The truck ignition coil upgrade

#181

Teching In

Join Date: Jul 2016

Location: Hermosa Beach Ca

Posts: 9

Likes: 0

Received 0 Likes

on

0 Posts

Too many to list in a lump forum.

Multiple control engines on chassis and engine dynos testing everything from plugs, wires, coils, igniters, CDI.

Dwell and Joules is what you are chasing.

You need to have the coil recover completely so it does not false fire,

RPM plays a huge factor in that charge time or recovery.

Dwell is the time, is your coil strong enough to dwell the length of time its needed too? and does it deliver a fat consistent spark.

Bigger drivers make more heat thus the heat sink to get rid of the heat.

Back to back dwell tests are ok but where you will see the difference is in RPM a lesser coil will stop fireing at a lower rpm.

take this lesson and increase dwell to suit your needs.

LS engines may never see these speeds unless dwell is too high.

Multiple control engines on chassis and engine dynos testing everything from plugs, wires, coils, igniters, CDI.

Dwell and Joules is what you are chasing.

You need to have the coil recover completely so it does not false fire,

RPM plays a huge factor in that charge time or recovery.

Dwell is the time, is your coil strong enough to dwell the length of time its needed too? and does it deliver a fat consistent spark.

Bigger drivers make more heat thus the heat sink to get rid of the heat.

Back to back dwell tests are ok but where you will see the difference is in RPM a lesser coil will stop fireing at a lower rpm.

take this lesson and increase dwell to suit your needs.

LS engines may never see these speeds unless dwell is too high.

#182

9 Second Club

A very vague answer from so much testing.

Do wires really make a difference in back to back tests ?

Do plugs really make a difference in back to back tests ?

Coils could potentially be a bigger topic of course...not to mention all 3 combined.

Do wires really make a difference in back to back tests ?

Do plugs really make a difference in back to back tests ?

Coils could potentially be a bigger topic of course...not to mention all 3 combined.

#183

FormerVendor

iTrader: (1)

Join Date: Nov 2008

Location: Santa Ana, CA. USA

Posts: 2,157

Likes: 0

Received 16 Likes

on

16 Posts

OK, we all know engine bench testing/rolling road testing methods are able to have repeatable results with errors note at low values.

We know that laboratory testing can also be done using static means.

One method that I use is to "run" the EMS, Coil, Wire, Boot, Sparkplug, Battery, and other items to simulate normal engine running on a bench using the CO-2 pressure chamber that I manufacture/sell to others.

Observation AND Measurement can then be made using my ECU's Data Logger for measurement of Dwell, Duty Cycle, Battery Voltage, MAP, and other values.

The Secondary output of the coil(s) in test is measured by using the Scope.

Those values, Voltage, Current, Wave Form, Arc duration are easily recorded by the "scopes" logger.

The NEXT requirement is to "pick" an engine to be "modeled".

I use EAP by Performance Trends.

This simulation of a running engine allows me to input Cylinder Pressure, Crankshaft Stroke Length, Rod Length, RPM and other items that are used the create the recorded output and component positions of the engine at any RPM.

These results are then compared to the data acquired from coil bench testing AND MATCHED for performance at best RPM.

Typically when the lab measurement of "best settings" for coil dwell, spark plug gap, wire Ohm ARE IMPLEMENTED, the engines measured output is greatest in a "live" test.

I am SURE GM does the same for their coil requirement though it is mostly done for their production standard engine tune.

Lance

We know that laboratory testing can also be done using static means.

One method that I use is to "run" the EMS, Coil, Wire, Boot, Sparkplug, Battery, and other items to simulate normal engine running on a bench using the CO-2 pressure chamber that I manufacture/sell to others.

Observation AND Measurement can then be made using my ECU's Data Logger for measurement of Dwell, Duty Cycle, Battery Voltage, MAP, and other values.

The Secondary output of the coil(s) in test is measured by using the Scope.

Those values, Voltage, Current, Wave Form, Arc duration are easily recorded by the "scopes" logger.

The NEXT requirement is to "pick" an engine to be "modeled".

I use EAP by Performance Trends.

This simulation of a running engine allows me to input Cylinder Pressure, Crankshaft Stroke Length, Rod Length, RPM and other items that are used the create the recorded output and component positions of the engine at any RPM.

These results are then compared to the data acquired from coil bench testing AND MATCHED for performance at best RPM.

Typically when the lab measurement of "best settings" for coil dwell, spark plug gap, wire Ohm ARE IMPLEMENTED, the engines measured output is greatest in a "live" test.

I am SURE GM does the same for their coil requirement though it is mostly done for their production standard engine tune.

Lance

#184

Teching In

Join Date: Jul 2016

Location: Hermosa Beach Ca

Posts: 9

Likes: 0

Received 0 Likes

on

0 Posts

Wires absolutely make a difference in back to back tests even the same wire with the boot half way down the insulator and boot completely covering insulator, and dielectric grease and no dielectric grease. Wire covering no wire covering. There is a lot on the table here in high horse power applications.

Some of the biggest scams out there are spark plugs. Best advice here is to keep the design simple and use good materials. Yes it makes a difference in plugs back to back. Same heat range different plug or same plug different heat range.

yes this is a bigger topic, You have to look at the ignition system as a whole.

There are also about 4 suppliers of the 585 coil to GM that also vary.

Even same year same line a week apart can have a different vendor of coil. Mitsubishi, Denso, Delphi, and other.

Some of the biggest scams out there are spark plugs. Best advice here is to keep the design simple and use good materials. Yes it makes a difference in plugs back to back. Same heat range different plug or same plug different heat range.

yes this is a bigger topic, You have to look at the ignition system as a whole.

There are also about 4 suppliers of the 585 coil to GM that also vary.

Even same year same line a week apart can have a different vendor of coil. Mitsubishi, Denso, Delphi, and other.

#185

9 Second Club

And still a vague answer.

It's all good and well saying yes these things can make a difference. That'd be like me saying fuel makes a difference, heads make a difference, turbos make a difference....and leaving it at that.

It's all good and well saying yes these things can make a difference. That'd be like me saying fuel makes a difference, heads make a difference, turbos make a difference....and leaving it at that.

#186

Teching In

Join Date: Jul 2016

Location: Hermosa Beach Ca

Posts: 9

Likes: 0

Received 0 Likes

on

0 Posts

What would you like to know specifically?

At 2.4ms of dwell a 585 coil will blow out (no spark) at 19,550 RPM with 300 psi of cylinder pressure on nitrogen at 14.8volts 72 degrees F 100kpa ambient sea level.

with an autolite 3923 plug at .060 gap. Super mag 7mm wires, dielectric grease and the boots pulled down over the insulator. I can lower that RPM number simply by raising the boot on the insulator with the terminal still clipped tight. Or by putting 2 plug wires together with a clothes pin it goes down to 15,000 rpm.

The heat sinks on all 8 coils run from 105 to 110F.

Testing all 8 coils at the same time the first one started to go out at 16,650 Rpm and the last one at 19,550

This test completed 6-13-13 but I could probably duplicate it today.

At 2.4ms of dwell a 585 coil will blow out (no spark) at 19,550 RPM with 300 psi of cylinder pressure on nitrogen at 14.8volts 72 degrees F 100kpa ambient sea level.

with an autolite 3923 plug at .060 gap. Super mag 7mm wires, dielectric grease and the boots pulled down over the insulator. I can lower that RPM number simply by raising the boot on the insulator with the terminal still clipped tight. Or by putting 2 plug wires together with a clothes pin it goes down to 15,000 rpm.

The heat sinks on all 8 coils run from 105 to 110F.

Testing all 8 coils at the same time the first one started to go out at 16,650 Rpm and the last one at 19,550

This test completed 6-13-13 but I could probably duplicate it today.

#188

9 Second Club

What would you like to know specifically?

At 2.4ms of dwell a 585 coil will blow out (no spark) at 19,550 RPM with 300 psi of cylinder pressure on nitrogen at 14.8volts 72 degrees F 100kpa ambient sea level.

with an autolite 3923 plug at .060 gap. Super mag 7mm wires, dielectric grease and the boots pulled down over the insulator. I can lower that RPM number simply by raising the boot on the insulator with the terminal still clipped tight. Or by putting 2 plug wires together with a clothes pin it goes down to 15,000 rpm.

The heat sinks on all 8 coils run from 105 to 110F.

Testing all 8 coils at the same time the first one started to go out at 16,650 Rpm and the last one at 19,550

This test completed 6-13-13 but I could probably duplicate it today.

At 2.4ms of dwell a 585 coil will blow out (no spark) at 19,550 RPM with 300 psi of cylinder pressure on nitrogen at 14.8volts 72 degrees F 100kpa ambient sea level.

with an autolite 3923 plug at .060 gap. Super mag 7mm wires, dielectric grease and the boots pulled down over the insulator. I can lower that RPM number simply by raising the boot on the insulator with the terminal still clipped tight. Or by putting 2 plug wires together with a clothes pin it goes down to 15,000 rpm.

The heat sinks on all 8 coils run from 105 to 110F.

Testing all 8 coils at the same time the first one started to go out at 16,650 Rpm and the last one at 19,550

This test completed 6-13-13 but I could probably duplicate it today.

ie does a particular lead or plug etc offer power/torque improvements over others tested in the majority of test engines ?

Ultimately that is what people here seek, more so given no LS engines run to 19,000rpm, or indeed 16,000rpm.

#189

FormerVendor

iTrader: (1)

Join Date: Nov 2008

Location: Santa Ana, CA. USA

Posts: 2,157

Likes: 0

Received 16 Likes

on

16 Posts

First, I would accept the above stated test as VALID due to the versed test criteria.

Next, I would like to share the knowledge I learned by READING the REPORT:

#1 Improper plug boot fitment WILL lower the ability to conduct current into the combustion chamber.

#2 The crossing of plug wires, HT wires touching other HT wires, WILL lower the ability to conduct current into the combustion chamber.

I so state that 100% of the members here at LS-tech can benefit with these test results.

The results prove that with proper wire fitment, missfire resistance can be increased with NO cost increase.

Lance

Next, I would like to share the knowledge I learned by READING the REPORT:

#1 Improper plug boot fitment WILL lower the ability to conduct current into the combustion chamber.

#2 The crossing of plug wires, HT wires touching other HT wires, WILL lower the ability to conduct current into the combustion chamber.

I so state that 100% of the members here at LS-tech can benefit with these test results.

The results prove that with proper wire fitment, missfire resistance can be increased with NO cost increase.

Lance

#190

9 Second Club

1...isnt it kinda obvious bad fitment isnt going to help ?

2. With almost all LS's being CNP, wires crossing or running beside each other isnt of any concern to us ?

So is the info of any real benefit ?

2. With almost all LS's being CNP, wires crossing or running beside each other isnt of any concern to us ?

So is the info of any real benefit ?

#191

Teching In

Join Date: Jul 2016

Location: Hermosa Beach Ca

Posts: 9

Likes: 0

Received 0 Likes

on

0 Posts

It is not just wire that can cause this mis-fire. Anything metal like a header or dip stick bracket. or AC line bracket. Or ungrounded metal test bench.

There is a ton to be learned from this that can be applied to this forum.

Like I said before none of these engines will hit the limits and demands we put on these coils in the lab but its good to know where they are.

Yes there are better plugs and leads but generalizing everyones application.

Make sure your wire is covered with non conductive heat wrap, has some resistance and is not solid core.

Spark plugs use good materials make sure the heat range fits your application, Gimics usually don't work that's why wheels are still round.

Push the boots all the way down on the ceramic part of the plug its amazing how much is wasted here.

There is a ton to be learned from this that can be applied to this forum.

Like I said before none of these engines will hit the limits and demands we put on these coils in the lab but its good to know where they are.

Yes there are better plugs and leads but generalizing everyones application.

Make sure your wire is covered with non conductive heat wrap, has some resistance and is not solid core.

Spark plugs use good materials make sure the heat range fits your application, Gimics usually don't work that's why wheels are still round.

Push the boots all the way down on the ceramic part of the plug its amazing how much is wasted here.

#196

So reading through all 10 pages of this post has my head spinning. Can anyone here help me with my specific setup? I have a 2000 Chevrolet silverado LS1. Can I use the MSD 8287 multiple spark coils or stock GM lS2 coils, in conjunction with a LS2 harness, and a modified LS2 bracket on my LS1 OEM Harness? When I say LS1 Harness I mean the stock connection that hooks up to the LS2 coil harness.

What confuses me the most is: Does the LS2 coil harness connect to LS1 wiring harness or do I need to change the connectors? I have seen that Michigan Motorsport makes relocation harnesses, would that be a good harmess for using the MSD coils as apposed to a stock LS2 coil harness?

Besides modifying the bracket, is there anything else I need?

Thank you very much for the help!

What confuses me the most is: Does the LS2 coil harness connect to LS1 wiring harness or do I need to change the connectors? I have seen that Michigan Motorsport makes relocation harnesses, would that be a good harmess for using the MSD coils as apposed to a stock LS2 coil harness?

Besides modifying the bracket, is there anything else I need?

Thank you very much for the help!

#197

I don't think anybody has ever shown spark power improvements with MSD coils. However, there have been many MSD coil failures reported leaving them with a less than stellar reputation. Perhaps they've improved them by now.

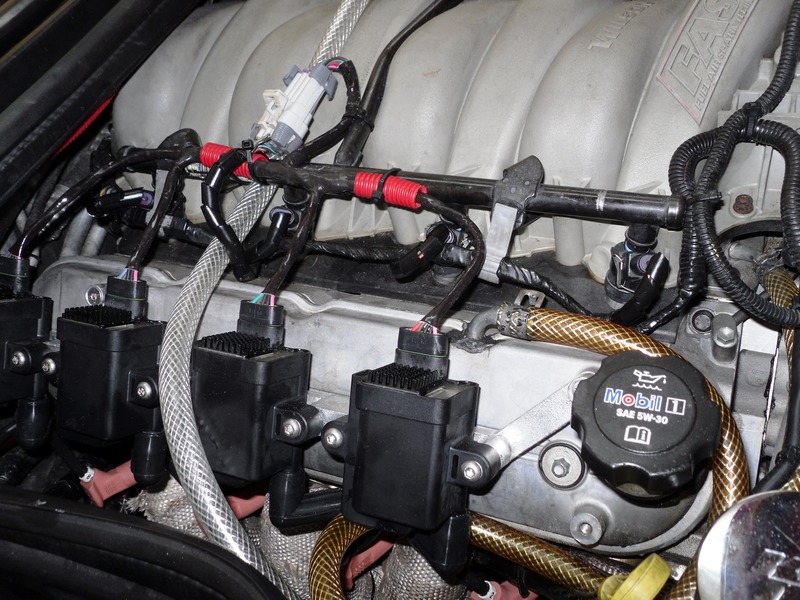

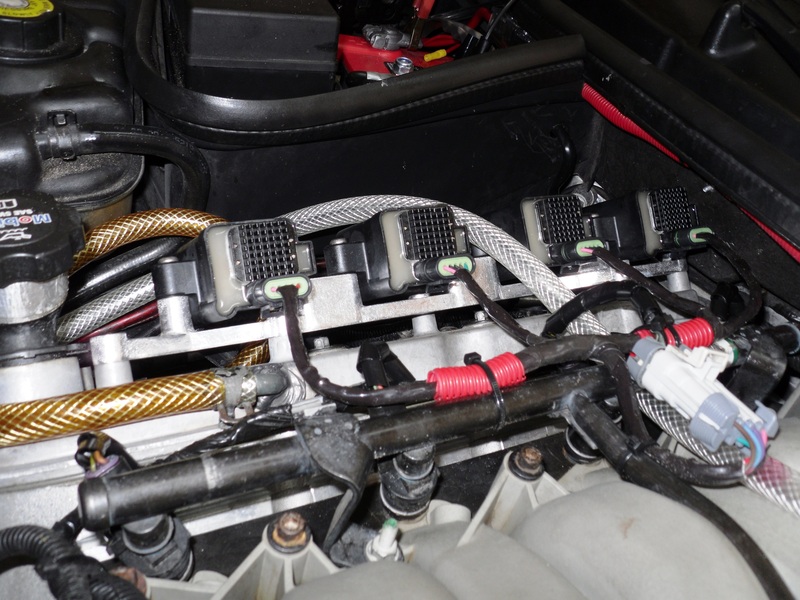

If your truck's factory coils have the heat sink on them, you already have the better coils, leave and use them. Is this what you have?

If your truck's factory coils have the heat sink on them, you already have the better coils, leave and use them. Is this what you have?

#198

9 Second Club

Early LS1 coils use a different 4 pin connector than later coils. Tbis is very apparent looking at the connector which is much smaller on the later stuff.

However the short harness between coils and car with the 7 pin connector will mate together ok to the car.

So make sure you get coils+harness

There isnt really much reason to change from stock coils in most cases. They work good. MSD are not a proven upgrade in any shape or form.

However the short harness between coils and car with the 7 pin connector will mate together ok to the car.

So make sure you get coils+harness

There isnt really much reason to change from stock coils in most cases. They work good. MSD are not a proven upgrade in any shape or form.

#199

Paul Bell and StevieTurbo Thank you. I have LS1 coils. from what I read from megasquirt, the LS2 truck coils are the bomb. 3 time more powerthan my stock LS1 coils. So that is what I was tring to get help with finding the ringht coils and harness that will work for my older LS1.

Do you know of anyone who sells a kit?

Thank you

Do you know of anyone who sells a kit?

Thank you