Help with N/A LS1 Catch can setup

#1

I know there's a lot of threads on the topic, so let me start by saying that I've read this prior to posting: https://ls1tech.com/forums/generatio...outing-ok.html.

I have an N/A LS1 with the -8002 LS6 valley cover (no built in orifice / PCV valve). It is a street car that I plan to autox / HPDE occasionally and was wondering if I need to run a dual can setup as 405HP implies in that thread.

https://ls1tech.com/forums/generatio...outing-ok.html

The thread also goes on to discuss inline check valves used in various locations. Are these more for turbo guys on the clean side, given that an N/A intake setup in theory can't pressurize the flow above atmospheric to open the valve? If installed between the TB and clean catch can (assuming dual can), I could imagine a scenario at high RPM where the crankcase approaches pressure levels greater than intake manifold pressure, in which case the catch can would be pressurized at a rate equivalent to the leak rate through the check valve. So this would result in no clean flow "into" the engine at high RPM. Is my thought process correct on this?

Below are the configurations I've found that I think may be useful to me. Any info as to what setup I should be running and whether or not check valves are needed given my intended use of the car would be greatly appreciated.

I do not have a rear port on my passenger valve cover. The diagram above got me thinking though - where should the rear driver's side be plumbed to and why?

I have an N/A LS1 with the -8002 LS6 valley cover (no built in orifice / PCV valve). It is a street car that I plan to autox / HPDE occasionally and was wondering if I need to run a dual can setup as 405HP implies in that thread.

https://ls1tech.com/forums/generatio...outing-ok.html

Originally Posted by 405HP_Z06

From my experience, the second catch can on the clean air side is needed when road racing the car. For normal street driving, the dirty side catch can is adequate to catch most air born vapor (assuming the catch can is designed correctly). However, during road racing the top end of the engine becomes loaded with oil causing the clean air side to ingest oil into the intake.

From my experience, when I'm street driving the dirty side catches most of the oil vapor. During HPDE weekends, the clean air side usually catches just as much or more than the dirty side. This is why I run two separate catch cans.

From my experience, when I'm street driving the dirty side catches most of the oil vapor. During HPDE weekends, the clean air side usually catches just as much or more than the dirty side. This is why I run two separate catch cans.

Below are the configurations I've found that I think may be useful to me. Any info as to what setup I should be running and whether or not check valves are needed given my intended use of the car would be greatly appreciated.

I do not have a rear port on my passenger valve cover. The diagram above got me thinking though - where should the rear driver's side be plumbed to and why?

#2

TECH Addict

iTrader: (7)

Get the Rx performance CC with the breather that goes on the oil cap. Their CC has a PCV valve built into it and the breather is a flow controlling check valve eliminating the TB tube as that is your new fresh air in. You will get 0 blow-by with this setup. That will be fine for an N/A setup.

#3

TECH Fanatic

iTrader: (6)

The vacuum pulled through the crankcase is very weak, so putting a check valve in the line might just shut it off altogether, or at least restrict it.

Also, I wouldn't use a breather it lets in unmetered air, but I realize some people have no problems doing that.

Agree about pressure going back up the clean air line at high rpm, sometimes I've found oil in that line, but not enough to go to the trouble of putting an extra catch can on it (which I don't really have space for anyway). If anything I'd just use an extra small filter made from light foam, which is what I use in my home-made catch can (not really a can, just a large filter) - I use a piece of foam shop vac filter, which works well.

Also, I wouldn't use a breather it lets in unmetered air, but I realize some people have no problems doing that.

Agree about pressure going back up the clean air line at high rpm, sometimes I've found oil in that line, but not enough to go to the trouble of putting an extra catch can on it (which I don't really have space for anyway). If anything I'd just use an extra small filter made from light foam, which is what I use in my home-made catch can (not really a can, just a large filter) - I use a piece of foam shop vac filter, which works well.

#5

Yeah I was skeptical of running a breather for that reason.

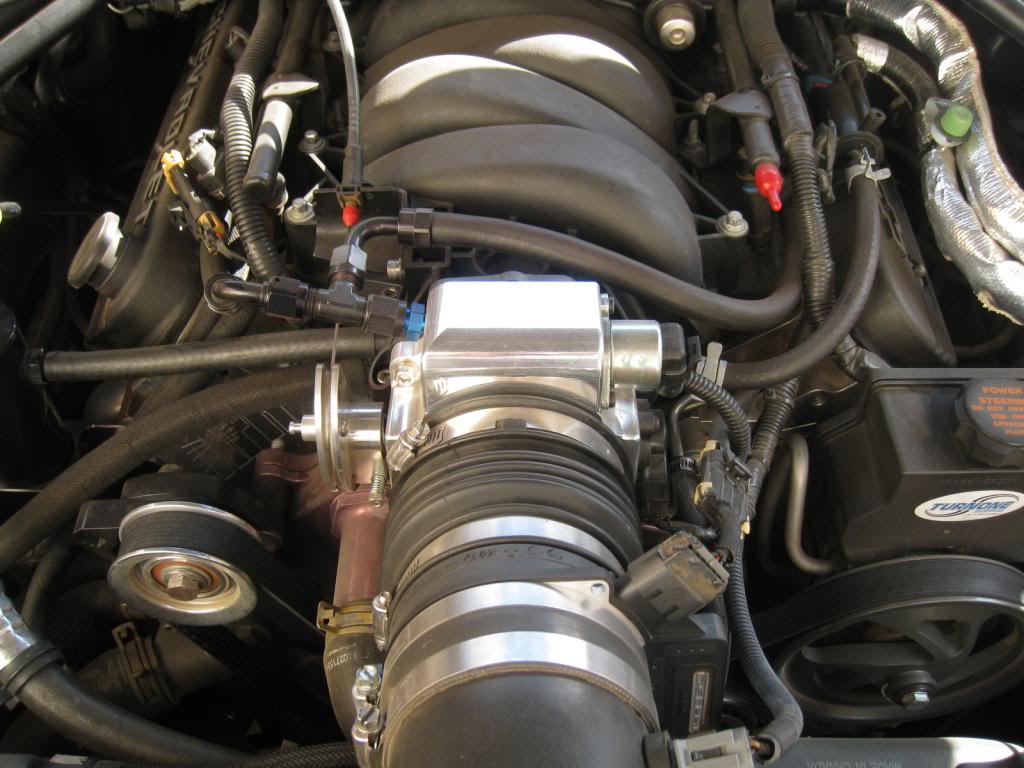

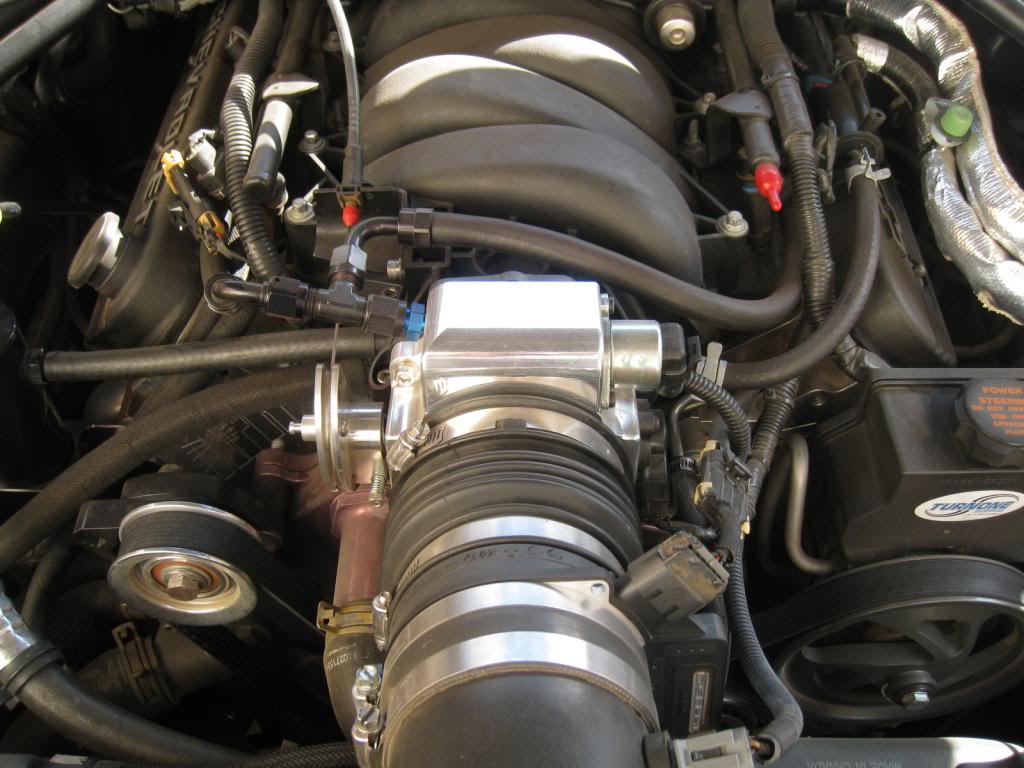

99Bluz28 - so you feel as though a single can would be sufficient configured as per the second diagram? Does the fact that I had to remove the baffles from my valve covers to clear my rocker arms change anything? Not sure what engine they are off of (bought them on ebay) but this is what I have. Not my exact covers but the "internals" of them are the same. Only one port per side - passenger front and driver's rear.

99Bluz28 - so you feel as though a single can would be sufficient configured as per the second diagram? Does the fact that I had to remove the baffles from my valve covers to clear my rocker arms change anything? Not sure what engine they are off of (bought them on ebay) but this is what I have. Not my exact covers but the "internals" of them are the same. Only one port per side - passenger front and driver's rear.

#6

TECH Senior Member

iTrader: (35)

Yeah I'd go with the 2nd diagram. I run mine very similar. ls6 valley cover with gmpp valve covers(no baffling) and I drilled and mounted -AN metal fittings in the stock gm fresh-air inlet location on the PS valvecover, and on the DS valve cover in the same location, and I've had no issues with oil getting up into the throttle body,. I also run a RX catch-can down below the passenger side headlight to maximize the CCs oil/water/combustion blow-by trapping efficiency .

Trending Topics

#8

Launching!

iTrader: (1)

Join Date: Nov 2004

Location: Jax, FL

Posts: 204

Likes: 0

Received 0 Likes

on

0 Posts

You might also look into one of Mightymouse's "boost" catch cans. It has a PCV valve built into it which eliminates the stock valve. It also has another valve built into the top which opens once the PCV valve closes to allow the valve covers to continue to push dirty air into the can rather than back up into the intake.

http://mightym0use.wix.com/mm-solutions#!mm-black/ca5m

http://mightym0use.wix.com/mm-solutions#!mm-black/ca5m

#9

TECH Addict

iTrader: (7)

Its not an open breather....its a check valve that is supposed to only allow enough air in for the ECU to compensate. I only have my car for reference but my tuner had no problem adjusting fuel trims when I switched headers.

I went this route because I was getting A LOT of oil up the TB tube into my FAST with just a CC. If my not be an issue for a cam only car though.

I went this route because I was getting A LOT of oil up the TB tube into my FAST with just a CC. If my not be an issue for a cam only car though.

#10

Super Hulk Smash

iTrader: (7)

I have the LS6 valley cover and I run the dirty side to the top of my CC and the clean side to the manifold with no PCV valve (no need).

But I too was wondering about the passenger side valve cover line that goes to the TB. I realize it's a vent port - but it seems like the TB is going to get mucked up.

I capped off my driver's side with the vacuum plug GM sells as part of the LS6 valley conversion (PN 12568011).

But I too was wondering about the passenger side valve cover line that goes to the TB. I realize it's a vent port - but it seems like the TB is going to get mucked up.

I capped off my driver's side with the vacuum plug GM sells as part of the LS6 valley conversion (PN 12568011).

#11

TECH Senior Member

iTrader: (35)

I have the LS6 valley cover and I run the dirty side to the top of my CC and the clean side to the manifold with no PCV valve (no need).

But I too was wondering about the passenger side valve cover line that goes to the TB. I realize it's a vent port - but it seems like the TB is going to get mucked up.

I capped off my driver's side with the vacuum plug GM sells as part of the LS6 valley conversion (PN 12568011).

But I too was wondering about the passenger side valve cover line that goes to the TB. I realize it's a vent port - but it seems like the TB is going to get mucked up.

I capped off my driver's side with the vacuum plug GM sells as part of the LS6 valley conversion (PN 12568011).

#12

Super Hulk Smash

iTrader: (7)

I still have the cross-over line I could re-install, but I capped the ports. I don't really want to re-install that thing...

But I see what you're saying. The original TB was just really gunked up there and didn't know how it was getting oil in there. Of course, the entire top end was gunked up with oil. Ugh.

But I see what you're saying. The original TB was just really gunked up there and didn't know how it was getting oil in there. Of course, the entire top end was gunked up with oil. Ugh.

#13

I think the problem with understanding proper routing is that flow directions (and quantities) are hard to verify and will vary depending on the mechanical condition of the engine as well as how it's driven.

I was doing some reading over on corvette forum last night

Under sustained high rpm conditions all ports essentially become vents for crankcase pressure if it gets high enough - some guys were suggesting that on built setups (and especially F/I) the singular vent on the LS6 valley didn't flow enough by itself and that the driver's side valve cover should also be hooked up as a vent to the dirty side.

I might just run a dual can setup and be done with it (with no check valves aside from the pcv valve on the dirty side between the CC outlet and intake) to keep the system free flowing and let it do what it wants. I have no way of knowing how much blow by I'll have, or what the flow requirements will be at any point in time.

Trying to think about this more simplistically - at the end of the day, the goal is to purge the crankcase of excess pressure, prevent combustion by-products from contaminating the oil and from diluting the fresh air/fuel charge through the intake. With the dual can setup, everything is filtered even if all 3 ports become vents for crankcase pressure (flow reverses on clean side). I don't care how the pressure relieves itself and makes its way back into the intake, so long as it isn't carrying any crap with it.

Thoughts?

I was doing some reading over on corvette forum last night

Under sustained high rpm conditions all ports essentially become vents for crankcase pressure if it gets high enough - some guys were suggesting that on built setups (and especially F/I) the singular vent on the LS6 valley didn't flow enough by itself and that the driver's side valve cover should also be hooked up as a vent to the dirty side.

I might just run a dual can setup and be done with it (with no check valves aside from the pcv valve on the dirty side between the CC outlet and intake) to keep the system free flowing and let it do what it wants. I have no way of knowing how much blow by I'll have, or what the flow requirements will be at any point in time.

Trying to think about this more simplistically - at the end of the day, the goal is to purge the crankcase of excess pressure, prevent combustion by-products from contaminating the oil and from diluting the fresh air/fuel charge through the intake. With the dual can setup, everything is filtered even if all 3 ports become vents for crankcase pressure (flow reverses on clean side). I don't care how the pressure relieves itself and makes its way back into the intake, so long as it isn't carrying any crap with it.

Thoughts?

#15

TECH Senior Member

iTrader: (35)

Yeah I remember now the 01-02 engines are noticeably more involved(more crap in the way) just to remove the DS valve cover PCV tube/line.

Here's how mine is currently set up, with fresh air inlet on/to both valve covers.

Here's how mine is currently set up, with fresh air inlet on/to both valve covers.

Last edited by 99Bluz28; 01-31-2014 at 05:27 PM.

#16

Again what I'm not really sure about is whether it'd make more sense to plumb the driver's side into the clean supply or into the dirty side vent with the valley cover. Not sure which side needs more capacity. Or does it even matter?

#17

TECH Senior Member

iTrader: (35)

The valley cover is the dirty side (w/ls6 valley cover) so you want to pull fresh air through both valve covers so you displace the combustion blow-by with continuous fresh air on both banks of the engine some what equally. Now with the regular LS1 PCV where vacuum is pulled out a valve cover I would have the fresh air inlet on the opposite valve cover to get the best ventilation through the engine.

#18

^^ I get that, I'm just saying I've seen it routed / recommended both ways. There was a guy making a case for the singular dirty side vent through the valley cover not being able to flow enough. Let me see if I can find the thread..

Edit: here we go.

http://forums.corvetteforum.com/c5-f...ac-thread.html

Truncated a bit to cut down on post length but interesting stuff in that thread. More stuff on Page 2 related to PCV system flow

Edit: here we go.

http://forums.corvetteforum.com/c5-f...ac-thread.html

Originally Posted by The Bat Car

.....

Understanding oil contamination from combustion byproducts

Most think of crankcase ventalation and evacuation as an eviromental issue, and just address releasing the excess crankcase pressure that is part of any big cube or FI build.

The evac system is not for the environment....it is to keep the engine alive and wear free as long as possible. Your not alone and 99% of car owners never think about it or realize whats happening over time. And yes, most will drive 50-75-100k plus miles and never know the damage gradually being done.

My qualifications?

over 35 years building race and performance engines.

Mechanical & Automotive engineer by trade

Graduate of the Reher Morrison Racing engine building school (one of the most respected in the world and a GM R&D contractor).

Owner and driver of drag teams with multiple Divisional, National & World championships in both NHRA & IHRA in several classes (this is where every minute detail in an engine matters)

And I tear down and build most every kind/brand of motor imaginable (except diesel) on a weekly basis.

So here goes:

Every motor has a certain amount of blow-by, the bigger the CI & the more boost the more blow-by (with everything else assumed is equal and no piston/ring/cylinder issue).

Most only look at the crankcase pressure portion and deal with that and that is only a small part of the crankcase evac systems function. The most important is the flushing & removal of the harmful combustion products before they have a chance to condense & settle into the crankcase oil.

These consist of:

Unburnt fuel

Carbon monoxide

water vapor

carbon particles

and several other harmful compounds that when mixed in the crankcase produce Sulfuric acid and as that accumulates past a certain PPM the bearing surfaces, wrist pins, and crank journals begin to be etched and start to damage. This is gradual of course so that’s why like you, most never realize whats happening.

The other very harmful byproduct is the very abrasive carbon particles (near diamond-like in abrasiveness) that many are to small to be caught by the oil filter and accelerate wear as well.

If you have a good cross flow of filtered fresh air entering one side of the crankcase (best is through a flow controlled breather), say the pass side oil fill cap, that fresh air will travel through the pass side valve cover, around the rockers, down the pushrod valley, through the center of the crankcase, (now on the LS6/2/3 valley cover with the fixed orifice it exits there drawn by vacuum so 1/2 the engine is still stagnant with foul compounds...especially the drivers side rocker area) up the drivers side pushrod valley, past the rockers and exits the rear of the drivers side valve cover flushing and pulling the compounds out BEFORE they can settle and condense into the crankcase. Now with out that flow the compounds settle and mix with the oil every time the engine cools. When started and run to operating temp the volatile of those are "flashed off" and again could be evacuated but if just venting with breathers, ONLY the excess crankcase pressure will exit and very little of the harmful compound mix goes with it and once the abrasive carbon particles mix with the oil they are there to stay reducing the protection your oil provides. Now if changing your oil after every track event then this is not an issue. But with a street driven car it is and I can tell you to just look at how dirt your oil gets as far as coloration when you eliminate the evacuation portion of a PCV system, but that tells very little. Send in an oil sample to a good analysis lab and the report back will verify everything I'm saying. The over the road trucking industry does this as a rule, and we do with our race engines as well looking for metal content that tells us a bearing is going away before we could ever detect it and knowing to freshen before a catastrophic failure.

Now back to the LS engine. Any built, big cube, or FI motor cannot breath using the valley cover fixed orifice as it is far to restrictive and excess pressure is a given. So we never use the valley cover vent tube but draw from the rear of the drivers side valve cover.

...

The only true solution for street driven cars is a oil separating crankcase evac system that will provide proper, continuous evac while operating under non-boost via the intake vacuum, and as soon as it senses pressurization a check valve senses this and closes blocking any chance of crankcase pressurization. Then as this happens a secondary valve opens and uses the suction/vacuum of the head unit to continue evacuation while the separating can traps & removes all the oil in suspension allowing only the gasses that do not effect the energy released per explosive event (you do NOT want ANY oil entering the intake air charge or residue/varnish forming on the compressor wheels throwing them off balance).

No oil caused detonation, no shortened engine life/increased wear, and the best of everything you need for the motor to perform properly & last as long as possible.

This thread shows others using it with the issues solved. READ it in detail and every step these owners did to solve the issues and the end result:

http://forums.corvetteforum.com/c5-f...olution-2.html

So build your own if you like (it is not hard) but the system works and works like a dream but if you have a piston/ring/cylinder issue you need to tear down and correct it.

..

You are going to want a crankcase vacuum guage (can be plumbed into the valve cover on the opposit side as the pump pulls or to the valley cover nipple) so you can mointor it down track at WOT when the pump is turning max RPM. Then adjust the valve so you don't exceed 15" vac. It is a sealed spring loaded unit with a lock nut so thats pretty easy. The other part is your motor needs to really well sealed to not have unfiltered air sucking dust/dirt directly into the crankcase. For a street driven car you can also add a moroso or specter type mini filter to it so that air is always filtered. If you do not have a relief valve then you risk engine damage from the oil being pulled off of the wrist pins & crank journals. Pulling less than 10" is not very effective in removing the harmful combustion by-products but it is still the best solution to all the issues described above. I also added pictures of a few of our alky drag motors to show the vac pumps and relief valves.

..

Now, and agin, thanks for a civil thread to discuss this. Anyone reading this is free to buy or do what they choose....I am just sharing a lifetime of knowledge gained in the performance & race industry and on the track where it counts. I am not very active here but there are a few other racers that know me personally and can vouch for my credentials. I am a paid engineer & tech consultant of Colorado Speed and have also a lifetime of designing & developing products for the aftermarket performance industry.

I also urge any that are serious about real performance to read David Rehers "Tech Tips" here: http://www.rehermorrison.com/blog/?p=638

Read years of them for knowledge that can't be bought....I trained there under Darrin Morgan, one of the worlds best when it comes to flow, velocity, and induction. He is right there with Tony Mamo and other greats in the racing industry. Even though I have been bulding race & performance engines for over 35 years, I still learn more every day from paying attention to the true geniuses like these guys. When I close my mind and decide to become ignorant is the day I give up. I am sure I will learn more in the years to come as well and will share it with any caring to learn.

We are no longer as active in racing as we had been in the past due to the economy and other factors as I age (mid 50's now) but still crew & support our family drivers and others from our teams in the past. We won the NHRA Super Gas World championship this year in Pomona and Peter & Emily will both be running the full season again in 2012. We still support multi time LSX/NMCA world Champion Edgar Perez as well when we can as well as several other drivers.

Understanding oil contamination from combustion byproducts

Most think of crankcase ventalation and evacuation as an eviromental issue, and just address releasing the excess crankcase pressure that is part of any big cube or FI build.

The evac system is not for the environment....it is to keep the engine alive and wear free as long as possible. Your not alone and 99% of car owners never think about it or realize whats happening over time. And yes, most will drive 50-75-100k plus miles and never know the damage gradually being done.

My qualifications?

over 35 years building race and performance engines.

Mechanical & Automotive engineer by trade

Graduate of the Reher Morrison Racing engine building school (one of the most respected in the world and a GM R&D contractor).

Owner and driver of drag teams with multiple Divisional, National & World championships in both NHRA & IHRA in several classes (this is where every minute detail in an engine matters)

And I tear down and build most every kind/brand of motor imaginable (except diesel) on a weekly basis.

So here goes:

Every motor has a certain amount of blow-by, the bigger the CI & the more boost the more blow-by (with everything else assumed is equal and no piston/ring/cylinder issue).

Most only look at the crankcase pressure portion and deal with that and that is only a small part of the crankcase evac systems function. The most important is the flushing & removal of the harmful combustion products before they have a chance to condense & settle into the crankcase oil.

These consist of:

Unburnt fuel

Carbon monoxide

water vapor

carbon particles

and several other harmful compounds that when mixed in the crankcase produce Sulfuric acid and as that accumulates past a certain PPM the bearing surfaces, wrist pins, and crank journals begin to be etched and start to damage. This is gradual of course so that’s why like you, most never realize whats happening.

The other very harmful byproduct is the very abrasive carbon particles (near diamond-like in abrasiveness) that many are to small to be caught by the oil filter and accelerate wear as well.

If you have a good cross flow of filtered fresh air entering one side of the crankcase (best is through a flow controlled breather), say the pass side oil fill cap, that fresh air will travel through the pass side valve cover, around the rockers, down the pushrod valley, through the center of the crankcase, (now on the LS6/2/3 valley cover with the fixed orifice it exits there drawn by vacuum so 1/2 the engine is still stagnant with foul compounds...especially the drivers side rocker area) up the drivers side pushrod valley, past the rockers and exits the rear of the drivers side valve cover flushing and pulling the compounds out BEFORE they can settle and condense into the crankcase. Now with out that flow the compounds settle and mix with the oil every time the engine cools. When started and run to operating temp the volatile of those are "flashed off" and again could be evacuated but if just venting with breathers, ONLY the excess crankcase pressure will exit and very little of the harmful compound mix goes with it and once the abrasive carbon particles mix with the oil they are there to stay reducing the protection your oil provides. Now if changing your oil after every track event then this is not an issue. But with a street driven car it is and I can tell you to just look at how dirt your oil gets as far as coloration when you eliminate the evacuation portion of a PCV system, but that tells very little. Send in an oil sample to a good analysis lab and the report back will verify everything I'm saying. The over the road trucking industry does this as a rule, and we do with our race engines as well looking for metal content that tells us a bearing is going away before we could ever detect it and knowing to freshen before a catastrophic failure.

Now back to the LS engine. Any built, big cube, or FI motor cannot breath using the valley cover fixed orifice as it is far to restrictive and excess pressure is a given. So we never use the valley cover vent tube but draw from the rear of the drivers side valve cover.

...

The only true solution for street driven cars is a oil separating crankcase evac system that will provide proper, continuous evac while operating under non-boost via the intake vacuum, and as soon as it senses pressurization a check valve senses this and closes blocking any chance of crankcase pressurization. Then as this happens a secondary valve opens and uses the suction/vacuum of the head unit to continue evacuation while the separating can traps & removes all the oil in suspension allowing only the gasses that do not effect the energy released per explosive event (you do NOT want ANY oil entering the intake air charge or residue/varnish forming on the compressor wheels throwing them off balance).

No oil caused detonation, no shortened engine life/increased wear, and the best of everything you need for the motor to perform properly & last as long as possible.

This thread shows others using it with the issues solved. READ it in detail and every step these owners did to solve the issues and the end result:

http://forums.corvetteforum.com/c5-f...olution-2.html

So build your own if you like (it is not hard) but the system works and works like a dream but if you have a piston/ring/cylinder issue you need to tear down and correct it.

..

You are going to want a crankcase vacuum guage (can be plumbed into the valve cover on the opposit side as the pump pulls or to the valley cover nipple) so you can mointor it down track at WOT when the pump is turning max RPM. Then adjust the valve so you don't exceed 15" vac. It is a sealed spring loaded unit with a lock nut so thats pretty easy. The other part is your motor needs to really well sealed to not have unfiltered air sucking dust/dirt directly into the crankcase. For a street driven car you can also add a moroso or specter type mini filter to it so that air is always filtered. If you do not have a relief valve then you risk engine damage from the oil being pulled off of the wrist pins & crank journals. Pulling less than 10" is not very effective in removing the harmful combustion by-products but it is still the best solution to all the issues described above. I also added pictures of a few of our alky drag motors to show the vac pumps and relief valves.

..

Now, and agin, thanks for a civil thread to discuss this. Anyone reading this is free to buy or do what they choose....I am just sharing a lifetime of knowledge gained in the performance & race industry and on the track where it counts. I am not very active here but there are a few other racers that know me personally and can vouch for my credentials. I am a paid engineer & tech consultant of Colorado Speed and have also a lifetime of designing & developing products for the aftermarket performance industry.

I also urge any that are serious about real performance to read David Rehers "Tech Tips" here: http://www.rehermorrison.com/blog/?p=638

Read years of them for knowledge that can't be bought....I trained there under Darrin Morgan, one of the worlds best when it comes to flow, velocity, and induction. He is right there with Tony Mamo and other greats in the racing industry. Even though I have been bulding race & performance engines for over 35 years, I still learn more every day from paying attention to the true geniuses like these guys. When I close my mind and decide to become ignorant is the day I give up. I am sure I will learn more in the years to come as well and will share it with any caring to learn.

We are no longer as active in racing as we had been in the past due to the economy and other factors as I age (mid 50's now) but still crew & support our family drivers and others from our teams in the past. We won the NHRA Super Gas World championship this year in Pomona and Peter & Emily will both be running the full season again in 2012. We still support multi time LSX/NMCA world Champion Edgar Perez as well when we can as well as several other drivers.

Last edited by ckpitt55; 02-01-2014 at 01:55 AM.