Oh great, SI6 cam & TEA 5.3L heads = no PTVC....

#1

TECH Regular

Thread Starter

iTrader: (1)

Join Date: May 2008

Location: Iowa

Posts: 475

Likes: 0

Received 0 Likes

on

0 Posts

Well i got my new SI6 Speed inc cam installed (235/240 .643/.609 111lsa) and degree'd in so today per the Comp cam card we checked piston to valve clearance w/ the new TEA ported 5.3L heads. To make a long story short, there isn’t any clearance…. The crank never stopped while turning but when we took the head back off to measure the clay and there were 2 nice 1/2 moon nicks in the top of the piston both intake and exhaust. So now what?

We used the “used” stock head gasket and the new 5.3L heads w/ 2.02int/1.55exh valves…… what are my options?

I just ordered the flycutting tools from Dave Lindy at "Lindy tools" so i can get at least .080” PTVC but I’m not sure how thick the stock pistons are. I do know I don’t want to take the engine out to change the pistons but I’m open for any advice at this point cuz I know what I’ve got won’t work........

By the way, whats the chances i bent the 2 valves in the new head? or better yet how do i check to see if i did?

We used the “used” stock head gasket and the new 5.3L heads w/ 2.02int/1.55exh valves…… what are my options?

I just ordered the flycutting tools from Dave Lindy at "Lindy tools" so i can get at least .080” PTVC but I’m not sure how thick the stock pistons are. I do know I don’t want to take the engine out to change the pistons but I’m open for any advice at this point cuz I know what I’ve got won’t work........

By the way, whats the chances i bent the 2 valves in the new head? or better yet how do i check to see if i did?

#6

TECH Enthusiast

iTrader: (2)

Very familiar with this cam grind. I have been for years.

235 / 240 .647 .610 111 LSA Is there and advance ground in? Check for ICL of 109 or another number other than 111.

Are the 5.3L heads milled.? Stock is around 62 to 63cc chambers for the 5.3 are they 59 cc's or milled aprox .030" ? Are you advancing the timing chain any? if so don't. If there is Advance ground in the Cam? Retard the Timing Chain if there is. IF the heads have been milled did you compensate for newer shorter pushrods? If not you need too.

You have 4 options.

* Cut Valve relief in the stock pistons. A Pain...

* Use thicker head gaskets. & Lengthen the pushrods so you don't get sowing machine effect on valve train. = Lower compression

* Retard the timing chain in -2 Deg increments. (not the best solution) But cheapest way.

* go with a new Cam grind.

I'll bet there is advance ground in.

I'll bet that the heads are milled perhaps. (look for a .030 markings on the heads, or on your invoice for the heads.

Good luck and you can call me or PM me with any questions.

Clint

303-250-1466

235 / 240 .647 .610 111 LSA Is there and advance ground in? Check for ICL of 109 or another number other than 111.

Are the 5.3L heads milled.? Stock is around 62 to 63cc chambers for the 5.3 are they 59 cc's or milled aprox .030" ? Are you advancing the timing chain any? if so don't. If there is Advance ground in the Cam? Retard the Timing Chain if there is. IF the heads have been milled did you compensate for newer shorter pushrods? If not you need too.

You have 4 options.

* Cut Valve relief in the stock pistons. A Pain...

* Use thicker head gaskets. & Lengthen the pushrods so you don't get sowing machine effect on valve train. = Lower compression

* Retard the timing chain in -2 Deg increments. (not the best solution) But cheapest way.

* go with a new Cam grind.

I'll bet there is advance ground in.

I'll bet that the heads are milled perhaps. (look for a .030 markings on the heads, or on your invoice for the heads.

Good luck and you can call me or PM me with any questions.

Clint

303-250-1466

#7

10 Second Club

iTrader: (2)

You can check the valves to see if they are bent buy fliping the heads upside down on a bench.Put a spark plug in and pour some gas into the chamber untill its almost full.If the valves are bent ,gas will seep out into the runners within a fem minuits.When yo check for P-V clearance you really need to get a degee wheel that comes with CHECKER springs.They are light weight springs that go in place of your valve springs.As you turn the engine over slowly as the valve starts to open you can push down on it to see how much clearance there is.The closest it comes to the piston is when the degree wheel is 5 to 10 degrees past top dead center on the intake valve.You can also measure this with a caliper or a dial indicator.Your pistons are ok with the marks in them,your gonna need to fly cut anyway.You can get a complete kit from summit with degree wheel,checker springs,dial indicator,and complete instructions.

Trending Topics

#10

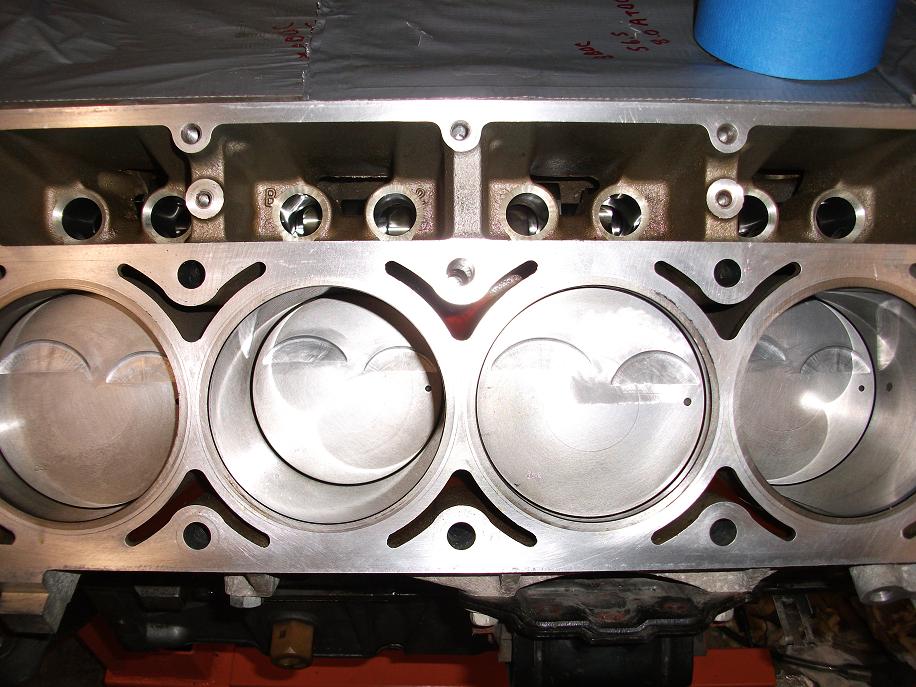

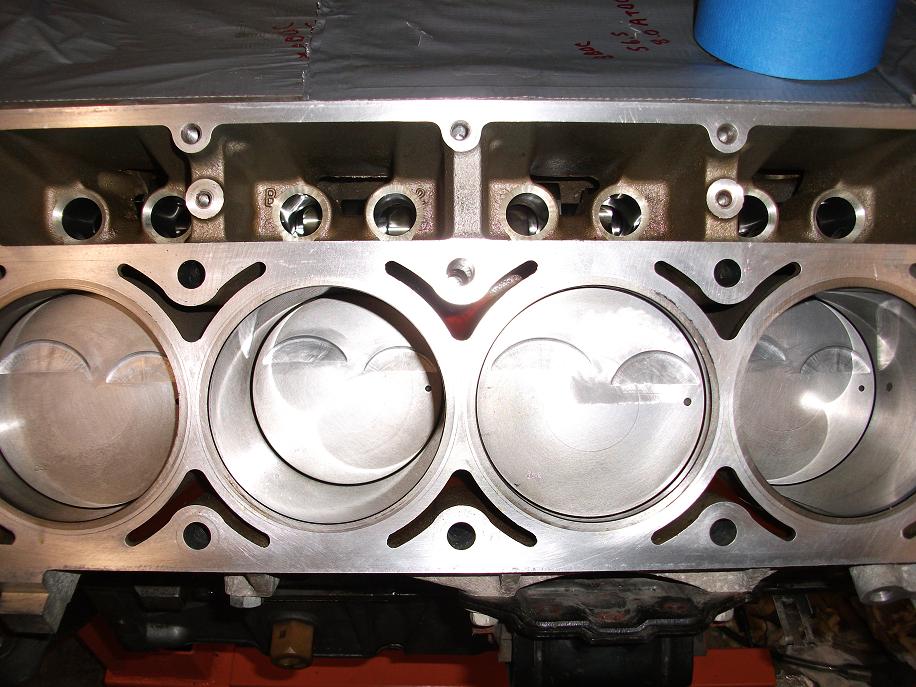

flycutt them and dont look back...i took off a little extra on mine just for added clearance and if i ever change the cam again...

this is a .110 cut on both...

lindy tool

this is a .110 cut on both...

lindy tool

#11

LS1Tech Premium Sponsor

iTrader: (4)

Without a doubt just flycut the pistons at this point. The camshaft should have clearance, it's very similar to the Tsunami by checking specs & we ship PRC heads all the time with Tsunami camshafts. That being said we've spent a lot of time working valve drop & chamber setups to create better p/v than the competitors cylinder heads. My guess is your probably just looking at a head with some milling, or possibly the valves are just setup really shallow in the heads.

Either way a little cutting on the pistons can easily fix it!

Either way a little cutting on the pistons can easily fix it!

__________________

Jason

Co-Owner, Texas Speed & Performance, Ltd.

2005 Twin Turbo C6

404cid Stroker, 67mm Twins

994rwhp/902lb ft @ 22 psi (mustang dyno) www.Texas-Speed.com

Jason

Co-Owner, Texas Speed & Performance, Ltd.

2005 Twin Turbo C6

404cid Stroker, 67mm Twins

994rwhp/902lb ft @ 22 psi (mustang dyno) www.Texas-Speed.com

#14

TECH Regular

Thread Starter

iTrader: (1)

Join Date: May 2008

Location: Iowa

Posts: 475

Likes: 0

Received 0 Likes

on

0 Posts

Holy crap, i guess i should check this more often lol

Ok where do i start,

1) Yes there is 1 deg of advance ground into cam

2) Mike @ TEA said he only milled the heads .003" to clean them up but said the chambers are 62.5-63cc now

3) ICL calls for 110 on cam card but with the adjustable crank gear at 0 with no advance or retard the ICL is 108.5 - With -2 retard it comes out to 112.25 - According to Larry & Comp they both said this cam is mid-high rpm so if i left it at "0" it'd move the power down in rpms a bit so i left it at "0"

4) I haven't checked to see if valves are bent yet but i will by using the gas method, i've done that before. Only problem is it was always on old heads that had carbon on them so you could see easily as it soaked through.

5) Everyone i talk to says keep the SI6 cam for my stick car, they said it will be sweet as hell when done. So i'm flycutting. I just received the tools from Lindy and going to do it tomorrow. I'll post tomorrow with hopefully some good news lol.

6) I used the degree wheel and dial indicator to do everything so far and i never did feel it hit the valves otherwise i would of stopped turning the wheel.

Talk to you all soon!

Ok where do i start,

1) Yes there is 1 deg of advance ground into cam

2) Mike @ TEA said he only milled the heads .003" to clean them up but said the chambers are 62.5-63cc now

3) ICL calls for 110 on cam card but with the adjustable crank gear at 0 with no advance or retard the ICL is 108.5 - With -2 retard it comes out to 112.25 - According to Larry & Comp they both said this cam is mid-high rpm so if i left it at "0" it'd move the power down in rpms a bit so i left it at "0"

4) I haven't checked to see if valves are bent yet but i will by using the gas method, i've done that before. Only problem is it was always on old heads that had carbon on them so you could see easily as it soaked through.

5) Everyone i talk to says keep the SI6 cam for my stick car, they said it will be sweet as hell when done. So i'm flycutting. I just received the tools from Lindy and going to do it tomorrow. I'll post tomorrow with hopefully some good news lol.

6) I used the degree wheel and dial indicator to do everything so far and i never did feel it hit the valves otherwise i would of stopped turning the wheel.

Talk to you all soon!

#16

#17

TECH Enthusiast

iTrader: (2)

Well i got my new SI6 Speed inc cam installed (235/240 .643/.609 111lsa) and degree'd in so today per the Comp cam card we checked piston to valve clearance w/ the new TEA ported 5.3L heads. To make a long story short, there isn’t any clearance…. The crank never stopped while turning but when we took the head back off to measure the clay and there were 2 nice 1/2 moon nicks in the top of the piston both intake and exhaust. So now what?

We used the “used” stock head gasket and the new 5.3L heads w/ 2.02int/1.55exh valves…… what are my options?

I just ordered the flycutting tools from Dave Lindy at "Lindy tools" so i can get at least .080” PTVC but I’m not sure how thick the stock pistons are. I do know I don’t want to take the engine out to change the pistons but I’m open for any advice at this point cuz I know what I’ve got won’t work........

By the way, whats the chances i bent the 2 valves in the new head? or better yet how do i check to see if i did?

We used the “used” stock head gasket and the new 5.3L heads w/ 2.02int/1.55exh valves…… what are my options?

I just ordered the flycutting tools from Dave Lindy at "Lindy tools" so i can get at least .080” PTVC but I’m not sure how thick the stock pistons are. I do know I don’t want to take the engine out to change the pistons but I’m open for any advice at this point cuz I know what I’ve got won’t work........

By the way, whats the chances i bent the 2 valves in the new head? or better yet how do i check to see if i did?

#18

I flycut mine .110...the stock pistons are around .250 thick if IIRC...

#19

TECH Regular

Thread Starter

iTrader: (1)

Join Date: May 2008

Location: Iowa

Posts: 475

Likes: 0

Received 0 Likes

on

0 Posts

Update: i got the car running and it sounds tough and doesnt' seem to have any major problems. BUT, it does have a vibration that definently rpm related, since i flycut my stuff could that of thrown the engine out of balance now? its from 2000-3500 rpms.

Only other thing that i can think of that i've done that have something to do with it is i added PFADT poly motor mounts and diff mount and it says right in the instructions "it will transfer more vibes than stock especially at lower rpms", only thing is the vibes i have is i can be sitting still, the clutch in or out and rev up the engine and then the vibes happen......... HELP ME!!!!

Thanks!

Only other thing that i can think of that i've done that have something to do with it is i added PFADT poly motor mounts and diff mount and it says right in the instructions "it will transfer more vibes than stock especially at lower rpms", only thing is the vibes i have is i can be sitting still, the clutch in or out and rev up the engine and then the vibes happen......... HELP ME!!!!

Thanks!