Cylinder head experts, Come in here!!!

#1

Lets hear what some people think about this. I posted this up on another forum. I used to work for a machine shop back in the day that did the work on these heads. These heads just recently saw the light of day, and they had a problem on start up.

This is what I found to be the problem...

does any-one disagree?

The "Machanic" states its my fault, and that the shop I used to work for installed a bent valve.

I pulled the paperwork on this order. All the valves were checked for vacuum, and all of them sealed.

Does any-one see this "mechanics" logic? Pretty night and day to me.

frequency101 wrote:

Well, got to look at the heads tonight...

Heres what I found, immediately when I saw the heads, it was painfully obvious the valve was bent due to debris getting into the engine (metallic).

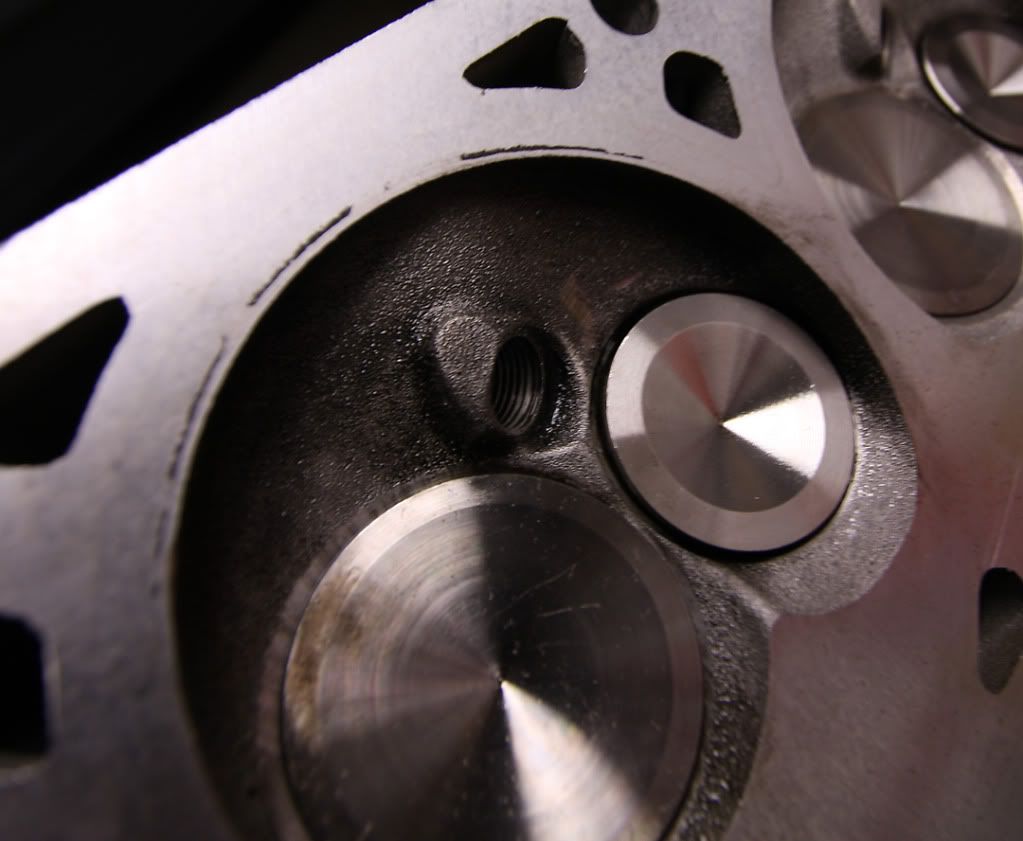

This picture is the condition of the heads immediately upon arrival. Note the valve off center, open on one end, closed on the other. This will happen if the smallest chunk of debris gets caught in the massive clamping force a valve provides...

A stainless valve will do exactly as this one will, bend, instead of break... this is a great feature all stainless valves provide, so if something goes wrong, you don't destroy the entire motor. A two piece valve would have crumbled into a thousand pieces instantly, and destroyed the entire block. This is why stainless valves are a must in high performance applications.

This picture shows the first point of contact of the debris before getting stuck in the exhaust valve. The debris was moving towards the exhuast valve at a decent speed, but not enough to puncture or damage the head to an irreparable state. The seat also attained minimal damage (nitrated seats are VERY heard, factory on all LS1+ engines)

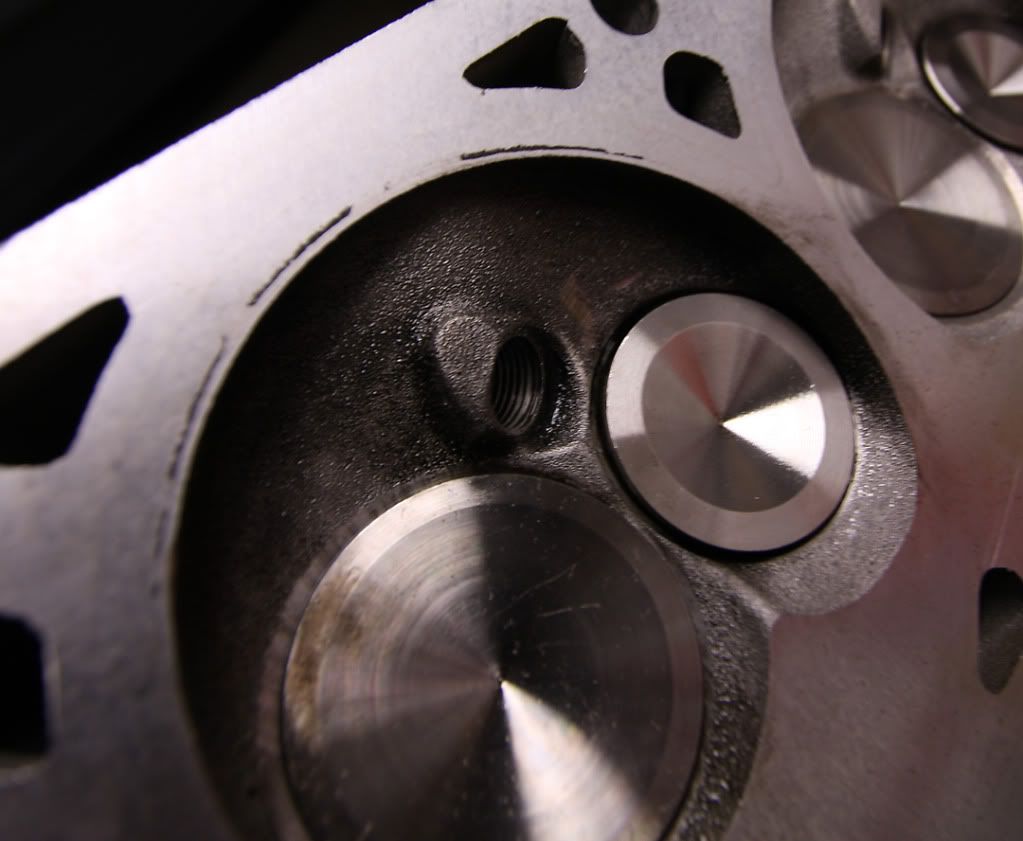

This shows the damage inflicted on the valve. Damage as seen here is actually much worse then what is visible... its the dent that ruins the valve surface by impacting the surface area... if the valve was still straight, it would take to much materiel on the exhaust side to save. This picture also shows where the valve was sealing for a short time prior to the debris. The valve was sealing on the bottom edge of the 45* angle, which is perfect on an exhaust valve that is designed to wear. The more it wears, the more the sealing area will climb towards the bottom of the valve.

Last, we see the valve cocked to the right. This permanently ruins the valve. The valve needs to be replaced at this point and thrown away. Unfortunately, these particular valves are nitrate coated... for high heat conditions under boost, so they are expensive. We can salvage the head and replace the valve...

The piston is another story.

Thanks,

-Kyle

Well, got to look at the heads tonight...

Heres what I found, immediately when I saw the heads, it was painfully obvious the valve was bent due to debris getting into the engine (metallic).

This picture is the condition of the heads immediately upon arrival. Note the valve off center, open on one end, closed on the other. This will happen if the smallest chunk of debris gets caught in the massive clamping force a valve provides...

A stainless valve will do exactly as this one will, bend, instead of break... this is a great feature all stainless valves provide, so if something goes wrong, you don't destroy the entire motor. A two piece valve would have crumbled into a thousand pieces instantly, and destroyed the entire block. This is why stainless valves are a must in high performance applications.

This picture shows the first point of contact of the debris before getting stuck in the exhaust valve. The debris was moving towards the exhuast valve at a decent speed, but not enough to puncture or damage the head to an irreparable state. The seat also attained minimal damage (nitrated seats are VERY heard, factory on all LS1+ engines)

This shows the damage inflicted on the valve. Damage as seen here is actually much worse then what is visible... its the dent that ruins the valve surface by impacting the surface area... if the valve was still straight, it would take to much materiel on the exhaust side to save. This picture also shows where the valve was sealing for a short time prior to the debris. The valve was sealing on the bottom edge of the 45* angle, which is perfect on an exhaust valve that is designed to wear. The more it wears, the more the sealing area will climb towards the bottom of the valve.

Last, we see the valve cocked to the right. This permanently ruins the valve. The valve needs to be replaced at this point and thrown away. Unfortunately, these particular valves are nitrate coated... for high heat conditions under boost, so they are expensive. We can salvage the head and replace the valve...

The piston is another story.

Thanks,

-Kyle

does any-one disagree?

The "Machanic" states its my fault, and that the shop I used to work for installed a bent valve.

I pulled the paperwork on this order. All the valves were checked for vacuum, and all of them sealed.

Does any-one see this "mechanics" logic? Pretty night and day to me.

#4

TECH Fanatic

iTrader: (2)

Ohhhh... I see.

Yea I bet the car ran like ****, that would effin blow.

Did it run shitty right off the bat or after a while of running?'

Either way, looks like your looking at a new valve and maybe a new head it that one isnt fixable. But being that its aluminum, it should be able to be fixed and a new seat ground in.

Yea I bet the car ran like ****, that would effin blow.

Did it run shitty right off the bat or after a while of running?'

Either way, looks like your looking at a new valve and maybe a new head it that one isnt fixable. But being that its aluminum, it should be able to be fixed and a new seat ground in.

#5

TECH Addict

ok let me get this straight. u had head work done at a machine shop. then u took the heads somewhere else to have them installed? so the person who installed it fukced up and left something in the motor which resulted in a bent valve. so its the mechanic who installed the heads fault. or at least thats how i understand it. correct me if i am wrong.

#6

The valve probably contacted the piston if it's bent.

The second pic.....where the screwdriver is pointing at some circular marks in the chamber....that's from the valve spring compressor, not the valve.

The second pic.....where the screwdriver is pointing at some circular marks in the chamber....that's from the valve spring compressor, not the valve.

#7

TECH Addict

well i can tell u that when i had piston to valve contact in my mustang there was deffinitely a mark left on the bottom side of the valve. and i dont see that in those pics, and i also don't see how PVC would leave that mark on the top side and no mark on the bottom side. just my .02 tho i could be wrong.