#24

Teching In

Join Date: Aug 2002

Location: Ventura County

Posts: 30

Likes: 0

Received 0 Likes

on

0 Posts

Giggity,

did you need to do anything to get the bearing off? Was the culprit the bearing in the AC compressor pulley?

I think I have the same problem that you had: hi pitch squeel at 2000+ rpm coming from the compressor. no squeel at idle. Although I do get the squeel when the AC is on as well.

Ive seen two items at the auto parts store (rockauto.com): 1. AC Condenser pulley bearning alone and 2. the pulley/bearing assembly. of course the pulley/bearing assembly is much more expensive. Id like to just replace the bearing. Can I take out the bearing out of my original pulley and replace just the bearing?

TIA

did you need to do anything to get the bearing off? Was the culprit the bearing in the AC compressor pulley?

I think I have the same problem that you had: hi pitch squeel at 2000+ rpm coming from the compressor. no squeel at idle. Although I do get the squeel when the AC is on as well.

Ive seen two items at the auto parts store (rockauto.com): 1. AC Condenser pulley bearning alone and 2. the pulley/bearing assembly. of course the pulley/bearing assembly is much more expensive. Id like to just replace the bearing. Can I take out the bearing out of my original pulley and replace just the bearing?

TIA

Last edited by DF; 09-04-2009 at 04:31 PM.

#25

Alright, here is my attempt at a write up. You will need your standard sockets and wrenches, screwdrivers, BFG or press, Snap ring pliers. Specialty tools include are the clutch plate puller kit.

And the AC Pulley/Hub puller

First clean the threads on the inside of the clutch plate out nicely so the puller can be installed.

Thread in the correct size puller tool and remove the clutch plate.

I decided to replace the clutch plate on mine because it looked fairly worn. As I suspected this was the source of the dragging noise I heard. After this was removed, the pulley spun freely without noise. But I chose to proceed with replacing the bearing

(worn clutch plate)

Once the clutch plate is out, remove the snap ring that holds the A/C compressor pulley in place.

Set the pulley puller up on the A/C compressor pulley and remove the pulley.

Use a Press or Hammer and other appropriate tool to remove the bearing from the puller. I had two options, the first being a large socket and the other is my custom made crank pulley install tool. The bearing comes out the front of the pulley.

There are several tangs on the front of the pulley that are there to hold the bearing in, they will be flattened out by the removal process.

Now use the press/BFH and appropriate tool to install the new bearing in the pulley. It should be pressed in until it bottoms out. The A/C compressor pulley can now be reinstalled on the compressor. Mine did not take much force to reinstall and I used a rubber mallet to tap it back onto the compressor. If yours does not go on freely, you could probably use the clutch plate install tool and large washer to press it on. Then reinstall the snap ring.

In order to proceed with installing the clutch plate, there is a key that needs to be removed from the clutch plate

Use a hammer and punch (or durable screwdriver) to remove this key from the clutch plate.

Install the key in the slot on the shaft of the compressor

Make sure the threads on the end of the compressor shaft are clean. Set the clutch plate (old or new) on the shaft so the keyway lines up with the key on the shaft. Assemble the clutch plate install tool and thread it onto the shaft of the compressor.

Tighten the clutch plate down onto the compressor until there is .020-.030” between the clutch plate and the AC compressor pulley. Less clearance may cause a dragging noise, more clearance may cause the clutch not to engage

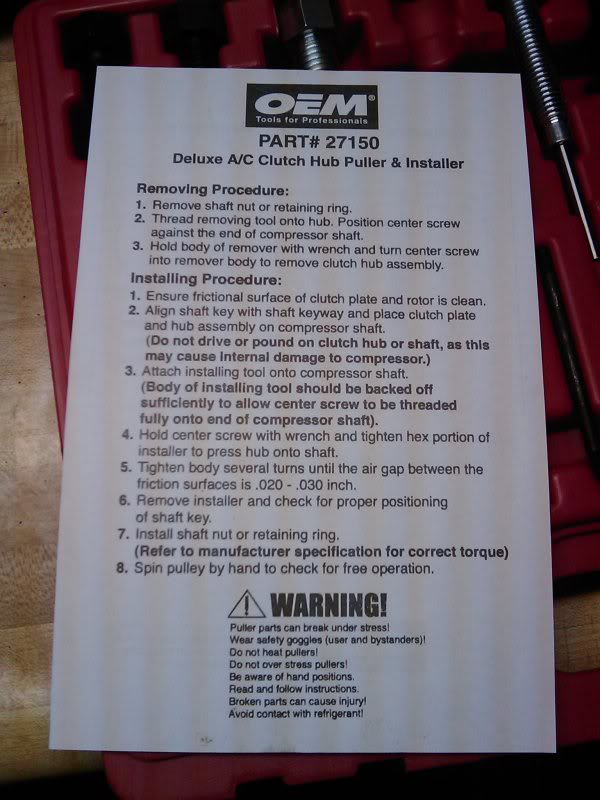

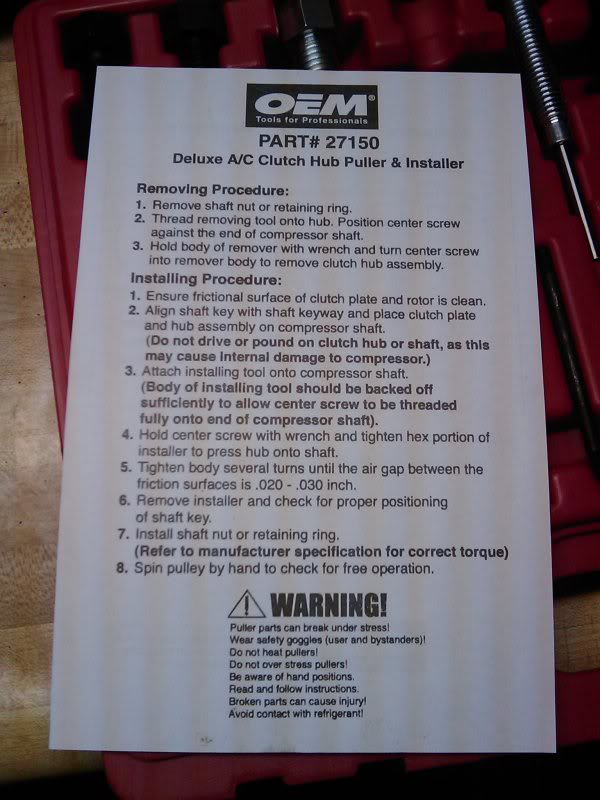

Here are the instructions included with the puller tool.

I was able to get both these tools as rentals from Autozone. I tried to get them from AdvanceAuto first, but they did not have them available. I am getting my replacement parts form rockauto.

And the AC Pulley/Hub puller

First clean the threads on the inside of the clutch plate out nicely so the puller can be installed.

Thread in the correct size puller tool and remove the clutch plate.

I decided to replace the clutch plate on mine because it looked fairly worn. As I suspected this was the source of the dragging noise I heard. After this was removed, the pulley spun freely without noise. But I chose to proceed with replacing the bearing

(worn clutch plate)

Once the clutch plate is out, remove the snap ring that holds the A/C compressor pulley in place.

Set the pulley puller up on the A/C compressor pulley and remove the pulley.

Use a Press or Hammer and other appropriate tool to remove the bearing from the puller. I had two options, the first being a large socket and the other is my custom made crank pulley install tool. The bearing comes out the front of the pulley.

There are several tangs on the front of the pulley that are there to hold the bearing in, they will be flattened out by the removal process.

Now use the press/BFH and appropriate tool to install the new bearing in the pulley. It should be pressed in until it bottoms out. The A/C compressor pulley can now be reinstalled on the compressor. Mine did not take much force to reinstall and I used a rubber mallet to tap it back onto the compressor. If yours does not go on freely, you could probably use the clutch plate install tool and large washer to press it on. Then reinstall the snap ring.

In order to proceed with installing the clutch plate, there is a key that needs to be removed from the clutch plate

Use a hammer and punch (or durable screwdriver) to remove this key from the clutch plate.

Install the key in the slot on the shaft of the compressor

Make sure the threads on the end of the compressor shaft are clean. Set the clutch plate (old or new) on the shaft so the keyway lines up with the key on the shaft. Assemble the clutch plate install tool and thread it onto the shaft of the compressor.

Tighten the clutch plate down onto the compressor until there is .020-.030” between the clutch plate and the AC compressor pulley. Less clearance may cause a dragging noise, more clearance may cause the clutch not to engage

Here are the instructions included with the puller tool.

I was able to get both these tools as rentals from Autozone. I tried to get them from AdvanceAuto first, but they did not have them available. I am getting my replacement parts form rockauto.

#26

TECH Fanatic

iTrader: (10)

Nice writeup, danbo.

OP: Your problem might only be rust between the clutch hub and plate. The car was sitting, and those 2 parts are just plain bare metal that rust easily. And now you are getting a hissing noise only when the compressor is disengaged.

I would try my luck at pulling the plate, cleaning the surfaces and resetting the air gap.

OP: Your problem might only be rust between the clutch hub and plate. The car was sitting, and those 2 parts are just plain bare metal that rust easily. And now you are getting a hissing noise only when the compressor is disengaged.

I would try my luck at pulling the plate, cleaning the surfaces and resetting the air gap.

#27

Now that i think of it, A noisy clutch bearing will make noise all the time. The only thing that will make noise when the AC is off, and not when it is On is the clutch. If you look at wear the bearing is installed, it is on the housing of the compressor.

I believe the common thought is that the bearing is on the shaft which would turn the same speed as the pulley when the clutch was engaged, causing the bearing not to spin. However the bearing is always spinning regardless of the clutch being engaged or not.

I believe the common thought is that the bearing is on the shaft which would turn the same speed as the pulley when the clutch was engaged, causing the bearing not to spin. However the bearing is always spinning regardless of the clutch being engaged or not.

#28

Launching!

iTrader: (1)

I know this thread is over half a decade old but wanted to bump it for anyone having AC clutch/bearing issues. Just completed replacing bearing plus clutch and followed this thread to a T. Worked great.

BTW, did this with the compressor still connected to the lines. Cumbersome but able to do the job.

BTW, did this with the compressor still connected to the lines. Cumbersome but able to do the job.

#30

Save the manuals!

iTrader: (5)

Bump again for this thread leading me through this.

FYI - The GM Factory Service Manual calls for a .015" Air Gap between the clutch plates, but my unit seemed happy just over .020" before I adjusted it down. .015" is also working well.

I put some tack welds on the new bearing to secure it in place in lieu of the depressions that get upset by the bearing swap. I used some duct tape to protect the plastic dust shield on the bearing from spatter and that worked really well. The spatter caused the duct tape to leave behind a bunch of charred goo, which I was able to wipe up with a paper towel and some alcohol.

FYI - The GM Factory Service Manual calls for a .015" Air Gap between the clutch plates, but my unit seemed happy just over .020" before I adjusted it down. .015" is also working well.

I put some tack welds on the new bearing to secure it in place in lieu of the depressions that get upset by the bearing swap. I used some duct tape to protect the plastic dust shield on the bearing from spatter and that worked really well. The spatter caused the duct tape to leave behind a bunch of charred goo, which I was able to wipe up with a paper towel and some alcohol.