cam swap just about done and but im in a jam.

#1

Banned

Thread Starter

iTrader: (3)

Join Date: Jan 2009

Location: Central ,CT

Posts: 859

Likes: 0

Received 0 Likes

on

0 Posts

Im just reasembling the car after installing my new comp cam.

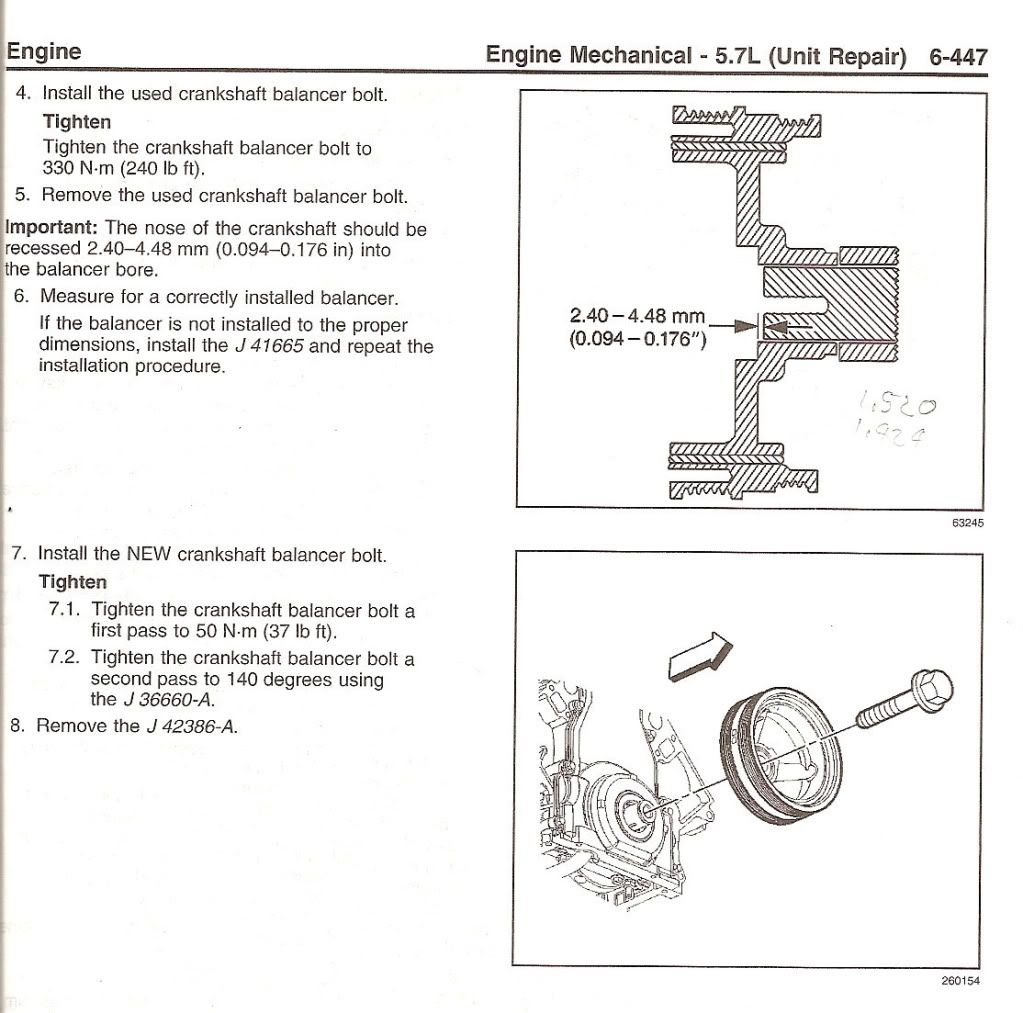

I purchased a powerbond 10% pulley, and I can't seem to get it to go on all the way. The pulley needs to go about another 2mm and it just wont go.

Ive got a impact gun and all the goodies, tried to spary it, heat it alittle (didnt go crazy).

I posted here because you guys doing cam swaps deal with the balancer alot.

Is there a trick im missing or something im forgeting?

Im going to pull the pulley back ff later today but I have to rent a diffrent puller so I didnt get to do it last night.

And help or ideas would be appreciated....

I purchased a powerbond 10% pulley, and I can't seem to get it to go on all the way. The pulley needs to go about another 2mm and it just wont go.

Ive got a impact gun and all the goodies, tried to spary it, heat it alittle (didnt go crazy).

I posted here because you guys doing cam swaps deal with the balancer alot.

Is there a trick im missing or something im forgeting?

Im going to pull the pulley back ff later today but I have to rent a diffrent puller so I didnt get to do it last night.

And help or ideas would be appreciated....

#2

Formerly darynC-10/23/10

iTrader: (19)

Join Date: Aug 2006

Location: gonzales louisiana

Posts: 2,301

Likes: 0

Received 0 Likes

on

0 Posts

do you know a depth gauge? measure the depth of the crank snout in conjunction with the pulley, if they dont match , then you may have a pulley for a different model or soemthing

#4

Banned

Thread Starter

iTrader: (3)

Join Date: Jan 2009

Location: Central ,CT

Posts: 859

Likes: 0

Received 0 Likes

on

0 Posts

Ya the pulley just wont set on the crank all the way.

Theres about 2mm that just wont go. tried everything....

But its worse , I tried installing the stock crank pulley now and have the same issue. I cant figure out what the hell is going on. Even took the timing cover off and did a test fit with just the pulley and no luck....

I didnt have much time to play with it tonight, but im realy stumped on such a stupid issue...

Theres about 2mm that just wont go. tried everything....

But its worse , I tried installing the stock crank pulley now and have the same issue. I cant figure out what the hell is going on. Even took the timing cover off and did a test fit with just the pulley and no luck....

I didnt have much time to play with it tonight, but im realy stumped on such a stupid issue...

Trending Topics

#8

Banned

iTrader: (8)

Join Date: Jun 2007

Location: san fernando valley, california

Posts: 3,093

Likes: 0

Received 1 Like

on

1 Post

make sure the inside of the pulley does not have any rough edges. and heating it is a good trick to use. i used a long stud to pull in the pulley enough on mine so that i can put in the stock bolt

Last edited by ae13291; 02-03-2010 at 11:33 PM.

#10

I put my pulley in the oven for a while and then quickly installed it on the crank snout and then tapped it with a rubber mallet until it was far enough that I could safely use the bolt to pull it into place. You should be able to eyeball the pulley by looking at the other pulleys and see if it is lining up.

Did you by any chance install a new timing set? I could see that causing an issue if the crank gear or oil pump drive were of a different thickness than the stock parts. If not then I'm sure your stock pulley should have seated right back up with a little effort.

Did you by any chance install a new timing set? I could see that causing an issue if the crank gear or oil pump drive were of a different thickness than the stock parts. If not then I'm sure your stock pulley should have seated right back up with a little effort.

#11

Banned

Thread Starter

iTrader: (3)

Join Date: Jan 2009

Location: Central ,CT

Posts: 859

Likes: 0

Received 0 Likes

on

0 Posts

I used a m16 x2x 120 bolt to draw it in, then used a stock one towrods the end.

Ill snapp a pic later tonight, I wonder if its possible the both pullies keep going on crooked and at the end it does fit into the oil pump??

I thought I remember seeing the edge of the pulley sitting flush with crank.

And I know you guys said it might be drawn in, but I dont think so by the way the belt looks alittle off the idler pulley.

Ill snapp some pics later., might try to heat like someone said.

Ill snapp a pic later tonight, I wonder if its possible the both pullies keep going on crooked and at the end it does fit into the oil pump??

I thought I remember seeing the edge of the pulley sitting flush with crank.

And I know you guys said it might be drawn in, but I dont think so by the way the belt looks alittle off the idler pulley.

Ill snapp some pics later., might try to heat like someone said.

#15

TECH Veteran

iTrader: (9)

it's the same as the SLP one right? if so your not gonna get it flush with it, look at where your belts run and how does the alignment of it look? my SLP didn't look flush at all and we we're worried until we called a buddy and he said thats just how they look and you'll know when you run it if the pulley isn't all the way on lol

#16

Banned

Thread Starter

iTrader: (3)

Join Date: Jan 2009

Location: Central ,CT

Posts: 859

Likes: 0

Received 0 Likes

on

0 Posts

Thanks for the replies guys.

The gap turns out to be normal. also Thanks to don from slowhawk performance for answer some of my questions.

I just didnt notice When I removed the stock pulley that it didnt sit flush.

Then When I was installing the power bond I wasnt sure if it was normal.

I feel like a dummy but Id rather ask and be safe then sorry.

All the belts line up good and Ill be doing the first strartup on the cam tomomo

The gap turns out to be normal. also Thanks to don from slowhawk performance for answer some of my questions.

I just didnt notice When I removed the stock pulley that it didnt sit flush.

Then When I was installing the power bond I wasnt sure if it was normal.

I feel like a dummy but Id rather ask and be safe then sorry.

All the belts line up good and Ill be doing the first strartup on the cam tomomo